Gas Line Drip Leg Code

Understanding Gas Line Drip Legs: Protecting Your HVAC Investment

When installing or upgrading your HVAC system, particularly gas-fired furnaces or boilers, one often-overlooked but crucial component is the drip leg, also known as a sediment trap. While seemingly simple, the drip leg plays a vital role in ensuring the longevity and efficient operation of your heating system. This guide will explain what a gas line drip leg is, why it's essential, relevant codes, and best practices for installation and maintenance.

What is a Gas Line Drip Leg?

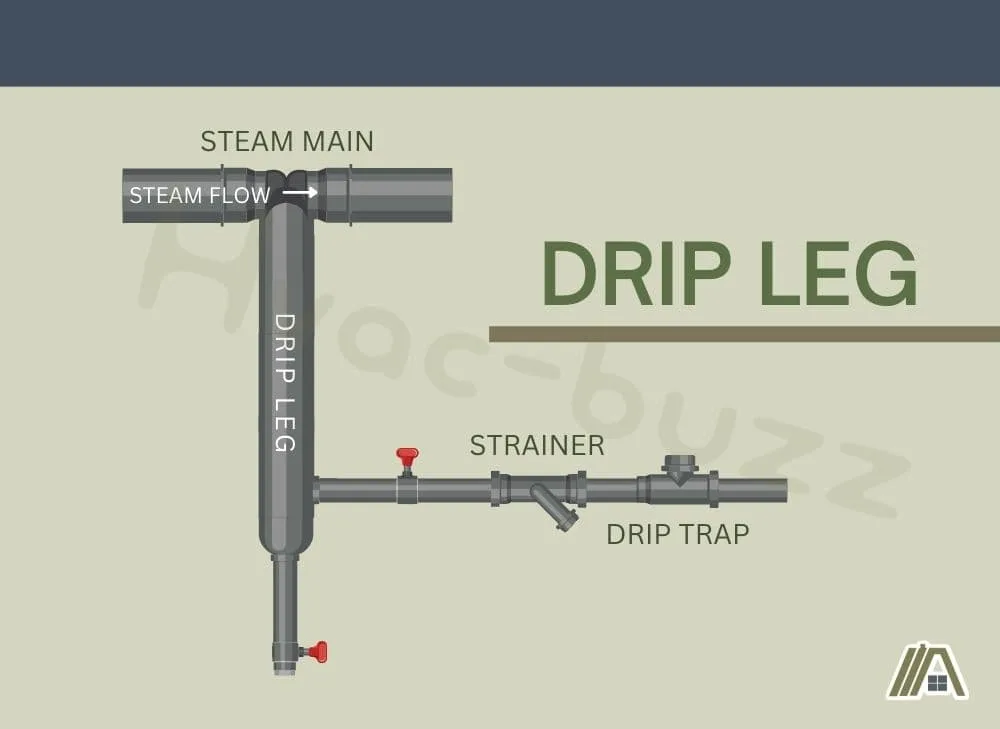

A gas line drip leg is a short, vertical section of pipe installed at the lowest point in a gas line, just before the connection to your furnace, boiler, or other gas appliance. It's designed to trap any sediment, debris, or moisture present in the gas supply line before it can reach and damage the sensitive components of your HVAC system, such as gas valves and burners.

Why is a Drip Leg Important?

The natural gas that fuels your HVAC system isn't always perfectly clean. It can contain small particles of rust, pipe scale, dirt, and even moisture. Without a drip leg, these contaminants would be carried directly into your appliance, leading to several potential problems:

- Clogged Gas Valves and Burners: Sediment can obstruct the small orifices in gas valves and burners, reducing gas flow and leading to inefficient combustion, poor heating performance, and even system shutdowns.

- Corrosion: Moisture in the gas line can cause corrosion of internal components, shortening the lifespan of your furnace or boiler.

- Erratic Operation: Debris can interfere with the proper functioning of safety devices and controls, resulting in unpredictable and potentially dangerous operation.

- Increased Maintenance Costs: Accumulated sediment can necessitate more frequent cleaning and repairs, increasing your long-term maintenance expenses.

Gas Line Drip Leg Code Requirements

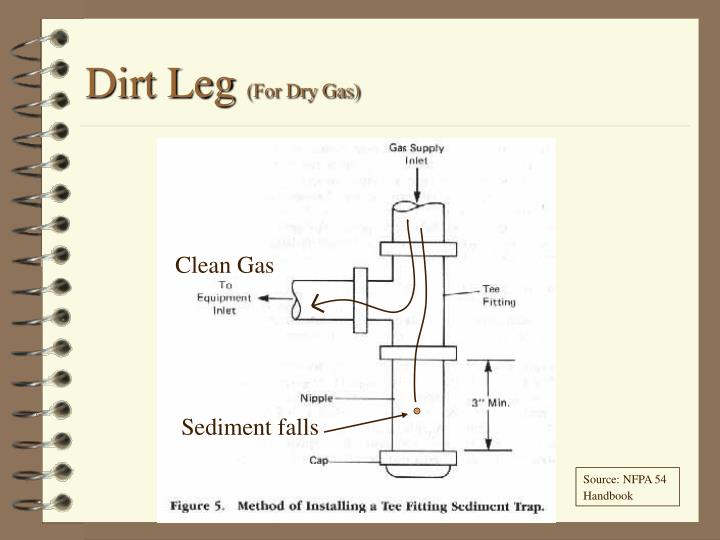

Most jurisdictions, adhering to national model codes like the International Fuel Gas Code (IFGC) and the National Fuel Gas Code (NFPA 54), mandate the installation of drip legs for gas-fired appliances. While specific requirements may vary slightly depending on your local codes, some common stipulations include:

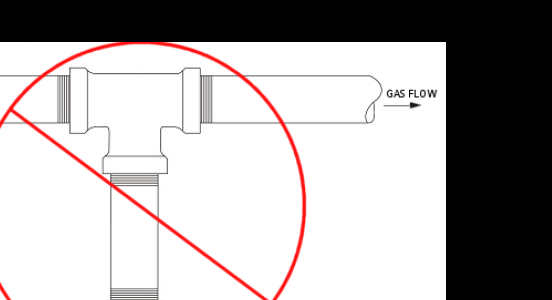

- Location: The drip leg must be installed as close as practicable to the appliance it serves, ideally just upstream of the appliance's shut-off valve.

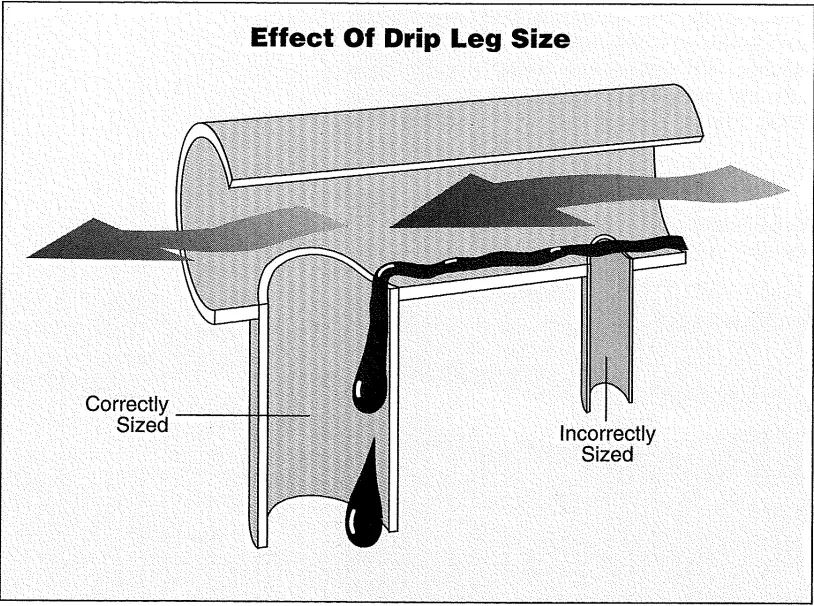

- Orientation: It must be installed vertically, with the capped end pointing downwards.

- Length: The drip leg typically needs to be at least 3 inches long. Local codes may specify a longer length.

- Material: The drip leg must be made of a material compatible with the gas piping, typically black iron or steel.

- Accessibility: The drip leg should be easily accessible for inspection and cleaning.

Important Note: Always consult your local building codes and regulations or a licensed HVAC professional to ensure compliance with specific drip leg requirements in your area. Improper installation can result in code violations and potentially hazardous situations.

Drip Leg Installation Best Practices

While a licensed professional should ideally handle gas line modifications, understanding the proper installation procedure is beneficial. Here's a general overview:

- Turn Off the Gas Supply: Before commencing any work on the gas line, shut off the gas supply to the appliance at the main shut-off valve.

- Cut and Thread the Pipe: Cut the existing gas line where the drip leg will be installed. Thread the ends of the pipe to accept fittings.

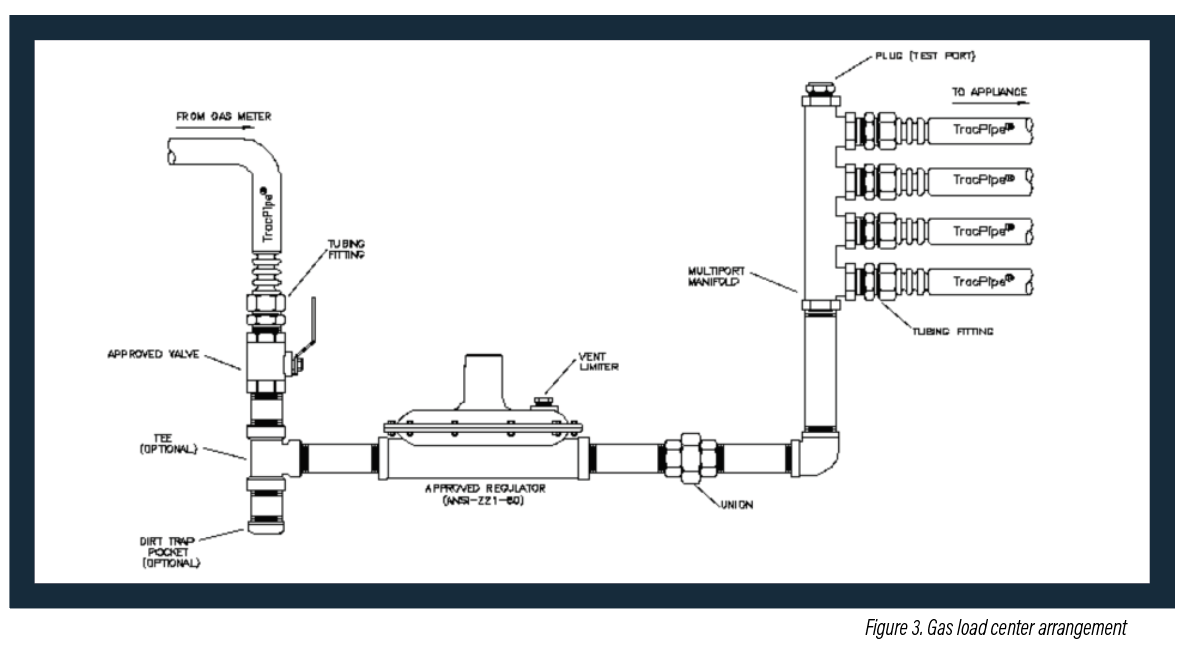

- Install a Tee Fitting: Install a tee fitting in the gas line, with the vertical branch pointing downwards.

- Attach the Drip Leg: Connect a section of pipe (at least 3 inches long) to the vertical branch of the tee fitting.

- Cap the Drip Leg: Cap the bottom of the drip leg with a threaded cap. This cap will allow you to remove sediment during maintenance.

- Install a Shut-Off Valve: Install a shut-off valve upstream of the tee fitting, if one isn't already present. This valve allows you to isolate the appliance for maintenance.

- Check for Leaks: After completing the installation, carefully check all connections for gas leaks using a soap and water solution. Bubbles indicate a leak.

Warning: Working with gas lines can be dangerous. If you're not comfortable performing this work yourself, hire a qualified HVAC technician or plumber.

Drip Leg Maintenance

Regular maintenance of your gas line drip leg is essential to ensure its continued effectiveness. Here's how to clean it:

- Turn Off the Gas Supply: As with installation, turn off the gas supply to the appliance.

- Loosen the Cap: Carefully loosen the cap at the bottom of the drip leg. Be prepared for a small amount of gas or liquid to escape.

- Clean Out Sediment: Remove the cap completely and allow any accumulated sediment or moisture to drain out. You can use a small brush or probe to dislodge stubborn debris.

- Reinstall the Cap: Clean the threads of the cap and the drip leg, then reinstall the cap securely.

- Check for Leaks: Turn the gas supply back on and check the cap for leaks using a soap and water solution.

The frequency of drip leg cleaning depends on the quality of your gas supply. A good rule of thumb is to inspect and clean it annually, or more often if you notice signs of reduced heating performance or frequent system shutdowns.

Common HVAC Brands and Drip Leg Considerations

While drip legs are a universal requirement for gas-fired appliances, certain HVAC brands offer features that complement their effectiveness:

- Carrier: Carrier furnaces often feature easily accessible gas valve assemblies, making maintenance easier should sediment reach those components despite the drip leg. Look for models with high AFUE (Annual Fuel Utilization Efficiency) ratings for optimal energy savings.

- Lennox: Lennox furnaces are known for their robust construction and reliable gas valve designs, minimizing the risk of damage from minor sediment exposure. They also offer models with variable-speed blowers, improving comfort and efficiency.

- Trane: Trane furnaces prioritize durability and often incorporate features to minimize the impact of contaminants on sensitive components. Consider models with their patented ComfortLink™ II communicating technology for enhanced control and diagnostics.

- Rheem: Rheem offers a wide range of gas furnaces at various price points, with many models featuring readily accessible components for maintenance. Their EcoNet® smart home system provides convenient control and monitoring.

When selecting a new furnace, consider models with readily accessible gas valve assemblies and burners, as this will simplify maintenance if sediment bypasses the drip leg. Pay attention to the AFUE rating, which indicates the furnace's energy efficiency. Higher AFUE ratings translate to lower heating bills.

Drip Leg Alternatives and Supplements

While the drip leg is the primary defense against sediment, some homeowners and contractors opt for additional measures to further protect their HVAC systems:

- Gas Line Filter: A gas line filter installed upstream of the appliance can provide an extra layer of protection by trapping even finer particles of sediment.

- Professional Gas Line Cleaning: Periodically having your gas line professionally cleaned can remove accumulated debris and improve the overall quality of your gas supply.

Cost Considerations

The cost of installing a gas line drip leg is relatively minimal, typically ranging from $50 to $150 if done as part of a larger HVAC installation or repair. However, neglecting to install a drip leg can result in significantly higher repair costs down the line, potentially costing hundreds or even thousands of dollars to replace damaged components.

Conclusion: Prioritizing Protection for Your HVAC System

A gas line drip leg is a simple yet essential component for any gas-fired HVAC system. By trapping sediment and moisture, it protects your furnace or boiler from damage, ensures efficient operation, and minimizes the risk of costly repairs. Always ensure that a drip leg is properly installed and maintained according to local codes and regulations. By prioritizing this often-overlooked detail, you can safeguard your HVAC investment and enjoy years of reliable and efficient heating.