Air Conditioner With Water Cooled Condenser

It's a sweltering summer day, and your air conditioner, the unsung hero of your home, suddenly falters. Instead of the blissful chill you expect, you're greeted with lukewarm air, or worse, no air at all. If you have an air conditioner with a water-cooled condenser, you might be facing a specific set of problems. One of the most common is reduced cooling capacity or the unit not cooling at all. This article will guide you through a systematic troubleshooting process, helping you diagnose the issue and potentially resolve it yourself, while knowing when to call in the professionals.

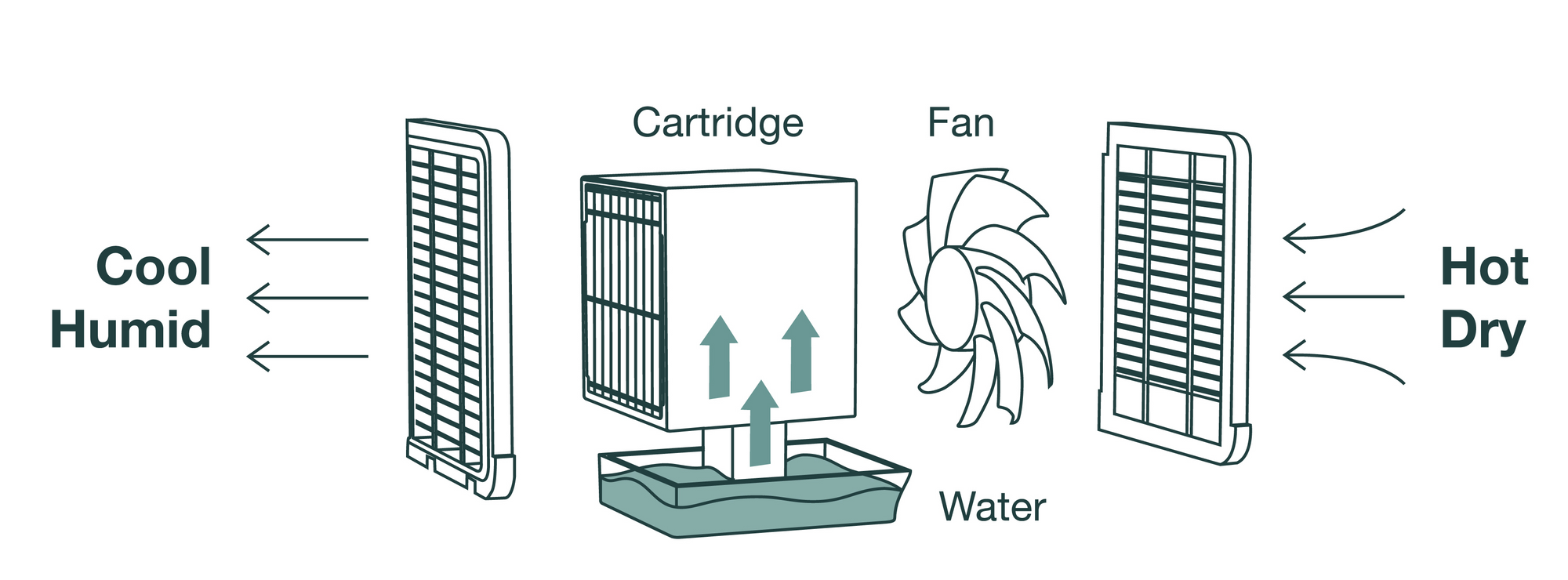

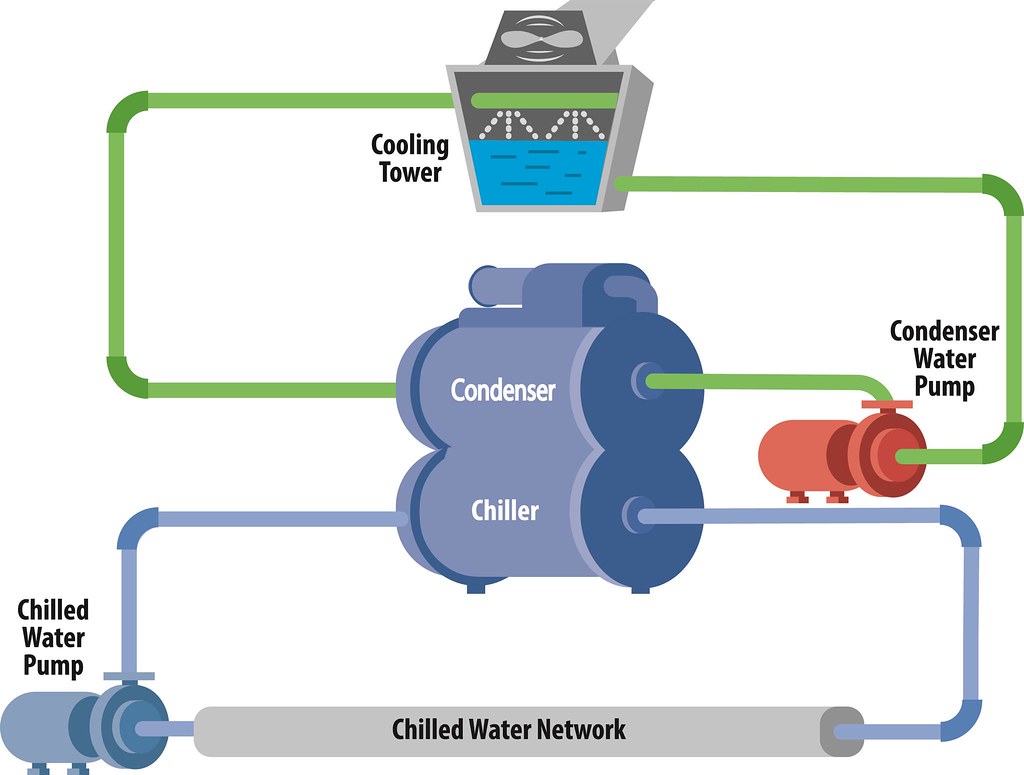

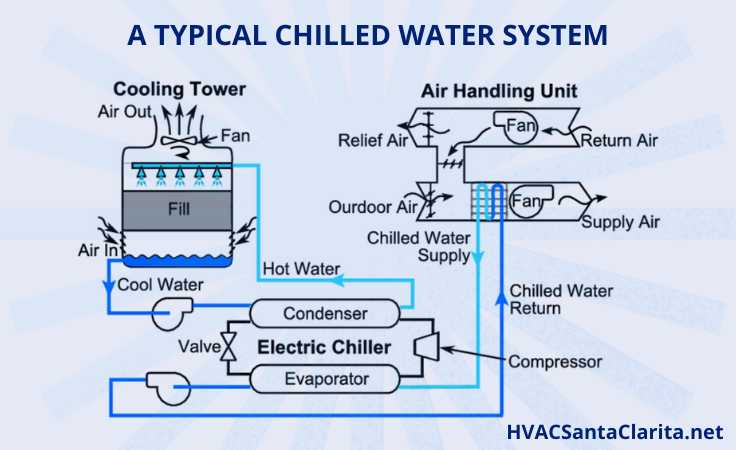

Understanding Water-Cooled Condensers

Before diving in, it's important to understand how a water-cooled condenser works. Unlike air-cooled systems that dissipate heat into the surrounding air, water-cooled condensers use a circulating water system to absorb and remove heat from the refrigerant. This water is then typically cooled in a cooling tower or by connection to a municipal water source before being recirculated back to the condenser. This method is often more efficient, especially in high-density areas or industrial settings, but it also introduces a new set of potential problems related to the water supply and cooling system.

Step 1: Initial Checks and Safety Precautions

Safety first! Before you begin any troubleshooting, always turn off the power to the air conditioner at the circuit breaker. This is crucial to prevent electrical shock.

Once the power is off, perform these initial checks:

- Inspect the Air Filter: A dirty air filter restricts airflow, reducing cooling efficiency and potentially causing the system to overheat. Replace it with a new one if it's clogged. This is a very common cause of poor performance.

- Check the Thermostat: Ensure the thermostat is set to "Cool" and the temperature is set lower than the current room temperature. Make sure the batteries in the thermostat are fresh. It sounds simple, but it's often overlooked!

- Listen for Obvious Noises: Unusual noises, such as banging, grinding, or hissing, can indicate mechanical problems. Note the type of noise and when it occurs (e.g., when the unit starts, runs, or stops).

Step 2: Examining the Water Supply and Condenser

This is where water-cooled systems differ significantly from air-cooled ones. You need to investigate the water supply to the condenser.

Water Supply Inspection

Verify Water Flow: Locate the water supply line to the condenser. Is there water flowing through it? You should be able to feel a slight vibration or hear the water moving. If not, check the following:

- Water Shut-Off Valves: Ensure that all water shut-off valves to the condenser are fully open. Sometimes, these valves are accidentally closed or partially closed during maintenance.

- Water Pressure: Check the water pressure at the supply line. Low water pressure can severely impact cooling performance. If you suspect low pressure, contact your water utility company to investigate.

- Water Filter/Strainer (if applicable): Many water-cooled systems have a filter or strainer to remove debris from the water supply. Locate this filter and clean it thoroughly. A clogged filter restricts water flow.

Condenser Inspection

Visual Inspection: Carefully inspect the condenser itself. Look for signs of:

- Corrosion: Corrosion can build up on the condenser surfaces, reducing its ability to transfer heat.

- Scale Buildup: Mineral deposits (scale) can accumulate on the condenser, insulating it and reducing its efficiency.

- Leaks: Check for water leaks around the condenser and associated piping. Leaks can indicate a failing seal or a corroded component.

DIY Fix: Cleaning the Condenser (Surface Cleaning ONLY)

Caution: Do not attempt to disassemble the condenser itself. This requires specialized knowledge and tools.

If you observe minor surface corrosion or scale buildup, you can attempt to clean the condenser externally. Do not use harsh chemicals or abrasive cleaners, as these can damage the condenser.

- Turn off the power to the air conditioner at the circuit breaker.

- Turn off the water supply to the condenser.

- Use a soft brush (like a toothbrush or small parts cleaning brush) and a mild soap solution to gently scrub the accessible surfaces of the condenser.

- Rinse thoroughly with clean water.

- Ensure the condenser is completely dry before restoring power and water supply.

- Turn the water supply back on slowly, checking for leaks.

- Turn the power back on at the circuit breaker.

Step 3: Checking the Cooling Tower/Water Recirculation System (If Applicable)

If your system uses a cooling tower or other water recirculation method, you'll need to inspect it as well.

Cooling Tower Inspection

- Water Level: Ensure the water level in the cooling tower is at the proper level. Low water levels can reduce cooling capacity and potentially damage the pump.

- Fan Operation: Check that the cooling tower fan is operating correctly. The fan helps to dissipate heat from the water.

- Debris and Algae: Clean any debris or algae from the cooling tower basin. These can restrict water flow and reduce cooling efficiency.

- Water Treatment: Many cooling towers require water treatment to prevent scale buildup and corrosion. Ensure that the water treatment system is functioning properly. This may involve adding chemicals to the water according to the manufacturer's instructions. Always follow safety precautions when handling chemicals.

Pump Inspection

- Pump Operation: Listen to the pump. Is it running smoothly? Unusual noises can indicate a problem with the pump.

- Pump Leaks: Check for water leaks around the pump.

- Pump Strainer: Clean the pump strainer to remove any debris that could be clogging the pump.

Step 4: Refrigerant Checks (Observe, Don't Touch!)

Important: Refrigerant handling requires specialized equipment and training. Do not attempt to add or remove refrigerant yourself. This is a job for a qualified HVAC technician.

However, you can observe for signs of a refrigerant problem:

- Ice Buildup: Ice buildup on the refrigerant lines can indicate a low refrigerant charge or a restriction in the refrigerant system.

- Hissing Sounds: Hissing sounds coming from the air conditioner can indicate a refrigerant leak.

- Lack of Cooling: Consistently poor cooling performance, even after cleaning the condenser and checking the water supply, can suggest a refrigerant issue.

When to Call a Professional

While you can perform many of the checks and simple fixes outlined above, some problems require the expertise of a qualified HVAC technician. Call a professional immediately if you encounter any of the following:

- Refrigerant Leaks: Any suspected refrigerant leak is a serious issue and requires immediate attention.

- Electrical Problems: If you suspect any electrical problems, such as blown fuses, tripped breakers, or burnt wires, do not attempt to fix them yourself.

- Mechanical Problems: Unusual noises, such as banging, grinding, or hissing, that persist after troubleshooting can indicate a mechanical problem requiring professional repair.

- Inability to Restore Cooling: If you have performed all the checks and simple fixes outlined above and the air conditioner is still not cooling properly, it's time to call a professional.

- Complex System Issues: If you have a complex water-cooled system with multiple components and you're unsure how to troubleshoot it, it's best to seek professional help.

- If you're uncomfortable: If at any point you feel uncomfortable or unsure about what you're doing, stop and call a professional. It's better to be safe than sorry.

Preventative Maintenance

The best way to avoid air conditioning problems is to perform regular preventative maintenance. Consider the following:

- Regular Filter Changes: Change your air filter every 1-3 months, depending on usage and air quality.

- Professional Tune-Ups: Schedule a professional tune-up for your air conditioner at least once a year. A technician can inspect the system, clean the coils, check the refrigerant charge, and identify potential problems before they become major issues.

- Water Treatment (if applicable): Maintain the water treatment system for your cooling tower or water recirculation system.

- Keep the Area Around the Condenser Clear: Ensure that there is adequate airflow around the condenser. Remove any obstructions, such as plants, bushes, or debris.

By following these troubleshooting steps and preventative maintenance tips, you can keep your water-cooled air conditioner running efficiently and reliably for years to come. Remember to prioritize safety and don't hesitate to call a professional when needed.