Can Pvc Be Used For Hot Water

The Burning Question: Can PVC Be Used For Hot Water? A Comprehensive HVAC Industry Guide

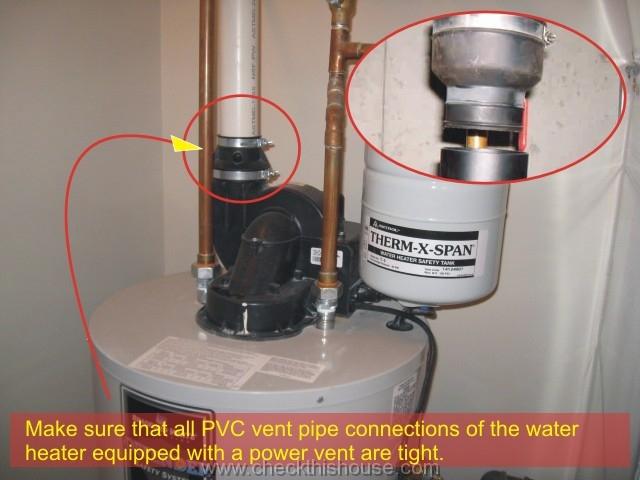

For HVAC professionals and students alike, understanding material properties is crucial. One question that frequently surfaces, especially in plumbing and hydronic heating discussions, is: Can PVC (Polyvinyl Chloride) be used for hot water systems? The short answer is generally no. However, the complete answer requires a deeper dive into PVC's limitations, alternative materials, and relevant code considerations.

Understanding PVC's Temperature Limitations

PVC is a thermoplastic material known for its rigidity, durability, and cost-effectiveness. It's widely used in cold water plumbing, drainage, and ventilation systems. However, PVC's Achilles' heel is its sensitivity to high temperatures. Standard PVC begins to soften and deform at temperatures above approximately 140°F (60°C). Domestic hot water systems often operate at temperatures between 120°F (49°C) and 140°F (60°C), with some systems even reaching higher temperatures for specific applications like dishwashers or sanitation.

Exposing PVC to prolonged periods of hot water can lead to:

- Softening and Sagging: The pipe loses its structural integrity, causing it to sag and potentially collapse.

- Joint Failure: Glued joints can weaken and leak as the PVC expands and contracts unevenly.

- Reduced Lifespan: The overall lifespan of the PVC piping system is significantly shortened.

- Potential for Bursting: In extreme cases, the weakened pipe can burst under pressure, causing water damage.

These issues pose significant safety and financial risks, making standard PVC unsuitable for hot water distribution.

CPVC: The Hot Water Alternative

While PVC isn't appropriate for hot water, CPVC (Chlorinated Polyvinyl Chloride) is specifically engineered for higher temperature applications. CPVC is produced by chlorinating PVC resin, which increases its chlorine content and, consequently, its temperature resistance. CPVC can typically withstand temperatures up to 200°F (93°C), making it a viable option for many residential and some commercial hot water systems.

Key Differences Between PVC and CPVC:

- Temperature Resistance: CPVC handles higher temperatures than PVC.

- Cost: CPVC is generally more expensive than PVC due to the additional manufacturing process.

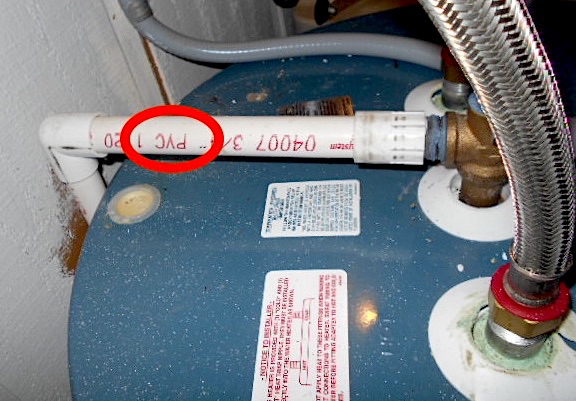

- Color: CPVC is often light yellow or cream-colored, while PVC is typically white or gray. However, color alone isn't a reliable indicator – always check the pipe markings.

- Installation: Both PVC and CPVC use solvent welding (gluing), but require different types of cement specifically formulated for each material.

Even with CPVC, it's crucial to adhere to the manufacturer's specifications and local plumbing codes regarding temperature and pressure limitations. Some high-temperature or high-pressure applications may still require alternative materials like copper or PEX.

Other Materials for Hot Water Systems

Beyond CPVC, several other materials are commonly used in hot water systems:

- Copper: A traditional choice known for its excellent heat transfer, durability, and resistance to high temperatures. However, copper is more expensive than plastic alternatives and requires soldering, which demands skilled labor.

- PEX (Cross-linked Polyethylene): A flexible plastic tubing that's easy to install and resistant to freezing. PEX is suitable for both hot and cold water distribution and is gaining popularity due to its lower cost and faster installation compared to copper.

- Stainless Steel: Offers excellent corrosion resistance and high-temperature performance. Stainless steel is often used in commercial and industrial applications where durability and longevity are paramount. However, it's the most expensive option.

Code Considerations and Regulations

Local plumbing codes and regulations dictate the acceptable materials for hot water systems. These codes are in place to ensure safety, prevent water contamination, and maintain system performance. Always consult the relevant codes in your area before selecting materials for a plumbing project. Violating these codes can result in fines, project delays, and potential legal liabilities.

Organizations like the International Association of Plumbing and Mechanical Officials (IAPMO) and the International Code Council (ICC) develop model codes that are often adopted or adapted by local jurisdictions. Understanding these codes is a fundamental skill for any HVAC or plumbing professional.

The HVAC Career Landscape: Opportunities and Salaries

The HVAC industry is experiencing strong growth, driven by factors such as increasing demand for energy-efficient systems, stricter building codes, and a growing emphasis on indoor air quality. The U.S. Bureau of Labor Statistics projects a [Insert Current BLS Data - typically around 5-10%] growth in employment for HVAC mechanics and installers over the next decade.

Salary Ranges:

Salaries in the HVAC field vary depending on experience, location, specialization, and certifications. Entry-level technicians can expect to earn between $35,000 and $45,000 per year, while experienced technicians with advanced certifications can earn upwards of $70,000 or more. Master technicians and business owners can command even higher incomes.

Example Career Paths:

- Entry-Level Technician: Starts with basic installations and maintenance tasks.

- Service Technician: Diagnoses and repairs HVAC systems.

- Installation Technician: Installs new HVAC systems in residential and commercial buildings.

- HVAC Designer: Designs HVAC systems for new construction and renovations.

- HVAC Sales Engineer: Sells HVAC equipment and services to commercial clients.

- HVAC Contractor/Business Owner: Manages and operates an HVAC business.

Certifications: Boosting Your Career Potential

Professional certifications are highly valued in the HVAC industry. They demonstrate competency, enhance credibility, and often lead to higher earning potential. Some key certifications include:

- NATE (North American Technician Excellence): NATE certification is widely recognized as a mark of excellence for HVAC technicians. It covers various specialties, including installation, service, and testing.

- EPA Section 608 Certification: Required for technicians who handle refrigerants. This certification ensures that technicians understand and comply with environmental regulations regarding refrigerant handling and disposal. There are different types depending on the equipment being serviced (Type I, Type II, Type III, and Universal).

- HVAC Excellence: Another reputable certification organization that offers various certifications for HVAC professionals.

- Manufacturer-Specific Certifications: Many HVAC equipment manufacturers offer certifications for their specific products. These certifications can be valuable for technicians who specialize in certain brands.

Investing in certifications demonstrates a commitment to professional development and can significantly enhance your career prospects.

The Importance of Continuing Education

The HVAC industry is constantly evolving with new technologies, regulations, and best practices. Continuing education is essential for staying up-to-date and maintaining a competitive edge. HVAC professionals should regularly attend training courses, workshops, and conferences to learn about the latest advancements and improve their skills.

Online resources, trade publications, and professional organizations also offer valuable opportunities for continuing education. Engaging in lifelong learning is crucial for a successful and fulfilling career in the HVAC industry.

Conclusion: Choose the Right Materials for the Job

In summary, while PVC is a versatile and cost-effective material for many plumbing applications, it's not suitable for hot water systems. CPVC, copper, PEX, and stainless steel are all viable alternatives, each with its own advantages and disadvantages. Selecting the appropriate material depends on factors such as temperature requirements, pressure ratings, cost considerations, and local code regulations. By understanding these factors and staying informed about industry best practices, HVAC professionals can ensure the safety, efficiency, and longevity of hot water systems.

Whether you're a student embarking on your HVAC career, an experienced technician seeking to advance your skills, or an employer looking to hire qualified professionals, remember that continuous learning and a commitment to quality are the keys to success in this dynamic and rewarding industry.