Foil Duct Tape Vs Duct Tape

Choosing the right tape for a repair or project can be surprisingly crucial. Two common contenders are foil duct tape and standard duct tape. While they might look similar at first glance, their properties and ideal uses differ significantly. Understanding these differences will help you make the best choice for your specific needs, ensuring a reliable and long-lasting solution.

What is Duct Tape?

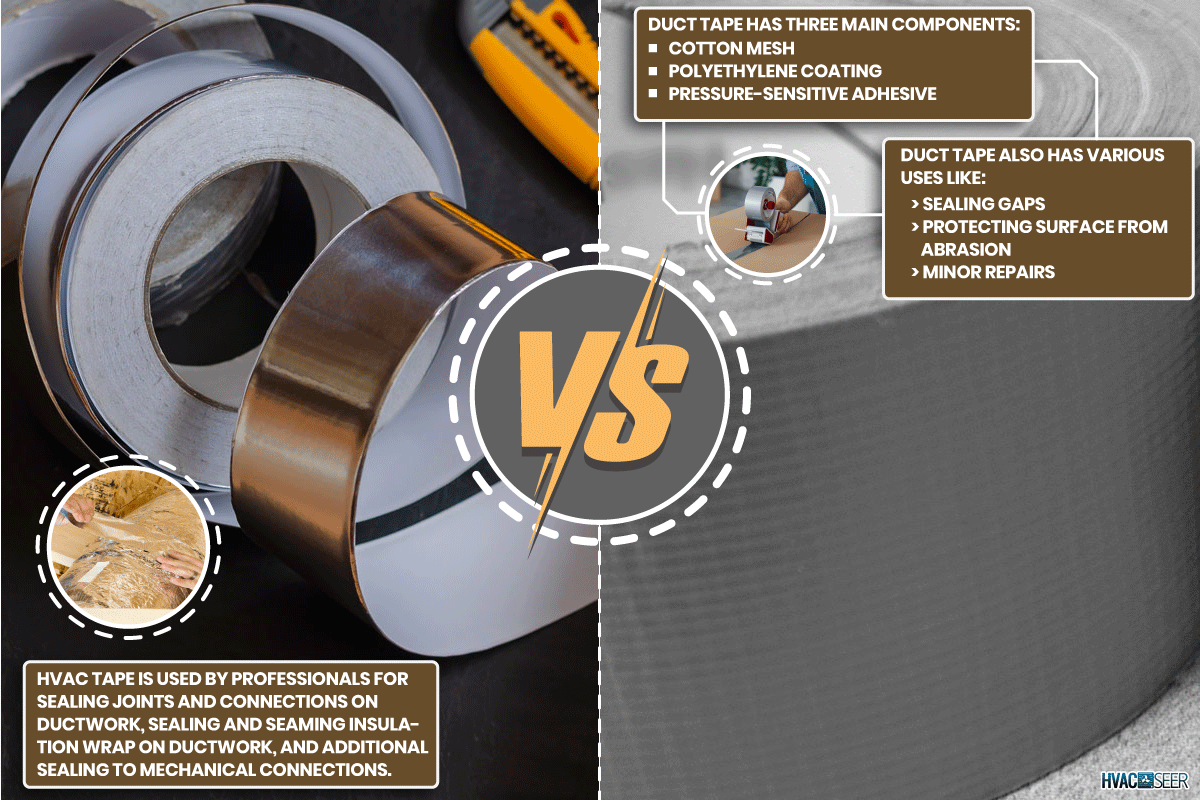

Duct tape, often mistakenly called "duck tape," is a versatile pressure-sensitive tape made of three layers: a fabric scrim (usually cotton), an adhesive layer (typically rubber-based), and a polyethylene (PE) coating. This construction gives it its characteristic strength, flexibility, and water resistance.

Key Features of Duct Tape:

- Strong Adhesive: Duct tape is known for its aggressive adhesive, capable of bonding to a wide range of surfaces.

- Water Resistance: The PE coating provides a degree of water resistance, making it suitable for temporary outdoor repairs.

- Flexibility: The fabric scrim allows the tape to conform to irregular shapes and surfaces.

- Tearability: While strong, duct tape can be easily torn by hand, making it convenient to use without tools.

- Versatility: Duct tape is a general-purpose tape suitable for a wide range of applications, from household repairs to DIY projects.

What is Foil Duct Tape?

Foil duct tape, on the other hand, features a thin layer of aluminum foil as its primary component. This foil is typically coated with an acrylic or rubber-based adhesive. Its design centers around reflecting heat and sealing ducts, particularly in HVAC (Heating, Ventilation, and Air Conditioning) systems.

Key Features of Foil Duct Tape:

- Heat Reflectivity: The aluminum foil reflects radiant heat, making it ideal for insulating and protecting surfaces from high temperatures.

- Vapor Barrier: Foil tape provides an excellent vapor barrier, preventing moisture from penetrating through joints and seams.

- Temperature Resistance: Foil tape can withstand higher temperatures than standard duct tape without losing its adhesive properties.

- Conformability: While less flexible than standard duct tape, foil tape can still conform to curved surfaces.

- Durability: Foil tape is generally more durable and resistant to aging than standard duct tape, particularly in harsh environments.

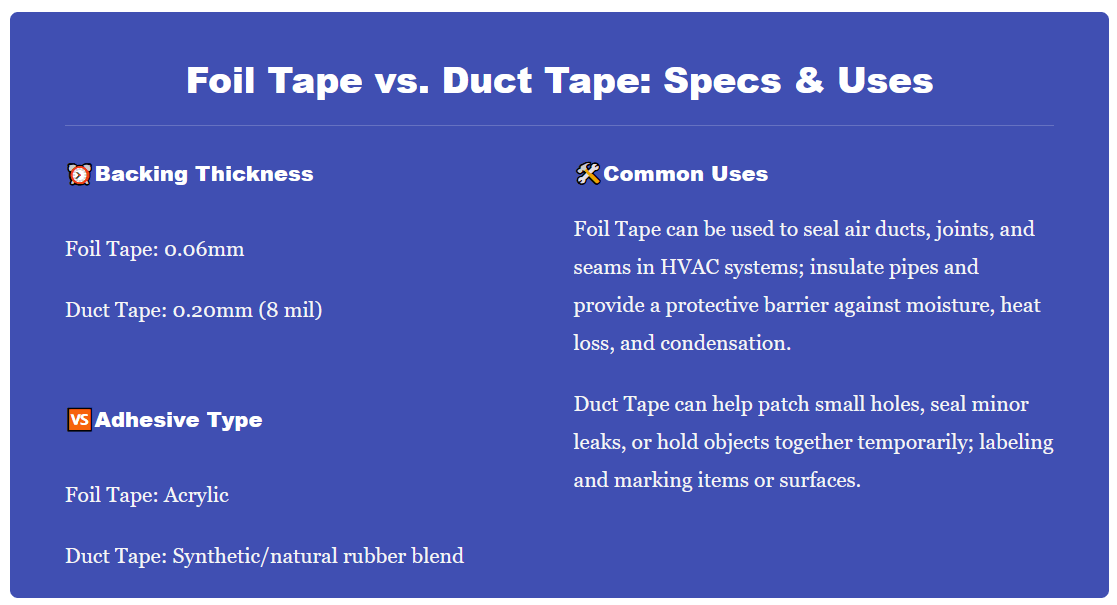

Key Differences: Duct Tape vs. Foil Duct Tape

The core difference lies in their composition and intended use. Here's a breakdown of the key distinctions:

Material Composition:

Duct Tape: Fabric scrim, rubber-based adhesive, and polyethylene coating.

Foil Duct Tape: Aluminum foil and acrylic or rubber-based adhesive.

Heat Resistance:

Duct Tape: Has limited heat resistance and can melt or degrade at high temperatures. Prolonged exposure to heat will cause the adhesive to dry out and fail.

Foil Duct Tape: Offers significantly higher heat resistance due to the aluminum foil layer. It's designed to withstand the temperatures commonly found in HVAC systems. It can be used in some instances to reflect heat from sensitive components.

Adhesion:

Duct Tape: Adheres well to a wide variety of surfaces, including rough and uneven materials. However, the adhesive can degrade over time, especially when exposed to UV light or extreme temperatures.

Foil Duct Tape: Primarily designed for adhesion to metal surfaces, such as ductwork. While it can adhere to other materials, its bond may not be as strong as duct tape on non-metallic surfaces. The adhesive is generally more resistant to high-temperature degradation.

Flexibility:

Duct Tape: Highly flexible and conformable, making it easy to wrap around objects and seal irregular shapes.

Foil Duct Tape: Less flexible than duct tape due to the rigid foil layer. It's better suited for sealing straight seams and joints.

Vapor Barrier:

Duct Tape: Offers some water resistance but is not a true vapor barrier. Moisture can still penetrate through the fabric scrim and adhesive layer over time.

Foil Duct Tape: Provides an excellent vapor barrier, preventing moisture from passing through sealed joints. This is particularly important in HVAC systems to prevent condensation and mold growth.

Appearance:

Duct Tape: Available in a variety of colors and patterns.

Foil Duct Tape: Typically silver or aluminum-colored due to the foil layer.

When to Use Duct Tape:

Duct tape is the ideal choice for general-purpose repairs and projects where strength, flexibility, and water resistance are needed, but extreme heat or vapor sealing isn't a concern.

Examples of Suitable Uses for Duct Tape:

- Temporary repairs around the house.

- Bundling cables and wires.

- Patching holes in tarps or plastic sheeting.

- Securing items during transport.

- DIY projects and crafts.

Important Note: While duct tape is versatile, it's generally not recommended for critical repairs or applications that require long-term durability, especially in demanding environments (e.g., high heat, direct sunlight, or constant moisture exposure). For such applications, consider using a more specialized tape or adhesive.

When to Use Foil Duct Tape:

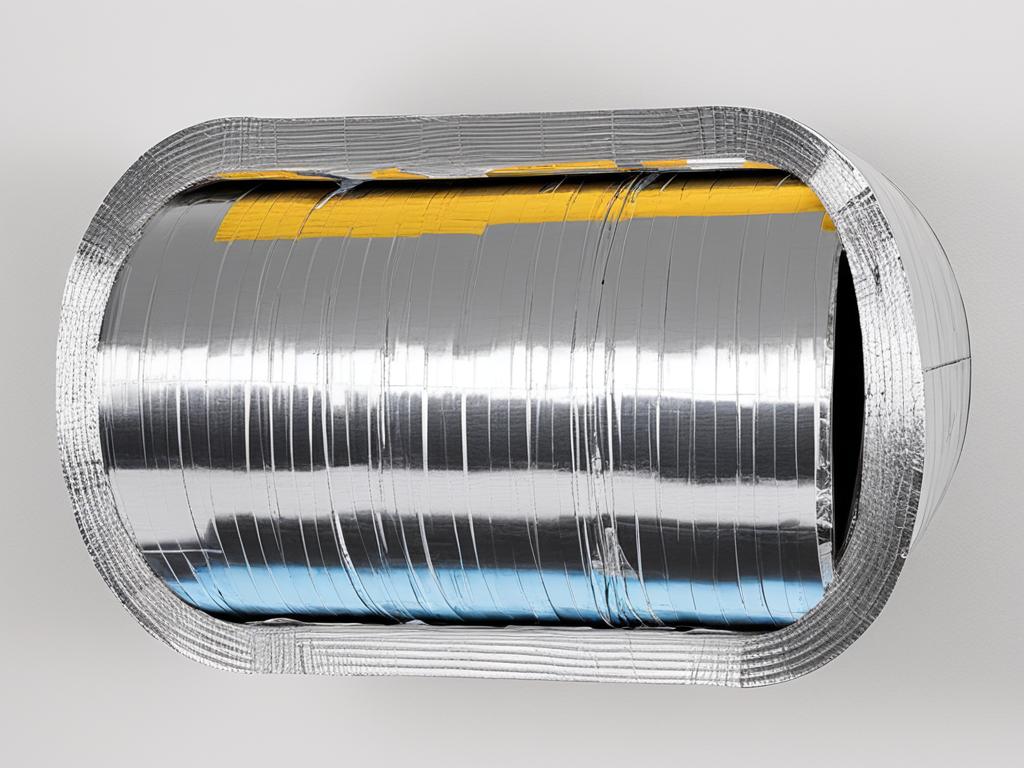

Foil duct tape is specifically designed for HVAC applications and situations where heat reflectivity, temperature resistance, and a vapor barrier are essential.

Examples of Suitable Uses for Foil Duct Tape:

- Sealing and insulating HVAC ductwork to prevent air leaks and energy loss.

- Wrapping pipes to protect them from heat or cold.

- Reflecting heat away from sensitive components.

- Creating a vapor barrier in construction projects.

- Patching metal surfaces, especially those exposed to high temperatures.

Think of your home's HVAC system. It circulates air to keep you comfortable. Imagine your air ducts as the "arteries" of your house. If these "arteries" have leaks, your HVAC system works harder, costing you money and impacting efficiency. Foil duct tape creates a tight seal for these systems.

Common Mistakes to Avoid:

Using the wrong tape can lead to problems down the line. Here are some common mistakes to avoid:

Using Duct Tape on HVAC Ducts:

This is a frequent error. While duct tape might seem like a quick fix, it will eventually dry out and fail due to the temperature fluctuations and moisture present in ductwork. This leads to air leaks and reduced HVAC efficiency. Always use foil duct tape specifically designed for HVAC systems.

Using Duct Tape for Electrical Repairs:

Duct tape is not an electrical insulator and should never be used to repair or insulate electrical wires. This can be extremely dangerous and create a fire hazard. Always use electrical tape specifically designed for electrical insulation.

Using Foil Duct Tape on Surfaces it Won't Adhere To:

Foil duct tape is most effective on clean, dry metal surfaces. Applying it to porous or dirty surfaces will result in a weak bond and premature failure. Clean the surface thoroughly before applying the tape.

Making the Right Choice:

When deciding between duct tape and foil duct tape, consider the following questions:

- What is the intended application? Is it a general-purpose repair, or does it require heat resistance, vapor sealing, or specific adhesion to metal?

- What are the environmental conditions? Will the tape be exposed to high temperatures, moisture, or UV light?

- What is the desired lifespan of the repair? Is it a temporary fix, or do you need a long-lasting solution?

By answering these questions, you can determine which type of tape is best suited for your needs.

Summary Table: Duct Tape vs. Foil Duct Tape

| Feature | Duct Tape | Foil Duct Tape |

|---|---|---|

| Material | Fabric scrim, rubber adhesive, PE coating | Aluminum foil, acrylic or rubber adhesive |

| Heat Resistance | Low | High |

| Flexibility | High | Low |

| Vapor Barrier | Poor | Excellent |

| Adhesion | Wide range of surfaces | Best on metal |

| Typical Uses | General repairs, bundling, patching | HVAC sealing, heat reflection, vapor barrier |

Conclusion

Duct tape and foil duct tape are valuable tools for different purposes. Duct tape excels in general repairs and projects where strength and flexibility are paramount, while foil duct tape is the superior choice for HVAC applications requiring heat resistance, vapor sealing, and adhesion to metal. Understanding their distinct characteristics and limitations ensures that you choose the right tape for the job, resulting in a more effective and durable solution.

By carefully considering the specific requirements of your project, you can confidently select the appropriate tape and achieve the desired results. Remember to always prioritize safety and use the correct materials for the task at hand.