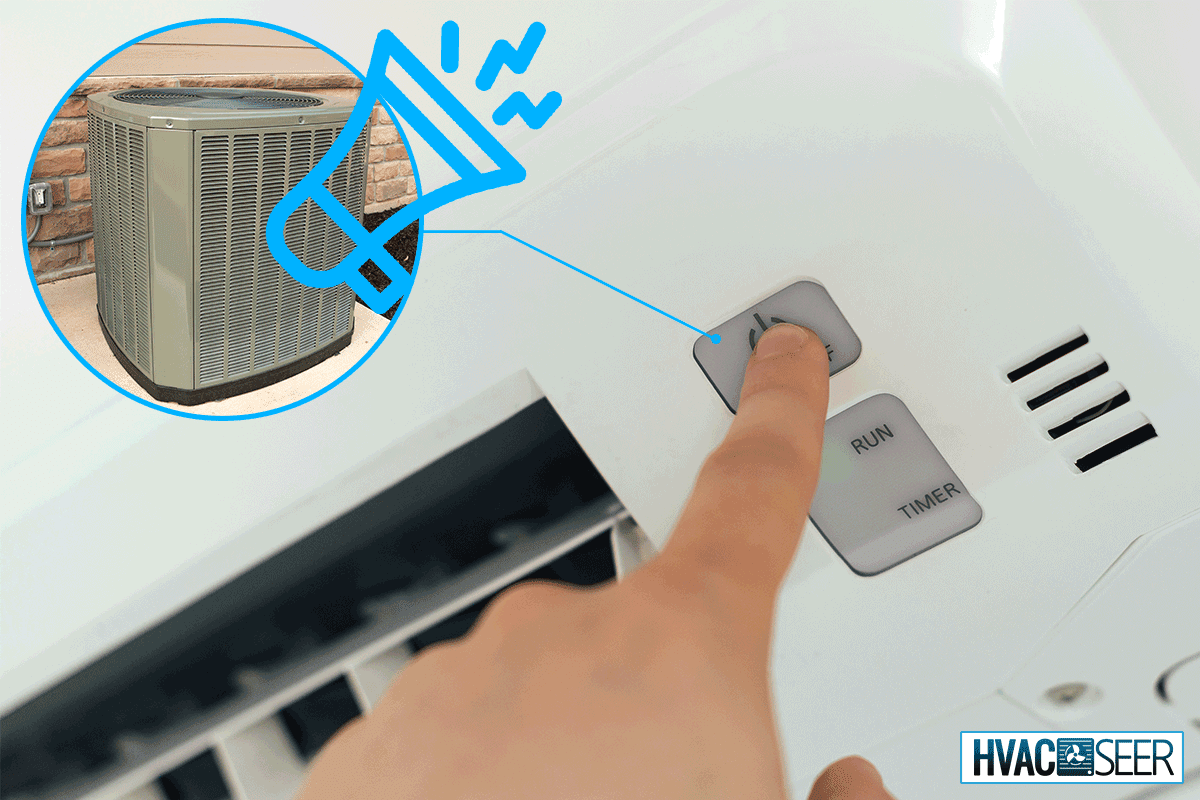

Heat Pump Makes Loud Noise When Turning On

A sudden, loud noise from your heat pump when it starts up can be startling, and naturally, concerning. It's a common issue homeowners face, often signaling a minor problem, but sometimes indicating a more serious underlying fault. This article will guide you through a logical troubleshooting process to diagnose the cause and potentially resolve the issue yourself. Remember, safety is paramount; if you're uncomfortable with any step, or if the problem persists after trying these solutions, call a qualified HVAC technician.

Understanding the Noise

Before diving into potential fixes, let's clarify what kind of noises we're talking about. Common startup noises include:

- Banging or Clanking: Often points to loose components or debris.

- Grinding: Suggests friction between moving parts.

- Screeching or Squealing: Could indicate a failing belt or a dry bearing.

- Humming (excessive and unusual): Might point to electrical issues or a failing compressor.

Pay close attention to the specific sound your heat pump is making. This detail will be crucial in narrowing down the possible causes.

Step-by-Step Troubleshooting Guide

Follow these steps systematically, starting with the easiest and safest checks. Remember to turn off the power to your heat pump at the breaker before performing any physical inspections or adjustments.

1. Check for Obstructions Around the Outdoor Unit

Why it matters: Debris like leaves, branches, snow, or ice can obstruct the fan blades, causing them to make noise upon startup. Even overgrown vegetation can interfere.

How to check:

- Visually inspect the area around the outdoor unit. Look for anything that might be touching or blocking the fan.

- Carefully remove any visible debris. Wear gloves to protect your hands from sharp objects.

- Ensure that the area around the unit is clear of vegetation by at least 2-3 feet.

The fix: Simply removing the obstruction may solve the problem. Turn the power back on and listen for the noise again.

2. Inspect the Fan Blades

Why it matters: Bent or damaged fan blades can cause vibrations and noise during startup.

How to check:

- With the power OFF, carefully inspect each fan blade for any signs of damage, such as bends, cracks, or breaks.

- Try to gently spin the fan blade by hand. Note if it spins freely or if there's resistance.

The fix: Minor bends can sometimes be carefully straightened. However, if a blade is severely damaged, replacement is recommended. This is often best left to a professional.

3. Tighten Loose Screws and Panels

Why it matters: Vibrations from the heat pump can loosen screws and panels over time, leading to rattling and banging noises.

How to check:

- Visually inspect the outdoor unit for any loose panels or screws.

- Using a screwdriver, carefully tighten any loose screws you find. Don't overtighten, as this can strip the threads.

The fix: Tightening loose components can significantly reduce noise. After tightening, power on the unit and listen for improvements.

4. Check the Compressor Mounting

Why it matters: The compressor is the heart of the heat pump and is mounted on rubber bushings to dampen vibrations. If these bushings are worn or damaged, the compressor can vibrate excessively, causing a loud noise.

How to check:

- Locate the compressor inside the outdoor unit. This may require removing an access panel (with the power OFF, of course!).

- Inspect the rubber bushings that support the compressor. Look for cracks, deterioration, or signs of wear.

The fix: Replacing compressor bushings is a more complex task, requiring specialized tools and knowledge of refrigerant handling. This is best left to a qualified HVAC technician. However, a visual inspection can at least confirm if this is a potential issue.

5. Lubricate the Fan Motor (If Accessible)

Why it matters: A dry fan motor bearing can cause a screeching or grinding noise upon startup. Some fan motors have lubrication ports.

How to check:

- With the power OFF, locate the fan motor.

- Look for small oil ports or grease fittings on the motor. Not all motors have these.

The fix:

- If you find oil ports, apply a few drops of electric motor oil to each port. Do not use WD-40 or other general-purpose lubricants.

- If you find grease fittings, use a grease gun to apply a small amount of grease.

Important Note: If your fan motor is sealed (no lubrication ports), attempting to lubricate it could damage it. If you're unsure, consult a professional.

6. Check the Reversing Valve

Why it matters: The reversing valve switches the heat pump between heating and cooling modes. Sometimes, debris or wear can cause it to make a loud "whooshing" or "thumping" noise when it activates.

How to check:

- Locate the reversing valve. It is typically a cylindrical component with several refrigerant lines connected to it. It's usually near the compressor.

- Observe the valve closely when the heat pump starts up. Listen for the noise specifically coinciding with the valve's operation.

The fix: Reversing valve issues are complex and require specialized tools and knowledge of refrigerant handling. This is definitely a job for a qualified HVAC technician. Attempting to repair it yourself could damage the system and potentially release refrigerant, which is harmful to the environment and your health.

7. Inspect the Contactor

Why it matters: The contactor is an electrical switch that controls power to the compressor and fan motor. A failing contactor can arc and create a loud buzzing or humming noise. Arcing can also damage the contactor and other electrical components.

How to check:

- With the power OFF at the breaker, locate the contactor inside the outdoor unit's control panel. Be extremely careful when working around electrical components.

- Visually inspect the contactor for signs of burning, pitting, or corrosion on the contacts.

The fix: Replacing a contactor involves working with electrical components and requires careful attention to safety. If you are not comfortable working with electricity, call a qualified HVAC technician or electrician. If you are experienced, ensure the power is off, and follow the manufacturer's instructions for replacement.

When to Call a Professional

While many startup noises can be resolved with simple DIY fixes, there are situations where professional help is essential. Call a qualified HVAC technician if:

- The noise persists after trying the troubleshooting steps above.

- You suspect a refrigerant leak (look for oily residue or a hissing sound).

- You are uncomfortable working with electrical components or refrigerant lines.

- You suspect a problem with the compressor, reversing valve, or other major components.

- You notice a burning smell.

- The heat pump is not heating or cooling properly.

Ignoring persistent or unusual noises can lead to more significant and costly repairs down the road. Don't hesitate to seek professional assistance if you're unsure about anything.

Preventative Maintenance

Regular maintenance can help prevent many of these issues from occurring in the first place. Consider these steps:

- Schedule annual professional maintenance: A qualified technician can inspect and clean the system, lubricate moving parts, and identify potential problems before they become major issues.

- Regularly clean the outdoor unit: Remove debris and vegetation from around the unit to ensure proper airflow.

- Change the air filter regularly: A dirty air filter can restrict airflow and put stress on the system.

By following these tips, you can keep your heat pump running smoothly and quietly for years to come.