Air Conditioner Condenser Not Turning On

Troubleshooting a Silent Savior: When Your Air Conditioner Condenser Refuses to Start

The dog days of summer are here, and a silent air conditioner condenser is the last thing any homeowner or business owner wants to encounter. When your cooling system fails to kick on, it's not just about discomfort; it's also about potential downtime, lost productivity, and a spike in energy bills as the system struggles to compensate. This article will guide you through diagnosing the issue, exploring potential causes, and providing practical solutions, emphasizing energy efficiency and long-term cost savings.

Understanding the Condenser's Role

Before diving into troubleshooting, it’s crucial to understand the condenser's critical function. Located outside your home, the condenser unit is responsible for releasing the heat absorbed by the refrigerant inside your house. It contains a compressor, a fan, and a coil. The compressor pressurizes the refrigerant, the fan blows air across the coil to dissipate heat, and the cooled refrigerant then returns indoors to cool your home. When the condenser fails, the entire cooling process grinds to a halt.

Common Reasons Your Condenser Isn't Starting

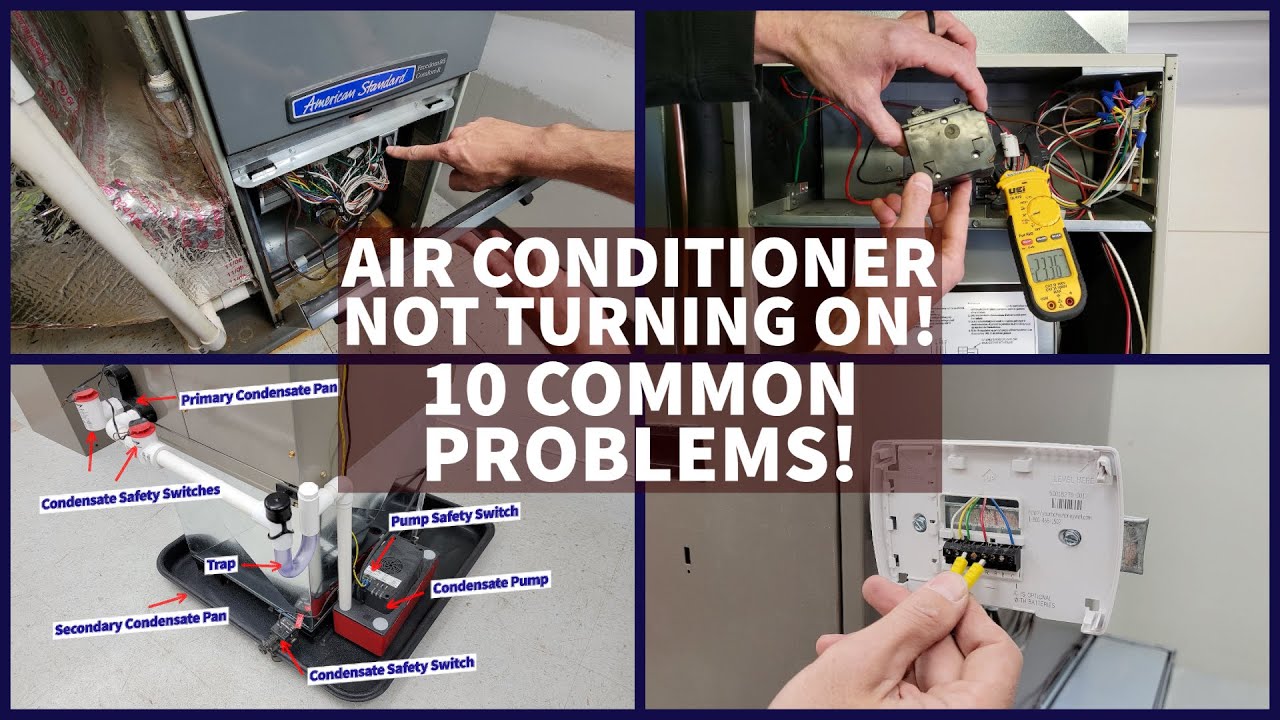

Several factors can prevent your air conditioner condenser from turning on. Here’s a breakdown of the most common culprits:

- Power Issues: The simplest yet often overlooked cause.

- Capacitor Problems: The capacitor provides the electrical surge needed to start the compressor and fan motor.

- Compressor Failure: The heart of the system.

- Dirty Condenser Coils: Dirt and debris act as insulation, preventing efficient heat transfer.

- Refrigerant Leaks: Low refrigerant levels can trigger safety mechanisms that shut down the compressor.

- Contactor Problems: A faulty contactor prevents power from reaching the compressor and fan.

- Overload Protection: The compressor is equipped with overload protection that trips when it overheats.

- Thermostat Issues: A malfunctioning thermostat might not be signaling the condenser to turn on.

- Wiring Problems: Loose or damaged wiring can disrupt the electrical circuit.

- Frozen Evaporator Coil: Although inside the house, a frozen evaporator coil can prevent the condenser from running.

Step-by-Step Troubleshooting Guide

Here's a structured approach to diagnosing the problem, starting with the easiest checks and progressing to more complex issues:

1. Verify Power Supply

Start with the basics. Check the circuit breaker dedicated to your air conditioner in your electrical panel. A tripped breaker is a common issue. Reset it and see if the condenser starts. Also, examine the disconnect switch near the condenser unit itself. Ensure it's in the "on" position. A loose connection or corroded contacts here can also be a problem.

2. Inspect the Capacitor

The capacitor is a cylindrical component usually located inside the condenser unit's control panel. WARNING: Capacitors store electricity and can deliver a dangerous shock even when the unit is off. If you're not comfortable working with electrical components, call a qualified HVAC technician. Look for signs of bulging, leaking, or corrosion. If you see any of these, the capacitor likely needs replacement. Testing a capacitor requires a multimeter with capacitance testing capability. A healthy capacitor will read within its specified microfarad (µF) range, typically printed on the component.

3. Clean the Condenser Coils

Over time, the condenser coils can become covered in dirt, leaves, and other debris, reducing their ability to release heat. Use a garden hose with a gentle spray nozzle to clean the coils from the inside out. Avoid using a high-pressure washer, as it can damage the delicate fins. According to the Energy Star program, cleaning your condenser coils annually can improve your system's efficiency by up to 15%, translating to significant energy savings.

4. Check the Contactor

The contactor is an electrical relay that switches power to the compressor and fan motor. With the power off, visually inspect the contactor for signs of damage, such as burned or pitted contacts. Use a multimeter to test for continuity across the terminals when the thermostat calls for cooling. If the contactor doesn't close properly, it needs to be replaced. Replacing a contactor is a relatively inexpensive repair that can save you from a much costlier compressor replacement.

5. Examine the Thermostat

Ensure your thermostat is set to "cool" and the temperature is set lower than the current room temperature. A faulty thermostat can prevent the condenser from receiving the signal to turn on. Try replacing the thermostat batteries. Consider upgrading to a smart thermostat. Smart thermostats like Nest or Ecobee offer features like remote control, programmable schedules, and energy usage monitoring, helping you optimize your cooling and heating and potentially qualify for rebates from your utility company.

6. Look for Refrigerant Leaks

Refrigerant leaks are difficult to detect without specialized equipment. Signs of a leak might include ice forming on the refrigerant lines or a hissing sound coming from the condenser unit. If you suspect a leak, call a qualified HVAC technician to diagnose and repair the leak, and recharge the system. Addressing refrigerant leaks promptly not only restores cooling performance but also prevents damage to the compressor and reduces environmental impact. Using the older R-22 refrigerant can be costly compared to the environmentally friendly and energy-efficient R-410A.

7. Inspect for Frozen Evaporator Coil

A frozen evaporator coil, located inside your home, can indirectly prevent the condenser from running. This is often caused by restricted airflow due to a dirty air filter or blocked vents. Check and replace your air filter regularly. Ensure that all vents are open and unobstructed. Allow the coil to thaw completely before restarting the system. To prevent future freezing, ensure proper airflow and consider having your system checked for refrigerant leaks or other issues by a professional.

8. Compressor Troubleshooting

Compressor issues are often the most expensive to resolve. Common problems include a failed compressor motor, locked rotor, or internal damage. Testing the compressor requires specialized tools and knowledge. If you suspect a compressor problem, it's best to call a qualified HVAC technician for diagnosis and repair or replacement. Considering the cost of a compressor replacement, it might be worthwhile to explore upgrading to a more energy-efficient system, especially if your existing unit is old or nearing the end of its lifespan.

The Benefits of Regular HVAC Maintenance

Preventive maintenance is key to avoiding costly repairs and maximizing the lifespan of your HVAC system. Regular maintenance includes:

- Cleaning condenser coils

- Replacing air filters

- Inspecting and tightening electrical connections

- Checking refrigerant levels

- Lubricating moving parts

- Calibrating the thermostat

A well-maintained HVAC system operates more efficiently, consumes less energy, and provides better indoor air quality. Many HVAC contractors offer maintenance agreements that provide regular checkups and discounts on repairs.

The ROI of Energy-Efficient HVAC Systems

Investing in an energy-efficient HVAC system can provide a significant return on investment over its lifespan. Look for systems with high Seasonal Energy Efficiency Ratio (SEER) ratings for cooling and Heating Seasonal Performance Factor (HSPF) ratings for heating. Systems with Energy Star certification meet stringent efficiency standards and may qualify for rebates and tax credits. According to the U.S. Department of Energy, upgrading to an Energy Star certified air conditioner can save you up to 20% on your cooling costs.

Smart HVAC Integration for Optimal Performance

Integrating your HVAC system with smart home technology can further enhance energy efficiency and comfort. Smart thermostats can learn your preferences and adjust the temperature automatically, optimizing energy usage. Smart sensors can monitor room temperature and humidity, providing real-time feedback to the system. Many smart HVAC systems also offer remote monitoring and control, allowing you to adjust settings from anywhere.

When to Call a Professional

While many HVAC issues can be resolved with basic troubleshooting, some problems require the expertise of a qualified HVAC technician. Call a professional if:

- You're not comfortable working with electrical components.

- You suspect a refrigerant leak.

- You're dealing with compressor issues.

- You've tried troubleshooting and the problem persists.

A qualified HVAC technician has the tools, knowledge, and experience to diagnose and repair complex HVAC problems safely and effectively. They can also advise you on the best options for upgrading to a more energy-efficient system.

Exploring Rebates and Incentives

Many utility companies and government agencies offer rebates and incentives for upgrading to energy-efficient HVAC systems. Check with your local utility company and the Energy Star website to see what programs are available in your area. These rebates can significantly reduce the upfront cost of upgrading your system and accelerate your return on investment. Additionally, tax credits may be available for certain energy-efficient home improvements.

Conclusion

A silent air conditioner condenser can be a frustrating problem, but with a systematic approach to troubleshooting, you can often identify and resolve the issue yourself. Remember to prioritize safety when working with electrical components and don't hesitate to call a professional if you're unsure. By maintaining your HVAC system regularly, investing in energy-efficient equipment, and exploring smart home integration, you can enjoy comfortable indoor temperatures while saving money on your energy bills.