Foam Core Vs Solid Core Pvc

Frequently Asked Questions: Foam Core vs. Solid Core PVC

Choosing the right PVC material for your project can be confusing. Foam core and solid core PVC offer distinct advantages and disadvantages. This FAQ aims to clarify the differences and help you make an informed decision.

1. What's the basic difference between foam core and solid core PVC?

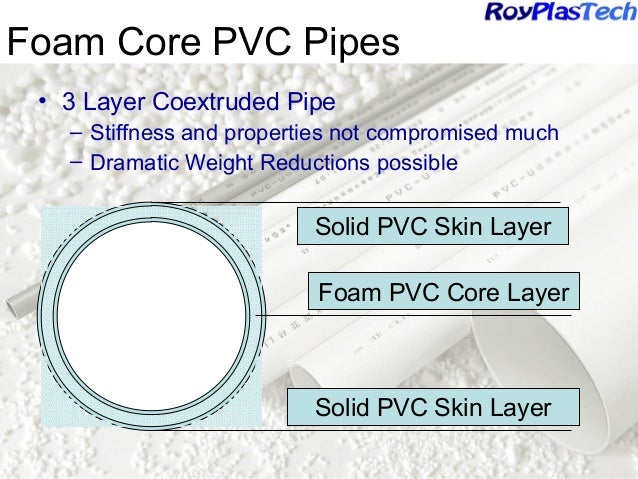

The core construction is the key difference. Solid core PVC is uniform in density throughout, meaning it's made of solid PVC material from surface to surface. Think of it like a solid piece of wood. Foam core PVC, on the other hand, has a solid PVC skin on the outside with a foamed PVC core in the middle. This core gives it a lighter weight and different properties. It's like a sandwich – solid exterior, softer interior.

2. Which type of PVC is stronger and more durable?

Generally, solid core PVC is significantly stronger and more durable than foam core PVC. The solid construction provides greater resistance to impact, bending, and pulling forces. While foam core PVC is still durable, it's not designed to withstand the same level of stress as its solid counterpart. Consider these factors when assessing durability:

- Impact Resistance: Solid core wins here. It can take more direct hits without cracking or denting.

- Screw Holding Power: Solid core provides superior screw holding power, which is crucial for secure fastening.

- Load-Bearing Capacity: If the application involves significant weight or stress, solid core is the better choice.

- Weather Resistance: Both are weather resistant, but solid core tends to hold up better under extreme conditions and prolonged UV exposure due to its higher density.

3. What are the main advantages of using foam core PVC?

Foam core PVC offers several key benefits, making it suitable for specific applications:

- Lighter Weight: This is the biggest advantage. Foam core is much lighter than solid core, making it easier to handle, transport, and install. This can significantly reduce labor costs, especially for large projects.

- Cost-Effectiveness: Foam core is typically less expensive than solid core, making it a budget-friendly option for projects where extreme strength isn't required.

- Ease of Cutting and Shaping: The softer core makes foam core PVC easier to cut, drill, and shape with standard woodworking tools. This is a great advantage for DIYers and installers who value ease of use.

- Good Insulation Properties: The foam core provides some insulation, which can be beneficial in certain applications, although it's not a primary insulator.

- Closed Cell Structure: Generally closed cell structure helps the material resist water absorption and resist rotting.

4. When should I use solid core PVC instead of foam core PVC?

Choose solid core PVC when strength, durability, and structural integrity are paramount. Common applications include:

- Load-Bearing Structures: Decks, railings, pergolas, and other structures that need to support significant weight.

- High-Traffic Areas: Door frames, window frames, and trim in areas with frequent use and potential for impact.

- Exterior Applications in Harsh Climates: Situations with extreme temperatures, intense sunlight, or frequent storms.

- Applications Requiring Strong Fasteners: Anywhere where screws or other fasteners need to hold securely over time.

- Signage That Needs to Be Rigid: If the sign is subject to wind load, a solid core will provide greater rigidity and prevent flexing.

- Areas Prone to Moisture: While both are water resistant, solid core's greater density means even greater resistance to prolonged moisture exposure.

5. How does the cost of foam core PVC compare to solid core PVC?

Foam core PVC is generally less expensive than solid core PVC. The price difference can vary depending on the thickness, size, and manufacturer, but foam core typically offers a more budget-friendly option. Consider these price factors:

- Material Costs: Foam core usually has a lower price per sheet or board foot.

- Labor Costs: The lighter weight and ease of cutting of foam core can sometimes lead to lower installation costs.

- Long-Term Costs: While the initial cost of solid core is higher, its greater durability may result in lower maintenance and replacement costs over the long run. This is particularly important to factor into the calculation.

6. Are there any specific installation considerations for each type of PVC?

Yes, there are some key installation differences to keep in mind:

- Foam Core: Requires more care when fastening. Over-tightening screws can compress the foam core and weaken the joint. Use appropriate screw lengths and consider using washers to distribute the load. Pre-drilling pilot holes is highly recommended to prevent splitting.

- Solid Core: Can be fastened more aggressively, but pre-drilling is still advisable, especially near edges. Use high-quality screws designed for PVC to prevent corrosion.

- Cutting: Foam core is easier to cut with standard woodworking tools, while solid core may require specialized blades for clean cuts.

- Sealing Edges: Both types benefit from sealing exposed edges with PVC edge banding or sealant to prevent moisture intrusion, especially in exterior applications.

- Expansion and Contraction: Both PVC types expand and contract with temperature changes. Leave appropriate expansion gaps during installation to prevent buckling or cracking. Consult the manufacturer’s specifications for the recommended expansion gap for your specific product and climate.

7. Can I paint or finish both foam core and solid core PVC?

Yes, both foam core and solid core PVC can be painted. However, proper preparation is crucial for a long-lasting finish:

- Cleaning: Thoroughly clean the surface with a mild detergent and water to remove any dirt, grease, or residue.

- Sanding: Lightly sand the surface with fine-grit sandpaper to create a slightly rough texture for better paint adhesion.

- Priming: Apply a high-quality primer specifically designed for PVC. This will help the paint adhere properly and prevent it from peeling or cracking.

- Painting: Use acrylic latex paint formulated for exterior use. Apply two or more thin coats, allowing each coat to dry completely before applying the next. Consider using light colors to minimize heat absorption, which can cause expansion and contraction.

- Edge Sealing: If you are cutting and painting, it's especially important to seal the edges to prevent moisture from penetrating into the core.

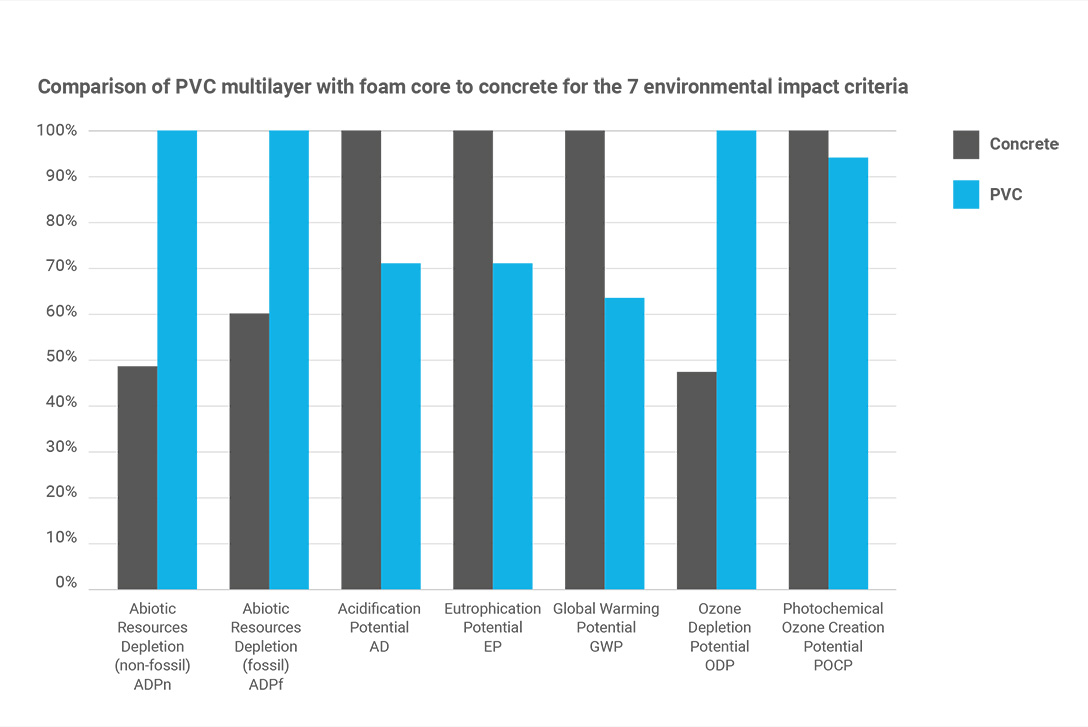

8. Are there any environmental considerations when choosing between foam core and solid core PVC?

Both foam core and solid core PVC are recyclable, but the specific recycling options available in your area may vary. Check with your local recycling center for more information. Some manufacturers also offer take-back programs for their PVC products.

- Material Composition: Consider the manufacturer's use of recycled content in their PVC products. Some manufacturers prioritize using recycled PVC in their production processes.

- Waste Reduction: Efficient cutting and installation practices can minimize waste during the project.

- Life Cycle Assessment: Consider the entire life cycle of the material, from production to disposal, when evaluating its environmental impact.

9. How do I choose the right thickness of PVC sheet for my project?

The appropriate thickness depends heavily on the intended application and the loads it will bear. Consult with a construction professional or refer to engineering guidelines for load-bearing calculations. For general guidelines:

- Thin Sheets (1/8" - 1/4"): Suitable for decorative applications, signage, or cladding where minimal load bearing is required.

- Medium Thickness Sheets (3/8" - 1/2"): Versatile for a variety of projects, including trim, light-duty shelving, and non-structural components.

- Thick Sheets (3/4" - 1"): Recommended for structural applications, load-bearing components, and areas with high impact or stress.

Always factor in the span between supports, the weight of the objects it will support, and any potential environmental loads (wind, snow) when determining the proper thickness.

10. Where can I purchase foam core and solid core PVC sheets?

Both foam core and solid core PVC sheets are widely available from:

- Home Improvement Stores: Major retailers like Home Depot and Lowe's carry a range of PVC sheets in various sizes and thicknesses.

- Lumber Yards: Local lumber yards often specialize in building materials and can offer a wider selection of PVC products, including specialty sizes and grades.

- Specialty Plastic Suppliers: These suppliers focus specifically on plastics and offer a vast array of PVC options, including custom sizes and colors.

- Online Retailers: Online marketplaces like Amazon and eBay also sell PVC sheets, but be sure to check the seller's reviews and product specifications carefully.

When purchasing, compare pricing between different sources and factor in shipping costs, especially for larger sheets. Inspect the materials carefully upon delivery to ensure they are free of damage.