Difference Between Fused And Non Fused Disconnect

Frequently Asked Questions: Fused vs. Non-Fused Disconnects

Disconnect switches are crucial safety components in electrical systems, allowing you to safely cut power to specific circuits or equipment for maintenance or repair. But what's the difference between fused and non-fused disconnects? This FAQ will break it down in plain language.

1. What exactly is a disconnect switch?

A disconnect switch, also known as a disconnect, is a mechanical switching device used to isolate a circuit or piece of equipment from its power source. Think of it as a very robust light switch for your entire circuit. Its primary function is to provide a visible and verifiable break in the electrical circuit, ensuring safety for anyone working on the disconnected equipment.

2. What's the key difference between a fused and non-fused disconnect?

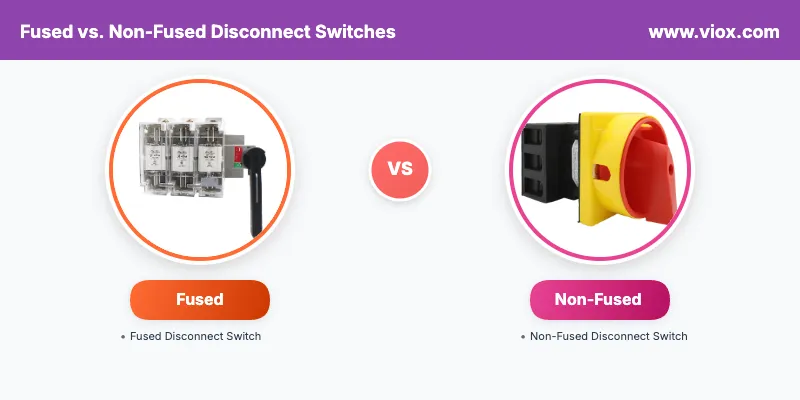

The fundamental difference is the presence of fuses.

- Fused disconnects incorporate fuses directly within the switch mechanism. These fuses provide overcurrent protection. If there's a surge of current exceeding the fuse's rating (due to a short circuit or overload), the fuse blows, interrupting the circuit and preventing damage to equipment and wiring.

- Non-fused disconnects simply provide a means to disconnect the circuit. They offer no overcurrent protection of their own. Overcurrent protection must be provided upstream (closer to the power source), usually by a circuit breaker or fuse panel.

In simpler terms, a fused disconnect is a disconnect and a circuit breaker in one unit, while a non-fused disconnect is just a disconnect.

3. When should I use a fused disconnect?

Fused disconnects are typically used when you need both a disconnect switch and overcurrent protection at the point of disconnect. Here are some common scenarios:

- Protecting sensitive equipment: If you have a piece of machinery or equipment that's particularly vulnerable to damage from overcurrent, a fused disconnect can provide an extra layer of protection right at the equipment.

- Long circuit runs: If the distance between the main circuit breaker and the equipment is significant, a fused disconnect at the equipment can protect the wiring along that run from overcurrent situations that might not trip the upstream breaker quickly enough.

- Motor circuits: Motors often have inrush currents when they start up. Fused disconnects with appropriately sized fuses can handle these inrush currents while still providing protection against sustained overloads.

- Compliance with codes: Some electrical codes may require the use of fused disconnects in specific applications. Always check your local codes and regulations.

The primary advantage of a fused disconnect is that it provides local overcurrent protection, isolating faults to a smaller area of the electrical system.

4. When is a non-fused disconnect appropriate?

Non-fused disconnects are generally used when overcurrent protection is already adequately provided upstream. Consider these situations:

- Existing overcurrent protection: If the circuit is already protected by a circuit breaker or fuse panel that's properly sized for the load, a non-fused disconnect can be used simply to provide a safe way to isolate the circuit.

- Simple on/off switching: For applications where you only need to be able to safely turn power on and off to a device or circuit, without needing additional overcurrent protection, a non-fused disconnect is sufficient.

- As part of a larger system with coordinated protection: In some complex electrical systems, overcurrent protection is carefully coordinated across multiple devices. A non-fused disconnect may be used as part of this coordinated system.

Non-fused disconnects are typically less expensive than fused disconnects, making them a cost-effective choice when overcurrent protection isn't needed at the point of disconnect.

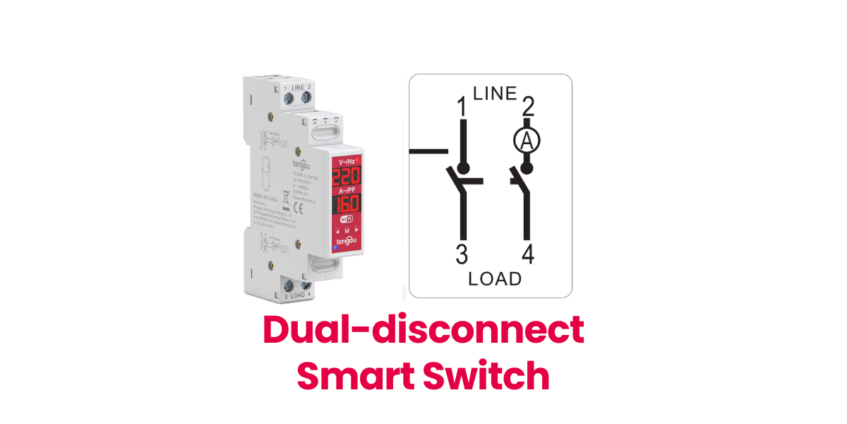

5. How do I choose the right size of disconnect switch (amps and voltage)?

Choosing the correct size disconnect is critical for safety and proper operation. You need to consider both the voltage and the amperage requirements of the circuit and the equipment it serves.

- Voltage Rating: The voltage rating of the disconnect switch must be equal to or greater than the voltage of the circuit. Using a disconnect with a lower voltage rating can be extremely dangerous.

- Ampere Rating: The ampere rating (or ampacity) of the disconnect switch must be equal to or greater than the full load current of the circuit it's disconnecting. For motor circuits, you also need to consider the motor's starting current (locked rotor current), which can be significantly higher than the full load current. Consult the motor's nameplate and the National Electrical Code (NEC) for guidance on sizing disconnects for motor applications.

- Horsepower Rating (for motor disconnects): If the disconnect is used for a motor, it needs to have a horsepower rating equal to or greater than the horsepower of the motor. This ensures the disconnect can handle the motor's starting current and operating load.

- Fuse Size (for fused disconnects): The fuses used in a fused disconnect must be sized appropriately to protect the circuit and equipment. This requires careful calculation based on the circuit's load, wire size, and the characteristics of the equipment being protected. Incorrectly sized fuses can be just as dangerous as no fuses at all!

It's always best to consult with a qualified electrician to determine the correct size and type of disconnect switch for your specific application. They can take into account all the relevant factors and ensure that the disconnect is properly installed and wired.

6. What are the safety considerations when working with disconnect switches?

Working with electrical systems is inherently dangerous, and disconnect switches are no exception. Here are some vital safety precautions:

- De-energize the circuit: Always de-energize the circuit before working on a disconnect switch or any connected equipment. Verify that the power is off using a reliable voltage tester. Never assume the circuit is dead just because the disconnect is open!

- Lockout/Tagout (LOTO): Use proper lockout/tagout procedures to prevent accidental re-energization of the circuit while you're working on it. This involves placing a lock and tag on the disconnect switch to indicate that it's been taken out of service and is not to be turned back on.

- Wear appropriate personal protective equipment (PPE): Wear safety glasses, gloves, and other appropriate PPE to protect yourself from electrical hazards.

- Inspect the disconnect switch: Before working on a disconnect switch, inspect it for any signs of damage, such as cracks, broken parts, or loose connections. If you find any damage, do not attempt to repair it yourself. Contact a qualified electrician to replace the disconnect.

- Work in dry conditions: Never work on electrical equipment in wet or damp conditions.

- Know your limits: If you're not comfortable working with electrical systems, or if you're unsure about any aspect of the task, do not attempt to do it yourself. Contact a qualified electrician to perform the work.

Electricity is dangerous, and safety should always be your top priority.

7. Can I replace a non-fused disconnect with a fused disconnect?

Yes, in most cases, you can replace a non-fused disconnect with a fused disconnect, provided you meet certain conditions:

- Proper Fuse Sizing: The most crucial aspect is correctly sizing the fuses for the circuit and the connected equipment. You must calculate the appropriate fuse size based on the circuit's ampacity, wire size, and the equipment's requirements. Using the wrong size fuses can lead to nuisance tripping or, even worse, failure to protect the circuit from overcurrent.

- Adequate Enclosure Size: Ensure the fused disconnect enclosure is large enough to accommodate the fuses and any necessary wiring.

- Correct Voltage Rating: Verify that the voltage rating of the fused disconnect is equal to or greater than the voltage of the circuit.

- Compatibility: Ensure the fused disconnect is compatible with the existing wiring and equipment.

- Code Compliance: Make sure the installation complies with all applicable electrical codes and regulations.

Upgrading to a fused disconnect can provide enhanced overcurrent protection, but it's essential to do it correctly. Consult with a qualified electrician to ensure the fuses are properly sized and the installation meets all safety and code requirements. Incorrect installation can be more dangerous than having a non-fused disconnect in the first place.

By understanding the differences between fused and non-fused disconnects, you can make informed decisions about which type of disconnect is best suited for your needs. Remember, when in doubt, always consult with a qualified electrician.