Feet Of Water To Psi Conversion

Understanding the relationship between Feet of Water (ft H2O) and Pounds per Square Inch (PSI) is crucial for various applications around your home, especially when dealing with plumbing, HVAC systems, and even swimming pools. While it might seem like an obscure conversion, it plays a vital role in troubleshooting pressure-related issues, ensuring optimal system performance, and preventing costly repairs. This guide will break down the conversion, provide practical examples, and equip you with the knowledge to tackle common pressure-related problems.

The Basics: Feet of Water to PSI Conversion

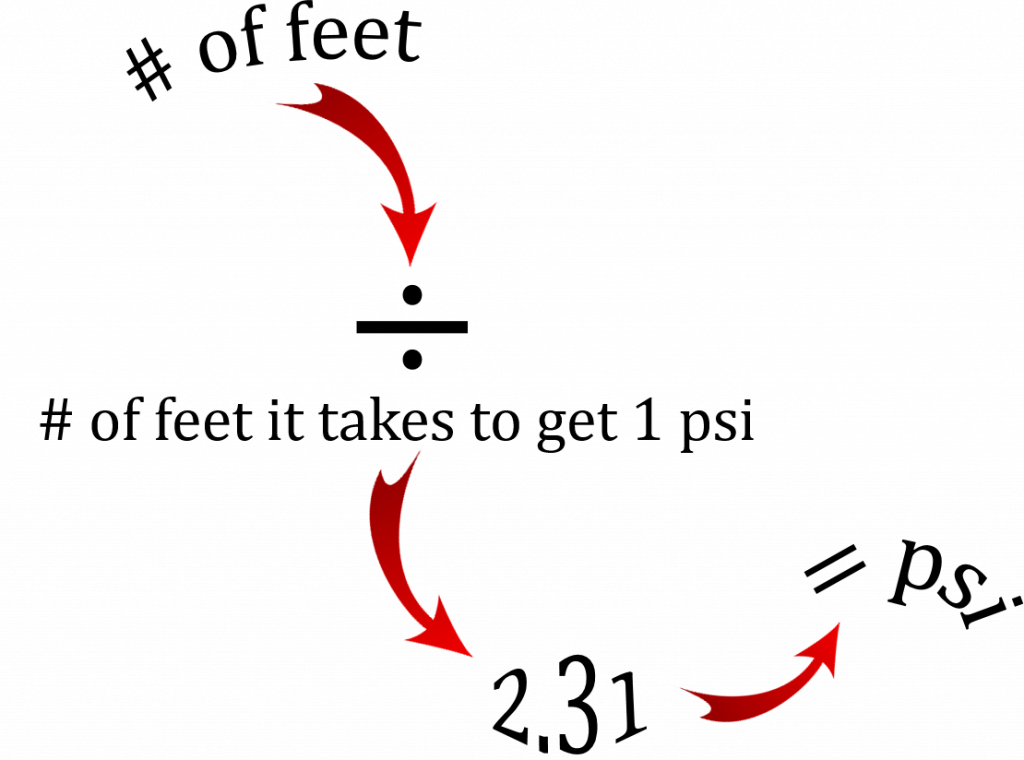

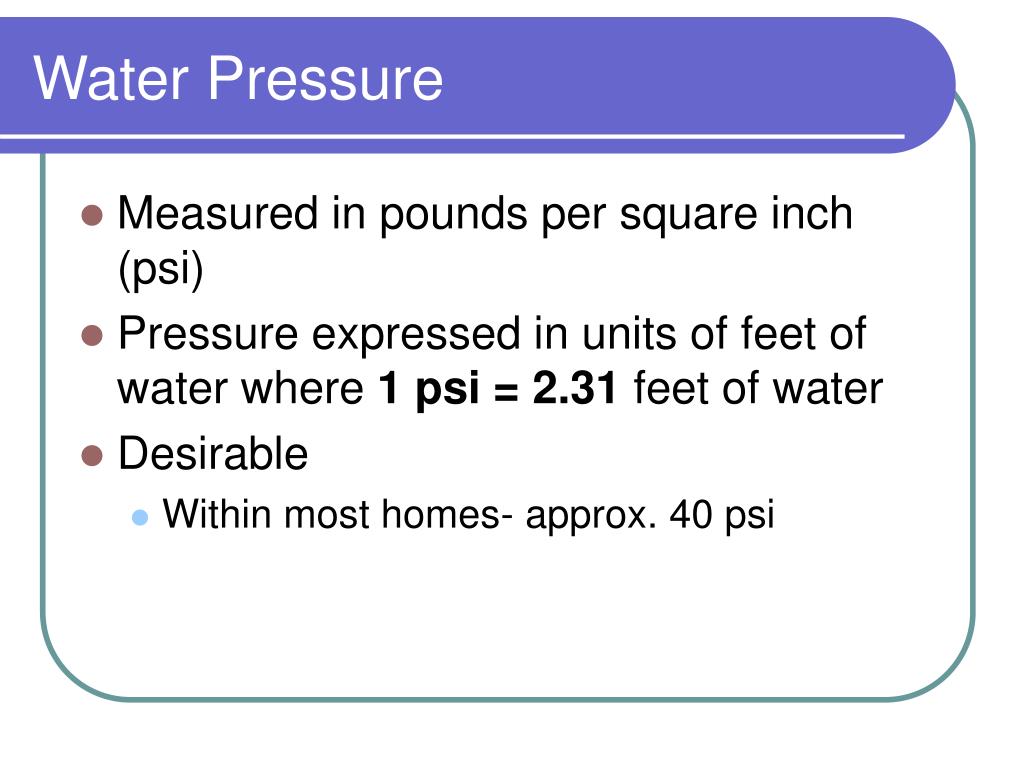

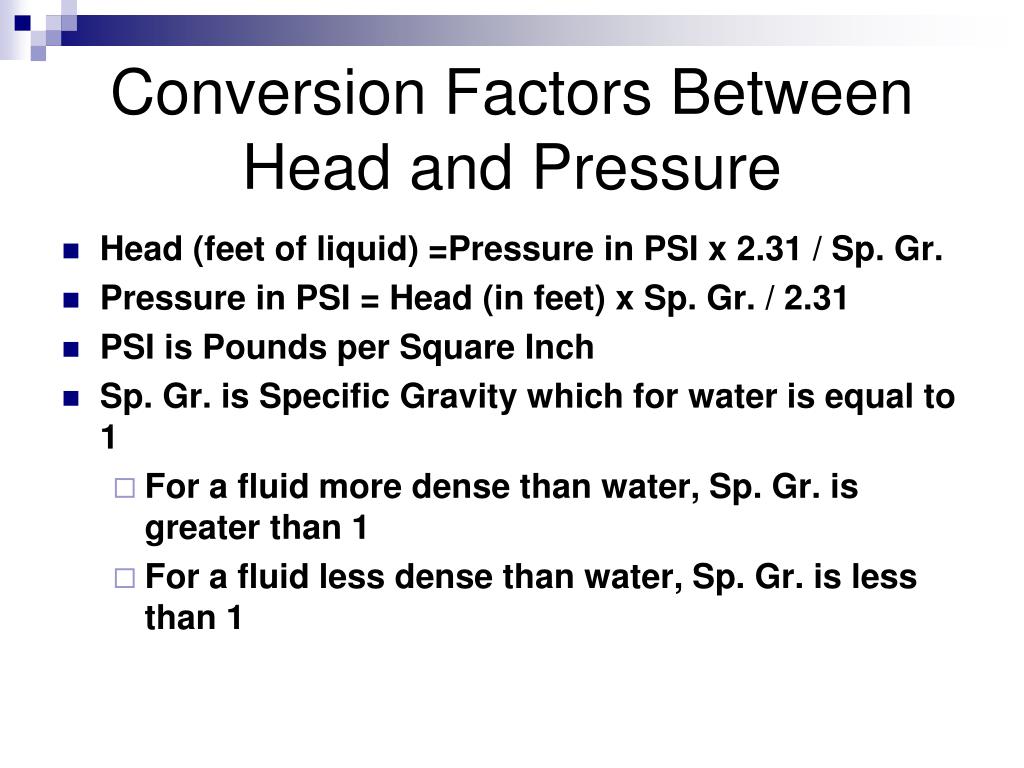

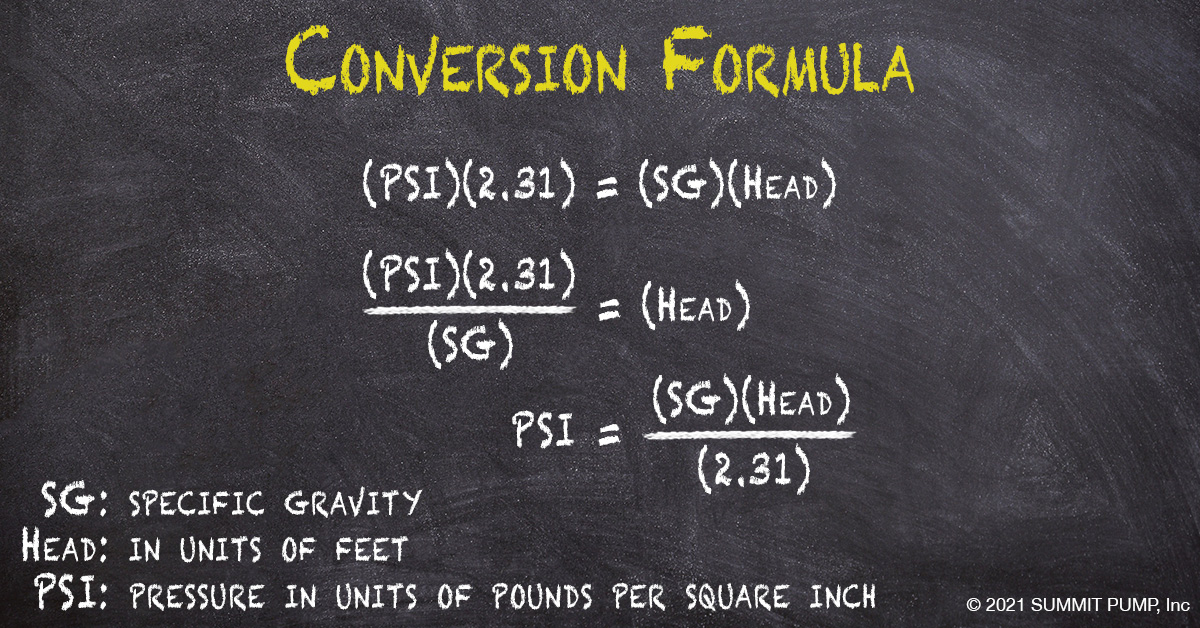

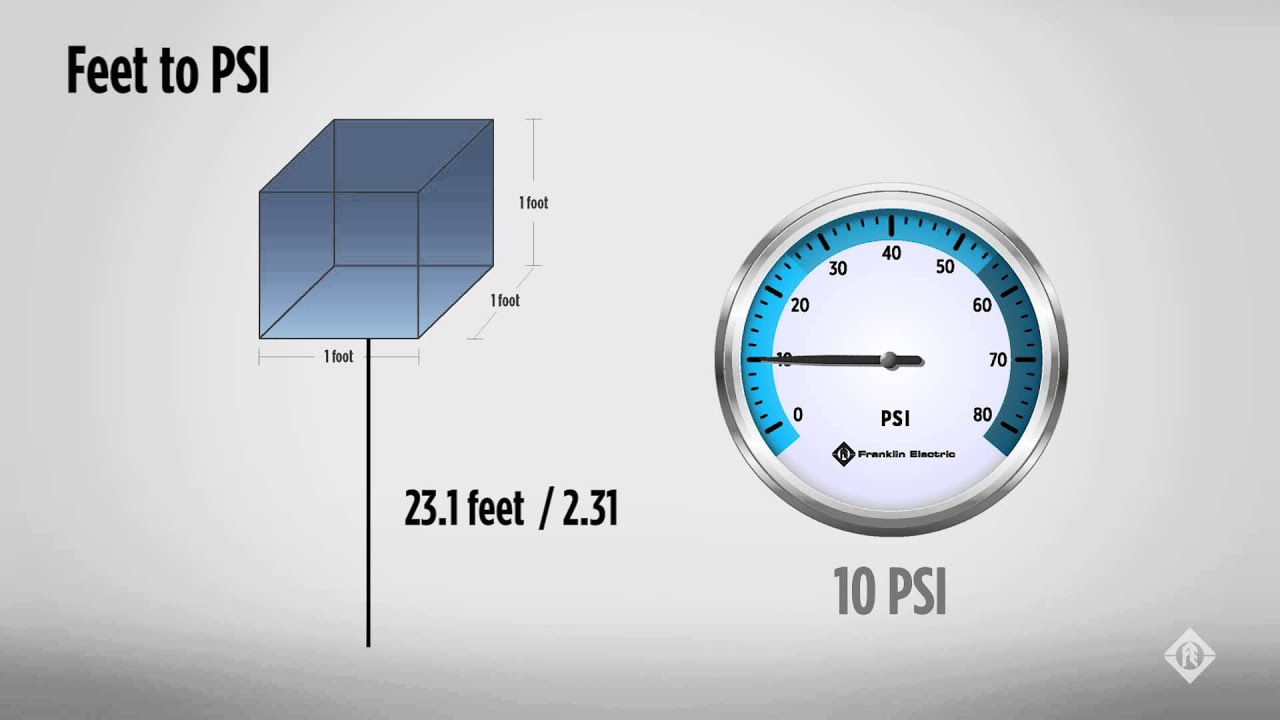

The conversion between feet of water and PSI is based on a simple principle: water pressure increases with depth. Essentially, the weight of the water column above a given point exerts pressure on that point. The standard conversion factor is:

1 ft H2O = 0.4335 PSI

Therefore, to convert feet of water to PSI, you simply multiply the number of feet of water by 0.4335.

PSI = ft H2O x 0.4335

Conversely, to convert PSI to feet of water, you divide the PSI value by 0.4335.

ft H2O = PSI / 0.4335

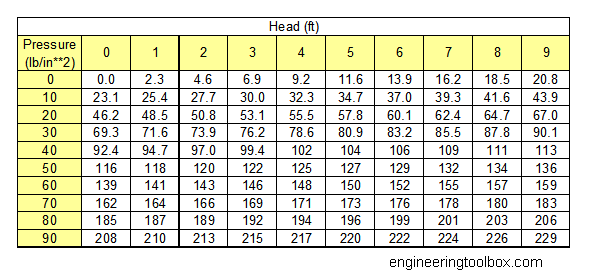

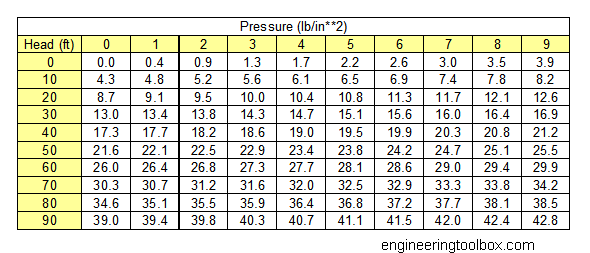

Let's illustrate with a few examples:

- Example 1: A water tank has a water level of 20 feet. What is the pressure at the bottom of the tank in PSI?

PSI = 20 ft H2O x 0.4335 = 8.67 PSI

- Example 2: A pressure gauge reads 50 PSI. What is the equivalent water column height in feet?

ft H2O = 50 PSI / 0.4335 = 115.34 ft H2O

Why is This Conversion Important for Homeowners?

Understanding this conversion is valuable in several scenarios:

- Water Pressure Troubleshooting: Low water pressure can be a common issue. Knowing the conversion allows you to relate static pressure readings to the height of your water source (e.g., well depth or municipal water tower height).

- HVAC System Maintenance: In closed-loop hydronic heating systems (baseboard heaters, radiant floors), maintaining proper water pressure is crucial for efficient operation. The conversion helps determine if the system is within the recommended pressure range.

- Swimming Pool Maintenance: Understanding water pressure is relevant when dealing with pool pumps, filters, and automatic cleaners.

- Sump Pump Systems: Calculating the head pressure (in feet) that your sump pump needs to overcome to effectively discharge water is essential for selecting the right pump. Converting this head pressure to PSI can also help in diagnosing pump performance issues.

Tools You Might Need

Here's a list of common tools you might use when investigating pressure-related issues:

- Pressure Gauge: For measuring water pressure. Analog gauges are readily available and affordable, while digital gauges offer more precision.

- Tape Measure: For measuring heights and distances, such as the height of a water tank or the depth of a well.

- Wrench Set: For tightening or loosening fittings and connections.

- Plumber's Tape (Teflon Tape): For sealing threaded connections to prevent leaks.

- Bucket: For catching water during repairs.

- Screwdrivers (Various sizes): For accessing components and making adjustments.

- Multimeter (Optional): For electrical testing in pump systems (if you are comfortable and qualified to do so).

Common Problems and Troubleshooting

Here are some common pressure-related problems you might encounter and how the ft H2O to PSI conversion can help in troubleshooting:

1. Low Water Pressure

Possible Causes:

- Municipal Water Supply Issues: Check with your neighbors to see if they are experiencing similar problems. Contact your local water authority.

- Clogged Pipes: Mineral buildup or sediment accumulation can restrict water flow.

- Pressure Regulator Failure: A faulty pressure regulator can prevent adequate pressure from reaching your fixtures.

- Well Pump Issues: Low well water level, a failing pump, or a clogged well screen can all contribute to low pressure.

Troubleshooting with ft H2O to PSI:

- Check Static Pressure: Use a pressure gauge at an outdoor faucet. A typical reading should be between 40-60 PSI.

- Convert to ft H2O: Convert the PSI reading to feet of water (PSI / 0.4335).

- Compare to Water Source Height: If you have a well, compare the equivalent water column height to the depth of your well. A significant discrepancy could indicate a problem with the well or pump.

- Check Pressure Regulator: If you have a pressure regulator, inspect it for leaks or damage. Test the pressure before and after the regulator to see if it is functioning correctly.

2. High Water Pressure

Possible Causes:

- Faulty Pressure Regulator: The most common cause of high water pressure is a malfunctioning pressure regulator.

- Municipal Water Supply Spikes: Although less common, fluctuations in the municipal water supply can lead to high pressure.

Troubleshooting with ft H2O to PSI:

- Check Static Pressure: Use a pressure gauge to measure the water pressure. High pressure is generally considered anything above 80 PSI.

- Convert to ft H2O: Convert the PSI reading to feet of water (PSI / 0.4335). This conversion is less critical in this scenario but can help visualize the pressure.

- Inspect Pressure Regulator: If you have a pressure regulator, inspect it for proper operation. Try adjusting the regulator to see if the pressure decreases. If the regulator is not responding, it likely needs to be replaced.

3. Hydronic Heating System Pressure Issues

Possible Causes:

- Air in the System: Air pockets can compress and affect pressure readings.

- Water Leaks: Leaks can cause a gradual drop in pressure.

- Expansion Tank Failure: The expansion tank is designed to accommodate changes in water volume due to temperature fluctuations. A faulty tank can lead to pressure fluctuations and system damage.

- Low Water Level: Insufficient water in the system.

Troubleshooting with ft H2O to PSI:

- Check Pressure Gauge: Monitor the pressure gauge on the boiler or heating system. The recommended pressure range is typically between 12-15 PSI when cold.

- Convert to ft H2O: Convert the PSI reading to feet of water (PSI / 0.4335). This conversion can help determine the height of the water column in the system.

- Bleed Air from the System: Bleed valves are located at various points in the system, typically at the highest points. Use these valves to release trapped air.

- Inspect for Leaks: Check all pipes, fittings, and radiators for leaks. Repair any leaks promptly.

- Check Expansion Tank: A properly functioning expansion tank should feel about half full when tapped. If it feels completely full or empty, it may need to be replaced.

Safety First!

Working with plumbing and HVAC systems involves inherent risks. Always remember the following safety precautions:

- Turn off the Water Supply: Before working on any plumbing, turn off the water supply at the main shut-off valve.

- Turn off the Power: Before working on any electrical components, turn off the power at the circuit breaker.

- Wear Safety Glasses: Protect your eyes from debris and splashing water.

- Wear Gloves: Protect your hands from hot surfaces, sharp edges, and chemicals.

- Work in a Well-Ventilated Area: When working with chemicals or solvents, ensure adequate ventilation.

- Follow Manufacturer's Instructions: Always refer to the manufacturer's instructions for specific tools and equipment.

When to Call a Professional

While many simple pressure-related issues can be addressed with basic DIY knowledge, some situations require the expertise of a qualified HVAC or plumbing professional. Consider calling a pro if:

- You are uncomfortable working with plumbing or electrical systems.

- You suspect a major leak or structural damage.

- You are unable to diagnose the problem after troubleshooting.

- You need to work on complex components, such as boilers, well pumps, or pressure regulators.

- You lack the necessary tools or experience to complete the repair safely and effectively.

Here's a list of potential repair costs (estimates only, actual costs may vary):

- Pressure Regulator Replacement: $150 - $400

- Well Pump Replacement: $800 - $2500

- Expansion Tank Replacement (HVAC): $200 - $600

- Leak Repair (Minor): $100 - $300

- Leak Repair (Major): $500 - $2000+

Final Thoughts

Understanding the conversion between feet of water and PSI empowers you to diagnose and troubleshoot various pressure-related issues around your home. While this knowledge is valuable, remember to prioritize safety and seek professional assistance when needed. By combining your DIY skills with a solid understanding of fundamental principles, you can maintain your home's systems efficiently and prevent costly repairs.