1/8 Pipe Thread Tap Drill Size

Understanding the proper drill size for tapping threads is crucial in various applications, from DIY home projects to professional HVAC installations. Specifically, knowing the correct 1/8 pipe thread tap drill size can save you time, money, and potential headaches. This article provides a comprehensive guide, tailored for homeowners aiming to improve energy efficiency, businesses transitioning to sustainable systems, smart home enthusiasts integrating HVAC controls, and HVAC contractors offering energy-efficient services.

The Importance of Choosing the Right Tap Drill Size

When creating threads for pipes and fittings, precision is paramount. The drill size before tapping directly impacts the strength and quality of the resulting thread. Using a drill that is too small can make tapping extremely difficult, potentially breaking the tap or producing weak threads. Conversely, a drill that is too large can result in shallow, easily stripped threads, leading to leaks and system failures. In HVAC systems, leaks are not just inconvenient; they represent wasted energy, increased costs, and potentially harmful refrigerant emissions.

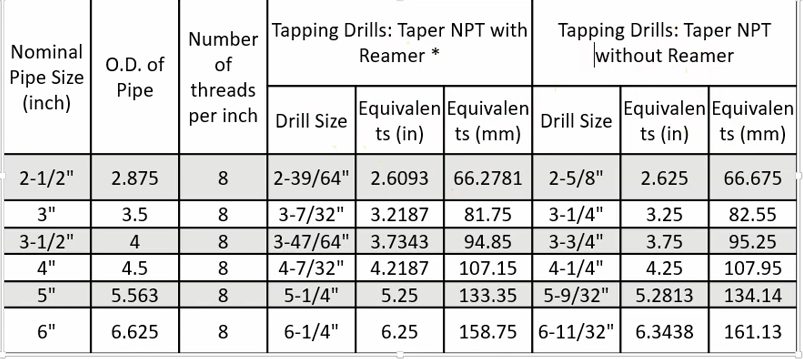

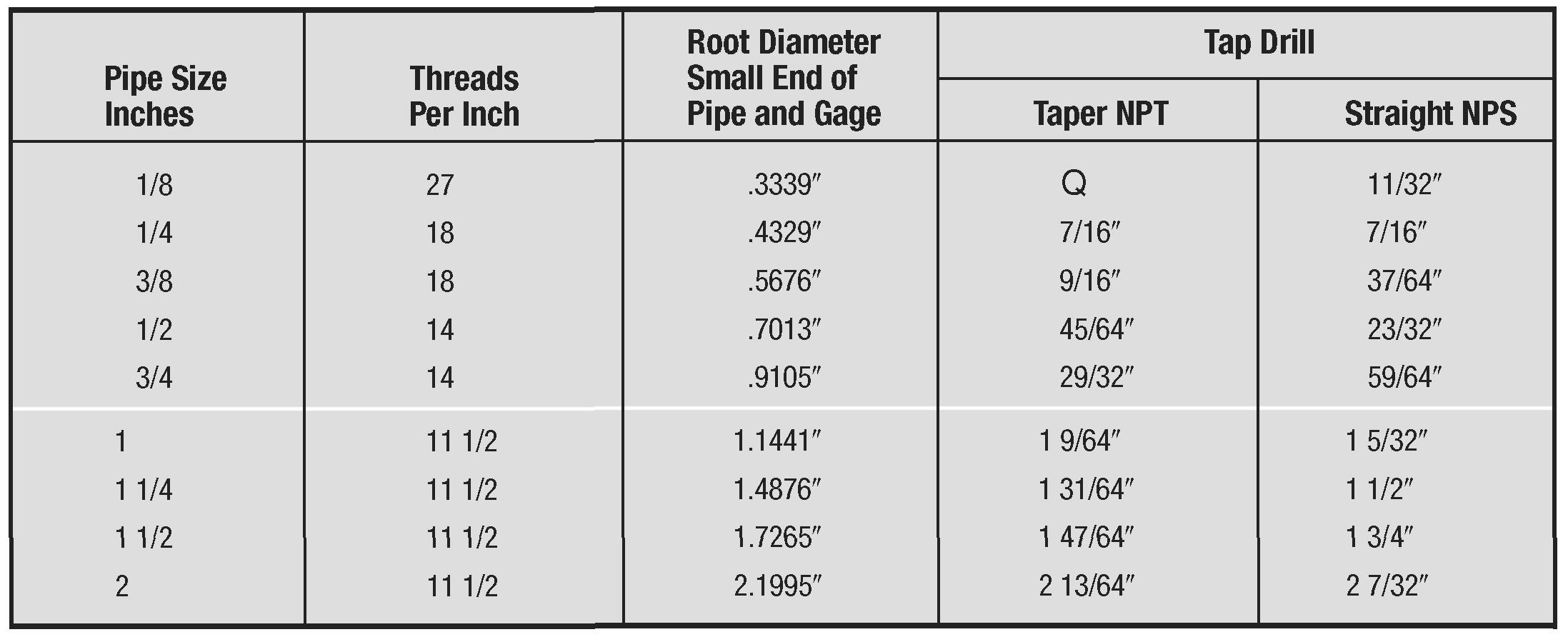

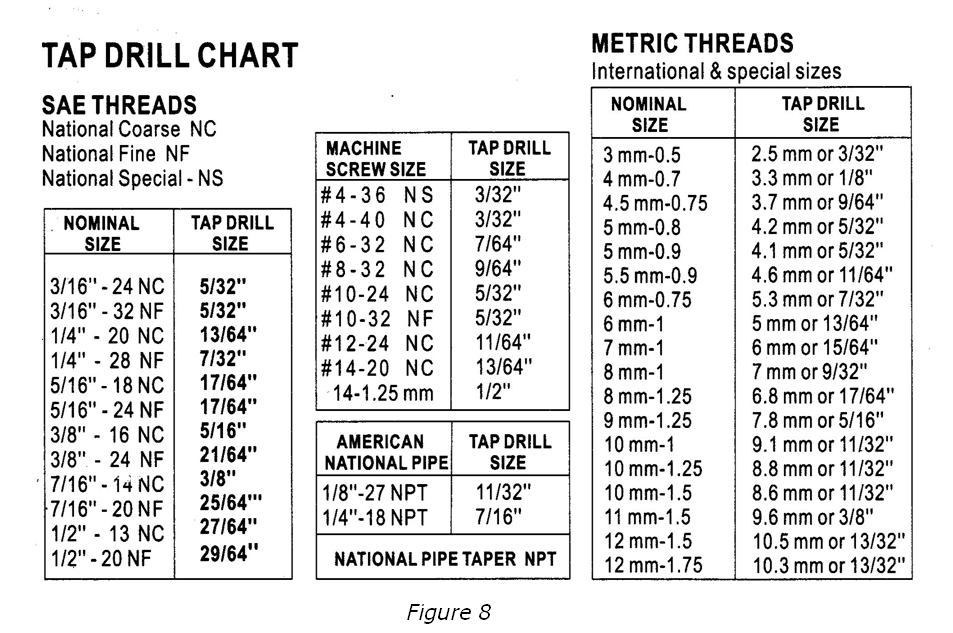

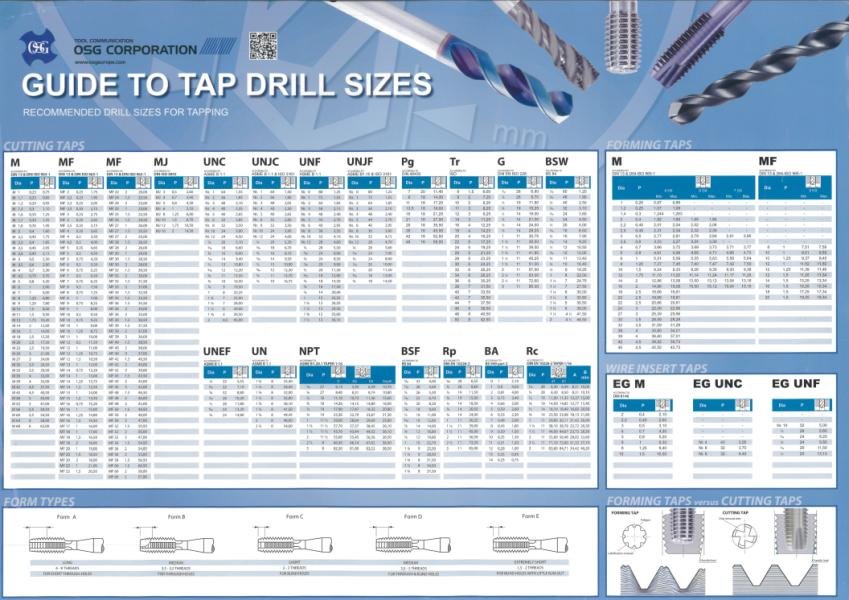

For a 1/8 pipe thread, specifically a 1/8-27 NPT (National Pipe Thread), the recommended tap drill size is typically 11/32 inch or 8.7mm. However, it's essential to always verify this information with the tap manufacturer's recommendations, as slight variations can exist.

Why NPT Matters in Energy Efficiency

NPT threads are tapered, meaning they gradually narrow along their length. This taper is essential for creating a tight, leak-proof seal, particularly when combined with a pipe sealant or thread tape. In HVAC systems, properly sealed pipe threads prevent refrigerant leaks, ensuring the system operates at peak efficiency. Leaks reduce cooling or heating capacity, forcing the system to work harder and consume more energy, ultimately increasing your utility bills.

Drilling for Success: A Step-by-Step Guide

Before you start drilling and tapping, gather your tools and materials:

- The correct tap drill (typically 11/32 inch or 8.7mm for 1/8 NPT)

- A 1/8 NPT tap

- A drill press or handheld drill (a drill press offers more precision)

- Cutting oil or lubricant

- A tap handle or wrench

- Safety glasses

- Gloves

Step 1: Preparation is Key

Securely clamp the workpiece. Ensure it is stable to prevent movement during drilling, which can lead to inaccurate holes and potential injury. Mark the center of the hole you intend to drill with a center punch. This will help guide the drill bit and prevent it from wandering.

Step 2: Drilling the Pilot Hole

Insert the 11/32-inch drill bit into the drill chuck and tighten securely. Apply cutting oil to the drill bit. This reduces friction, dissipates heat, and extends the life of the drill bit. Drill slowly and steadily, applying consistent pressure. Avoid forcing the drill, as this can damage the bit or the workpiece. If using a handheld drill, keep it as perpendicular as possible to the surface.

Step 3: Tapping the Threads

Apply cutting oil to the tap. This will help it cut smoothly and prevent binding. Insert the tap into the drilled hole and start turning it by hand, ensuring it is aligned properly. Use a tap handle or wrench to apply even pressure. Turn the tap a few turns, then back it off slightly to break the chip and prevent it from binding. Continue this process until the tap has created the desired thread depth. Remove the tap and clean the threads of any debris.

Step 4: Inspection and Testing

Inspect the threads visually for any imperfections. Test the fit of a pipe fitting to ensure it screws in smoothly and snugly. Use pipe sealant or thread tape when assembling the final connection to create a leak-proof seal.

Energy Savings and ROI: The HVAC Connection

Properly installed and maintained HVAC systems are essential for energy efficiency. Leaky pipe threads in refrigerant lines can lead to significant energy losses and increased operating costs. According to the Environmental Protection Agency (EPA), refrigerant leaks contribute to global warming and can reduce the efficiency of air conditioning and refrigeration equipment by as much as 20%. By ensuring tight, leak-proof connections using properly tapped threads and appropriate sealants, you can minimize energy waste and reduce your carbon footprint.

Consider the long-term ROI. Investing in the right tools and techniques for proper pipe threading can save you money in the long run by preventing leaks, reducing energy consumption, and extending the lifespan of your HVAC equipment. Furthermore, by maintaining an energy-efficient HVAC system, you may be eligible for rebates and incentives from your local utility company or government programs.

Smart HVAC Integration: Monitoring for Efficiency

Integrating your HVAC system with smart home technology can further enhance energy efficiency. Smart thermostats, for example, allow you to remotely control your heating and cooling settings, optimizing energy usage based on your schedule and preferences. Sensors can detect leaks and other potential problems, alerting you to take corrective action before they escalate into major energy losses.

Some advanced smart HVAC systems even incorporate sensors that monitor refrigerant levels and pressures, providing early warnings of potential leaks. This proactive approach can save you money on repairs and prevent costly energy waste. By combining proper pipe threading techniques with smart HVAC technology, you can create a truly energy-efficient and cost-effective home comfort system.

Energy Star and HVAC Efficiency

When upgrading your HVAC system, look for Energy Star certified equipment. Energy Star products meet strict energy-efficiency guidelines set by the EPA, ensuring optimal performance and reduced energy consumption. Properly installed and maintained Energy Star HVAC systems can save you up to 30% on your energy bills compared to older, less efficient models.

Troubleshooting Common Pipe Threading Problems

Even with careful preparation and execution, problems can sometimes arise during the pipe threading process. Here are some common issues and how to address them:

- Tap Breaking: This can happen if the drill hole is too small, the tap is forced, or the material is too hard. Use the correct tap drill size, apply plenty of cutting oil, and avoid excessive force.

- Threads Stripping: This can occur if the drill hole is too large, the tap is dull, or the threads are over-tightened. Use the correct tap drill size, replace worn taps, and avoid over-tightening fittings.

- Leaks: This can be caused by improperly tapped threads, damaged fittings, or inadequate sealant. Inspect the threads carefully, replace damaged fittings, and use a high-quality pipe sealant or thread tape.

For HVAC Contractors: Selling Energy-Efficient Solutions

As an HVAC contractor, you play a crucial role in promoting energy efficiency. By offering energy-efficient HVAC systems, providing expert installation services, and educating your clients about the benefits of smart home integration, you can help them save money on their energy bills and reduce their environmental impact.

Highlight the ROI of energy-efficient upgrades, emphasizing the long-term savings and potential rebates. Offer maintenance services to ensure systems operate at peak efficiency and prevent leaks. By positioning yourself as a trusted advisor and provider of energy-efficient solutions, you can build a loyal customer base and grow your business.

"Energy efficiency isn't just good for the environment; it's good for your bottom line."

Conclusion

Mastering the art of pipe threading, particularly understanding the correct 1/8 pipe thread tap drill size, is a fundamental skill for anyone working with HVAC systems or undertaking plumbing projects. By using the right tools, techniques, and sealants, you can create tight, leak-proof connections that minimize energy waste and reduce your operating costs. Whether you're a homeowner, a business owner, a smart home enthusiast, or an HVAC contractor, investing in energy efficiency is a smart decision that benefits both your wallet and the planet.