Changing A 3 Phase Motor To Single Phase

Converting a 3-Phase Motor to Single-Phase: Is It a Smart Energy Move?

The hum of machinery, the whir of fans – these are the sounds of both progress and, often, significant energy consumption. If you're a homeowner, business owner, or HVAC professional focused on reducing your carbon footprint and energy bills, you've likely encountered the debate around 3-phase versus single-phase motors. While 3-phase motors are typically more efficient and powerful, sometimes the existing infrastructure limits your options. Let's explore the possibilities of converting a 3-phase motor to single-phase operation, weighing the pros, cons, and crucial energy considerations.

Understanding the Basics: 3-Phase vs. Single-Phase Power

Before diving into conversion, it's essential to grasp the fundamental difference between 3-phase and single-phase power. Single-phase power, commonly found in residential settings, delivers power through two wires: a hot wire and a neutral wire. The voltage fluctuates in a sinusoidal wave. Three-phase power, primarily used in industrial and commercial applications, utilizes three hot wires, each carrying a voltage that is 120 degrees out of phase with the others. This staggered delivery results in smoother, more consistent power, leading to higher efficiency and greater torque in motors. Think of it like paddling a boat; single-phase is like one person paddling, while three-phase is like three people paddling in perfect unison, resulting in a smoother and more powerful motion.

Energy Star certified appliances and HVAC systems are designed to optimize energy use, and understanding the underlying power principles can help you make informed decisions when upgrading or modifying your systems.

The Feasibility of Conversion: Why and When?

Converting a 3-phase motor to single-phase is generally not recommended for applications requiring high performance or sustained heavy loads. The motor's horsepower and torque will be significantly reduced – often by as much as 50%. However, there are specific scenarios where it might be considered:

- Limited Power Availability: If you lack access to 3-phase power but have a 3-phase motor you want to repurpose for a light-duty application.

- Cost Constraints: Replacing a 3-phase motor with a single-phase equivalent might be more expensive than attempting a conversion, particularly for smaller motors.

- Short-Term Solutions: As a temporary workaround until a proper 3-phase power supply can be established.

It is crucial to understand that a converted 3-phase motor operating on single-phase power will likely experience increased heat generation and reduced lifespan. This is due to the inherent inefficiencies of running a motor designed for balanced power on an unbalanced single-phase supply.

Conversion Methods: Static and Rotary Phase Converters

There are two primary methods for converting a 3-phase motor to single-phase operation:

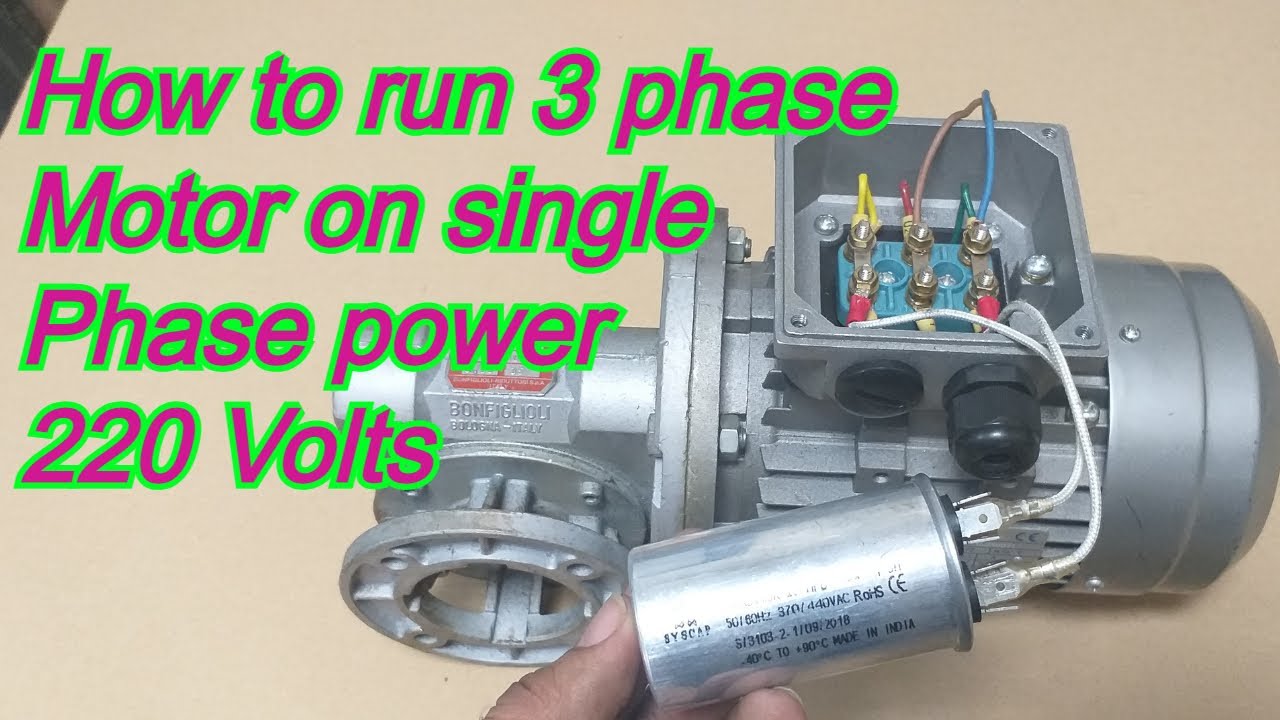

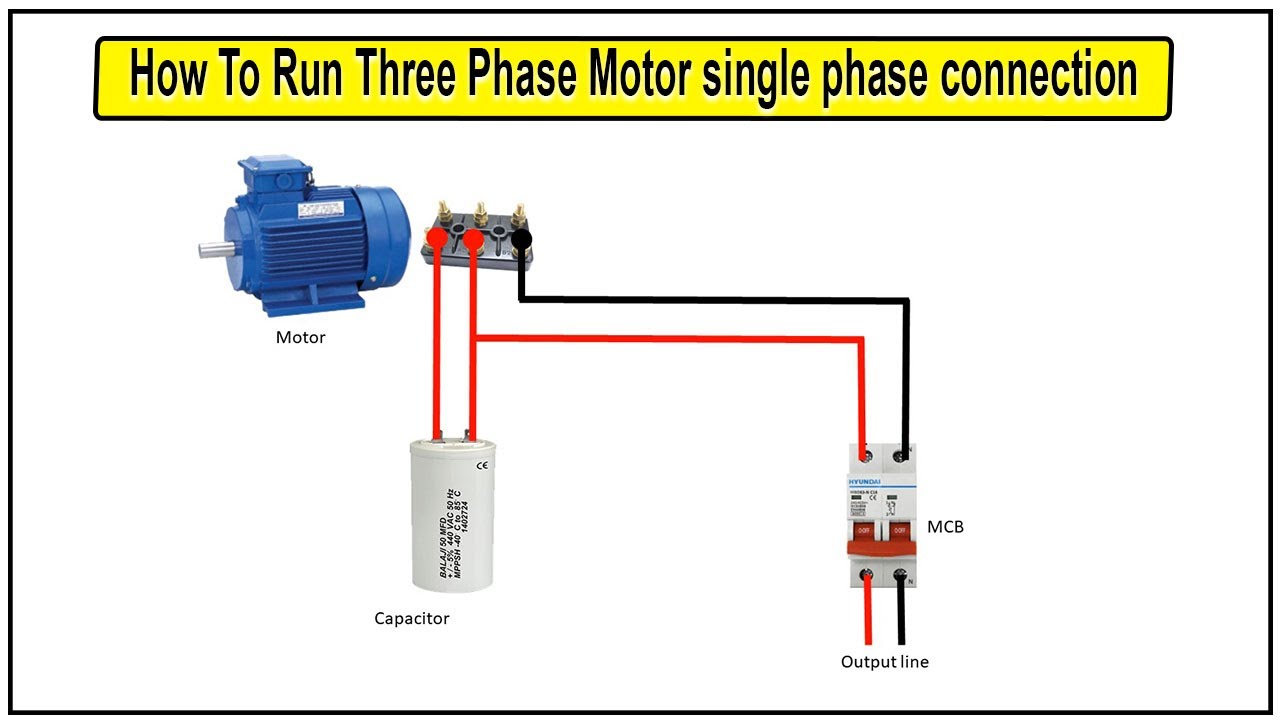

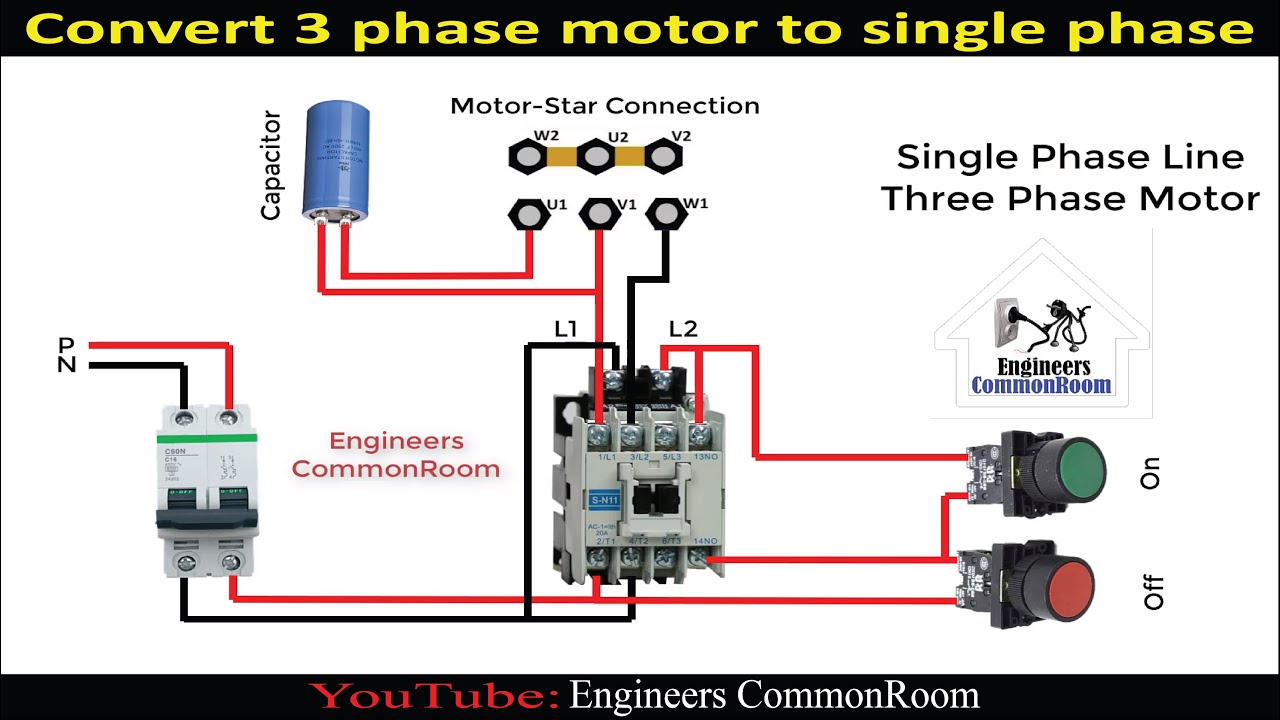

- Static Phase Converters: These are the simplest and least expensive option. They use capacitors to create a simulated third phase, allowing the motor to start and run on single-phase power. However, only two of the three motor windings are energized when running, resulting in reduced horsepower and efficiency. Static converters are best suited for applications where the motor is rarely under full load.

- Rotary Phase Converters: These utilize an idler motor to generate a true third phase. The idler motor runs continuously, acting as a rotating transformer to convert single-phase power into 3-phase power. Rotary converters offer significantly better performance than static converters, providing closer to the motor's rated horsepower and improved efficiency. However, they are more expensive and require more maintenance due to the moving parts. Rotary converters are ideal for applications requiring more consistent power, such as powering machinery for extended periods.

Selecting the right converter depends heavily on the motor's size, the load requirements, and your budget. Always consult with a qualified electrician or motor specialist before making a decision.

Wiring Considerations and Safety Precautions

Wiring a 3-phase motor for single-phase operation requires careful attention to detail and adherence to all applicable electrical codes. Incorrect wiring can damage the motor, the converter, and even pose a safety hazard. Always disconnect the power supply before working on any electrical equipment.

Here are some general wiring guidelines (Note: This is for informational purposes only and should not be taken as professional electrical advice. Always consult with a licensed electrician.):

- Identify the motor's windings: Use a multimeter to determine which terminals correspond to each winding.

- Connect the capacitors (for static converters): Follow the wiring diagram provided with the converter to connect the appropriate capacitors to the motor windings.

- Provide adequate overcurrent protection: Install appropriately sized fuses or circuit breakers to protect the motor and the converter from overloads.

- Ground the motor properly: Ensure that the motor frame is properly grounded to prevent electrical shock hazards.

The Energy Efficiency Trade-Off: Is Conversion Worth It?

While converting a 3-phase motor to single-phase might seem like a cost-effective solution in certain situations, it's crucial to consider the long-term energy implications. Running a 3-phase motor on single-phase power almost always results in reduced efficiency and increased energy consumption.

Data Point: A 3-phase motor converted to single-phase using a static converter can experience a 20-40% reduction in efficiency, translating to higher energy bills and increased operating costs. Conversely, a rotary converter can reduce the efficiency loss to 10-20%.

Before opting for conversion, perform a thorough cost-benefit analysis. Compare the cost of the converter, the potential increase in energy consumption, and the reduced lifespan of the motor against the cost of replacing the motor with a single-phase equivalent or upgrading to a 3-phase power supply.

Smart HVAC Integration and Energy Monitoring

Integrating a converted motor into a smart HVAC system can provide valuable insights into its energy performance. Smart thermostats and energy monitoring systems can track energy consumption, identify inefficiencies, and alert you to potential problems. By monitoring the motor's current draw and operating temperature, you can detect early signs of overload or overheating, potentially preventing costly repairs or premature failure.

Furthermore, smart HVAC systems can optimize the motor's operation by adjusting fan speeds or other parameters based on real-time conditions, minimizing energy consumption without compromising performance.

Exploring Rebates and Incentives

Many utility companies and government agencies offer rebates and incentives for energy-efficient upgrades, including replacing inefficient motors. Before converting a 3-phase motor to single-phase, investigate whether you might qualify for rebates by installing a new, high-efficiency single-phase motor. These rebates can significantly offset the upfront cost of a new motor, making it a more financially attractive option in the long run.

Check the Energy Star website and your local utility provider's website for information on available rebates and incentives.

Conclusion: A Case-by-Case Decision

Converting a 3-phase motor to single-phase is a complex decision with significant energy implications. While it might offer a temporary solution or a cost-effective option in certain limited scenarios, it's essential to carefully weigh the trade-offs in terms of efficiency, performance, and motor lifespan.

Ultimately, the best approach is to thoroughly assess your needs, consult with qualified professionals, and prioritize energy efficiency whenever possible. Replacing the motor with a properly sized single-phase motor or upgrading to a 3-phase power supply are often the most sustainable and cost-effective solutions in the long run. By focusing on energy efficiency, you can reduce your environmental impact, lower your energy bills, and create a more comfortable and sustainable environment for your home or business.