Furnace Will Not Turn On With Thermostat

A cold house with a furnace that refuses to ignite is a homeowner's nightmare. When your thermostat demands heat, but your furnace remains stubbornly silent, a systematic troubleshooting approach is crucial. This guide breaks down common reasons why your furnace won't turn on with the thermostat, providing solutions suitable for homeowners and valuable insights for HVAC technicians and facility managers.

Understanding the Basics: How Your Furnace Should Work

Before diving into diagnostics, let's review the typical furnace operation sequence. When your thermostat calls for heat, it sends a signal to the furnace's control board. This activates a series of steps:

- Inducer Motor Activation: The inducer motor, a small fan, starts to vent combustion gases from the furnace and create a negative pressure within the heat exchanger. This negative pressure is confirmed by a pressure switch.

- Ignition Sequence: Depending on your furnace type (gas or oil), the ignition process varies. Gas furnaces use either a hot surface igniter, a spark igniter, or a pilot light. Oil furnaces atomize the fuel oil and ignite it with an electric spark.

- Main Burner Ignition: Once the igniter is hot enough or the pilot light is lit, the main gas valve opens, allowing fuel to flow to the burners. The flame is continuously monitored by a flame sensor.

- Blower Motor Activation: After a set delay (typically 30-90 seconds), the blower motor turns on, circulating heated air through your home's ductwork.

If any of these steps fail, the furnace will likely shut down as a safety precaution.

Common Culprits: Diagnosing the Problem

Now, let's examine the most frequent causes for a furnace refusing to respond to the thermostat.

1. Thermostat Issues

The thermostat is the command center. A malfunctioning thermostat can prevent the furnace from ever receiving the call for heat.

- Dead Batteries: This is the simplest fix. Replace the batteries in your thermostat, even if the display is still lit. Weak batteries can cause unreliable signals.

- Incorrect Settings: Ensure the thermostat is set to "Heat" mode and the temperature is set higher than the current room temperature. Verify that the thermostat is not in "Cool" or "Off" mode.

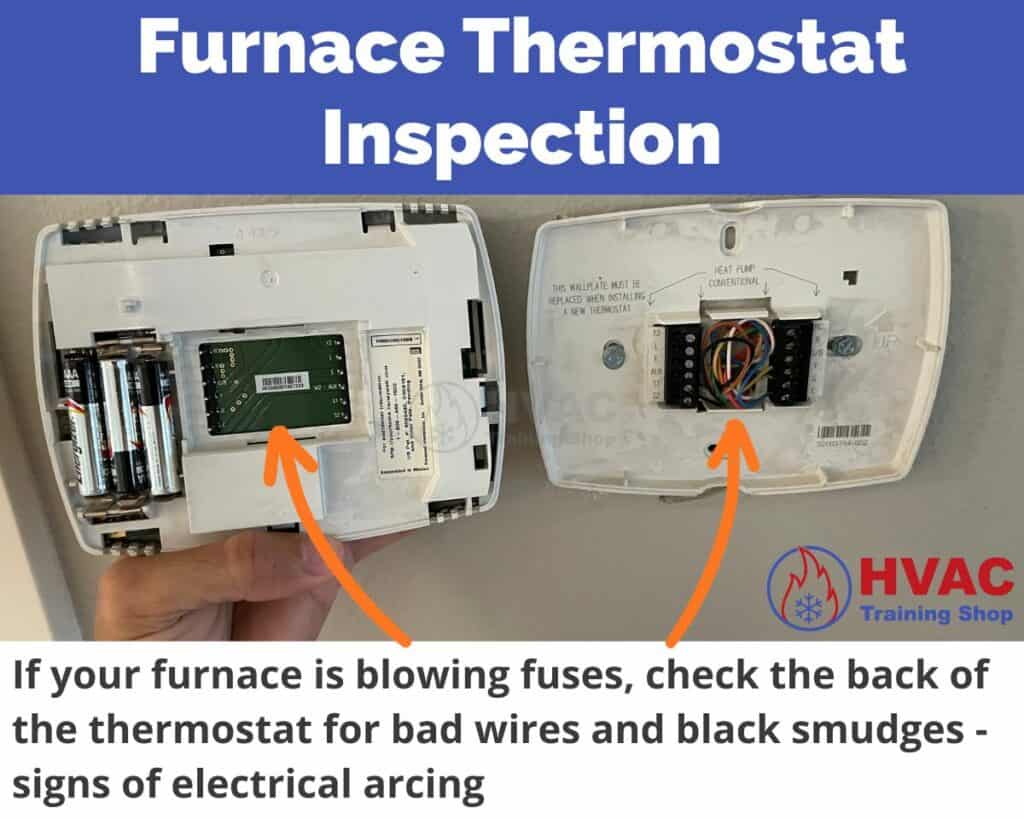

- Wiring Problems: Check the wiring connections at the thermostat base. Loose or corroded wires can disrupt communication. Consult your thermostat manual for the correct wiring diagram. A common setup uses a red wire (R) for power, a white wire (W) for heat, and sometimes a green wire (G) for the fan.

- Faulty Thermostat: If you've ruled out other issues, the thermostat itself may be defective. Consider replacing it. Smart thermostats offer enhanced features and programmability.

Technician Tip: Use a multimeter to verify voltage between the R and W terminals when the thermostat is calling for heat. If there's no voltage, the thermostat is likely the problem.

2. Electrical Problems

Furnaces rely on a consistent power supply. Disruptions can halt operation.

- Tripped Circuit Breaker: Locate your electrical panel and check the circuit breaker for the furnace. A tripped breaker indicates an overload or short circuit. Reset the breaker. If it trips again immediately, there's a more serious electrical problem requiring professional attention.

- Disconnected Power Switch: Many furnaces have a dedicated power switch, often located on the side of the unit or near the return air duct. Ensure this switch is in the "On" position.

- Blown Fuse: Some furnaces have a fuse located on the control board. Inspect the fuse for damage. If it's blown, replace it with a fuse of the same amperage rating.

3. Gas Supply Issues (Gas Furnaces)

A gas furnace needs a reliable gas supply to operate.

- Gas Valve Off: Check the main gas valve near the furnace. Make sure it's open. Also, check the gas meter valve outside your home.

- Pilot Light Out: Older furnaces use a pilot light. If the pilot light is out, relight it according to the manufacturer's instructions. Many modern furnaces use electronic ignition and do not have a pilot light.

- Gas Line Problems: Kinks or leaks in the gas line can restrict gas flow. Contact a qualified gas technician to inspect and repair any gas line issues. Never attempt to repair gas lines yourself.

4. Safety Switch Problems

Furnaces have safety switches to prevent operation under unsafe conditions.

- Furnace Door Switch: This switch prevents the furnace from operating when the blower compartment door is open. Ensure the door is securely closed. Sometimes the switch can become dislodged or faulty.

- Limit Switch: The limit switch monitors the furnace's internal temperature. If the furnace overheats, the limit switch trips, shutting off the burner. This is often caused by a dirty air filter restricting airflow. Let the furnace cool down, then replace the air filter and try resetting the limit switch (if it has a manual reset button).

- Rollout Switch: Located near the burners, the rollout switch detects flame rollout (flames escaping from the burner area). If it detects flame rollout, it shuts off the gas supply. This is a serious safety issue requiring immediate professional attention.

- Pressure Switch: As mentioned earlier, the pressure switch confirms that the inducer motor is creating sufficient negative pressure. A blocked vent pipe or a faulty inducer motor can prevent the pressure switch from closing.

5. Ignition System Problems

The ignition system is responsible for lighting the fuel.

- Faulty Hot Surface Igniter: Hot surface igniters are fragile and can burn out over time. Visually inspect the igniter for cracks or breaks. Use a multimeter to test its resistance. A failed igniter needs replacement.

- Faulty Spark Igniter: Spark igniters generate a spark to ignite the fuel. If the spark igniter is not sparking, check the wiring connections and the igniter module.

- Faulty Flame Sensor: The flame sensor detects the presence of a flame. If the flame sensor is dirty or faulty, it will signal the control board to shut off the gas valve, even if there is a flame present. Clean the flame sensor with fine steel wool or replace it.

6. Blower Motor Problems

The blower motor circulates heated air throughout your home.

- Blower Motor Not Starting: If the blower motor isn't running, check the blower motor capacitor. A faulty capacitor is a common cause of blower motor failure. Also, inspect the blower motor windings for shorts or opens using a multimeter.

- Dirty Blower Wheel: A dirty blower wheel reduces airflow and can cause the furnace to overheat. Clean the blower wheel regularly.

Preventative Maintenance: Keeping Your Furnace Running Smoothly

Regular maintenance can significantly reduce the likelihood of furnace problems. Here are some key preventative measures:

- Replace Air Filters Regularly: Change your air filter every 1-3 months, or more frequently if you have pets or allergies. A dirty air filter restricts airflow, causing the furnace to work harder and potentially overheat. MERV ratings indicate the filter's efficiency in trapping particles.

- Schedule Annual Professional Inspections: A qualified HVAC technician can inspect your furnace for potential problems, clean components, and ensure proper operation. This is especially important for gas furnaces, as it helps to detect gas leaks and carbon monoxide issues.

- Inspect Vents and Flues: Check for obstructions in the furnace's vent pipes and chimney flue. Blocked vents can lead to carbon monoxide buildup.

- Clean Burners Regularly: Dirty burners can reduce efficiency and cause incomplete combustion. A professional cleaning can ensure optimal burner performance.

Cost Considerations

Repairing a furnace can range from a simple fix like replacing a thermostat battery (under $10) to a more complex repair like replacing a blower motor ($300-$800). Replacing a furnace can cost between $4,000 and $10,000 depending on the size, efficiency, and brand. AFUE (Annual Fuel Utilization Efficiency) ratings indicate a furnace's energy efficiency. Higher AFUE ratings mean lower heating costs. Consider a high-efficiency furnace (90% AFUE or higher) when replacing your old unit.

When to Call a Professional

While some furnace problems can be resolved with DIY troubleshooting, others require the expertise of a qualified HVAC technician. Contact a professional if:

- You smell gas. Evacuate your home immediately and call your gas company.

- You suspect a carbon monoxide leak. Install carbon monoxide detectors and call your fire department.

- You are uncomfortable working with electricity or gas.

- You have tried troubleshooting the problem yourself and are unable to resolve it.

By understanding the basics of furnace operation and following a systematic troubleshooting approach, you can diagnose and potentially resolve common furnace problems. Remember that safety is paramount, and when in doubt, always consult a qualified HVAC professional.