Hot Water Recirculating System With Dedicated Return Line Diagram

Hot Water Recirculating System With Dedicated Return Line: A Comprehensive Guide

Tired of waiting for hot water to reach your faucet? A hot water recirculating system can provide instant hot water, saving you time, water, and energy. This guide focuses on systems with a dedicated return line, offering a detailed look at their benefits, drawbacks, installation, and cost.

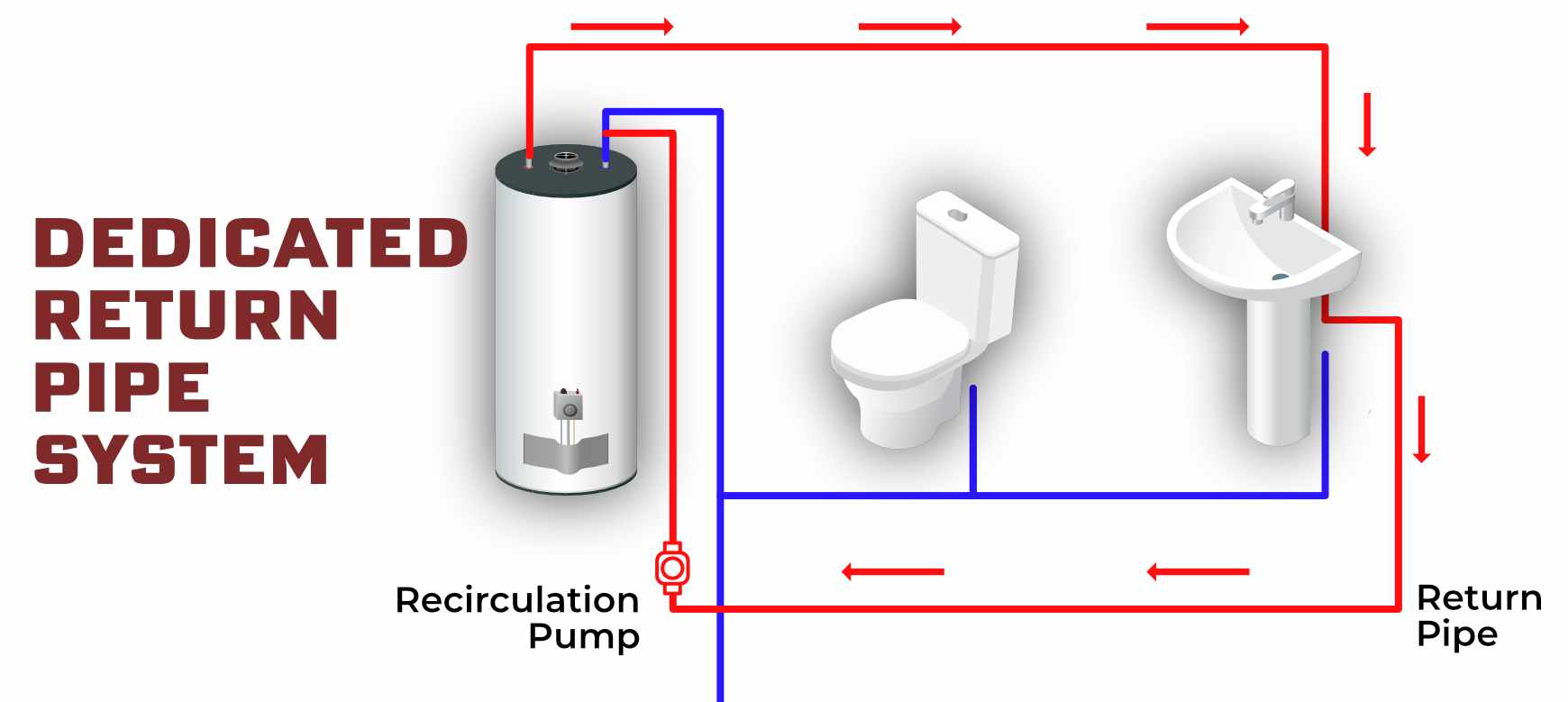

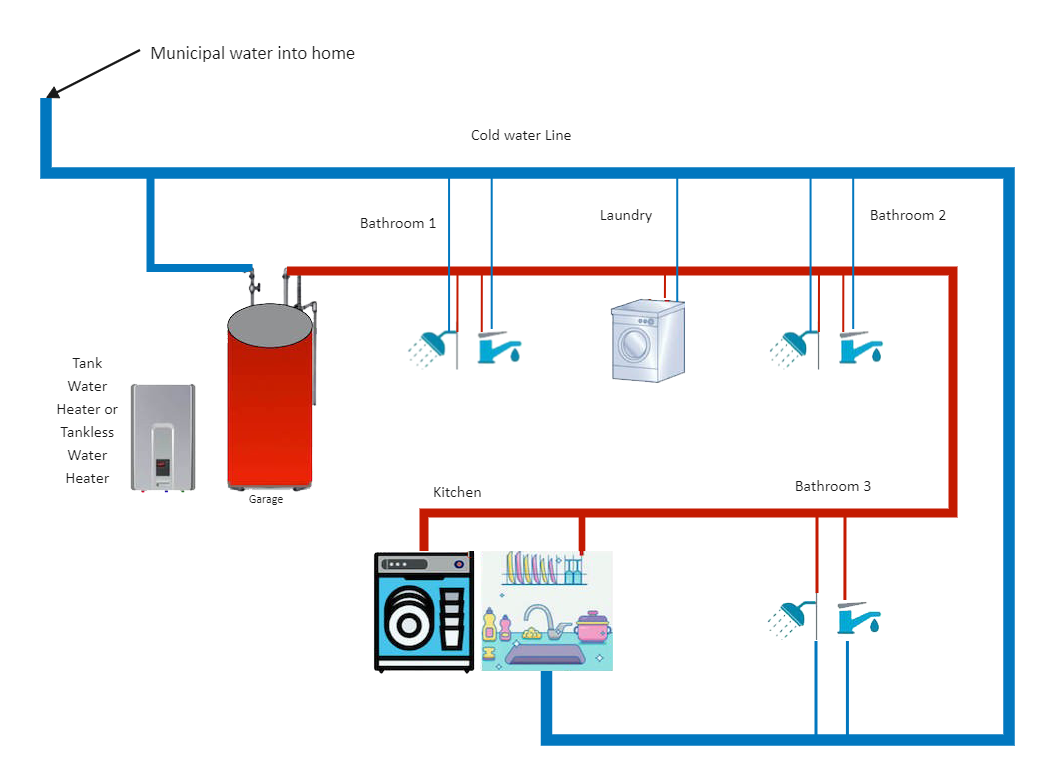

Understanding Hot Water Recirculating Systems

Hot water recirculating systems work by continuously circulating hot water through your plumbing system. Instead of waiting for cold water to be pushed out of the pipes, hot water is always available near your fixtures. A dedicated return line system is the most efficient type, using a separate pipe to bring cooled water back to the water heater for reheating. This distinguishes it from systems that use the cold water line as a return, which can affect the temperature of your cold water.

Benefits of a Dedicated Return Line System

- Instant Hot Water: Eliminates the wait time for hot water, providing it almost immediately at your faucets and showers.

- Water Conservation: Reduces water waste by eliminating the need to run the tap while waiting for hot water. This translates to lower water bills and a smaller environmental footprint.

- Energy Efficiency: Although the system uses energy to circulate water, the reduction in water waste can often offset the energy consumption. Programmable timers and smart controls further optimize energy efficiency.

- Comfort and Convenience: Enhances daily life by providing immediate hot water for tasks like washing hands, shaving, and preparing meals.

- Increased Home Value: Can be an attractive selling point for potential homebuyers, demonstrating a commitment to energy efficiency and convenience.

Drawbacks to Consider

- Installation Costs: Dedicated return line systems are more expensive to install than systems that use the cold water line, primarily due to the cost of running a separate pipe.

- Energy Consumption: While designed to be energy efficient, a poorly configured or constantly running system can increase energy consumption. Insulating pipes helps mitigate heat loss.

- Potential for Scalding: Improper temperature settings or a lack of anti-scald valves can increase the risk of scalding, especially for young children and elderly individuals.

- Complexity of Installation: Requires professional installation and may necessitate opening walls to run the return line.

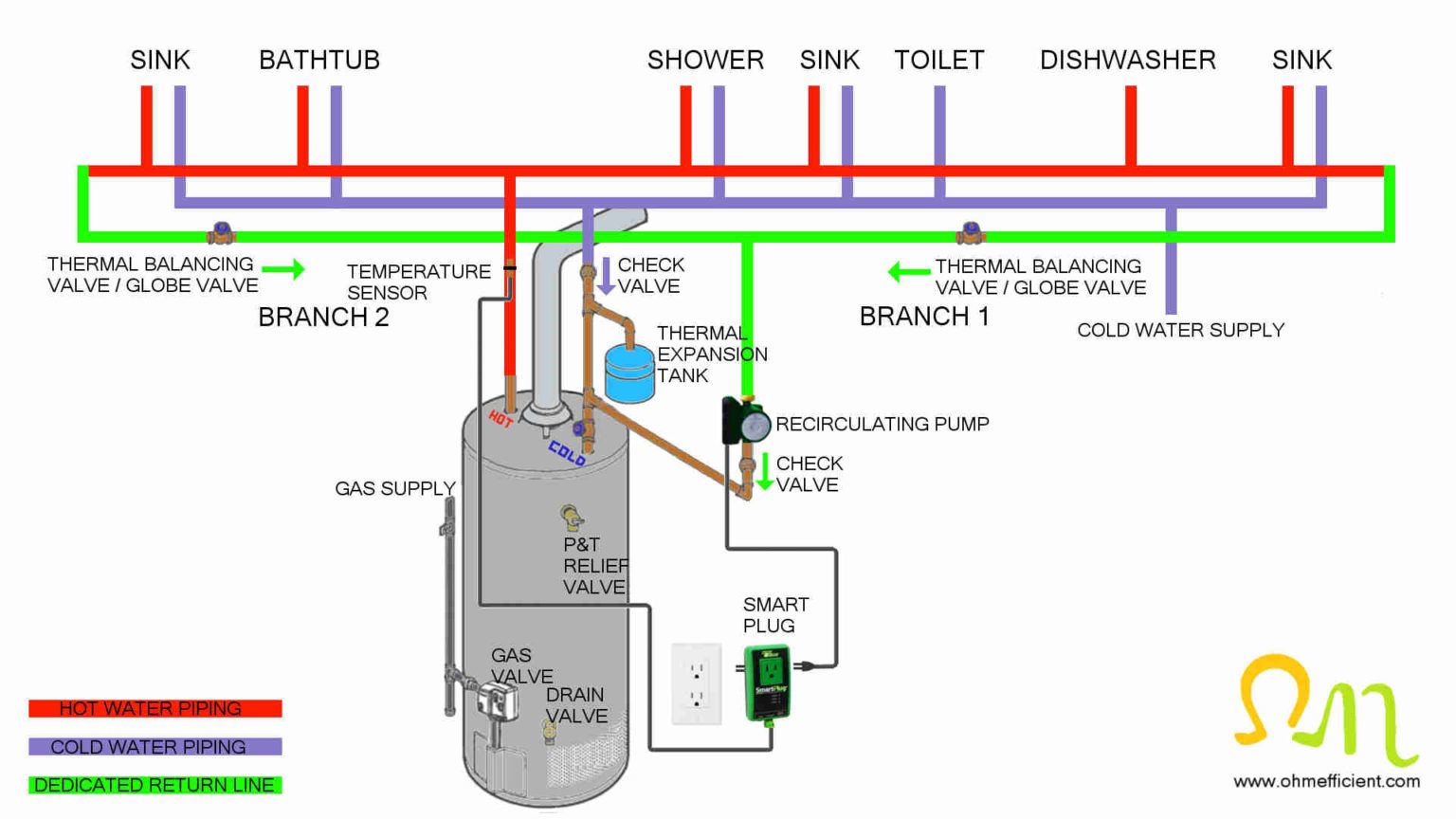

Components of a Dedicated Return Line System

A typical system consists of the following:

- Water Heater: The existing water heater acts as the heat source. Its capacity should be adequate to handle the increased demand from the recirculating system.

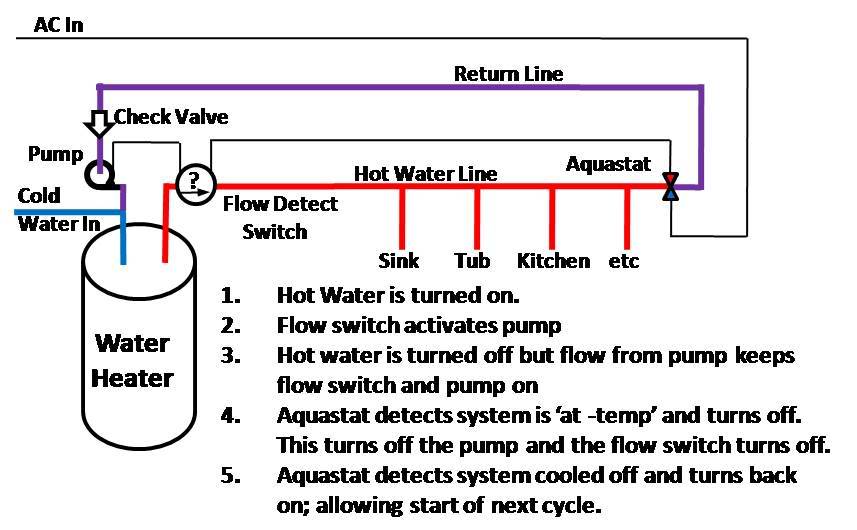

- Circulating Pump: A small pump, typically installed near the water heater, circulates the water through the plumbing system.

- Dedicated Return Line: A separate pipe that runs from the furthest fixture back to the water heater.

- Check Valve: Prevents backflow of water, ensuring proper circulation.

- Timer or Smart Controller: Allows you to schedule the pump's operation, further optimizing energy efficiency. Smart controllers can learn your usage patterns and adjust accordingly.

- Temperature Sensor (Optional): Monitors the water temperature in the return line and adjusts the pump's operation to maintain a consistent hot water supply.

Installation Considerations

Installing a dedicated return line system is generally best done during new construction or a major renovation. Retrofitting an existing home can be more challenging and expensive, as it may require opening walls to run the return line.

- Planning: Determine the optimal location for the return line, considering the layout of your plumbing system and the location of your fixtures.

- Pipe Selection: Use appropriate piping materials, such as copper or PEX, that are rated for hot water applications.

- Insulation: Insulate all hot water pipes, including the return line, to minimize heat loss and improve energy efficiency.

- Pump Placement: Install the circulating pump near the water heater, ensuring easy access for maintenance.

- Electrical Connection: Ensure a proper electrical connection for the pump, following local electrical codes.

- Testing: After installation, thoroughly test the system to ensure proper circulation and temperature regulation.

Popular Brands and Models

Several reputable brands offer circulating pumps suitable for dedicated return line systems. Here are a few examples:

- Grundfos: Known for their high-quality, energy-efficient pumps. Models like the UP 15-10B7 are popular choices.

- Taco: Offers a wide range of pumps for residential and commercial applications. The 006-B4 is a commonly used model.

- Watts: Provides various plumbing and heating solutions, including circulating pumps. The Watts Premier Instant Hot Water Recirculation System is a complete kit for easy installation.

- Laing Thermotech: Specializes in hot water recirculation pumps known for their quiet operation and energy efficiency.

Cost Considerations

The cost of a dedicated return line system varies depending on several factors, including the complexity of the installation, the length of the return line, and the type of pump and controls used.

- Pump: $100 - $500, depending on the brand and features.

- Piping and Fittings: $50 - $200, depending on the length of the return line and the materials used.

- Installation: $500 - $2000 or more, depending on the complexity of the installation and the labor rates in your area.

- Timer or Smart Controller: $50 - $200.

Therefore, the total cost of a dedicated return line system can range from $700 to $2700 or more. It's essential to obtain quotes from multiple contractors to get an accurate estimate for your specific situation.

Maintenance and Troubleshooting

Proper maintenance is crucial for ensuring the long-term performance of your hot water recirculating system.

- Annual Inspection: Inspect the pump, pipes, and fittings annually for leaks or damage.

- Pump Lubrication (if applicable): Some pumps require occasional lubrication. Refer to the manufacturer's instructions.

- Sediment Flushing: Periodically flush the water heater to remove sediment buildup, which can reduce its efficiency.

- Check Valve Inspection: Ensure the check valve is functioning properly to prevent backflow.

Common problems include:

- Pump Failure: If the pump stops working, check the power supply and the pump motor. You may need to replace the pump.

- Leaks: Repair any leaks immediately to prevent water damage.

- Insufficient Hot Water: Check the temperature settings on the water heater and the recirculating system. Also, ensure the pump is running as scheduled.

- Noisy Operation: Pump noise can indicate air in the system or a worn pump.

Warranty Information

Most circulating pumps come with a manufacturer's warranty, typically ranging from 1 to 3 years. Review the warranty terms carefully to understand what is covered and what is not. Professional installation may be required to maintain the validity of the warranty.

Conclusion

A hot water recirculating system with a dedicated return line offers significant benefits in terms of convenience, water conservation, and energy efficiency. While the initial investment may be higher than other types of recirculating systems, the long-term savings and enhanced comfort can make it a worthwhile investment. Carefully consider your needs, budget, and installation options before making a decision. Consult with a qualified plumber to determine the best solution for your home.

Disclaimer

AFUE, SEER, and HSPF ratings are typically associated with furnaces, air conditioners, and heat pumps, respectively, and are not directly applicable to hot water recirculating systems. However, choosing an energy-efficient water heater to work with the recirculating system is crucial for overall energy savings.

This guide provides general information and should not be considered professional advice. Always consult with a qualified contractor for specific recommendations and installation services.