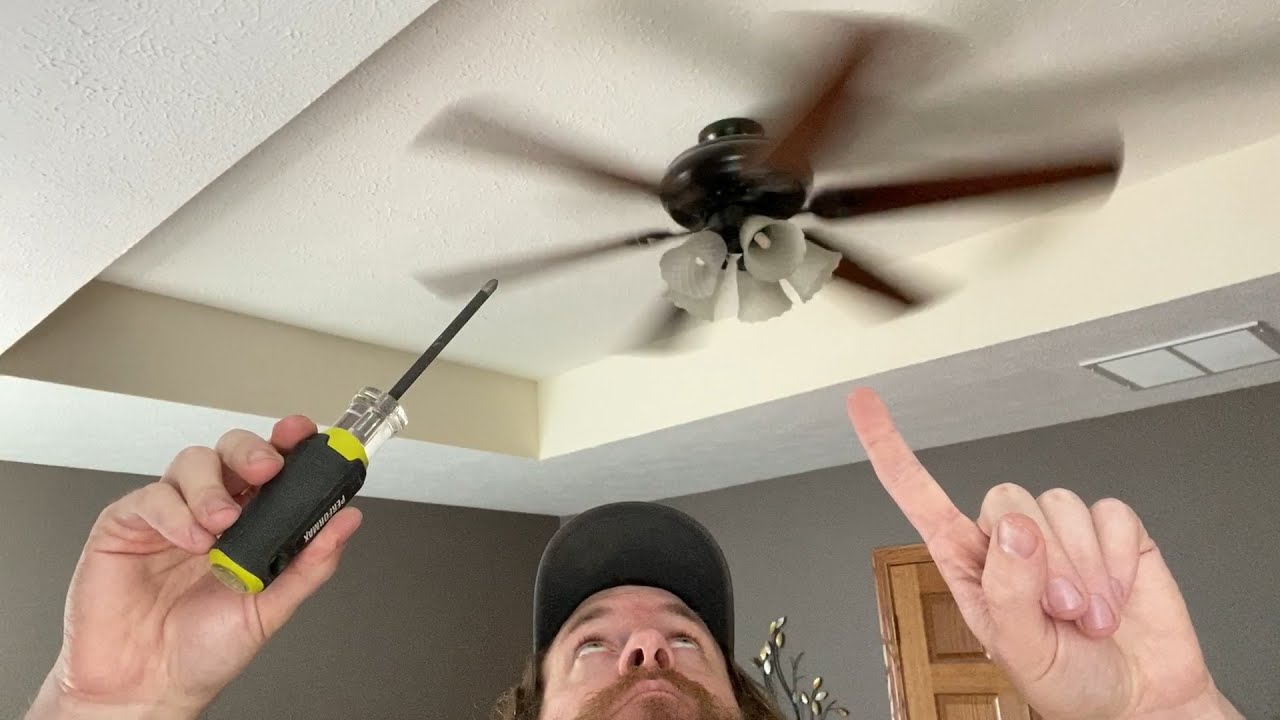

Ceiling Fan Clicking Noise At High Speed

Ceiling fans are ubiquitous in both residential and commercial spaces, offering an energy-efficient way to circulate air and improve comfort. However, one common complaint is a clicking noise, particularly at high speed. Understanding the causes of this noise and how to address it is crucial for HVAC technicians, installers, and even homeowners. This article delves into the potential culprits behind ceiling fan clicking, troubleshooting tips, and the importance of proper installation and maintenance, all within the context of a thriving HVAC career field.

Diagnosing the Click: Common Causes

A clicking sound emanating from a ceiling fan at high speed isn't just annoying; it can indicate an underlying problem. Pinpointing the exact cause is the first step towards a solution. Here are some of the most frequent offenders:

- Loose Screws and Fasteners: This is perhaps the most common reason. Over time, vibrations can loosen screws holding the fan blades, motor housing, light fixture, or mounting bracket in place. Even slightly loose screws can cause a clicking noise as components shift against each other.

- Blade Imbalance: An unbalanced fan blade creates wobble, leading to clicking as the blades brush against the motor housing or other parts. This imbalance can result from blade damage, warping, or even dust accumulation.

- Motor Issues: A failing motor can produce a variety of noises, including clicking. This could be due to worn bearings, internal friction, or electrical arcing. Motor problems are often more complex to diagnose and repair.

- Light Kit Problems: If your ceiling fan has a light kit, loose bulbs, glass shades, or connections within the kit can create clicking sounds. The chain pull cords can also contribute to noise if they are striking the light fixture.

- Wiring Issues: Loose wire connectors or wires rubbing against the fan housing can also generate clicks. Safety is paramount when dealing with electrical components.

- Dry Bearings: Like any motor, a ceiling fan motor relies on bearings to facilitate smooth rotation. Over time, these bearings can dry out, causing friction and noise.

- Mounting Bracket Issues: The mounting bracket, responsible for securing the fan to the ceiling, can loosen or develop play. This can result in movement and clicking, especially if the fan is not properly anchored.

Troubleshooting Steps for HVAC Technicians and DIYers

Addressing a clicking ceiling fan requires a systematic approach. Here's a breakdown of troubleshooting steps applicable to HVAC professionals and homeowners alike:

- Safety First: Always turn off the power to the ceiling fan at the circuit breaker before attempting any inspection or repair.

- Visual Inspection: Carefully examine the fan blades, motor housing, light kit, and mounting bracket for any signs of damage, looseness, or wear.

- Tighten Screws: Tighten all screws and fasteners associated with the fan blades, motor housing, light kit, and mounting bracket. Use a properly sized screwdriver to avoid stripping the screw heads.

- Balance the Blades: Use a blade balancing kit, typically consisting of weights, to identify and correct any blade imbalance. Follow the instructions included with the kit. Clean the blades as well. Excess dust can contribute to imbalance.

- Inspect the Light Kit: Ensure all bulbs are securely tightened and that any glass shades are properly attached. Check for loose connections within the light kit wiring.

- Check Wiring: Carefully inspect the wiring connections within the fan housing, ensuring that all connections are secure and that no wires are rubbing against the housing.

- Lubricate Bearings: If the clicking persists after tightening screws and balancing the blades, the bearings may need lubrication. Consult the fan's manual for recommended lubricants.

- Mounting Bracket Stability: Ensure the mounting bracket is securely attached to the ceiling joist. If necessary, reinforce the attachment with additional screws or bracing.

Important Note: If you suspect a motor issue or are uncomfortable working with electrical components, it's best to consult a qualified HVAC technician. Electrical work can be dangerous if not performed correctly.

The HVAC Career Connection: Opportunities and Expertise

Troubleshooting and repairing ceiling fans, while seemingly simple, falls within the broader skillset of an HVAC technician. The ability to diagnose mechanical and electrical issues, coupled with strong problem-solving skills, is highly valued in the HVAC industry.

According to the Bureau of Labor Statistics, the job outlook for HVAC technicians is projected to grow 6 percent from 2022 to 2032, about as fast as the average for all occupations. This translates to roughly 38,000 openings for HVAC technicians each year, driven by construction growth and the need to replace aging equipment. The median annual wage for HVAC mechanics and installers was $59,620 in May 2023.

Certifications: Enhancing Your HVAC Credentials

Obtaining industry-recognized certifications can significantly enhance your career prospects and earning potential. Some key certifications for HVAC professionals include:

- NATE (North American Technician Excellence): NATE certification demonstrates your expertise in specific HVAC areas, such as installation, service, and maintenance.

- EPA Section 608 Certification: This certification is required for technicians who handle refrigerants. It covers regulations related to refrigerant recovery, recycling, and reclamation.

- HVAC Excellence Certifications: HVAC Excellence offers a range of certifications covering various aspects of HVAC technology and service.

These certifications not only validate your skills but also provide employers with confidence in your abilities. NATE and EPA 608 certifications are particularly well-regarded within the industry.

Career Paths in HVAC: Beyond Basic Repairs

A career in HVAC offers diverse opportunities, ranging from entry-level installation and repair to specialized roles such as:

- HVAC Technician: Responsible for installing, maintaining, and repairing HVAC systems.

- HVAC Service Manager: Oversees a team of technicians, ensuring efficient service delivery and customer satisfaction.

- HVAC Design Engineer: Designs HVAC systems for residential and commercial buildings, considering factors such as energy efficiency and building codes.

- HVAC Sales Engineer: Sells HVAC equipment and services to businesses and individuals.

- HVAC Instructor: Teaches HVAC principles and practices at vocational schools and community colleges.

Consider the career path of Sarah, an HVAC apprentice who started by assisting senior technicians with basic tasks like ceiling fan installation and maintenance. Through on-the-job training, formal education, and NATE certification, she progressed to become a lead HVAC technician, specializing in energy-efficient system design. Her career trajectory exemplifies the growth potential within the HVAC field.

Employer Perspective: The Value of Skilled Technicians

For employers in the HVAC industry, hiring skilled and certified technicians is crucial for maintaining customer satisfaction and ensuring high-quality service. A well-trained technician can efficiently diagnose and resolve issues, minimizing downtime and maximizing system performance.

Employers often seek candidates with the following attributes:

- Technical Skills: A solid understanding of HVAC principles, including electrical, mechanical, and refrigeration systems.

- Problem-Solving Abilities: The capacity to diagnose and troubleshoot complex issues effectively.

- Customer Service Skills: The ability to communicate clearly and professionally with customers.

- Certifications: NATE, EPA 608, and other industry-recognized certifications.

- Safety Awareness: A strong commitment to safety practices and procedures.

Investing in employee training and development is also essential for retaining skilled technicians and ensuring that they stay up-to-date with the latest technologies and best practices. Employers that prioritize training and offer competitive compensation packages are more likely to attract and retain top talent.

Preventive Maintenance: Avoiding Future Clicking

The best way to prevent a clicking ceiling fan is through regular preventive maintenance. Here are some key maintenance tasks that can help keep your fan running smoothly:

- Regular Cleaning: Dust the fan blades and motor housing regularly to prevent dust accumulation, which can contribute to imbalance.

- Tighten Screws Annually: Check and tighten all screws and fasteners at least once a year.

- Lubricate Bearings (if applicable): If the fan has oil ports for bearing lubrication, follow the manufacturer's instructions for lubrication.

- Inspect Blades for Damage: Periodically inspect the blades for cracks, warping, or other damage. Replace damaged blades promptly.

By incorporating these preventive maintenance steps into your routine, you can minimize the likelihood of encountering a clicking ceiling fan and extend the lifespan of your fan.

Conclusion: The Importance of Knowledge and Skill

Addressing a clicking ceiling fan involves understanding the potential causes, employing systematic troubleshooting techniques, and implementing preventive maintenance measures. For HVAC technicians, this seemingly minor task underscores the importance of technical skills, problem-solving abilities, and a commitment to customer service. As the HVAC industry continues to grow, skilled and certified technicians will remain in high demand, offering rewarding career opportunities for those who are passionate about providing quality service and ensuring comfortable indoor environments. Whether you're an aspiring HVAC professional, a seasoned technician, or an employer seeking top talent, investing in knowledge and skill is essential for success in this dynamic field. Remember, even a seemingly simple problem like a clicking ceiling fan provides an opportunity to showcase your expertise and build lasting relationships with clients. Keep your knowledge sharp, your tools ready, and your commitment to quality unwavering.