1 Stage Vs 2 Stage Vacuum Pump

Achieving a proper vacuum is paramount when installing or servicing air conditioning and refrigeration systems. Removing non-condensables like air and moisture is crucial for system longevity and optimal performance. The tool of choice for this task is the vacuum pump, and understanding the difference between 1-stage and 2-stage vacuum pumps is essential for everyone from homeowners to seasoned HVAC professionals.

Understanding the Basics of Vacuum Pumps

Before diving into the specifics, let's clarify what a vacuum pump does and why it's important. In HVAC/R systems, refrigerants undergo phase changes (liquid to gas and vice versa) to absorb and release heat. The presence of air, moisture, or other non-condensable gases interferes with this process, leading to:

- Reduced Cooling Capacity: The system won't cool as effectively, leading to discomfort and higher energy bills.

- Increased Head Pressure: The compressor has to work harder, shortening its lifespan.

- Corrosion: Moisture reacts with refrigerant and oil, forming acids that corrode internal components.

- Refrigerant Breakdown: Contaminants can degrade the refrigerant, affecting its performance and potentially leading to costly replacements.

- Compressor Failure: Ultimately, a contaminated system can lead to compressor failure, the most expensive repair in an HVAC system.

A vacuum pump removes these contaminants by creating a deep vacuum within the system. The depth of the vacuum is measured in microns (µm). One micron is one-millionth of a meter of mercury. A lower micron reading indicates a deeper vacuum, meaning more contaminants have been removed.

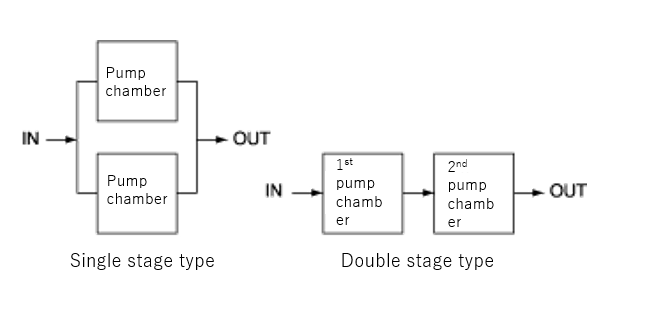

1-Stage Vacuum Pumps: A Single Effort

A 1-stage vacuum pump uses a single rotor and vane mechanism to draw air and moisture out of the system. Imagine a piston in a cylinder – it pulls air in, compresses it, and expels it. This process happens in a single stage. These pumps are typically less expensive and lighter than their 2-stage counterparts, making them suitable for some applications.

Advantages of 1-Stage Pumps:

- Lower Cost: Generally more affordable, making them attractive for budget-conscious users or infrequent use.

- Simpler Design: Easier to maintain and repair due to their less complex construction.

- Lighter Weight: More portable for technicians on the go.

Disadvantages of 1-Stage Pumps:

- Lower Ultimate Vacuum: Typically achieve a vacuum of around 75-150 microns, which may not be sufficient for all refrigerants or systems.

- Slower Evacuation: Take longer to reach the desired vacuum level compared to 2-stage pumps.

- Less Efficient: Less efficient at removing moisture and non-condensables.

Example: A homeowner replacing a small window AC unit might find a 1-stage pump adequate for evacuating the system. However, for a larger central AC system, a 2-stage pump is highly recommended.

2-Stage Vacuum Pumps: Doubling Down on Vacuum

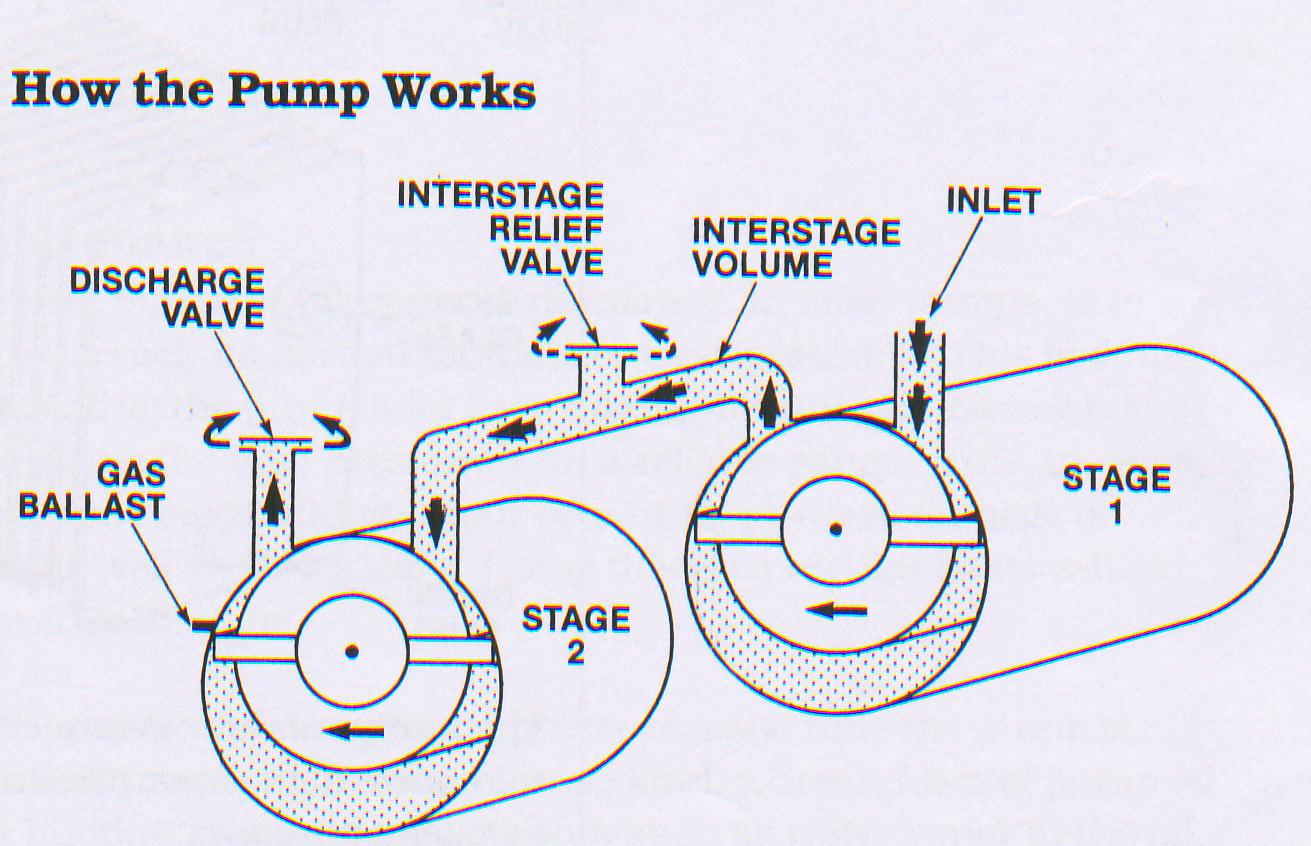

A 2-stage vacuum pump, as the name implies, uses two separate stages to achieve a deeper and more thorough vacuum. The first stage removes the bulk of the air and moisture, while the second stage focuses on pulling out the remaining contaminants and achieving a much lower micron level. Think of it as a "turbocharged" vacuum pump.

How 2-Stage Pumps Work:

In a 2-stage pump, the first stage acts like a standard 1-stage pump, removing a significant portion of the air and moisture. The exhaust from the first stage then feeds into the second stage, which further compresses and removes the remaining contaminants. This sequential process allows the pump to achieve a much deeper vacuum and remove even trace amounts of moisture.

Advantages of 2-Stage Pumps:

- Deeper Ultimate Vacuum: Achieve a much lower micron level (typically below 20-50 microns), ensuring thorough contaminant removal.

- Faster Evacuation: Evacuate systems much faster than 1-stage pumps, saving time and increasing efficiency.

- More Efficient: More effective at removing moisture and non-condensables, leading to a cleaner and more reliable system.

- Suitable for All Refrigerants: Compatible with all types of refrigerants, including newer, more sensitive refrigerants like R-410A and R-32.

Disadvantages of 2-Stage Pumps:

- Higher Cost: More expensive than 1-stage pumps, representing a larger initial investment.

- More Complex Design: More complex to maintain and repair.

- Heavier Weight: Typically heavier than 1-stage pumps.

Example: An HVAC technician working on a complex VRF (Variable Refrigerant Flow) system in a large commercial building would absolutely need a 2-stage vacuum pump to ensure proper evacuation and prevent future issues. The cost of a system failure due to improper evacuation far outweighs the initial cost of the pump.

Choosing the Right Vacuum Pump: A Comparison

The table below summarizes the key differences between 1-stage and 2-stage vacuum pumps:

| Feature | 1-Stage Vacuum Pump | 2-Stage Vacuum Pump |

|---|---|---|

| Cost | Lower | Higher |

| Ultimate Vacuum | 75-150 Microns | Below 20-50 Microns |

| Evacuation Speed | Slower | Faster |

| Efficiency | Less Efficient | More Efficient |

| Complexity | Simpler | More Complex |

| Weight | Lighter | Heavier |

| Best For | Small systems, infrequent use, budget-conscious users | Large systems, frequent use, critical applications, all refrigerants |

Key Considerations for Technicians and Facility Managers

For HVAC technicians and facility managers responsible for maintaining HVAC systems, the choice between a 1-stage and 2-stage vacuum pump is often a matter of professional necessity. Here are some key considerations:

- Types of Systems Serviced: If you primarily work on small residential systems, a 1-stage pump *might* suffice. However, for larger commercial systems, VRF systems, or systems using newer refrigerants, a 2-stage pump is essential.

- Frequency of Use: If you use a vacuum pump frequently, the faster evacuation time and increased efficiency of a 2-stage pump will save you time and money in the long run.

- Refrigerant Types: Some refrigerants are more sensitive to moisture and non-condensables than others. If you work with these refrigerants, a 2-stage pump is a must.

- Long-Term Cost: While a 2-stage pump has a higher initial cost, the reduced risk of system failure and improved efficiency can result in significant cost savings over the lifespan of the HVAC systems you maintain.

- Reputation and Reliability: Investing in a high-quality 2-stage pump from a reputable manufacturer can ensure reliable performance and minimize downtime.

In addition to the pump itself, it's crucial to invest in quality vacuum hoses, gauges, and other accessories to ensure accurate readings and prevent leaks. Regular maintenance of your vacuum pump, including oil changes and cleaning, is also essential for prolonging its lifespan and maintaining its performance.

Conclusion

While 1-stage vacuum pumps offer a budget-friendly option for certain applications, 2-stage vacuum pumps provide superior performance and are generally the preferred choice for most HVAC professionals and facility managers. The deeper vacuum, faster evacuation time, and increased efficiency of a 2-stage pump ensure thorough contaminant removal, leading to more reliable, efficient, and longer-lasting HVAC systems. Ultimately, investing in a quality 2-stage vacuum pump is an investment in the long-term health and performance of your HVAC systems.