Expansion Ratio Of Water To Steam

Understanding the Explosive Power of Water: Expansion Ratio of Water to Steam

Water, seemingly harmless in its liquid state, undergoes a dramatic transformation when heated to its boiling point. This transformation results in a significant volume increase, a phenomenon known as the expansion ratio of water to steam. Understanding this ratio is crucial for anyone dealing with steam-based heating systems, whether you're a homeowner, a DIY enthusiast, or a seasoned HVAC professional. This article dives deep into the science behind this expansion, its implications for your home's heating system, and how to safely manage it.

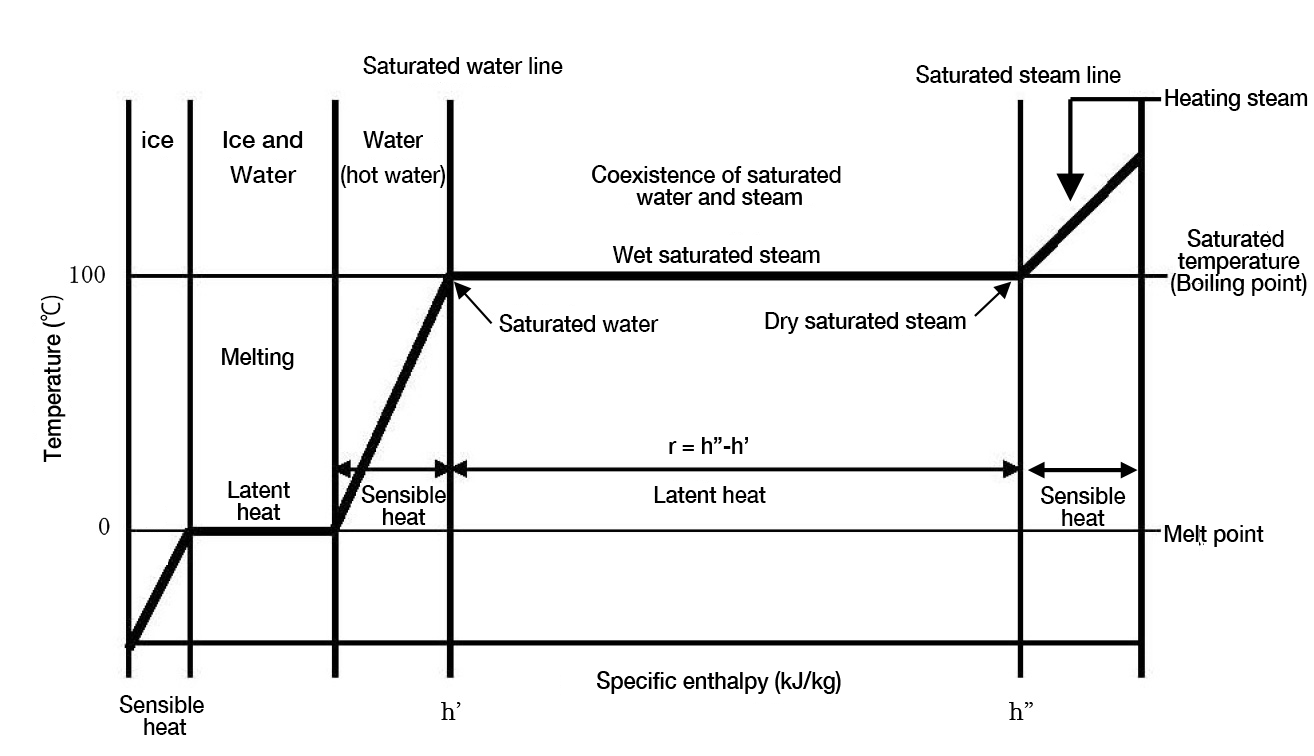

The Science Behind the Expansion

At standard atmospheric pressure (14.7 psi), water boils at 212°F (100°C). When water reaches this temperature and transitions to steam, its volume increases dramatically. The commonly cited expansion ratio is approximately 1:1600 to 1:1700. This means that one volume of liquid water turns into 1600 to 1700 volumes of steam. This immense volume change is due to the molecules spreading far apart as they transition into the gaseous state.

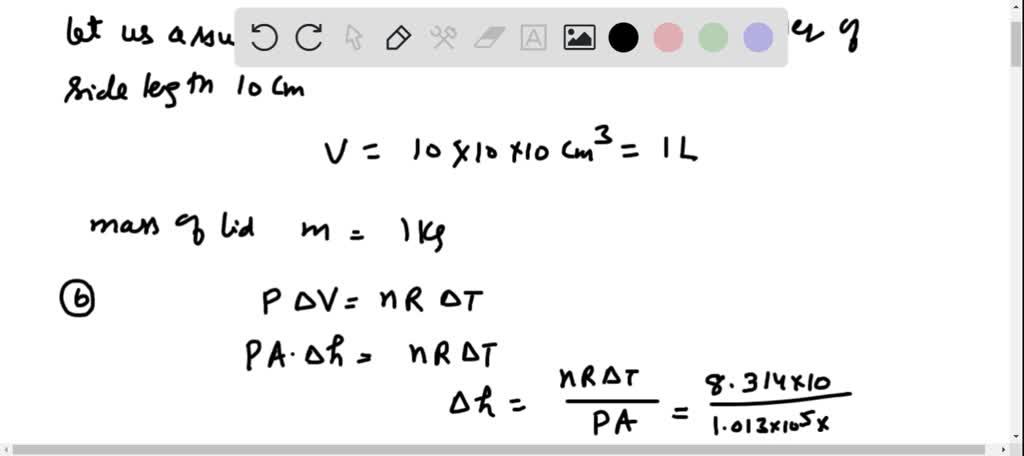

However, the expansion ratio isn't a fixed number. It's affected by several factors, including:

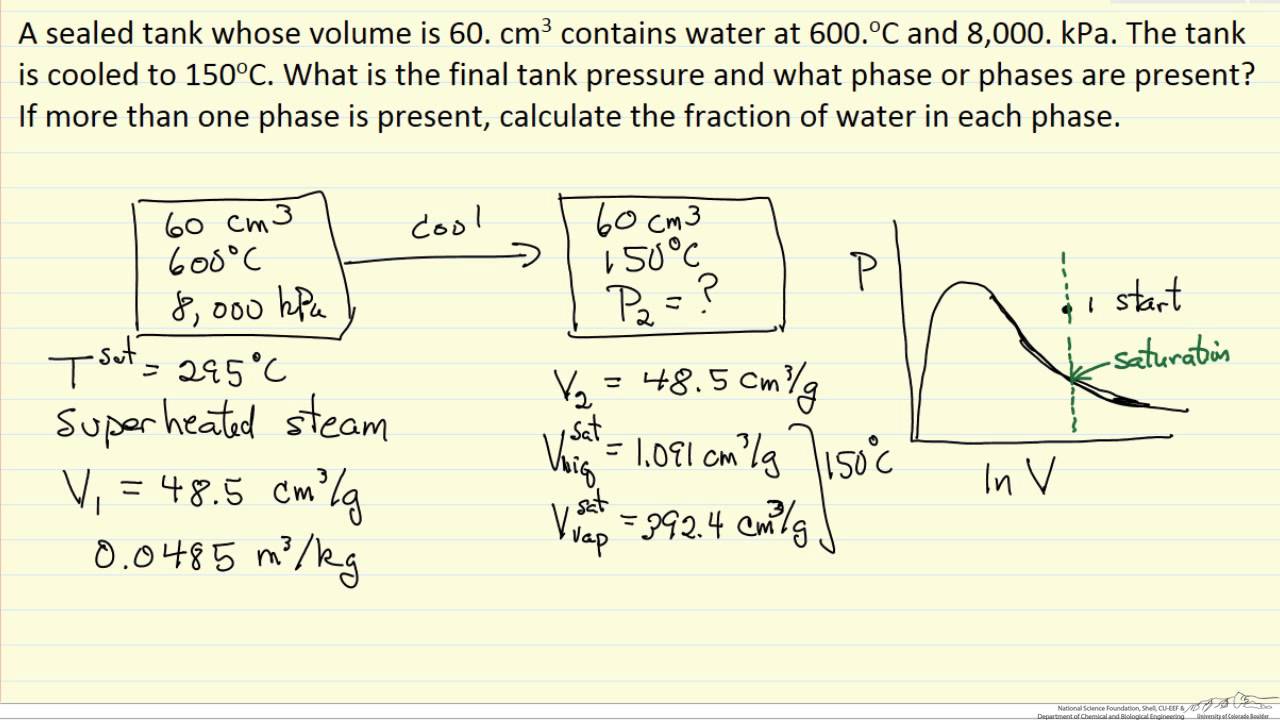

- Pressure: Higher pressure reduces the expansion ratio. At higher pressures, the steam is more compressed, reducing the volume it occupies.

- Temperature: While the boiling point remains the same at a given pressure, superheating the steam (heating it beyond the boiling point) can slightly increase its volume.

Why the Expansion Ratio Matters for Homeowners

The expansion ratio of water to steam has significant implications for the design and operation of steam heating systems commonly found in older homes. Here's why you should care:

- Proper Venting: Steam systems need adequate venting to allow air to escape as the steam expands. Without proper venting, the steam can't efficiently circulate, leading to uneven heating and potential damage to the system.

- Pressure Relief Valves: These safety devices are designed to release excess pressure in the system. If the pressure builds up too high (due to a malfunctioning component or overfilling), the relief valve will open, preventing a potential explosion.

- Expansion Tanks: Expansion tanks provide a space for the expanding water (during the heating process) to go without causing a pressure surge in the system. They accommodate the volume change and help maintain stable pressure.

- Preventing Water Hammer: Water hammer is the banging noise you sometimes hear in steam pipes. It's caused by steam collapsing and creating a vacuum, which then allows water to slam against the pipes. Understanding the expansion ratio helps prevent conditions that lead to water hammer.

Troubleshooting Common Steam Heating Issues Related to Expansion

Many problems in steam heating systems are indirectly related to the water-to-steam expansion. Here's how to troubleshoot some common issues:

1. Radiators Not Heating Evenly

Possible Cause: Air trapped in the system preventing steam from reaching all radiators, or a blocked vent.

DIY Solution:

- Bleed the Radiators: Use a radiator key to carefully open the air vent on each radiator. Let the air escape until water starts to trickle out, then close the vent. Be prepared with a towel to catch any water.

- Check Air Vents: Ensure the air vents on each radiator are clean and functioning properly. You might need to replace them if they're clogged or damaged.

When to Call a Pro: If bleeding the radiators and checking the air vents doesn't solve the problem, there might be a more serious issue, such as a blockage in the pipes or a problem with the boiler.

2. Banging or Clanging Noises (Water Hammer)

Possible Cause: Condensation build-up in the pipes, incorrect pipe pitch, or malfunctioning steam traps.

DIY Solution:

- Insulate Pipes: Insulating exposed pipes can help reduce condensation and water hammer.

- Check Pipe Pitch: Ensure the pipes are properly pitched (sloped slightly downwards) to allow condensate to drain back to the boiler. This is difficult to DIY and usually requires a professional.

When to Call a Pro: Water hammer can be a sign of serious problems with the steam system. It's best to consult with a qualified HVAC technician to diagnose and fix the issue, especially if it's persistent.

3. Pressure Relief Valve Leaking

Possible Cause: Excessive pressure in the system, a faulty pressure relief valve, or overfilling the boiler.

DIY Solution:

- Check the Boiler Water Level: Make sure the water level in the boiler is at the correct level. Overfilling can cause excessive pressure.

- Inspect the Pressure Relief Valve: Look for signs of damage or corrosion. If the valve is old or appears damaged, it likely needs to be replaced.

When to Call a Pro: A leaking pressure relief valve is a serious safety concern. If you're not comfortable replacing the valve yourself, or if the problem persists after replacing it, call a professional HVAC technician immediately.

4. High Heating Bills

Possible Cause: Inefficient steam distribution, leaks in the system, or a malfunctioning boiler.

DIY Solution:

- Seal Leaks: Inspect pipes and radiators for any signs of leaks. Seal any small leaks you find with appropriate sealant.

- Improve Insulation: Insulating your home properly can reduce heat loss and lower your heating bills.

When to Call a Pro: High heating bills can be a sign of a serious problem with your steam system. A professional HVAC technician can perform a thorough inspection to identify the source of the problem and recommend solutions.

Safety Precautions When Working With Steam Systems

Steam systems operate at high temperatures and pressures, so it's essential to take safety precautions when working on them:

- Turn Off the Boiler: Always turn off the boiler and allow it to cool down completely before attempting any repairs.

- Wear Safety Gear: Wear safety glasses, gloves, and appropriate clothing to protect yourself from burns and other injuries.

- Never Open a Pressurized System: Never attempt to open a steam system while it's under pressure. This can cause serious injury or death.

- Be Aware of Hot Surfaces: Be careful when working around hot pipes and radiators.

Tools and Parts You Might Need

- Radiator key

- Adjustable wrench

- Pipe wrench

- Screwdrivers (various sizes)

- Safety glasses

- Gloves

- Pipe sealant

- Replacement air vents

- Replacement pressure relief valve

- Insulation

When to Call a Professional HVAC Technician

While some steam heating issues can be addressed with DIY solutions, others require the expertise of a qualified HVAC technician. Here are some situations where it's best to call a pro:

- You're not comfortable working on the system.

- The problem is complex or persistent.

- You suspect a gas leak.

- The pressure relief valve is leaking.

- You're unsure of what to do.

Trying to fix complex problems without the proper knowledge and tools can lead to further damage and potentially dangerous situations. Always err on the side of caution and call a professional when in doubt.

Estimating Repair Costs

The cost of repairing a steam heating system can vary widely depending on the nature of the problem. Here are some general estimates:

- Replacing an air vent: $20 - $50 per vent

- Replacing a pressure relief valve: $100 - $300

- Repairing a leaking pipe: $100 - $500

- Replacing a steam trap: $200 - $600

- Replacing a boiler: $5,000 - $10,000+

These are just estimates, and the actual cost may vary depending on your location, the complexity of the repair, and the contractor you choose. Always get multiple quotes from qualified HVAC technicians before proceeding with any major repairs.

Understanding the expansion ratio of water to steam is a cornerstone of maintaining a safe and efficient steam heating system. By understanding the underlying principles and being proactive with maintenance, you can keep your home warm and comfortable for years to come. Remember, safety is paramount, and when in doubt, always consult with a qualified HVAC professional. Ignoring seemingly minor issues can lead to major problems and costly repairs down the road.