2 Psi Gas Pipe Sizing Chart

Understanding gas pipe sizing is crucial for ensuring the safe and efficient operation of any gas-powered appliance, from your furnace to your water heater. This guide focuses specifically on 2 PSI gas piping systems, commonly used for residential and commercial applications. We'll break down the principles, the charts, and the considerations you need to make to size your gas pipes correctly.

Why Proper Gas Pipe Sizing Matters

Imagine trying to drink a milkshake through a tiny straw. You'd struggle to get enough, and it would be a frustrating experience. Similarly, undersized gas pipes restrict the flow of gas, potentially starving your appliances and leading to:

- Incomplete combustion: This means the gas isn't burning fully, resulting in wasted fuel, reduced efficiency, and the production of dangerous carbon monoxide.

- Appliance malfunction: Appliances may not operate correctly or at all if they don't receive enough gas.

- Safety hazards: Gas leaks can occur due to stress on the system caused by inadequate pipe size.

Oversized pipes, on the other hand, are generally less problematic from a safety standpoint, but they can lead to increased material costs and potentially lower gas pressure at the appliance due to a larger volume to fill. The goal is to find the optimal balance.

Understanding 2 PSI Gas Piping Systems

Most residential gas appliances operate at a very low pressure, typically measured in inches of water column (WC). However, running gas lines over long distances at these low pressures requires very large pipes, which can be expensive and impractical. That's where 2 PSI systems come in.

A 2 PSI system uses a higher pressure (2 pounds per square inch) for the main gas line. This allows you to use smaller diameter pipes for longer runs. Near the appliance, a pressure regulator reduces the gas pressure back down to the appliance's required operating pressure (typically 4-7 inches WC for natural gas or 10-12 inches WC for propane).

Think of it like a highway system: larger highways (2 PSI lines) handle the bulk of the traffic over long distances, and then smaller local roads (regulated pressure lines) distribute the traffic to individual destinations (appliances).

Key Factors Influencing Gas Pipe Sizing

Several factors influence the required pipe size for a 2 PSI gas system:

- Gas type: Natural gas and propane have different densities and heating values (BTUs per cubic foot), affecting the required flow rate.

- Appliance BTU input: Each appliance requires a specific amount of gas (measured in BTUs per hour) to operate. This information is usually found on the appliance's nameplate.

- Pipe length: Longer pipe runs result in greater pressure loss due to friction.

- Number of fittings: Each elbow, tee, or other fitting adds resistance to the gas flow, increasing pressure loss.

- Allowable pressure drop: The maximum permissible pressure drop from the meter to the furthest appliance.

- Pipe material: Different materials (e.g., steel, copper, polyethylene) have different internal roughness, which affects friction and pressure drop.

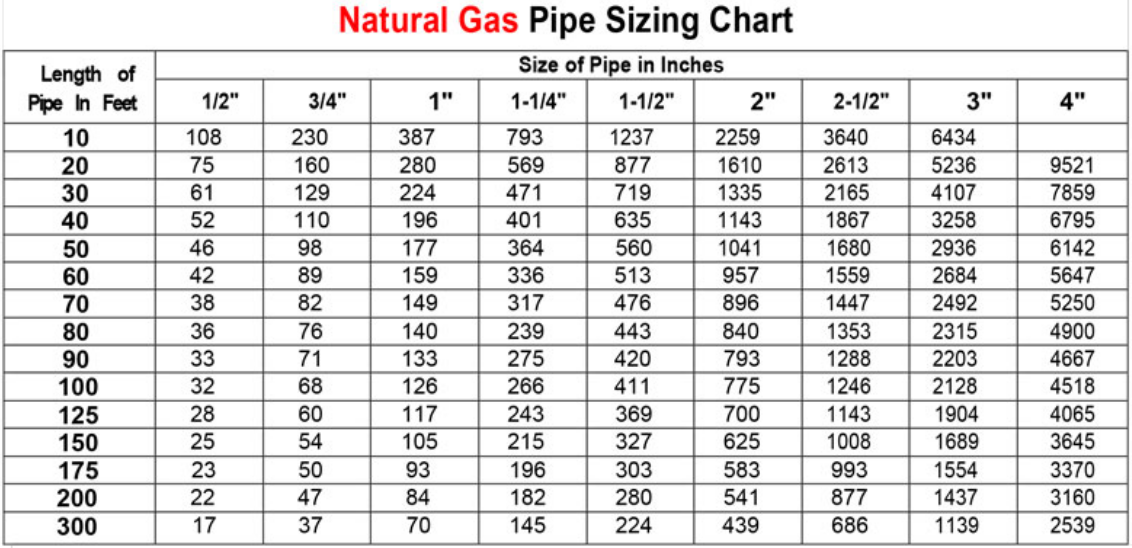

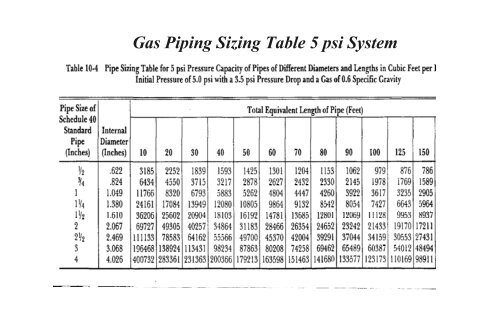

Decoding the 2 PSI Gas Pipe Sizing Chart

A 2 PSI gas pipe sizing chart is a table that provides the maximum allowable length of pipe for a given pipe size, gas type, BTU load, and pressure drop. It essentially does the complex calculations for you.

Here's how to interpret a typical chart:

- Identify the Gas Type: The chart will specify whether it's for natural gas or propane.

- Determine the BTU Load: Sum the BTU input ratings of all appliances served by the pipe section you're sizing.

- Choose the Pipe Material: Common options are steel and polyethylene (PE). Select the appropriate table for your material.

- Select the Allowable Pressure Drop: 2 PSI systems often use a pressure drop of 1 PSI.

- Find the Pipe Size: Look for the pipe size (e.g., 1/2", 3/4", 1", etc.) in the leftmost column.

- Read the Maximum Length: In the row corresponding to your chosen pipe size, find the column that matches your total BTU load. The value at that intersection is the maximum allowable length of that pipe size for that BTU load and pressure drop.

Example: Let's say you're using steel pipe and need to supply 150,000 BTU/hr of natural gas with a 1 PSI pressure drop. Looking at a typical chart, you might find that 3/4" pipe has a maximum allowable length of 50 feet for that BTU load. This means if the actual pipe length is 50 feet or less, 3/4" pipe is sufficient. If the length is greater than 50 feet, you'll need to increase the pipe size to 1" or larger.

Accounting for Fittings (Equivalent Length)

Fittings introduce resistance to gas flow, which is equivalent to adding length to the pipe. To account for fittings, you need to determine their equivalent length and add it to the actual pipe length.

Equivalent length is the length of straight pipe that would produce the same pressure drop as the fitting. Fitting manufacturers typically provide equivalent length values for their products. These values are often expressed in feet. For example:

- 90-degree elbow: Might have an equivalent length of 2 feet.

- Tee (flow through): Might have an equivalent length of 1 foot.

- Tee (branch flow): Might have an equivalent length of 5 feet.

To calculate the total equivalent length:

- Determine the equivalent length of each fitting in the pipe section.

- Add up the equivalent lengths of all the fittings.

- Add the total equivalent length to the actual length of the pipe. This gives you the total effective length.

You then use the total effective length in the gas pipe sizing chart to determine the appropriate pipe size.

Step-by-Step Example of Gas Pipe Sizing

Let's walk through a complete example:

Scenario: You need to supply a furnace (100,000 BTU/hr) and a water heater (40,000 BTU/hr) with natural gas using a 2 PSI steel pipe system. The actual pipe length is 40 feet. The system includes three 90-degree elbows and one tee (flow-through). The allowable pressure drop is 1 PSI.

- Calculate Total BTU Load: 100,000 BTU/hr + 40,000 BTU/hr = 140,000 BTU/hr

- Determine Equivalent Length of Fittings:

- Three 90-degree elbows: 3 elbows * 2 ft/elbow = 6 feet

- One tee (flow-through): 1 tee * 1 ft/tee = 1 foot

- Total fitting equivalent length: 6 feet + 1 foot = 7 feet

- Calculate Total Effective Length: 40 feet (actual length) + 7 feet (fitting equivalent length) = 47 feet

- Consult the 2 PSI Gas Pipe Sizing Chart: Look at the chart for steel pipe, natural gas, 1 PSI pressure drop. Find the row for different pipe sizes and the column for 140,000 BTU/hr.

- Analyze the Chart:

- Let's assume the chart shows that 1/2" pipe is limited to 30 feet for 140,000 BTU/hr. This is not sufficient because our total effective length is 47 feet.

- Let's assume the chart shows that 3/4" pipe is limited to 60 feet for 140,000 BTU/hr. This is sufficient because our total effective length is 47 feet, which is less than 60 feet.

- Conclusion: You should use 3/4" steel pipe for this application.

Important Considerations and Cautions

- Always consult local codes and regulations: Gas piping installations must comply with local building codes, which may have specific requirements for pipe sizing, materials, and installation practices. These codes supersede any general guidelines.

- Use the correct chart: Make sure you're using a chart specifically designed for 2 PSI systems and the appropriate gas type and pipe material.

- Err on the side of caution: If you're unsure about the correct pipe size, it's always better to choose a slightly larger size.

- Professional installation: Gas piping should be installed by a qualified and licensed professional. Improper installation can lead to dangerous leaks and other safety hazards.

- Pressure testing: After installation, the gas piping system must be pressure tested to ensure there are no leaks.

- Altitude: At higher altitudes, the density of gas decreases, which can affect the required pipe size. Consult a professional for guidance on altitude corrections.

- Future expansion: Consider future appliance additions when sizing your gas piping. It's often wise to upsize the pipes slightly to accommodate future needs.

Where to Find 2 PSI Gas Pipe Sizing Charts

2 PSI gas pipe sizing charts are readily available online from various sources, including:

- Pipe manufacturers: Manufacturers of steel, copper, and polyethylene pipes often provide sizing charts in their product catalogs or on their websites.

- Gas utility companies: Some gas utility companies provide sizing charts for their service areas.

- Plumbing and heating supply distributors: These distributors often have sizing charts available to their customers.

- Online engineering resources: Various websites offer engineering calculators and sizing charts for gas piping.

Always verify the accuracy and reliability of the chart you're using by cross-referencing it with other sources and consulting with a qualified professional.

Conclusion

Sizing gas pipes for a 2 PSI system requires careful consideration of several factors, including gas type, BTU load, pipe length, fittings, and allowable pressure drop. Using a 2 PSI gas pipe sizing chart is essential for determining the correct pipe size to ensure safe and efficient operation. However, remember to always comply with local codes, account for fittings, and consider future expansion. When in doubt, consult with a qualified and licensed gas piping professional. By understanding the principles and following the steps outlined in this guide, you can confidently size your 2 PSI gas piping system and ensure the safe and reliable operation of your gas appliances.