Back Pressure Regulator Vs Pressure Reducing Regulator

Navigating the world of HVAC systems requires a deep understanding of various components and their functions. Among the most critical are pressure regulators, but understanding the nuances between different types is essential for efficient system operation and troubleshooting. This article delves into the differences between two frequently confused types: Back Pressure Regulators (BPRs) and Pressure Reducing Regulators (PRRs), offering insights valuable for students, experienced technicians, and employers alike.

Understanding Pressure Regulation in HVAC Systems

Pressure regulation is vital for maintaining system stability, preventing equipment damage, and ensuring optimal performance. Fluctuations in pressure can lead to inefficiencies, safety hazards, and premature component failure. Both BPRs and PRRs play crucial roles, but their application depends on the specific requirements of the HVAC system.

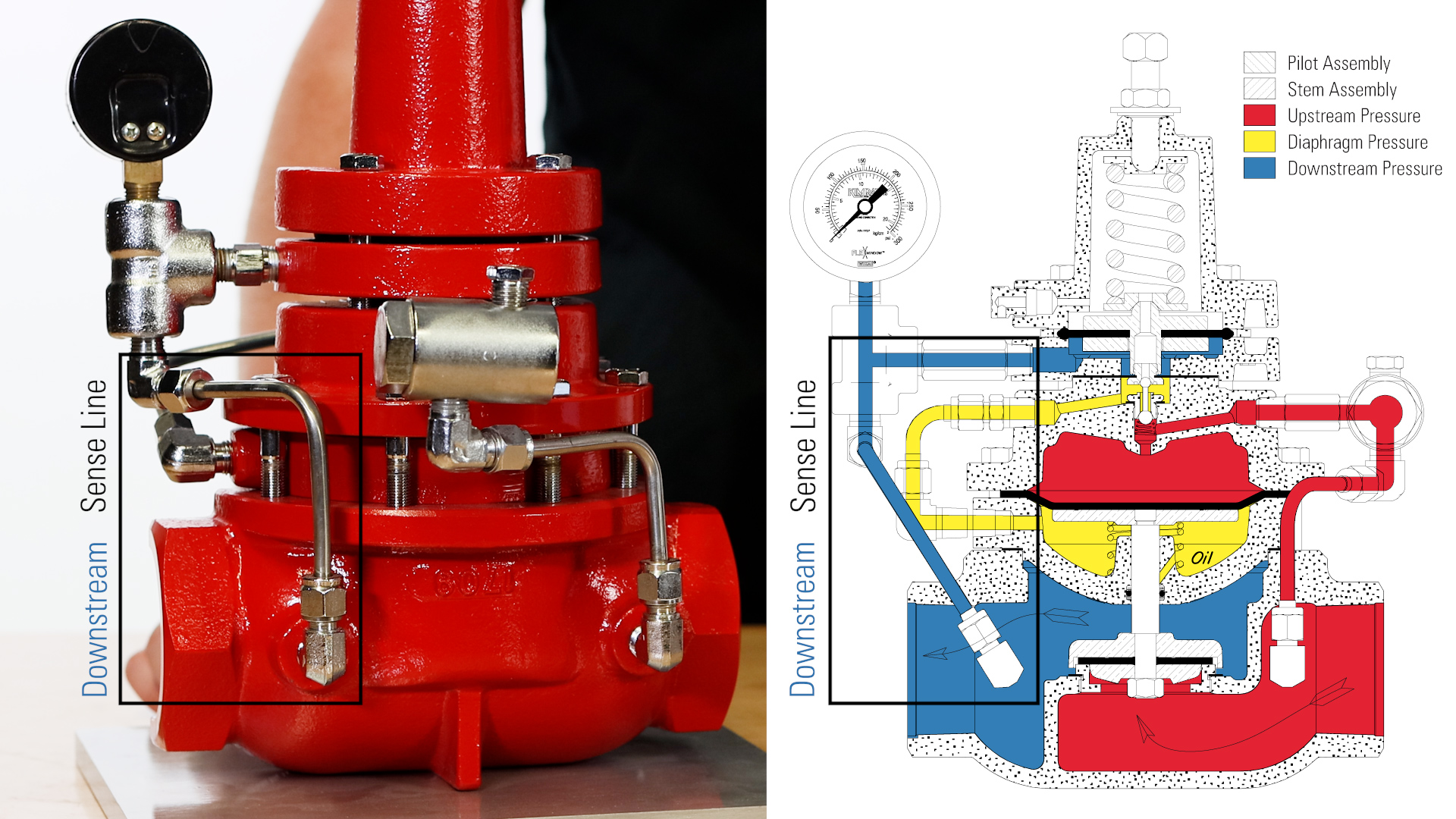

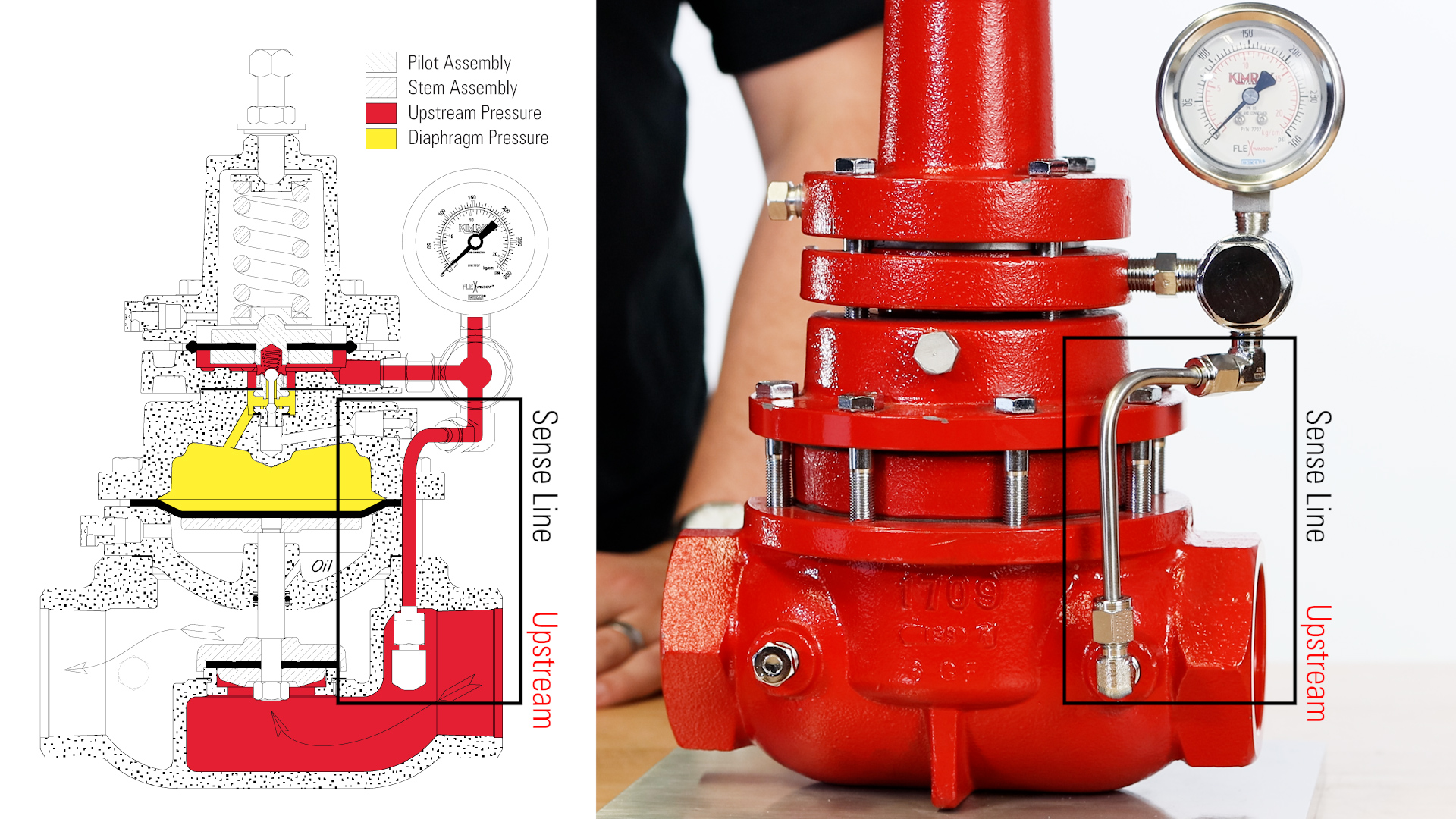

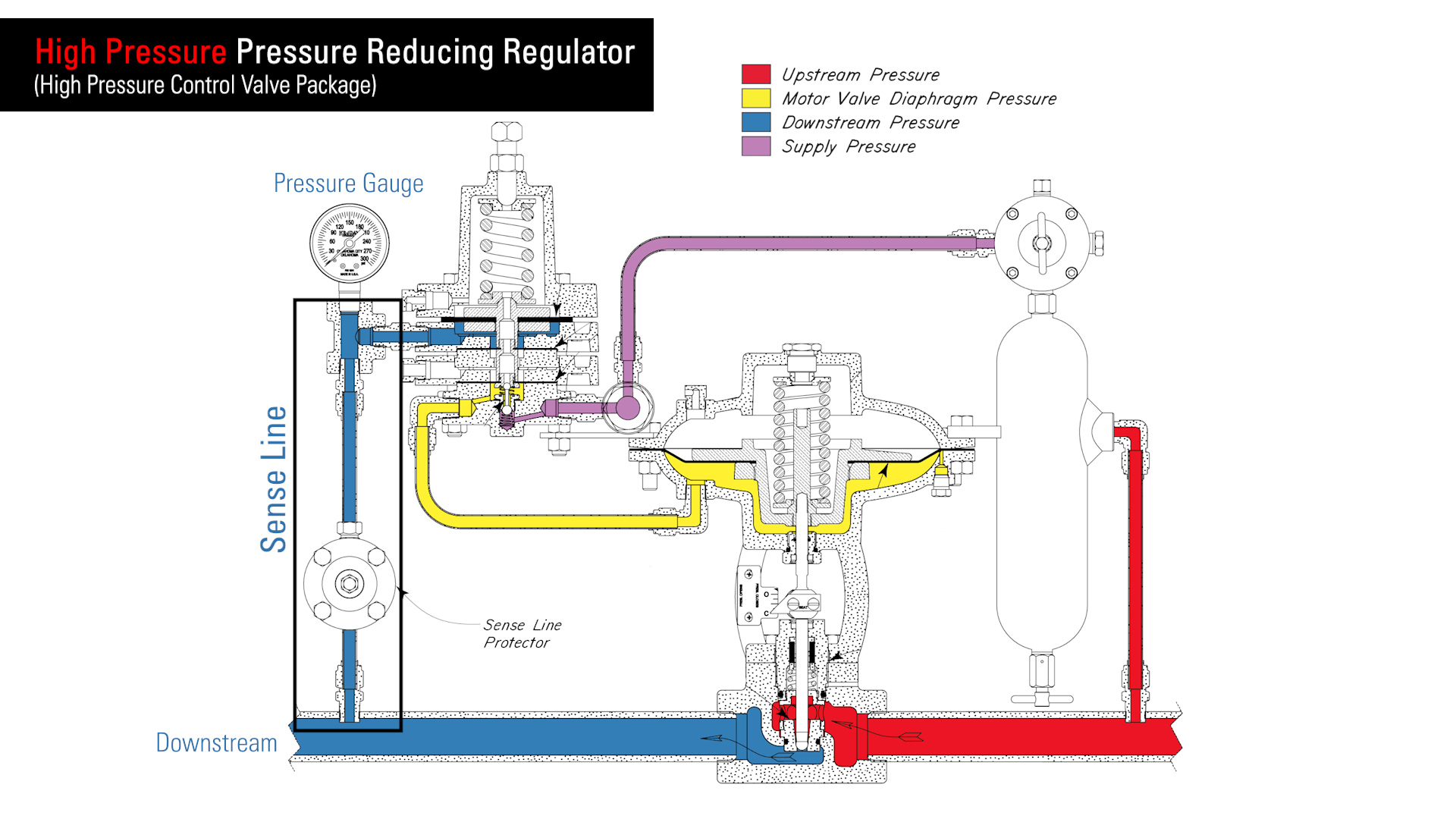

Pressure Reducing Regulators (PRRs): Controlling Downstream Pressure

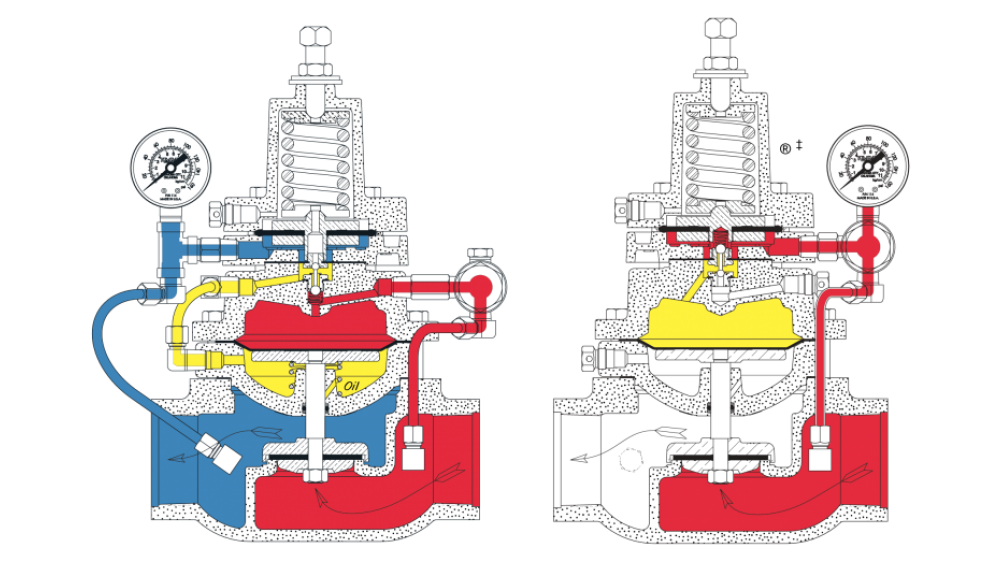

A Pressure Reducing Regulator, also known as a pressure regulator or let-down valve, is designed to reduce a higher upstream pressure to a lower, more manageable downstream pressure. Its primary function is to maintain a constant outlet pressure regardless of fluctuations in the inlet pressure or flow rate. This is critical in applications where a constant pressure is required for downstream equipment to function correctly.

Functionality: PRRs achieve pressure reduction through a throttling mechanism. A spring-loaded valve is adjusted to a desired outlet pressure. When the downstream pressure exceeds the setpoint, the valve closes slightly, restricting flow and reducing pressure. Conversely, if the downstream pressure drops below the setpoint, the valve opens further, increasing flow and raising the pressure. This continuous adjustment ensures a stable outlet pressure.

Applications: PRRs are commonly used in HVAC systems to:

- Control refrigerant pressure in refrigeration circuits.

- Regulate gas pressure in heating systems (e.g., natural gas furnaces).

- Maintain water pressure in hydronic heating and cooling systems.

- Protect sensitive equipment from overpressure.

Example: Consider a natural gas furnace. A PRR is used to reduce the high-pressure gas from the supply line to a lower, safer pressure suitable for the burner. This ensures consistent and efficient combustion.

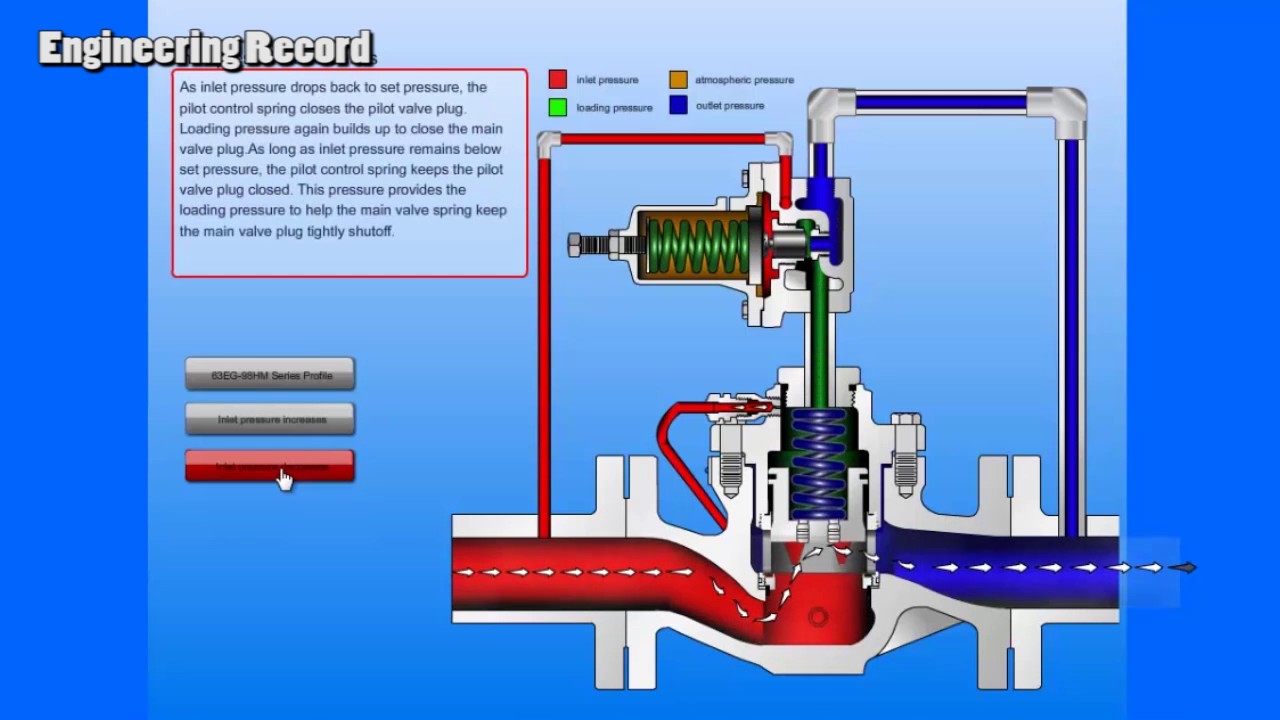

Back Pressure Regulators (BPRs): Maintaining Upstream Pressure

A Back Pressure Regulator, also known as a pressure sustaining valve or relief valve, is designed to maintain a minimum upstream pressure. Unlike PRRs, which control downstream pressure, BPRs control the pressure before the valve. They work by opening only when the upstream pressure exceeds a pre-set level, allowing excess pressure to be relieved to a lower pressure system or vent.

Functionality: BPRs operate in a reverse manner compared to PRRs. They remain closed until the upstream pressure reaches the setpoint. Once the setpoint is exceeded, the valve opens, releasing fluid or gas to maintain the desired upstream pressure. The valve modulates its opening to precisely control the pressure, preventing it from dropping below the setpoint.

Applications: BPRs are used in HVAC systems to:

- Maintain a minimum pressure in a refrigerant receiver.

- Prevent cavitation in pumps by ensuring sufficient suction head pressure.

- Protect equipment from vacuum conditions.

- Regulate pressure in closed-loop systems.

Example: In a refrigeration system, a BPR might be used after the evaporator to maintain a minimum evaporator pressure. This prevents the evaporator from freezing up and ensures efficient heat transfer.

Key Differences Summarized

PRR (Pressure Reducing Regulator): Reduces a higher upstream pressure to a lower downstream pressure, maintaining a constant outlet pressure.

BPR (Back Pressure Regulator): Maintains a minimum upstream pressure by relieving excess pressure when the setpoint is exceeded.

Career Paths and Certifications in HVAC

A solid understanding of pressure regulation is crucial for a successful career in HVAC. The industry offers diverse career paths, from entry-level technician positions to specialized roles such as system designers and project managers.

Entry-Level Technician: Typically requires a high school diploma or equivalent, completion of a vocational training program, and/or an apprenticeship. Responsibilities include installing, maintaining, and repairing HVAC systems under the supervision of experienced technicians. According to the Bureau of Labor Statistics (BLS), the median annual wage for HVACR mechanics and installers was $51,390 in May 2022. Job outlook is projected to grow 6 percent from 2022 to 2032, about as fast as the average for all occupations.

Experienced Technician: Requires several years of experience, often with specialized training in specific areas such as refrigeration or controls. Responsibilities include troubleshooting complex system problems, performing advanced repairs, and mentoring junior technicians. Salaries for experienced technicians can range from $60,000 to $80,000 or more, depending on experience and location.

HVAC System Designer: Requires a bachelor's degree in mechanical engineering or a related field. Responsibilities include designing HVAC systems for new buildings and retrofitting existing systems to improve energy efficiency and performance. Salaries for HVAC system designers can range from $70,000 to $100,000 or more, depending on experience and education.

Essential Certifications:

- EPA Section 608 Certification: Required for technicians who handle refrigerants.

- NATE (North American Technician Excellence) Certification: Demonstrates competency in specific areas of HVAC, such as installation, service, and repair. NATE-certified technicians are often preferred by employers and customers.

- HVAC Excellence Certification: Another respected certification that validates technical skills and knowledge.

- Various manufacturer-specific certifications: Demonstrate proficiency in working with specific brands and models of HVAC equipment.

Pursuing certifications can significantly enhance career prospects and earning potential. NATE certification, for example, often leads to higher pay and increased job opportunities. According to industry surveys, NATE-certified technicians earn, on average, 5-10% more than their non-certified counterparts.

Practical Applications and Troubleshooting

Knowing how to diagnose and troubleshoot issues related to pressure regulators is a critical skill for HVAC technicians. Here are some common problems and troubleshooting tips:

PRR Troubleshooting:

- Low downstream pressure: Check for a clogged strainer, incorrect pressure setting, or a malfunctioning regulator.

- High downstream pressure: Check for a stuck valve, incorrect pressure setting, or a damaged diaphragm.

- Pressure fluctuations: Check for a pulsating inlet pressure, a worn valve seat, or an improperly sized regulator.

BPR Troubleshooting:

- Low upstream pressure: Check for a blocked outlet, a malfunctioning regulator, or insufficient flow from the source.

- High upstream pressure: Check for a stuck valve, an incorrect pressure setting, or a malfunctioning control system.

- Pressure instability: Check for rapid changes in flow demand, a worn valve seat, or an improperly sized regulator.

When troubleshooting pressure regulators, always follow the manufacturer's recommendations and safety precautions. Use appropriate tools and equipment, and ensure the system is properly isolated before performing any maintenance or repairs.

The Employer's Perspective

For employers in the HVAC industry, hiring skilled workers with a strong understanding of pressure regulation is essential for ensuring the quality and reliability of their services. When recruiting HVAC technicians, employers should prioritize candidates with:

- Relevant training and certifications (e.g., EPA 608, NATE).

- Hands-on experience working with various types of pressure regulators.

- Strong troubleshooting and problem-solving skills.

- A commitment to safety and quality.

Investing in employee training and development is also crucial for retaining skilled workers and keeping up with the latest technological advancements. Employers can offer:

- On-the-job training.

- Tuition reimbursement for relevant courses and certifications.

- Opportunities to attend industry conferences and workshops.

Conclusion

Understanding the difference between Back Pressure Regulators and Pressure Reducing Regulators is fundamental for anyone involved in the HVAC industry. Whether you are a student just starting your journey, an experienced technician looking to advance your career, or an employer seeking qualified professionals, mastering the principles of pressure regulation is essential for success. By investing in training, certifications, and continuous learning, you can stay ahead of the curve and contribute to the advancement of the HVAC industry.