Does Expansion Tank Go On Hot Or Cold Side

Maintaining a comfortable indoor environment is crucial for both homes and businesses, but the energy costs associated with heating and cooling can quickly add up. A well-functioning HVAC system, especially one that incorporates energy-efficient components, is essential for minimizing these expenses. One critical, often-overlooked component is the expansion tank. Understanding its function and proper placement can significantly impact your system's efficiency and longevity.

The Role of Expansion Tanks in HVAC Systems

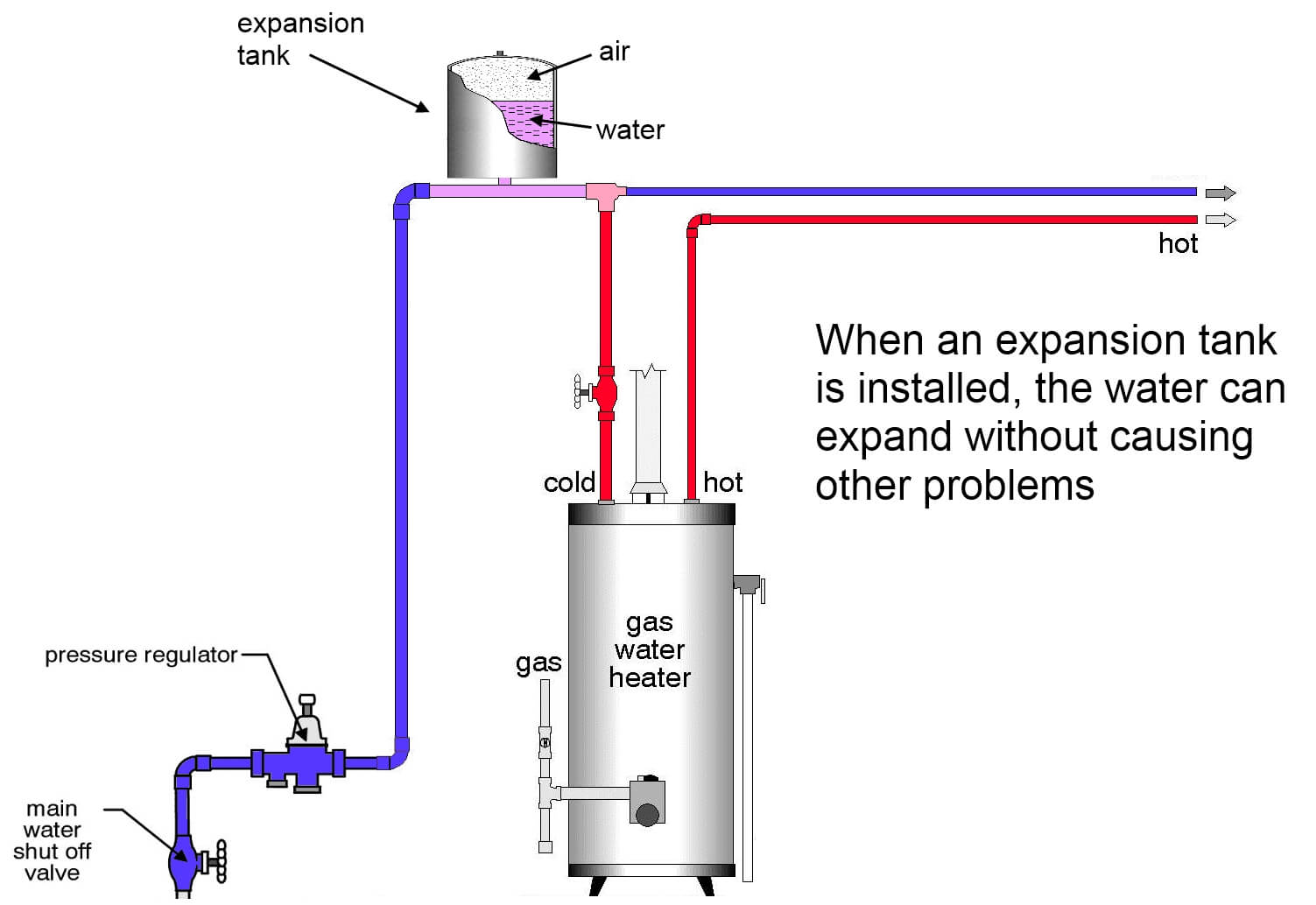

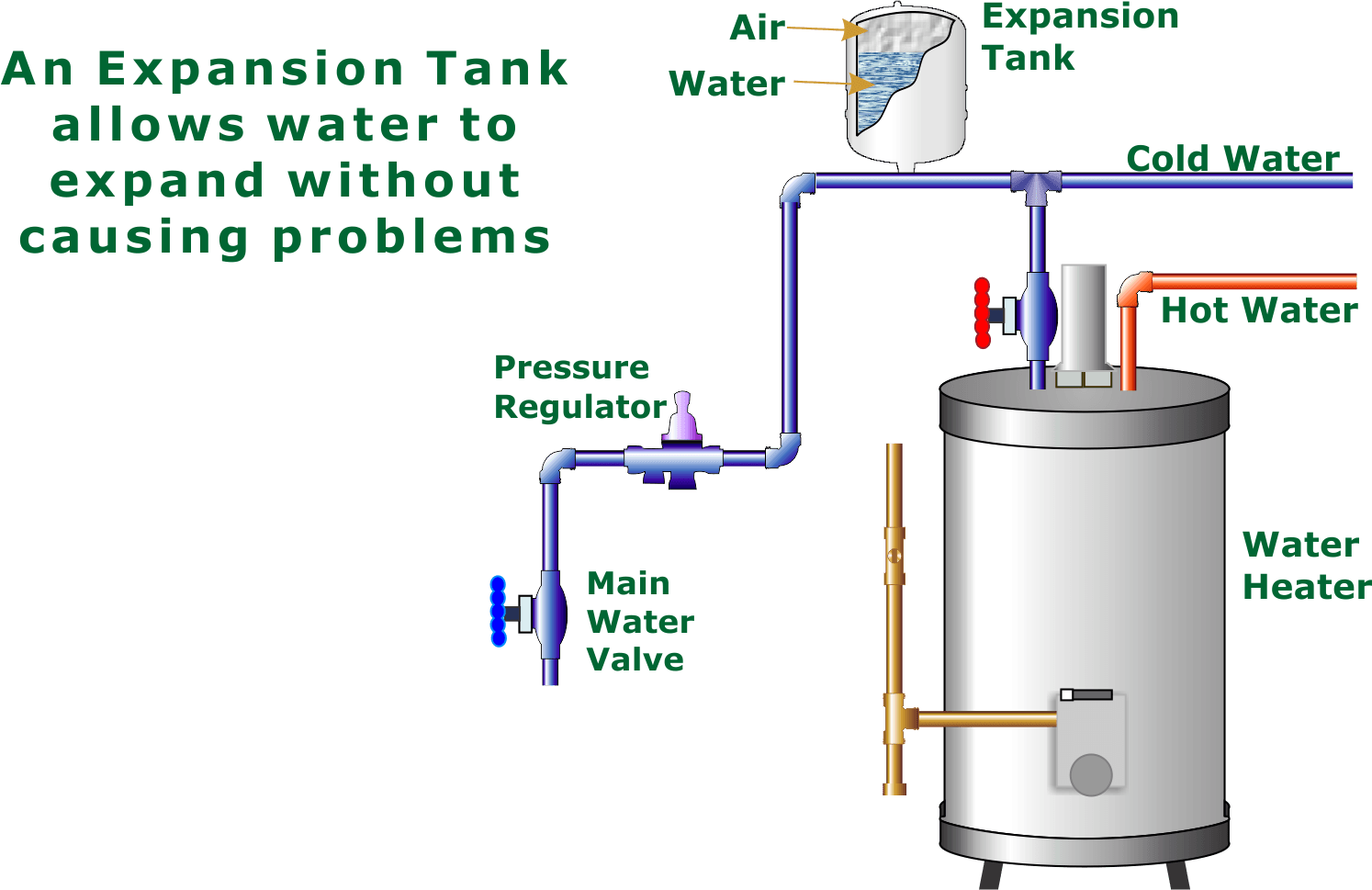

An expansion tank is a vital component in closed-loop hydronic heating and cooling systems (those using water or another liquid as a heat transfer medium). Its primary purpose is to accommodate the expansion and contraction of the fluid as it heats and cools. Water expands when heated, and without an expansion tank, this increased volume would cause a dangerous pressure buildup that could damage your boiler, pipes, and other system components. Conversely, when the water cools, it contracts, and the expansion tank helps maintain adequate pressure to prevent air from entering the system, which can lead to corrosion and reduced efficiency.

Choosing the right type of expansion tank, properly sizing it, and ensuring it is installed correctly are all critical factors in ensuring optimal system performance. Ignoring these aspects can lead to frequent maintenance, premature component failure, and higher energy bills.

Hot Side or Cold Side: Where Does the Expansion Tank Belong?

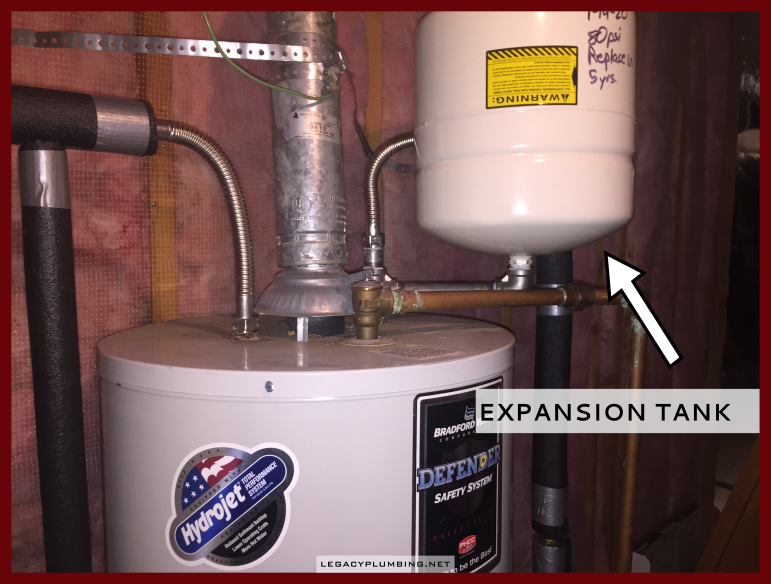

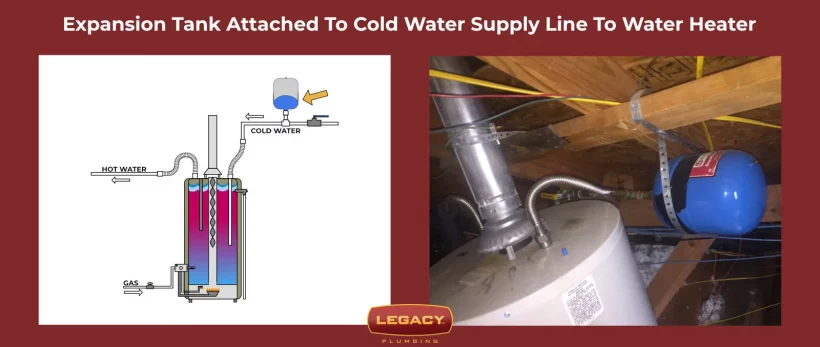

The question of whether an expansion tank should be installed on the hot or cold side of a hydronic system is a common one, and the answer is: the cold side. While there are nuances to consider depending on the specific system design, placing the expansion tank on the cold-water supply line *before* the boiler is generally the recommended practice. Let's delve into the reasons behind this.

Why the Cold Side is Preferable

Installing the expansion tank on the cold side offers several significant advantages:

- Reduced Stress on the Bladder: Expansion tanks contain a bladder that separates the compressed air from the system water. Placing the tank on the cold side exposes the bladder to lower temperatures, extending its lifespan. High temperatures can degrade the bladder material over time, leading to premature failure. A cooler environment helps maintain the bladder's integrity and reduces the frequency of replacements.

- Optimized Pressure Management: By connecting to the cold-water supply, the expansion tank can effectively manage pressure fluctuations before the water enters the boiler. This helps to maintain a more stable pressure throughout the entire system, minimizing stress on the boiler and other components. Stable pressure contributes to more consistent heating and cooling performance.

- Improved System Efficiency: Consistent pressure, aided by the cold-side location of the expansion tank, reduces the risk of cavitation (formation of vapor bubbles) within the system. Cavitation can damage pumps and reduce heat transfer efficiency. Preventing it contributes to smoother operation and improved overall energy efficiency.

- Easier Maintenance: Locating the expansion tank on the cold side often makes it more accessible for maintenance and inspection. The cooler temperatures make it easier to handle the tank and perform necessary checks, such as verifying the pre-charge pressure.

Understanding Pre-Charge Pressure

The pre-charge pressure of an expansion tank is the air pressure within the tank before the system is filled with water. This pressure is critical for the tank to function correctly. It should be set slightly below the system's fill pressure, typically around 12-15 PSI. Properly setting the pre-charge ensures that the tank can effectively absorb the expanding water as the system heats up.

Using a standard tire pressure gauge to check the pre-charge regularly will help you keep your system in top shape.

Potential Issues with Hot-Side Installation

While technically possible in some systems, installing an expansion tank on the hot side can lead to several problems:

- Increased Bladder Degradation: As mentioned earlier, high temperatures can significantly shorten the lifespan of the bladder. This results in more frequent replacements and higher maintenance costs.

- Less Efficient Pressure Control: Managing pressure fluctuations after the water has already been heated is less effective than managing them on the cold side. This can lead to greater stress on system components and potentially less stable heating or cooling.

- Potential for Scalding: If the expansion tank fails on the hot side, there is a greater risk of scalding from escaping hot water. While safety features are in place, the risk is inherently higher compared to a cold-side failure.

Smart HVAC Integration and the Expansion Tank

Integrating your HVAC system with smart technology offers even greater control and energy savings. While the expansion tank itself isn't directly controlled by smart devices, a well-maintained and properly functioning expansion tank *complements* the benefits of a smart system.

Smart thermostats, for example, can optimize heating and cooling schedules based on occupancy, weather conditions, and user preferences. This reduces overall energy consumption. However, if the expansion tank is not functioning correctly and causing pressure fluctuations, it can negatively impact the efficiency of the entire system, negating some of the savings provided by the smart thermostat.

Similarly, smart sensors can monitor system performance, including water pressure and temperature. By detecting anomalies, such as unusually high pressure readings, these sensors can alert you to potential issues with the expansion tank, allowing you to address them promptly before they lead to more significant problems.

Using a smart control system to monitor water pressure and temperature and pairing it with scheduled expansion tank maintenance ensures that you are maximizing both comfort and energy savings.

Energy Savings, ROI, and Available Rebates

While the expansion tank itself might not seem like a significant source of energy savings, its proper function indirectly contributes to overall system efficiency, leading to tangible cost reductions.

- Reduced Boiler Stress: A properly functioning expansion tank minimizes stress on the boiler, extending its lifespan and reducing the need for costly repairs or replacements. This translates to long-term savings.

- Improved System Efficiency: By maintaining stable pressure and preventing cavitation, the expansion tank helps ensure that the system operates at its optimal efficiency. This reduces energy consumption and lowers your monthly utility bills.

- Reduced Water Waste: A leaking or malfunctioning expansion tank can lead to water loss as the system attempts to compensate for pressure fluctuations. Addressing these issues promptly prevents water waste and reduces water bills.

The ROI (Return on Investment) for a properly installed and maintained expansion tank is primarily realized through reduced maintenance costs, extended equipment lifespan, and improved energy efficiency. While the initial cost of the tank and installation may be relatively low, the long-term savings can be substantial.

Energy Star often partners with local utilities to provide rebates and incentives for energy-efficient HVAC upgrades. While a simple expansion tank replacement may not qualify on its own, it can be part of a larger system upgrade that does qualify for rebates. Check with your local utility company and Energy Star's website for available programs in your area. Be sure to ask your HVAC contractor if they are familiar with local incentive programs.

Choosing the Right Expansion Tank and Professional Installation

Selecting the right expansion tank depends on factors such as the size of your system, the operating temperature, and the maximum system pressure. Consult with a qualified HVAC contractor to determine the appropriate tank size and type for your specific needs. They can also ensure proper installation, including setting the correct pre-charge pressure and connecting the tank to the cold-water supply line.

When selecting a contractor, look for one with experience in energy-efficient HVAC systems and a strong reputation for quality workmanship. Ask for references and check online reviews to get a sense of their expertise and customer satisfaction. A qualified contractor will be able to assess your system's needs and recommend the best solutions for maximizing efficiency and minimizing energy costs.

Key Takeaways: Optimizing Expansion Tank Performance for Energy Efficiency

In conclusion, the proper installation and maintenance of an expansion tank are essential for ensuring the efficient and reliable operation of your hydronic HVAC system. Placing the expansion tank on the cold side of the system offers numerous advantages, including reduced bladder stress, optimized pressure management, and improved overall efficiency.

By integrating smart HVAC technology, such as smart thermostats and sensors, you can further enhance system performance and realize even greater energy savings. Remember to consult with a qualified HVAC contractor to determine the best expansion tank for your needs and ensure proper installation and maintenance.

Taking these steps will not only improve your indoor comfort but also reduce your energy bills and contribute to a more sustainable future. Prioritizing efficiency within your HVAC system translates to lower costs and a reduced environmental impact. Consider reaching out to a local HVAC specialist to explore your options and discover the possibilities for energy-efficient solutions tailored to your specific requirements.