Average Cost Of 2 1 2 Ton Ac Unit

Understanding the cost of a new air conditioning unit is crucial whether you're a homeowner, property manager, or HVAC technician. A 2.5-ton AC unit is a common size for many homes, but the actual cost can vary significantly. This article breaks down the average cost of a 2.5-ton AC unit, factors influencing the price, and related considerations.

Average Cost Breakdown: 2.5-Ton AC Unit

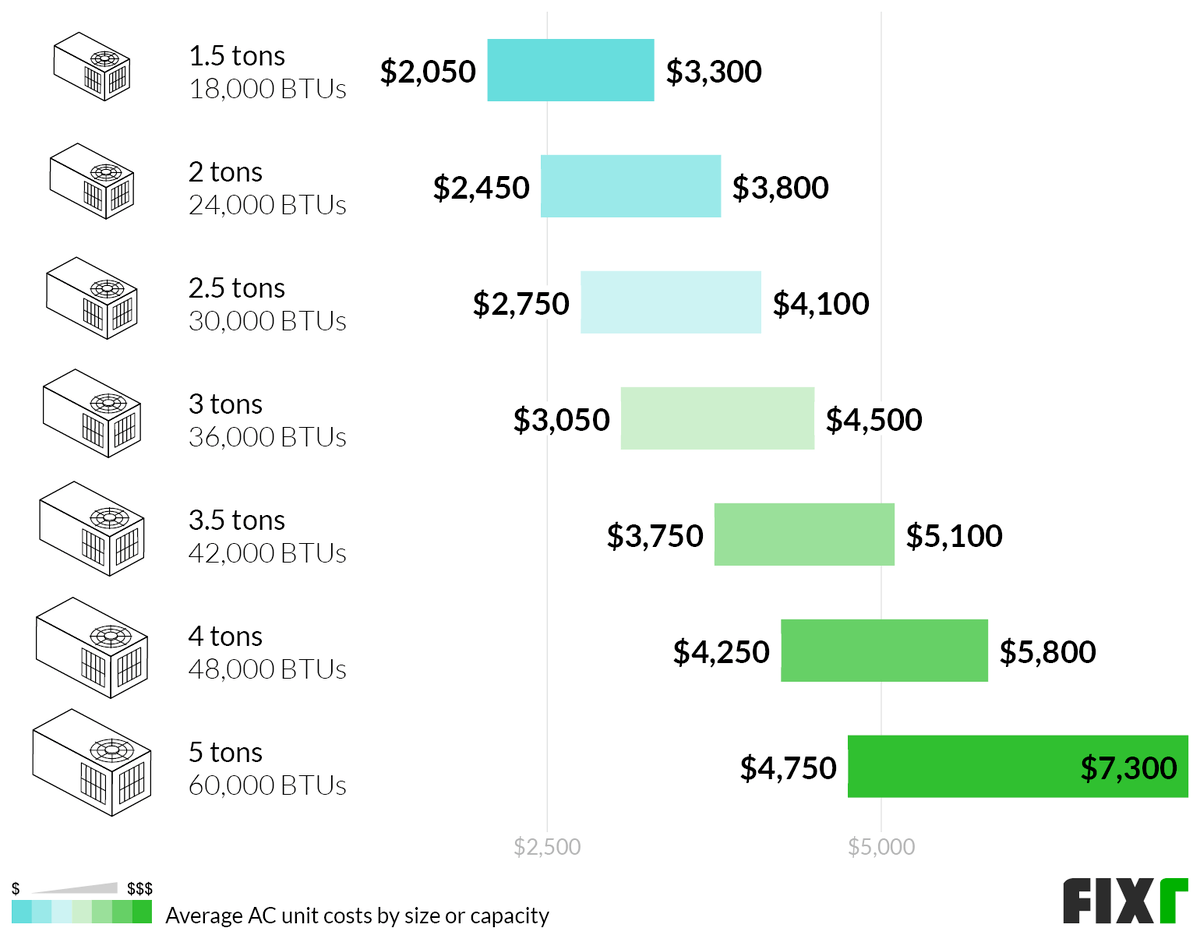

The total cost of a 2.5-ton air conditioning unit typically includes the unit itself, installation labor, and any additional materials required for the job. The cost can range from $3,500 to $7,000, but this is a broad estimate. Let's delve into more specific figures:

- Unit Price Only: Expect to pay between $1,500 and $3,500 for the 2.5-ton AC unit itself. This price depends on the brand, SEER rating, and features.

- Installation Costs: Installation labor can add another $2,000 to $3,500 to the total cost. This includes the removal of the old unit, proper connection of the new unit, refrigerant charging, and system testing.

- Permits and Inspections: Some municipalities require permits and inspections for HVAC installations. These fees can range from $50 to $500, depending on your location.

Factors Influencing the Cost

Several factors can significantly impact the overall cost of a 2.5-ton AC unit:

SEER Rating

The Seasonal Energy Efficiency Ratio (SEER) rating indicates how efficiently the unit cools your home. Higher SEER ratings mean better energy efficiency and lower utility bills, but they also come with a higher upfront cost. For example:

- 13-14 SEER: This is the minimum SEER rating allowed in many regions. A 2.5-ton unit with this rating might cost $1,500 - $2,000.

- 15-17 SEER: Offers better energy efficiency. Expect to pay $2,000 - $2,800 for the unit.

- 18+ SEER: High-efficiency units provide significant energy savings but can cost $2,800 - $3,500 or more.

Example: If you live in a hot climate with long cooling seasons, investing in a higher SEER rating can result in substantial long-term savings. A 16 SEER unit will save more money over its lifespan than a 13 SEER unit, potentially offsetting the higher initial cost.

Brand

Different brands have varying reputations for quality, reliability, and price. Carrier, Trane, and Lennox are considered premium brands and typically command higher prices. Goodman and Rheem are often seen as more budget-friendly options.

Example: A 2.5-ton Carrier unit with a 16 SEER rating might cost $2,700, while a comparable Goodman unit could be priced around $2,200. The difference reflects brand reputation, warranty terms, and potentially, component quality.

Installation Complexity

The complexity of the installation significantly affects labor costs. Factors that can increase installation costs include:

- Ductwork Modifications: If your existing ductwork needs to be modified or replaced, this will add to the labor cost.

- Accessibility: Difficult access to the indoor or outdoor unit location can increase labor time.

- Electrical Work: If your electrical panel needs upgrades to handle the new unit, this will add to the cost.

- Refrigerant Line Set: Replacing or extending the refrigerant line set can also increase the cost.

Example: A simple replacement of an existing unit in an easily accessible location might cost $2,000 for labor. However, if the ductwork needs significant modifications, the labor cost could increase to $3,000 or more.

Additional Features

Some AC units come with additional features that can increase their cost, such as:

- Smart Thermostats: Allow remote control and energy monitoring.

- Variable-Speed Compressors: Offer more precise temperature control and energy efficiency.

- Zoning Systems: Allow you to control the temperature in different areas of your home independently.

Example: A 2.5-ton unit with a variable-speed compressor and a smart thermostat might cost $500 - $1,000 more than a basic single-speed unit.

Long-Term Cost Considerations

Beyond the initial purchase and installation costs, consider the long-term operational costs of a 2.5-ton AC unit:

Energy Efficiency

A higher SEER rating translates to lower monthly energy bills. Calculate the potential savings over the unit's lifespan (typically 15-20 years) to determine if the upfront investment in a more efficient unit is worthwhile.

Maintenance

Regular maintenance is essential to keep your AC unit running efficiently and extend its lifespan. Budget for annual maintenance costs, which typically range from $100 to $300 per year. This includes cleaning coils, checking refrigerant levels, and inspecting components.

Repair Costs

Even with regular maintenance, AC units can experience breakdowns. Be prepared for potential repair costs. A comprehensive warranty can help mitigate these expenses.

Installation Best Practices

Proper installation is crucial for optimal performance and longevity of your AC unit. Here are some best practices to ensure a successful installation:

- Hire a Licensed HVAC Contractor: Ensure the contractor is licensed, insured, and experienced in installing AC units.

- Proper Sizing: Ensure the 2.5-ton unit is the correct size for your home. An oversized or undersized unit will operate inefficiently and may not provide adequate cooling. A Manual J load calculation should be performed.

- Ductwork Inspection: Have the contractor inspect your ductwork for leaks and insulation issues. Repairing these issues will improve efficiency.

- Refrigerant Charge: Ensure the unit is properly charged with refrigerant. An improper refrigerant charge can significantly reduce efficiency and damage the compressor.

- System Testing: After installation, the contractor should test the system to ensure it is operating correctly and efficiently.

Technician Tip: Always check the subcooling and superheat readings to ensure the refrigerant charge is within the manufacturer's specifications.

DIY vs. Professional Installation

While it might be tempting to install an AC unit yourself to save money, it's generally not recommended unless you have extensive HVAC experience. Improper installation can void the warranty, reduce efficiency, and even damage the unit. Hiring a professional ensures the job is done correctly and safely.

“Improper installation is a major cause of AC unit failures. It's always best to hire a qualified HVAC technician to ensure proper installation and avoid costly problems down the road.”

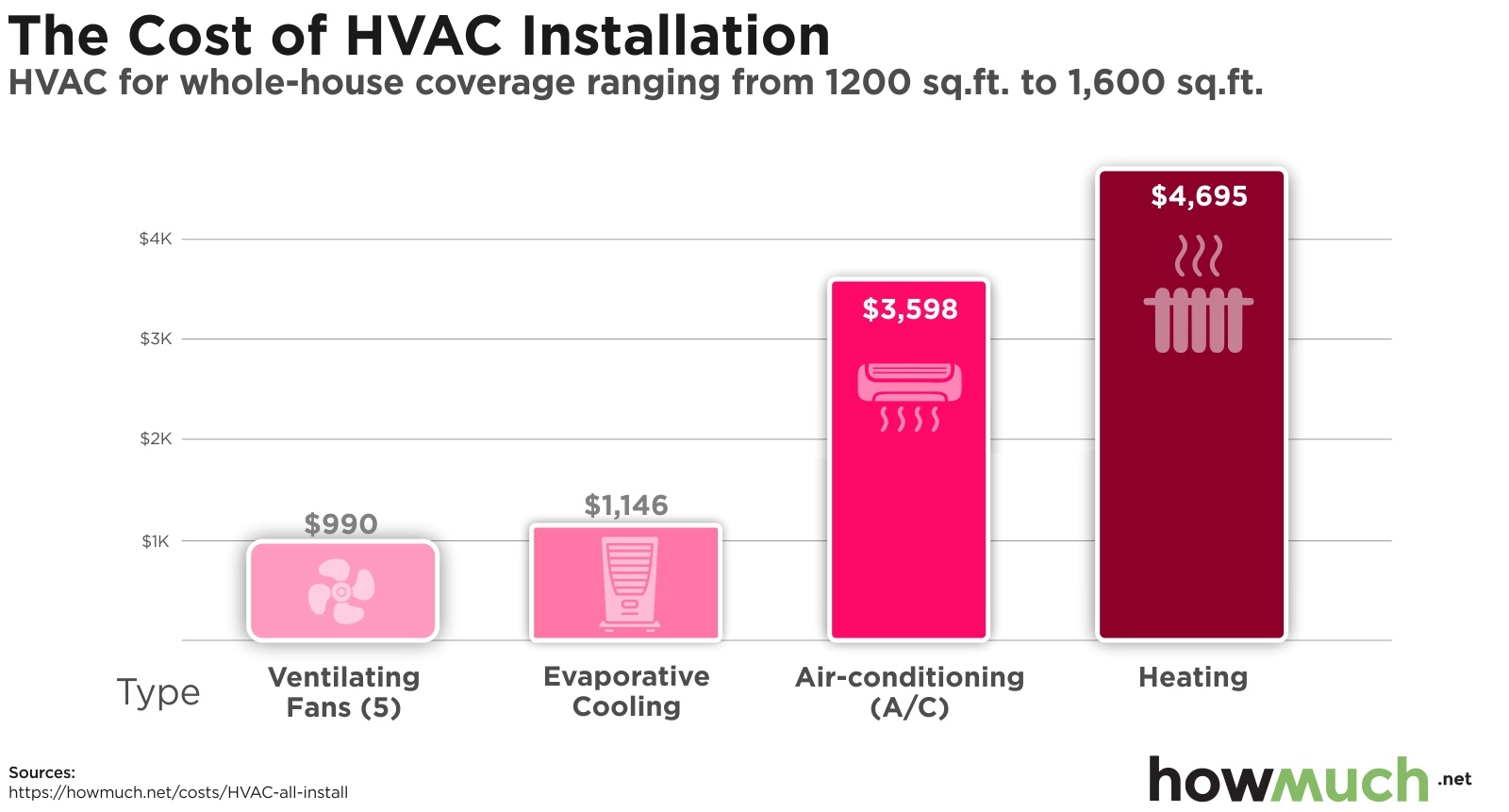

Alternatives to Traditional AC Units

Depending on your needs and budget, you might consider alternatives to traditional AC units:

- Ductless Mini-Split Systems: These systems are ideal for homes without ductwork or for zoning specific areas.

- Window AC Units: A more affordable option for cooling a single room.

- Evaporative Coolers (Swamp Coolers): Effective in dry climates, these coolers use evaporation to cool the air.

- Heat Pumps: Provide both heating and cooling and can be very energy-efficient.

Financing Options

If you're concerned about the upfront cost of a new AC unit, consider financing options. Many HVAC contractors offer financing plans, and you might also be eligible for rebates or tax credits for energy-efficient upgrades.

Conclusion

The average cost of a 2.5-ton AC unit ranges from $3,500 to $7,000, including the unit and installation. However, the actual cost can vary depending on the SEER rating, brand, installation complexity, and additional features. By understanding these factors and considering long-term operational costs, you can make an informed decision that meets your needs and budget. Always prioritize proper installation by a licensed HVAC professional to ensure optimal performance and longevity.