Air Conditioner Compressor Won't Turn On

One of the most frustrating HVAC problems, especially during peak cooling season, is an air conditioner compressor that refuses to turn on. A silent compressor means no cold air, unhappy customers, and potential revenue loss for your business. Whether you're a budding HVAC technician, a seasoned pro, or a business owner, understanding the root causes of this issue and how to address them is crucial. This article provides a comprehensive guide to troubleshooting a non-starting AC compressor, along with insights into career paths and industry trends.

Understanding the Importance of the Compressor

The compressor is the heart of any air conditioning system. It's responsible for compressing refrigerant, increasing its temperature and pressure, and circulating it throughout the system. Without a functioning compressor, the entire cooling process grinds to a halt. Replacing a compressor can be one of the most expensive HVAC repairs, highlighting the importance of accurate diagnosis and preventive maintenance.

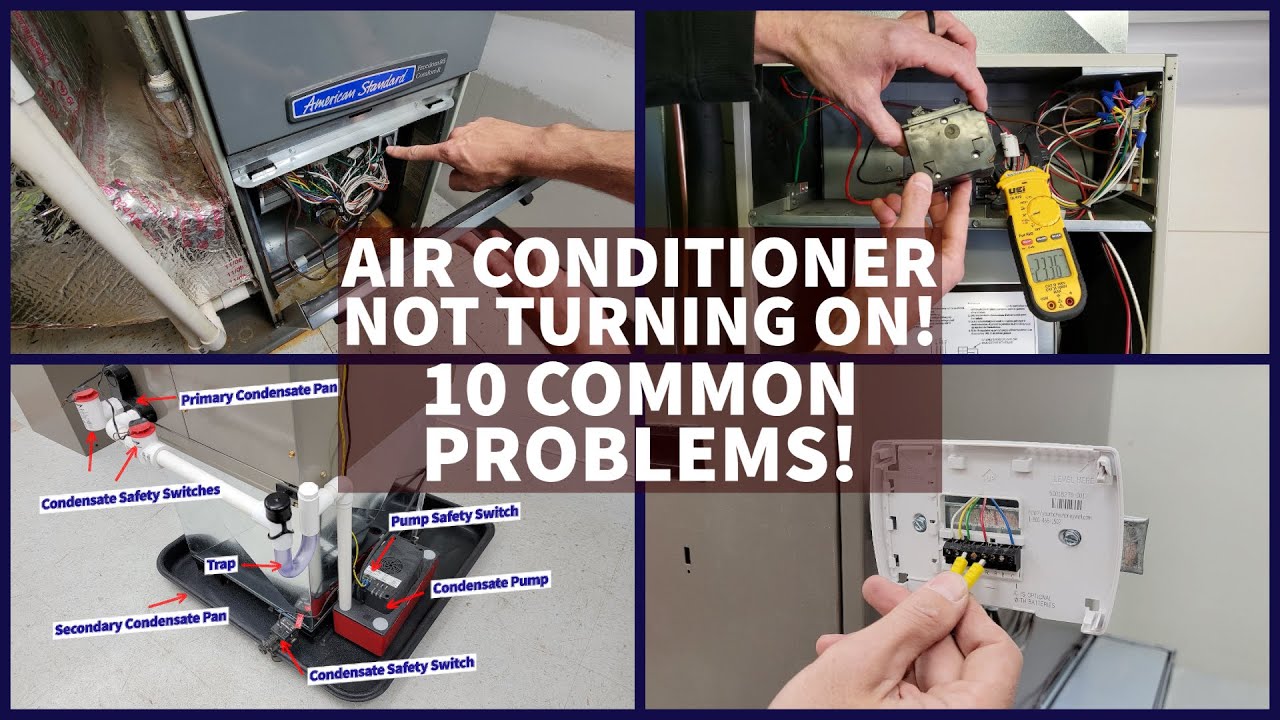

Common Causes and Troubleshooting Steps

When an AC compressor fails to start, the problem could stem from several different issues. Here's a breakdown of common causes and corresponding troubleshooting steps:

1. Power Issues

Problem: Lack of power to the unit or compressor.

Troubleshooting:

- Check the circuit breaker: Ensure the breaker for the AC unit hasn't tripped. Reset it if necessary.

- Inspect the disconnect switch: Make sure the disconnect switch (usually located near the outdoor unit) is in the "on" position.

- Test the voltage: Use a multimeter to verify that the correct voltage is reaching the compressor. A qualified electrician may be needed if you are not comfortable with electrical testing.

- Check wiring: Look for loose or corroded wiring connections at the compressor, capacitor, and contactor.

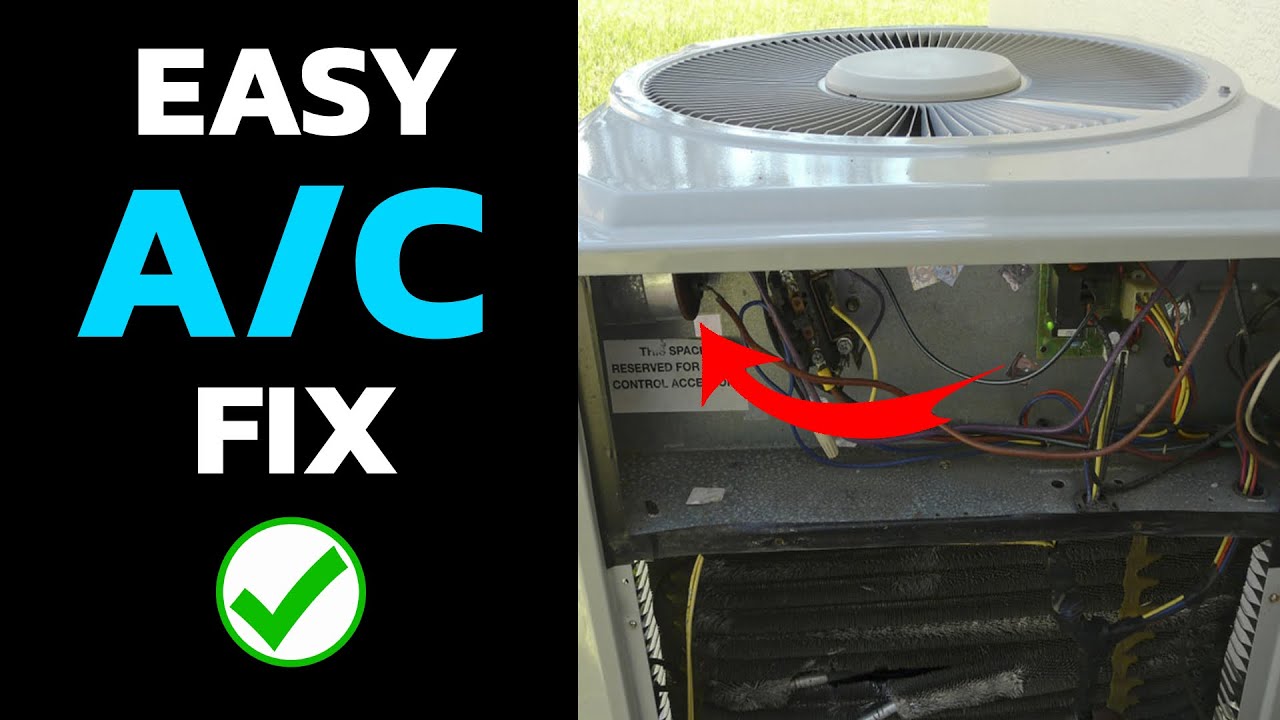

2. Faulty Capacitor

Problem: A capacitor provides the initial jolt of energy needed to start the compressor motor. If it's weak or failed, the compressor may hum but not start.

Troubleshooting:

- Visual inspection: Look for bulges, leaks, or other signs of damage on the capacitor.

- Capacitance test: Use a capacitance meter to measure the capacitor's microfarad (µF) rating. Compare the reading to the capacitor's label. A significant deviation indicates a problem.

- Replacement: If the capacitor is faulty, replace it with one of the same voltage and microfarad rating. Always disconnect power before working on electrical components.

Note: Capacitors can hold a dangerous electrical charge even after the power is turned off. Discharge the capacitor using a properly insulated screwdriver before handling it.

3. Defective Contactor

Problem: The contactor is an electrical relay that switches power to the compressor when the thermostat calls for cooling. A faulty contactor can prevent the compressor from receiving power.

Troubleshooting:

- Visual inspection: Look for pitted or burnt contacts on the contactor.

- Continuity test: Use a multimeter to check for continuity across the contactor terminals when the thermostat is calling for cooling. If there's no continuity, the contactor is likely bad.

- Voltage test: Verify that the correct voltage is reaching the contactor coil.

- Replacement: Replace the contactor if it's faulty.

4. Compressor Overload Protector (OLP)

Problem: The OLP is a safety device that protects the compressor motor from overheating. It will trip and shut down the compressor if it detects excessive temperatures.

Troubleshooting:

- Wait and Reset: Allow the compressor to cool down for several hours. Sometimes the OLP will automatically reset.

- Check Wiring: Inspect the wiring to the OLP for damage.

- Continuity test: Use a multimeter to check continuity on the OLP. If there is no continuity when it should be present, replace.

5. Locked Rotor

Problem: The compressor motor is physically seized and unable to turn.

Troubleshooting:

- Resistance test: Use a multimeter to measure the resistance between the compressor terminals. A very low or zero resistance reading indicates a shorted motor winding. A very high or infinite resistance reading indicates an open winding.

- Locked rotor amp test: Use an ammeter to measure the current draw of the compressor when it's attempting to start. A significantly higher than normal reading can indicate a locked rotor.

- Visual Inspection: Check for physical damage or signs of overheating on the compressor.

- Replacement: A locked rotor typically requires compressor replacement.

6. Refrigerant Issues

Problem: Low refrigerant levels can cause the compressor to overheat and shut down. In some cases, a system designed with low-pressure cut-off switch will stop the compressor from turning on when refrigerant levels are low.

Troubleshooting:

- Check refrigerant levels: Use gauges to measure the system's refrigerant pressures. Low pressures indicate a leak.

- Leak detection: Use a leak detector to find and repair any refrigerant leaks.

- Recharge the system: Once the leaks are repaired, recharge the system with the correct amount of refrigerant.

7. Compressor Failure

Problem: Internal mechanical or electrical failure within the compressor.

Troubleshooting:

- All the above checks: Rule out all other potential causes before assuming compressor failure.

- Professional diagnosis: A qualified HVAC technician will use specialized equipment and techniques to diagnose internal compressor problems.

- Replacement: Compressor failure usually necessitates a complete compressor replacement.

HVAC Career Paths and Job Outlook

The HVAC industry offers a wide range of career paths, from entry-level technicians to highly specialized engineers and business owners. The U.S. Bureau of Labor Statistics projects a 6% growth in employment for HVACR mechanics and installers from 2022 to 2032, about as fast as the average for all occupations. This growth is driven by increased construction, the need to replace aging equipment, and growing demand for energy-efficient systems. The median annual wage for HVACR mechanics and installers was $59,620 in May 2023.

Entry-Level Technician

Typically involves assisting experienced technicians with installations, repairs, and maintenance. Requires a high school diploma or equivalent, and often includes on-the-job training or vocational school.

HVAC Technician

Performs a variety of tasks, including diagnosing problems, repairing equipment, installing new systems, and performing routine maintenance. Requires formal training, such as an apprenticeship or associate's degree, and often requires state licensing.

HVAC Installer

Specializes in installing new HVAC systems. Requires knowledge of building codes, ductwork design, and electrical wiring.

HVAC Service Manager

Oversees a team of technicians, schedules service calls, manages inventory, and ensures customer satisfaction. Requires strong leadership and communication skills.

HVAC Design Engineer

Designs HVAC systems for new and existing buildings. Requires a bachelor's degree in mechanical engineering and knowledge of thermodynamics, fluid mechanics, and building codes.

Importance of Certifications

Certifications play a crucial role in advancing your career in the HVAC industry. They demonstrate your knowledge and skills to employers and customers, and can lead to higher earning potential.

EPA Section 608 Certification

Required by the Environmental Protection Agency (EPA) for technicians who handle refrigerants. This certification ensures that technicians understand proper refrigerant handling procedures to protect the environment.

NATE Certification

The North American Technician Excellence (NATE) certification is a widely recognized industry standard. NATE-certified technicians have demonstrated their knowledge and skills through rigorous testing. Employers often prefer to hire NATE-certified technicians, and some manufacturers offer extended warranties on equipment installed by NATE-certified professionals.

HVAC Excellence Certification

Another respected certification program that offers various certifications for different HVAC specialties.

Other Specialized Certifications

Depending on your area of specialization, you may also consider certifications in areas such as geothermal, solar thermal, or building automation systems.

Real-World Examples of Career Paths

Example 1: John starts as an entry-level technician, assisting senior technicians with installations and repairs. He attends night classes to earn his associate's degree in HVAC technology. After several years of experience, he obtains his NATE certification and becomes a lead technician, responsible for diagnosing complex problems and training junior technicians. He later becomes a service manager, overseeing a team of technicians and managing service operations.

Example 2: Sarah graduates with a bachelor's degree in mechanical engineering and specializes in HVAC design. She works for an engineering firm, designing HVAC systems for commercial buildings. She earns her Professional Engineer (PE) license and eventually starts her own consulting firm, providing energy-efficient HVAC design services to clients.

Industry Trends and the Future of HVAC

The HVAC industry is constantly evolving, driven by technological advancements, stricter energy efficiency standards, and growing environmental concerns. Some key trends shaping the future of HVAC include:

- Smart HVAC Systems: Integration of sensors, controls, and data analytics to optimize performance and energy efficiency.

- Energy Efficiency: Growing demand for high-efficiency equipment and systems that reduce energy consumption and lower utility bills.

- Refrigerant Regulations: Phasing out of ozone-depleting refrigerants and adoption of more environmentally friendly alternatives.

- Renewable Energy: Increasing use of renewable energy sources, such as solar and geothermal, for heating and cooling.

- Building Automation: Integration of HVAC systems with other building systems, such as lighting, security, and access control, to create intelligent and energy-efficient buildings.

Conclusion

A non-starting AC compressor is a common but complex issue that requires a systematic approach to troubleshooting. By understanding the potential causes, mastering the troubleshooting steps, and staying up-to-date on industry trends, HVAC technicians can provide valuable service and build successful careers. For employers, investing in training and certification for their employees is essential for maintaining a competitive edge and delivering high-quality service to customers. Whether you are looking to enter the field, advance your career, or grow your business, the HVAC industry offers tremendous opportunities for those who are willing to learn and adapt.