Difference Between Pex A And B

Choosing the right piping for your plumbing or radiant heating system is crucial for its long-term performance and reliability. Among the various options available, PEX (cross-linked polyethylene) tubing has gained immense popularity due to its flexibility, durability, and cost-effectiveness. However, not all PEX is created equal. Understanding the difference between PEX A and PEX B is essential for making an informed decision.

What is PEX? A Quick Overview

Before diving into the specifics of PEX A and PEX B, let's briefly recap what PEX is. PEX is a type of polyethylene that has undergone a cross-linking process. This process alters the molecular structure of the plastic, creating strong bonds between the polymer chains. The result is a material that is more durable, flexible, and resistant to high temperatures and pressures than standard polyethylene.

Think of un-crosslinked polyethylene as a plate of spaghetti – the strands are long and can easily slide past each other. Cross-linking is like adding sauce that binds the strands together, making the whole structure stronger and more resistant to movement. This enhanced strength and flexibility make PEX ideal for plumbing applications.

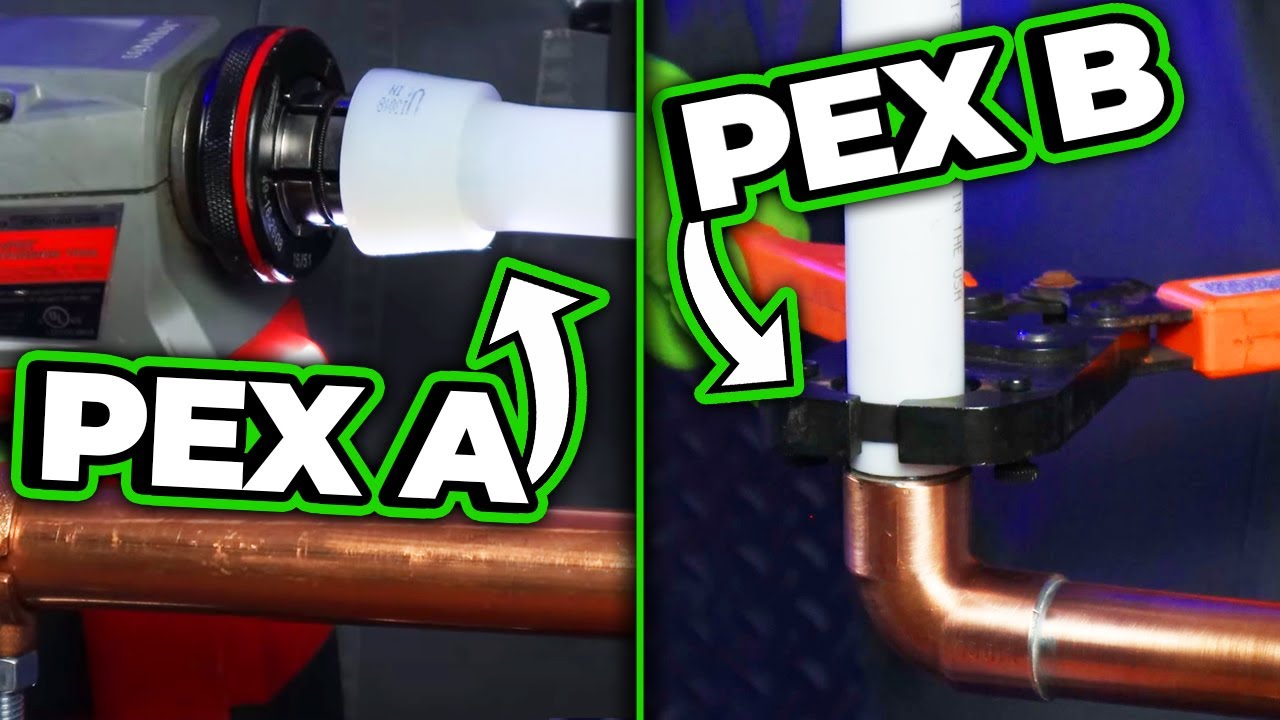

PEX A: The Engel Method

PEX A is manufactured using the Engel method, also known as the peroxide method. This process involves cross-linking the polyethylene during the extrusion process using high temperatures and organic peroxides. This results in a more uniform and flexible material compared to other PEX types.

Key Characteristics of PEX A:

- Superior Flexibility: PEX A is the most flexible type of PEX. This makes it easier to install, especially in tight spaces or when dealing with complex layouts. It can bend around corners with fewer fittings, reducing potential leak points.

- Kink Repair: A major advantage of PEX A is its ability to have kinks repaired using a heat gun. This is possible because the cross-linking process in PEX A allows the material to "remember" its original shape. When heated, the plastic returns to its pre-kinked state. This saves time and money compared to replacing an entire section of pipe.

- Expansion Fittings: PEX A typically uses expansion fittings, which involve expanding the end of the tubing and inserting a fitting. As the tubing contracts, it creates a strong, leak-proof seal. These fittings are known for their reliability.

- Higher Cost: PEX A is generally more expensive than PEX B due to the manufacturing process and its superior properties.

Imagine a rubber band. A PEX A rubber band can be stretched further and will return to its original shape more readily than a PEX B rubber band.

PEX B: The Silane or Moisture Cure Method

PEX B is manufactured using the silane method or the moisture cure method. In this process, the cross-linking occurs after the extrusion when the pipe is exposed to moisture. A silane grafting agent is added to the polyethylene resin during the extrusion process. This agent reacts with moisture in the air or water to create cross-links.

Key Characteristics of PEX B:

- Greater Rigidity: PEX B is stiffer than PEX A. This can make it more challenging to work with in tight spaces or complex installations.

- Kink Repair Limitations: While minor kinks in PEX B may be repairable in some cases, it's generally not recommended or as effective as with PEX A. Major kinks usually require cutting and replacing the damaged section.

- Crimp Fittings: PEX B is commonly used with crimp fittings or clamp fittings. These fittings involve sliding a metal ring over the tubing and then crimping or clamping it onto the fitting. While crimp fittings are generally reliable, it’s important to use the correct tools and techniques to ensure a proper seal.

- Lower Cost: PEX B is typically less expensive than PEX A, making it a more budget-friendly option.

Think of PEX B like a garden hose. It's flexible enough for general use, but if you bend it sharply, it might crease and not easily return to its original shape.

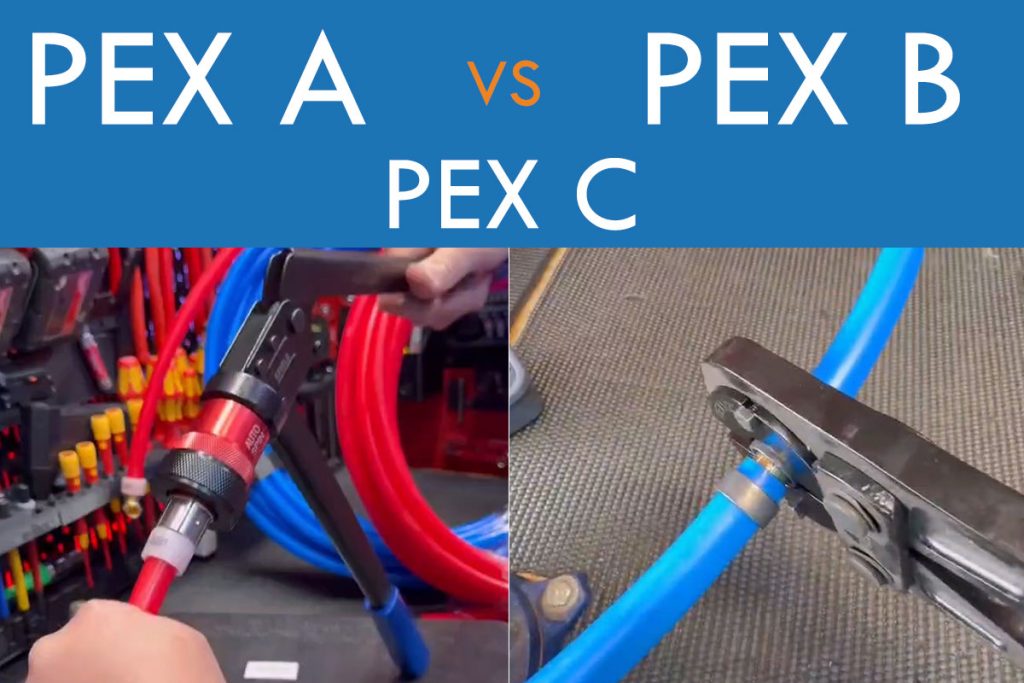

PEX C: The Electron Beam Method

While less common than PEX A and B, PEX C is another type of PEX manufactured using the electron beam method. This process involves bombarding the extruded polyethylene with an electron beam, which induces cross-linking. PEX C often has properties that fall somewhere between PEX A and PEX B in terms of flexibility and cost. While it's available, its market share is considerably smaller than PEX A and B, so we will not focus on it.

PEX A vs. PEX B: A Detailed Comparison

To help you decide which type of PEX is best for your needs, here's a detailed comparison of PEX A and PEX B:

Flexibility:

- PEX A: Most flexible. Easier to bend, maneuver, and install, especially in tight spaces. Requires fewer fittings.

- PEX B: Less flexible. Can be more challenging to work with in confined areas. May require more fittings.

Kink Repair:

- PEX A: Kinks are repairable with a heat gun. Returns to its original shape when heated.

- PEX B: Kinks are generally not repairable. Requires cutting and replacing the damaged section.

Fitting Types:

- PEX A: Expansion fittings. Known for their reliability and create a strong, leak-proof seal.

- PEX B: Crimp or clamp fittings. Requires proper tools and techniques to ensure a secure connection.

Cost:

- PEX A: More expensive. Higher manufacturing costs.

- PEX B: Less expensive. More budget-friendly option.

Temperature and Pressure Ratings:

- PEX A: Typically rated for the same temperature and pressure as PEX B. Common ratings are 160 PSI at 73°F, 100 PSI at 180°F, and 80 PSI at 200°F. Always check the manufacturer's specifications.

- PEX B: Typically rated for the same temperature and pressure as PEX A. Common ratings are 160 PSI at 73°F, 100 PSI at 180°F, and 80 PSI at 200°F. Always check the manufacturer's specifications.

Durability:

- PEX A: Highly durable due to the uniform cross-linking. Good resistance to cracks and bursts.

- PEX B: Durable, but can be more prone to kinking or cracking if bent sharply or repeatedly.

Which PEX is Right for You? Considerations for Your Project

Choosing between PEX A and PEX B depends on your specific needs and budget. Here are some factors to consider:

- Project Complexity: For complex projects with tight spaces or many bends, PEX A's superior flexibility and kink repair capabilities make it a better choice.

- Budget: If you're on a tight budget, PEX B offers a more cost-effective solution.

- DIY vs. Professional Installation: While both PEX A and PEX B can be installed by DIYers, PEX A might be easier to work with due to its flexibility and the forgiveness offered by its kink repair feature. However, both require careful installation to ensure leak-free connections.

- Radiant Heating Systems: Both PEX A and PEX B are commonly used in radiant heating systems. However, some installers prefer PEX A for its flexibility and ability to handle the thermal expansion and contraction associated with heating systems.

- Water Quality: Both PEX A and PEX B are resistant to corrosion and mineral buildup. However, water quality can still impact the lifespan of any plumbing system. Consider installing a water filter if you have hard water or other water quality issues.

Making the Final Decision

Ultimately, the best choice between PEX A and PEX B depends on your specific needs and priorities. If flexibility, kink repair, and long-term reliability are paramount, and budget is less of a concern, PEX A is the superior option. If you're looking for a cost-effective solution for a simpler project and are comfortable working with slightly less flexible material, PEX B can be a suitable choice.

It's always a good idea to consult with a qualified plumber or plumbing supply professional to discuss your project and determine the best PEX type for your specific application. They can provide expert advice based on your local building codes, water quality, and other relevant factors.

By understanding the differences between PEX A and PEX B, you can make an informed decision that will ensure a durable, reliable, and efficient plumbing or radiant heating system for years to come.