Gas Valve On Or Off Position

Frequently Asked Questions About Gas Valve On/Off Positions

This article provides clear and concise answers to common questions about gas valve operation and safety in residential and commercial settings. Understanding the on/off positions of your gas valves is crucial for maintaining safety and preventing accidents. We aim to provide a reliable resource for homeowners and facility managers alike.

Question 1: How can I tell if my gas valve is on or off?

The easiest way to determine if your gas valve is on or off depends on the type of valve. There are typically two common types:

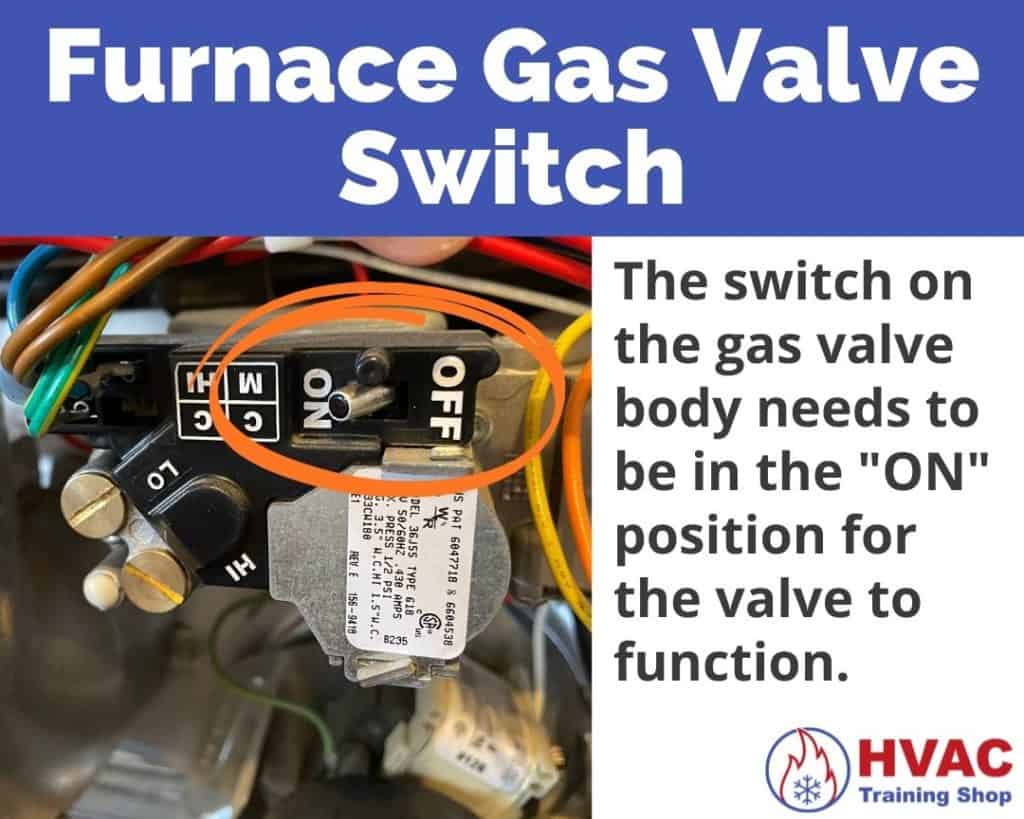

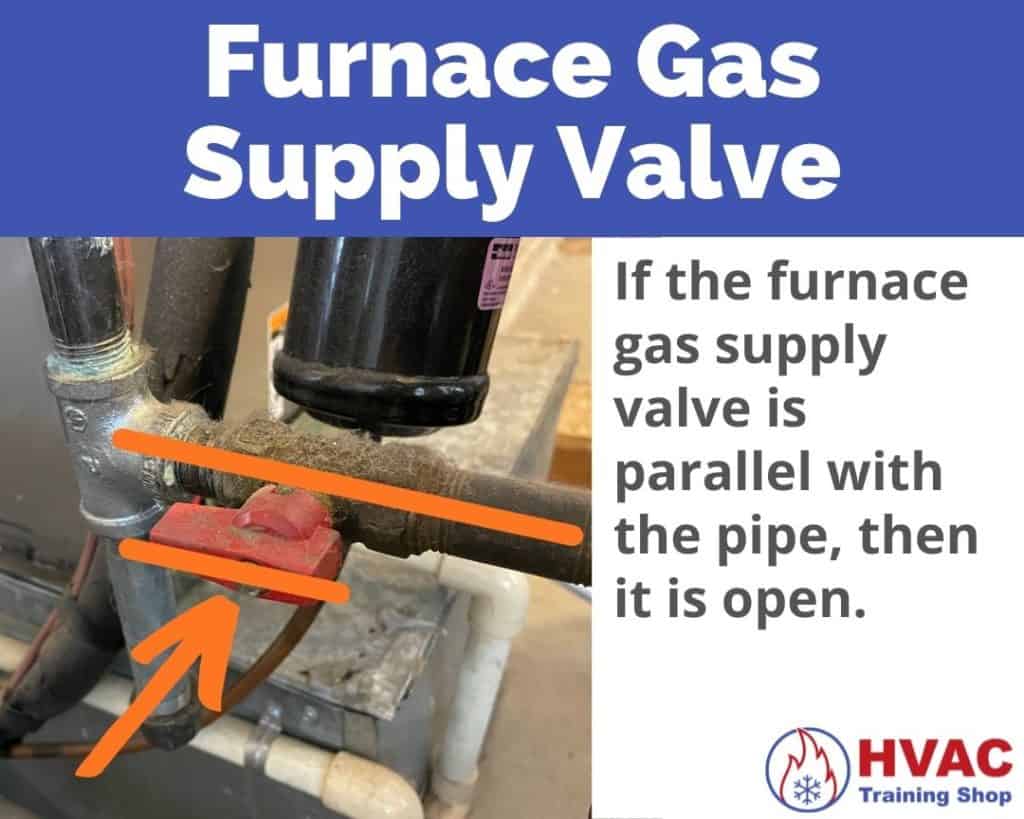

- Quarter-Turn Ball Valve: This type is most common. When the handle is parallel to the gas pipe, the valve is on, allowing gas to flow. When the handle is turned perpendicular (at a right angle) to the pipe, the valve is off, blocking the gas flow. Think of it as the handle pointing in the direction of gas flow when it's on.

- Multi-Turn Valve (Gate Valve or Globe Valve): These valves have a round handle that you must turn multiple times to open or close. These are less common for quick shut-off situations. Turn the handle clockwise to close (off) the valve and counter-clockwise to open (on) the valve. There usually isn't a visual indicator, so turning the handle all the way in either direction until it stops is the best way to ensure it's fully on or off.

Always double-check visually to confirm the handle position of quarter-turn valves. For multi-turn valves, listen carefully as you turn the handle to detect the point where the valve fully closes or opens.

Question 2: Where are the main gas shut-off valves usually located?

Knowing the location of your main gas shut-off valve is essential for safety. Here's where to look:

- Near the Gas Meter: This is the most common location. Look for a valve on the pipe leading into your gas meter. This valve controls the gas supply to your entire property.

- Outside Your Home: Some homes have a gas shut-off valve located outside, often near the foundation of the building.

- Inside Your Home (Less Common): In some older homes, the main shut-off valve might be located inside, often in the basement or utility room, near where the gas line enters the house.

Important: Take the time to locate your main gas shut-off valve *today*. Show all adult members of your household where it is and how to operate it. In an emergency, you don't want to waste time searching.

Question 3: When should I turn off the gas valve?

There are several situations where turning off the gas valve is crucial for safety:

- Gas Leak: If you suspect a gas leak (smell gas, hear a hissing sound), immediately turn off the gas supply at the main shut-off valve and evacuate the building. Call the gas company or emergency services from a safe location.

- Earthquake or Other Natural Disaster: After an earthquake or any event that could have damaged gas lines, turn off the gas supply as a precaution.

- Appliances Not in Use for Extended Periods: If you're going on vacation or leaving your property unoccupied for a long time, consider turning off the gas supply.

- Appliance Repair or Replacement: Before working on any gas-powered appliance, turn off the gas supply to that specific appliance at its individual shut-off valve (if equipped). If there is no individual shut-off valve, turn off the main gas supply.

- Flooding: If your property is flooding, there's a risk of water damaging gas appliances and potentially creating a dangerous situation. Turn off the gas as a precaution.

Remember: When in doubt, it's always safer to turn off the gas supply.

Question 4: Can I turn off the gas valve myself, or should I call a professional?

In an emergency, such as a suspected gas leak, you should immediately turn off the gas valve yourself. This is a critical safety measure that can prevent serious harm.

However, after turning off the gas due to a leak or other emergency, do not attempt to turn it back on yourself. Always call your gas company or a qualified HVAC technician to inspect the system and ensure it's safe to restore gas service. They have specialized equipment to detect leaks and identify any underlying problems.

For routine maintenance or appliance repairs, if you're comfortable and familiar with your gas system, you can turn off the gas to individual appliances at their shut-off valves (if equipped). However, if you're unsure about anything, it's always best to call a professional.

Never attempt to repair a gas leak yourself. Gas leaks are extremely dangerous and require professional attention.

Question 5: What happens if I accidentally turn off the gas valve?

Accidentally turning off the gas valve can be inconvenient, but it's usually not dangerous as long as you follow the correct procedures for restoring gas service.

Here's what to do:

- Don't Panic: Remain calm and assess the situation.

- Check Appliances: Make sure all gas appliances (furnace, water heater, stove, etc.) are turned off. This is crucial to prevent a dangerous build-up of gas when the supply is restored.

- Carefully Turn the Valve Back On: Slowly turn the gas valve back to the "on" position. If it's a quarter-turn valve, make sure the handle is parallel to the gas pipe. If it's a multi-turn valve, turn it counter-clockwise until it's fully open.

- Relight Pilot Lights: You will need to relight the pilot lights on any appliances that use them (older furnaces, water heaters, and some stoves). Follow the manufacturer's instructions for relighting pilot lights. If you're unsure how to do this, consult the appliance's manual or call a qualified technician.

- Monitor for Gas Odor: After restoring gas service, carefully monitor for any signs of a gas leak (smell of gas). If you detect a gas odor, immediately turn off the gas valve again, evacuate the building, and call the gas company or emergency services.

Important Note: If you're uncomfortable relighting pilot lights or if you suspect a gas leak at any time, do not attempt to restore gas service yourself. Call a qualified technician to inspect the system and ensure it's safe.

Question 6: Are there different types of gas valves, and do they operate differently?

Yes, there are several types of gas valves, although the quarter-turn ball valve is the most common for residential and commercial applications requiring quick shut-off capabilities. Other types include:

- Quarter-Turn Ball Valve: As mentioned before, these are easy to operate with a simple quarter-turn of the handle. The position of the handle indicates whether the valve is open or closed. These are the most common for main shut-off valves and appliance isolation.

- Multi-Turn Valve (Gate Valve or Globe Valve): These valves require multiple turns of the handle to fully open or close. They are less common for emergency shut-off situations but are sometimes used in older systems. These valves are not ideal for scenarios where a quick shutoff is critical.

- Needle Valve: Needle valves are designed for precise flow control and are typically used in specialized applications where very small adjustments to gas flow are required.

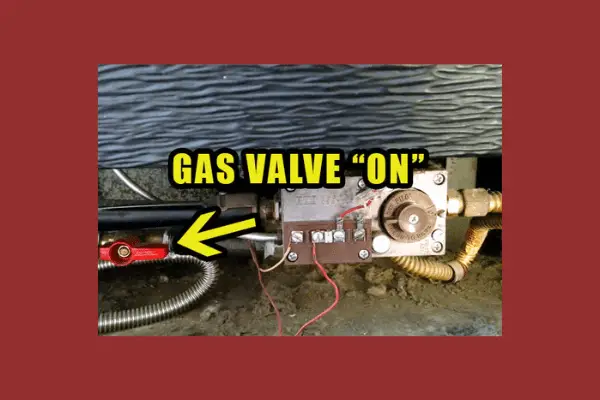

- Solenoid Valve: These are electrically operated valves used in appliances like furnaces and water heaters. They open and close based on electrical signals from the appliance's control system. They aren't typically used as manual shut-off valves.

While the basic principle of stopping gas flow remains the same, the operation and indication of the valve's state (open or closed) varies between these types. The quarter-turn ball valve is designed for ease of use and quick action, making it the preferred choice for emergency shut-off situations.

Question 7: What maintenance should I perform on my gas valves?

Regular maintenance can help ensure your gas valves operate correctly and prevent potential problems.

- Visual Inspection: Periodically inspect your gas valves for signs of corrosion, damage, or leaks. Look for rust, stains, or bubbling around the valve body or connections.

- Operate the Valve: Occasionally (at least once a year) operate the gas valves to ensure they don't become stuck or difficult to turn. Slowly turn the valve to the "off" position and then back to the "on" position. This helps prevent corrosion and ensures smooth operation.

- Lubrication (If Applicable): Some older multi-turn valves may require lubrication to keep them operating smoothly. Consult a qualified technician if you're unsure whether your valve needs lubrication and what type of lubricant to use.

- Professional Inspection: Have a qualified HVAC technician inspect your gas system, including the gas valves, at least every two years. They can identify potential problems and perform necessary repairs or replacements.

Important: If you notice any signs of damage, corrosion, or leaks on your gas valves, do not attempt to repair them yourself. Call a qualified technician immediately. Gas leaks are extremely dangerous and require professional attention.

By understanding the operation and maintenance of your gas valves, you can ensure the safety and efficiency of your gas system.