Double Wide Mobile Home Ceiling Ductwork Diagram

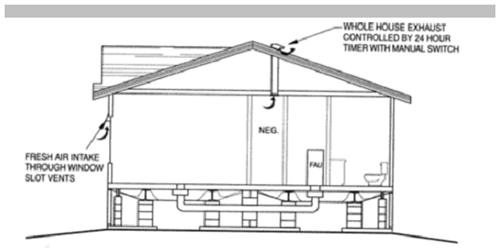

Many double-wide mobile homeowners experience uneven heating or cooling. One room might be freezing while another is stuffy. Often, the culprit lies within the ceiling ductwork. This article provides a systematic approach to troubleshooting common ductwork issues, helping you pinpoint the problem and potentially save on HVAC repair costs. Remember, safety first! If you're uncomfortable with any step, call a professional.

Understanding Your Double-Wide's Ceiling Ductwork

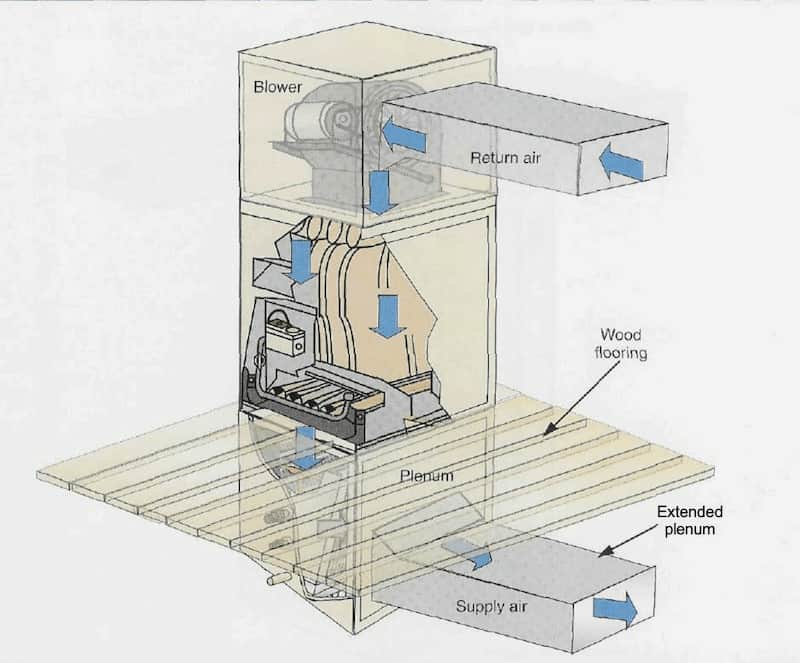

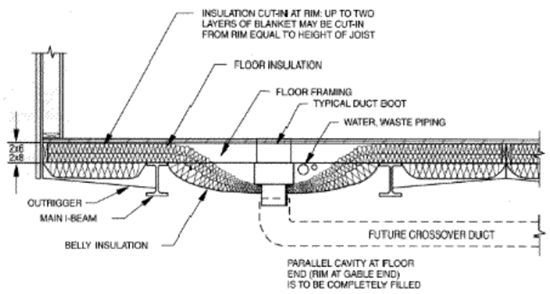

Double-wide mobile home ductwork is typically located in the ceiling cavity, often utilizing flex duct (flexible insulated tubing) connected to a main metal duct that runs down the center of the home. This design, while efficient for manufacturing, can be prone to issues like leaks, kinks, and disconnections. A basic understanding of how your ductwork is laid out is crucial for effective troubleshooting. Unfortunately, a precise diagram rarely comes standard, so this guide focuses on common trouble spots.

Diagnosing the Problem: A Step-by-Step Approach

Before you start, turn off your HVAC system. Safety is paramount. Here's a methodical approach to diagnosing common ceiling ductwork problems:

Step 1: The Obvious Checks (No Tools Required)

Begin with the easiest checks. These won't require any tools and can often reveal simple solutions.

- Check the Air Vents: Are all vents open and unobstructed? Make sure furniture, rugs, or curtains aren't blocking airflow. Close vents in rooms you aren't using to direct more airflow to problem areas.

- Listen for Air Leaks: With the HVAC system off, walk through your home and listen carefully near ceiling vents and the seams of ceiling panels. A hissing or whistling sound suggests an air leak. Mark the location of suspected leaks for later inspection.

- Inspect the Thermostat: Ensure the thermostat is set correctly for heating or cooling and that the batteries (if applicable) are functioning. A faulty thermostat can lead to inaccurate temperature readings and inconsistent system operation.

- Inspect the Furnace/AC Unit Filter: A dirty filter restricts airflow and can cause your system to work harder, leading to uneven heating or cooling. Replace the filter if it's dirty.

Step 2: Visual Inspection (Minimal Tools Required)

This step requires a stepladder and a flashlight. You'll be looking for visible signs of damage or disconnection in accessible areas of your ductwork.

- Accessing the Ductwork: Gaining access to the ductwork in a double-wide can be tricky. The main access points are typically around the furnace/AC unit and through any removable ceiling panels or light fixture openings. Use caution when climbing a ladder and avoid stepping on or leaning against unsupported ceiling panels.

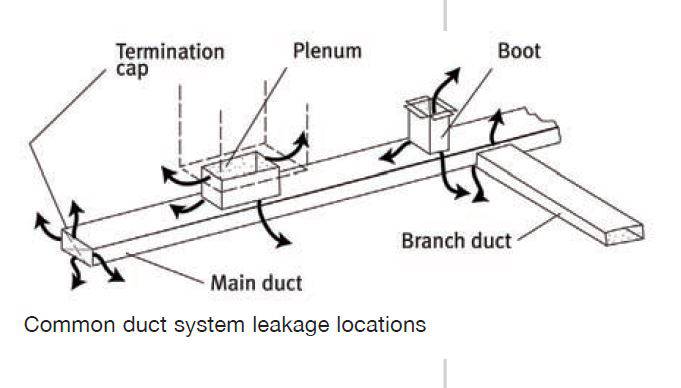

- Check for Disconnected Ducts: Look for sections of flex duct that have become detached from the main duct or from vents. Disconnections are a common cause of air loss and uneven heating/cooling.

- Inspect for Kinks or Crushes: Flex duct is susceptible to kinking or crushing, which severely restricts airflow. Pay particular attention to areas where the duct bends or passes through tight spaces.

- Look for Tears or Holes: Examine the flex duct for any visible tears, holes, or signs of damage from rodents or insects. Even small holes can lead to significant air leaks.

- Check for Sagging Ducts: Over time, flex duct can sag due to its own weight, creating low spots where condensation can accumulate. This can lead to mold growth and reduced airflow.

- Inspect the Insulation: Ensure the insulation surrounding the flex duct is intact and properly secured. Damaged or missing insulation reduces the duct's ability to maintain temperature, leading to energy loss.

Step 3: The "Hand Test" (Requires Assistance)

This test requires a helper and relies on feeling for airflow at different points in the ductwork. Turn your HVAC system on for this test, but only briefly.

- At the Vents: Have your helper stand near the thermostat while you check the airflow at each vent. Compare the strength of the airflow between vents. A significant difference indicates a problem in the ductwork leading to the weaker vent.

- Near Suspected Leaks: If you identified potential air leaks in Step 1, hold your hand near those areas while the system is running. You should feel a noticeable draft if there's a leak.

- Along the Duct Runs (If Accessible): If you can safely access sections of the ductwork, have your helper turn on the system briefly while you feel along the duct for airflow. This can help pinpoint leaks that aren't immediately visible.

DIY Solutions: What You Can Fix Yourself

After diagnosing the problem, you might be able to address some issues yourself. However, always prioritize safety and don't attempt repairs beyond your skill level.

- Reconnecting Disconnected Ducts: If you find a disconnected duct, you can often reconnect it using duct tape and/or metal clamps (available at most hardware stores). Ensure the connection is secure and airtight. Wrap the joint with several layers of duct tape, overlapping each layer for a tight seal.

- Repairing Small Tears or Holes: Small tears or holes in the ductwork can be patched with duct tape. Clean the area around the hole before applying the tape, and use multiple layers for a durable seal. For larger holes, you may need to use a patch made from sheet metal or fiberglass mesh, secured with duct tape and/or mastic sealant.

- Straightening Kinks: Gently try to straighten any kinks in the flex duct. If the kink is severe or the duct is damaged, you may need to replace that section of duct. Be careful not to tear the duct further.

- Securing Sagging Ducts: If you find sagging ducts, you can use straps or supports to lift them and prevent further sagging. Make sure the supports are securely attached to the ceiling joists and that they don't compress the ductwork.

- Sealing Air Leaks at Vent Connections: Use caulk or duct sealant to seal any gaps around the vent connections to the ceiling. This prevents air from escaping into the ceiling cavity.

Tools You Might Need

* Stepladder * Flashlight * Duct tape (high-quality, foil-backed preferred) * Utility knife * Metal clamps * Caulk or duct sealant * Gloves * Safety glasses * Screwdriver (various sizes)When to Call a Professional

While some ductwork issues can be addressed with DIY solutions, certain problems require the expertise of a qualified HVAC technician. Here are some situations where professional help is essential:

- Extensive Damage: If the ductwork is severely damaged, with multiple tears, holes, or collapsed sections, it's best to call a professional. Replacing large sections of ductwork requires specialized tools and knowledge.

- Mold Growth: If you find mold growing on or inside the ductwork, don't attempt to clean it yourself. Mold can be harmful to your health, and professional remediation is necessary.

- Complex Ductwork Systems: If your double-wide has a complex ductwork system with multiple branches and dampers, diagnosing and repairing problems can be challenging. A professional can identify the root cause of the issue and provide effective solutions.

- Furnace/AC Unit Issues: If you suspect the problem is related to the furnace or AC unit itself, rather than the ductwork, call a professional. Attempting to repair these components without proper training can be dangerous and may void your warranty.

- Uncertainty: If you're unsure about any aspect of the troubleshooting process or feel uncomfortable performing the repairs, it's always best to err on the side of caution and call a professional.

Preventative Maintenance: Keeping Your Ductwork Healthy

Regular maintenance can help prevent ductwork problems and ensure your HVAC system operates efficiently. Here are some tips for keeping your ductwork healthy:

- Regular Filter Changes: Change your furnace/AC unit filter regularly, as recommended by the manufacturer. A clean filter reduces strain on the system and improves airflow.

- Annual Inspection: Have your ductwork inspected annually by a qualified HVAC technician. They can identify potential problems before they become major issues.

- Seal Air Leaks: Periodically check for air leaks around vents and duct connections and seal them with caulk or duct sealant.

- Keep Vents Clean: Dust and debris can accumulate on vents, restricting airflow. Clean vents regularly with a vacuum cleaner or damp cloth.

- Rodent Control: Implement rodent control measures to prevent rodents from damaging your ductwork.

Conclusion

Troubleshooting ductwork in a double-wide mobile home can seem daunting, but by following a systematic approach, you can often identify and address common problems yourself. Remember to prioritize safety, use the right tools, and don't hesitate to call a professional when needed. With a little knowledge and effort, you can improve the efficiency of your HVAC system and enjoy a more comfortable home.