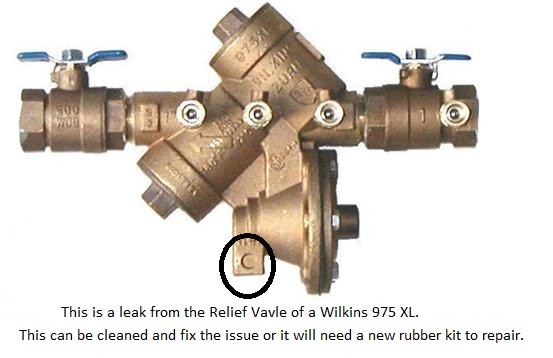

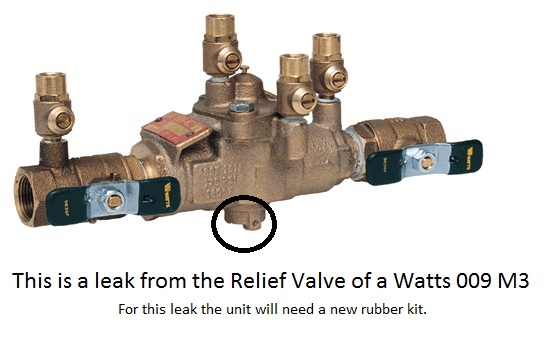

Backflow Preventer Leaking From Relief Valve

Frequently Asked Questions About Backflow Preventer Leaking From Relief Valve

A leaking backflow preventer relief valve can be concerning. This FAQ addresses common questions to help you understand why it's happening and what to do about it. Our goal is to provide clear, concise answers so you can take the appropriate action.

Question 1: What exactly is a backflow preventer, and why does it have a relief valve?

A backflow preventer is a crucial plumbing device designed to protect your potable (drinking) water supply from contamination. It prevents potentially harmful water from flowing backward (backflowing) into your clean water pipes.

Think of it this way: Imagine a situation where water pressure drops unexpectedly (e.g., during firefighting or a water main break). Without a backflow preventer, contaminated water from sources like irrigation systems, swimming pools, or even industrial processes could be sucked back into your drinking water supply. This is backflow, and it can have serious health consequences.

The relief valve is a safety mechanism built into the backflow preventer. Its primary function is to release excess pressure that may build up within the device. This can happen for several reasons, such as thermal expansion of water or a malfunctioning internal check valve. The relief valve opens to relieve this pressure, preventing damage to the backflow preventer and potentially preventing a more significant plumbing issue.

Question 2: Why is my backflow preventer's relief valve leaking water? Is it normal?

A small, occasional drip from the relief valve might be considered normal, especially if it's due to thermal expansion. However, consistent or excessive leaking is almost always a sign that something is wrong and requires investigation. Several factors can cause a backflow preventer relief valve to leak:

- Thermal Expansion: As water heats up, it expands. If the water in the backflow preventer is trapped, this expansion can increase the pressure, causing the relief valve to weep or drip. This is more common in systems with a check valve after the backflow preventer, creating a closed system.

- Debris or Sediment: Small particles of dirt, rust, or sediment can get lodged in the internal seals and seats of the backflow preventer, preventing them from sealing properly. This can lead to pressure buildup and subsequent leakage from the relief valve.

- Worn or Damaged Seals: Over time, the rubber seals and O-rings inside the backflow preventer can deteriorate, crack, or become brittle. This compromises their ability to create a watertight seal, resulting in leaks.

- High Water Pressure: Excessively high water pressure in your system can put undue stress on the backflow preventer and its components, causing the relief valve to open and leak.

- Malfunctioning Check Valve(s): The backflow preventer relies on internal check valves to prevent backflow. If one or more of these check valves are failing to close properly, it can lead to pressure imbalances and leakage from the relief valve.

- Freezing Temperatures: In colder climates, if the backflow preventer is not properly insulated, the water inside can freeze and expand, causing damage to the internal components and leading to leaks.

- Water Hammer: Sudden pressure surges in your water lines (water hammer) can shock the backflow preventer and damage its internal components, leading to leakage.

The bottom line: While a small drip might be acceptable, any significant or continuous leak from the relief valve should be considered a problem that needs to be addressed.

Question 3: Can I fix the leaking relief valve myself, or do I need to call a professional?

The answer depends on your plumbing skills and the severity of the leak. Some minor issues, like debris buildup, might be resolved with some basic troubleshooting, but most backflow preventer repairs require specialized knowledge and tools.

Here's a general guideline:

- Simple Troubleshooting (Proceed with Caution):

- Flushing: If you suspect debris, you *might* try flushing the backflow preventer. Consult your device's manual. This usually involves carefully opening and closing specific valves to clear out any trapped sediment. Important: Turn off the water supply upstream of the backflow preventer *before* attempting any maintenance.

- Visual Inspection: Check for obvious signs of damage, such as cracks or broken parts.

- When to Call a Professional:

- Persistent Leaking: If the leak continues after flushing.

- Significant Leaking: Any substantial amount of water escaping from the relief valve.

- Lack of Knowledge: If you are not comfortable working with plumbing or do not understand how backflow preventers work.

- Suspected Internal Damage: If you suspect that the internal components of the backflow preventer are damaged.

- Testing Requirements: Many jurisdictions require certified backflow testers to inspect and repair backflow preventers.

Important: Backflow preventers are critical for protecting your water supply, and improper repairs can lead to contamination. If you are unsure about anything, it's always best to err on the side of caution and call a qualified plumber or certified backflow preventer technician. Furthermore, be aware that working on backflow preventers might be regulated in your area, potentially requiring special licenses and permits.

Question 4: What are the potential consequences of ignoring a leaking backflow preventer relief valve?

Ignoring a leaking relief valve can lead to a range of problems, some more serious than others:

- Water Waste: Even a small, continuous drip can waste a significant amount of water over time, leading to higher water bills.

- Property Damage: Leaking water can damage surrounding structures, especially if the backflow preventer is located indoors or near sensitive materials. This can lead to costly repairs.

- Reduced Water Pressure: A leaking relief valve can reduce the overall water pressure in your system.

- Backflow Contamination: While the relief valve itself *doesn't directly cause backflow*, the underlying issue causing the leak (e.g., a faulty check valve) could compromise the backflow preventer's ability to prevent backflow. This is the most serious consequence, as it can lead to contamination of your drinking water supply.

- Code Violations: Many municipalities have regulations regarding backflow preventers. A malfunctioning or leaking device could result in code violations and fines.

Don't ignore the problem! Promptly addressing a leaking relief valve can prevent more significant and costly issues down the road.

Question 5: How much does it typically cost to repair or replace a backflow preventer?

The cost of repairing or replacing a backflow preventer can vary widely depending on several factors:

- Type of Backflow Preventer: Different types of backflow preventers have different complexities and costs.

- Extent of Damage: Minor repairs, such as replacing a seal, will be much less expensive than a complete replacement.

- Labor Costs: Plumber or technician labor rates vary depending on location and experience.

- Accessibility: If the backflow preventer is difficult to access, the labor costs may be higher.

- Local Regulations: Local regulations may require specific testing and certifications, which can add to the cost.

General Estimates:

- Minor Repairs (e.g., seal replacement): $100 - $300

- Major Repairs (e.g., replacing internal components): $200 - $600

- Replacement: $300 - $1500+ (including the cost of the new device and installation). More complex devices can cost even more.

Important: These are just *estimates*. It's always best to get quotes from multiple qualified plumbers or backflow preventer technicians in your area to get a more accurate idea of the cost.

Question 6: How can I prevent my backflow preventer from leaking in the future?

While you can't completely eliminate the risk of leaks, here are some steps you can take to minimize problems and extend the life of your backflow preventer:

- Regular Inspections and Testing: Have your backflow preventer inspected and tested annually by a certified technician. This will help identify potential problems early on and ensure that the device is functioning correctly. Many municipalities require annual testing.

- Proper Winterization: In colder climates, protect your backflow preventer from freezing temperatures by insulating it properly. This may involve wrapping it with insulation or installing a heated enclosure.

- Maintain Water Pressure: Ensure that your water pressure is within the recommended range for your plumbing system. Consider installing a pressure reducing valve (PRV) if your water pressure is consistently too high.

- Install a Water Hammer Arrestor: Water hammer arrestors can help absorb pressure surges and protect your plumbing system, including your backflow preventer, from damage.

- Flush Regularly: Periodically flush your plumbing system to remove sediment and debris that can accumulate in the backflow preventer. Consult your device's manual or a plumber for instructions.

- Avoid Over-Tightening Connections: When making any plumbing connections near the backflow preventer, avoid over-tightening the fittings. This can damage the internal components.

- Use a Strainer/Filter: Consider installing a strainer or filter upstream of the backflow preventer to capture sediment and debris before they reach the device.

Question 7: Are there different types of backflow preventers, and does the type affect the leaking?

Yes, there are several types of backflow preventers, each designed for different applications and levels of hazard. The most common types include:

- Reduced Pressure Principle (RP) Backflow Preventer: Offers the highest level of protection. It has two independently acting check valves and a pressure-regulated zone between them. This type is often used for high-hazard situations.

- Double Check Valve Assembly (DCVA): Provides a good level of protection and is commonly used for moderate-hazard applications. It has two independently acting check valves but no pressure-regulated zone.

- Pressure Vacuum Breaker Assembly (PVBA): Designed for irrigation systems and other non-potable water applications. It's installed above the highest point in the system.

- Atmospheric Vacuum Breaker (AVB): The simplest type, also used for irrigation and similar applications. It's installed directly on the fixture it's protecting.

How Type Affects Leaking:

While the underlying causes of leaking (debris, worn seals, etc.) are generally the same across different types of backflow preventers, the specific components that fail and the symptoms may vary.

- RP Backflow Preventers: These are more complex and have more components that can potentially fail, including the relief valve itself, which is crucial to its operation. Leaking from the relief valve is a common symptom of an RP backflow preventer malfunction.

- DCVA: Because they lack a relief valve, DVCAs usually manifest leakage through the test cocks or from the valve body itself when internal components fail.

- PVBA & AVB: These are generally less prone to leaking but can fail due to debris or damage to the internal components. Leaking often occurs from the vent or the valve body.

The type of backflow preventer you have will influence the troubleshooting process and the specific repairs needed. Refer to the manufacturer's documentation for your specific device for detailed information on maintenance and repair.