Difference Between Pex A And Pex

PEX A vs. PEX: Common Questions Answered

PEX (Cross-linked Polyethylene) is a popular piping material used in residential and commercial plumbing. However, not all PEX is created equal. This article answers some frequently asked questions about the differences between PEX A and other types of PEX to help you make informed decisions about your plumbing projects.

Question 1: What exactly is PEX, and why is it used for plumbing?

PEX stands for Cross-linked Polyethylene. It's a type of plastic tubing that's flexible, durable, and resistant to freezing and bursting. The "cross-linking" process improves the material's strength and temperature resistance compared to standard polyethylene. PEX is widely used for plumbing because:

- It's flexible, making installation easier, especially in tight spaces.

- It's less prone to leaks than rigid pipes due to fewer connections.

- It's resistant to corrosion and mineral buildup.

- It's cost-effective compared to copper or CPVC.

- It's temperature-resistant, handling both hot and cold water effectively.

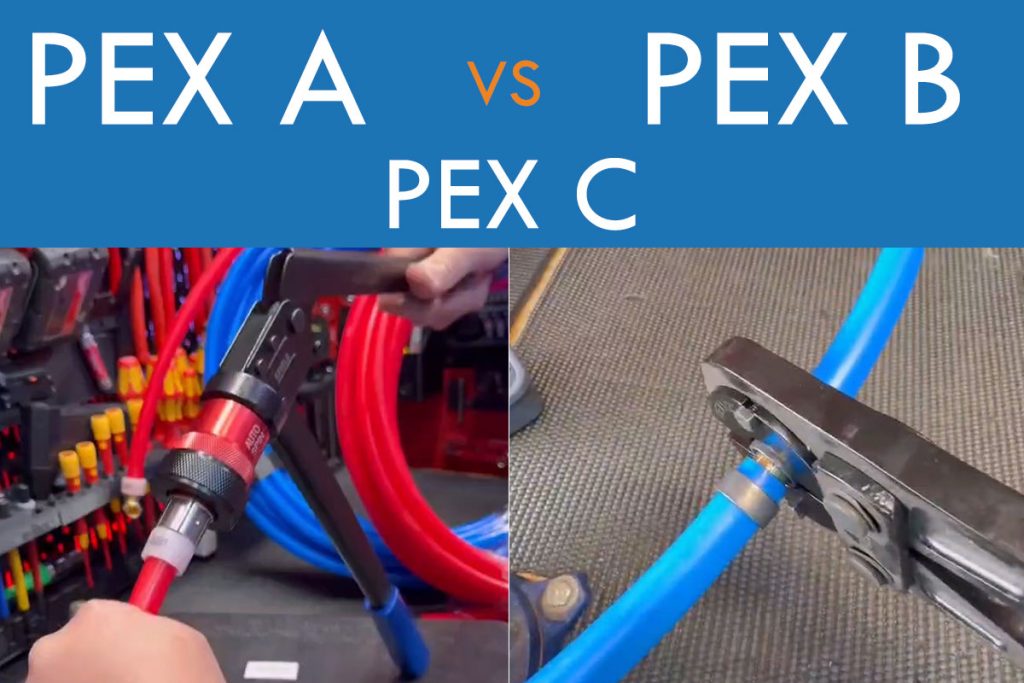

Question 2: What are the different types of PEX (PEX A, PEX B, and PEX C), and what are the key differences between them?

There are three main types of PEX, categorized by the method used to create the cross-linking:

- PEX A (Engel Method): Cross-linking occurs during the manufacturing process, before the tube is formed. This results in the highest degree of cross-linking (typically around 80%), making it the most flexible and durable type of PEX.

- PEX B (Silane Method): Cross-linking happens after the tube is extruded, using moisture and heat. It's more rigid than PEX A and has a slightly lower temperature and pressure rating. The degree of cross-linking is generally lower than PEX A.

- PEX C (Electron Beam Method): Cross-linking is achieved by exposing the tube to an electron beam after extrusion. It's the most rigid of the three types and can sometimes be more prone to kinking. It tends to have the least amount of "memory."

Here's a table summarizing the key differences:

| Feature | PEX A | PEX B | PEX C |

|---|---|---|---|

| Cross-linking Method | Engel (during manufacturing) | Silane (after extrusion) | Electron Beam (after extrusion) |

| Flexibility | Most Flexible | Less Flexible | Least Flexible |

| Cross-linking Degree | Highest (around 80%) | Medium | Lowest |

| Kinking | Least likely to kink | More likely to kink | Most likely to kink |

| Expansion Capability | Excellent (can be expanded for fittings) | Limited | Limited |

| Cost | Generally more expensive | Mid-range | Least expensive |

Question 3: What are the advantages of using PEX A over other types of PEX?

PEX A offers several advantages, making it a premium choice for plumbing systems:

- Superior Flexibility: Its high flexibility makes it easier to install in tight spaces and around corners, reducing the need for numerous fittings.

- Expansion Fittings: PEX A is specifically designed for use with expansion fittings (also known as cold expansion fittings). This type of fitting creates a very secure and reliable connection that's less prone to leaks. The PEX A pipe is expanded using a special tool, and a ring is slid over the pipe. When the pipe retracts to its original size it creates a seal.

- Kink Repair: If PEX A is kinked, it can often be repaired using a heat gun. The heat will allow the material to return to its original shape. PEX B and PEX C are very difficult, if not impossible to unkink.

- Higher Burst Pressure: PEX A generally has a higher burst pressure rating compared to PEX B and PEX C, providing an extra margin of safety.

- Better Chemical Resistance: PEX A tends to have better resistance to certain chemicals found in water, contributing to its longevity.

Question 4: What are the disadvantages of PEX A?

While PEX A offers numerous benefits, there are a few potential downsides to consider:

- Higher Cost: PEX A is typically more expensive than PEX B and PEX C.

- Specialized Tools: While some fitting methods work with all types of PEX, PEX A is most effectively installed using expansion fittings, which require a specialized (and potentially expensive) expansion tool. While alternative tools are available, they may not provide the same level of consistent reliability.

- UV Sensitivity: All types of PEX are susceptible to UV degradation. They should not be exposed to direct sunlight for extended periods. However, some believe that PEX A is slightly more sensitive to UV exposure than PEX B.

Question 5: When is it appropriate to use PEX A versus PEX B or PEX C?

The best type of PEX depends on the specific application and your budget. Here's a general guideline:

- PEX A is ideal for:

- Whole-house plumbing systems, especially where flexibility and reliability are paramount.

- Radiant floor heating systems, due to its flexibility and resistance to high temperatures.

- Complex installations with many bends and turns.

- Applications where the ability to repair kinks is valuable.

- PEX B and PEX C are suitable for:

- Smaller plumbing projects, such as replacing a section of pipe or installing a single fixture.

- Applications where budget is a primary concern.

- Straight runs of pipe where flexibility is not critical.

Consider these factors when choosing:

- Budget: PEX A is more expensive upfront.

- Complexity of the project: Complex projects benefit from PEX A's flexibility.

- Long-term reliability: PEX A is generally considered the most durable option.

- Installation method: Are you comfortable using expansion fittings, or do you prefer crimp or clamp fittings?

- Local building codes: Check local codes to ensure that the PEX type you choose is approved for your application.

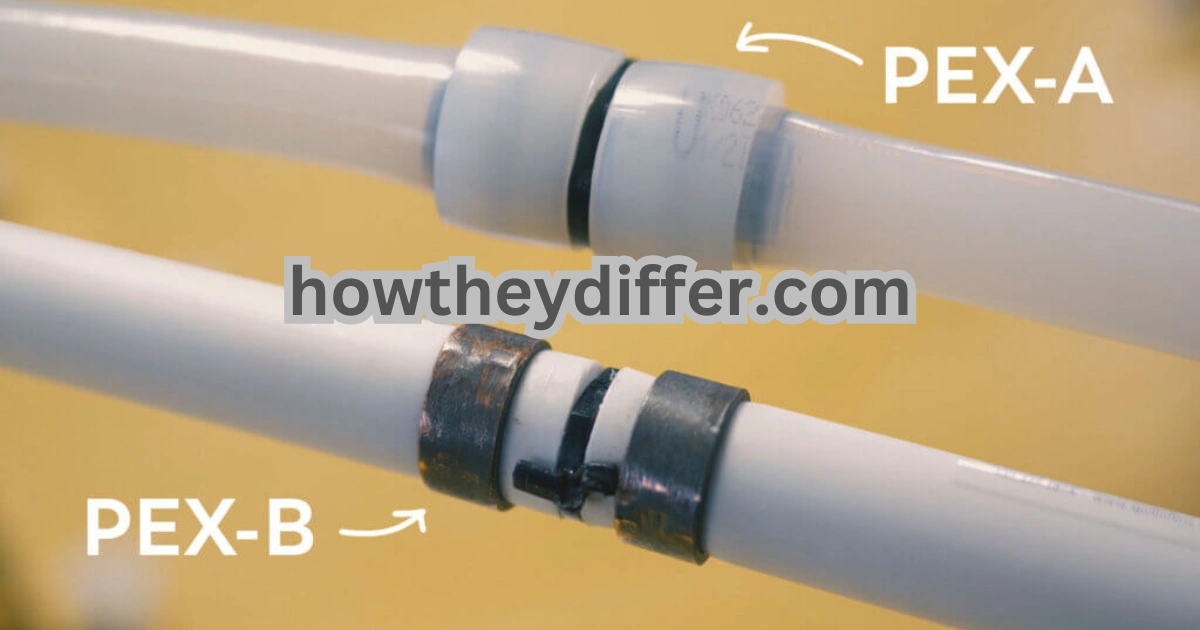

Question 6: Are the fittings interchangeable between PEX A, PEX B, and PEX C?

The interchangeability of fittings depends on the fitting type, not just the PEX type. There are three main types of PEX fittings:

- Crimp Fittings: Crimp fittings use a copper or stainless steel ring that is crimped onto the PEX pipe using a crimping tool. These are generally compatible with PEX B and PEX C, but they are not recommended for PEX A.

- Clamp (or cinch) Fittings: Clamp fittings are similar to crimp fittings but use a stainless steel clamp instead of a ring. These are also generally compatible with PEX B and PEX C and are also not recommended for PEX A.

- Expansion Fittings: Expansion fittings (also known as cold expansion fittings or ProPEX fittings) use a tool to expand the PEX pipe, allowing it to be fitted over a fitting with barbs. A PEX ring is pre-positioned on the pipe and slides into place to create a secure connection as the pipe retracts. Expansion fittings are designed specifically for PEX A and are not compatible with PEX B or PEX C.

Important Note: While it *might* be physically possible to force a crimp or clamp fitting onto PEX A, it's strongly discouraged because it can compromise the integrity of the connection and lead to leaks. Always use the fitting type recommended for the specific type of PEX you are using.

Question 7: How do I choose the right size of PEX for my plumbing project?

Choosing the correct PEX size is crucial for ensuring adequate water pressure and flow. The most common sizes are 1/2 inch, 3/4 inch, and 1 inch, but other sizes are also available. Here are some general guidelines:

- 1/2 inch PEX: Typically used for individual fixtures (sinks, toilets, showers) and short runs.

- 3/4 inch PEX: Often used for main water lines, longer runs, and supplying multiple fixtures.

- 1 inch PEX: May be required for very long runs, high-demand applications, or large homes.

Here are some factors to consider:

- Fixture Units (FU): Plumbing codes use fixture units to estimate water demand. Each fixture (toilet, sink, shower, etc.) is assigned a FU value. You need to calculate the total FU for your plumbing system to determine the appropriate pipe size. This information is usually located in the local plumbing code.

- Length of the run: Longer runs require larger pipes to compensate for friction loss.

- Water pressure: Low water pressure may necessitate larger pipes.

- Number of fixtures: Supplying multiple fixtures simultaneously requires a larger pipe.

- Local plumbing codes: Always consult local plumbing codes for specific requirements regarding pipe sizing. They often have tables and guidelines to help you determine the appropriate size based on fixture units and pipe length.

Best Practice: When in doubt, it's always best to consult with a licensed plumber to ensure you select the correct PEX size for your plumbing system. They can assess your specific needs and ensure compliance with local codes.