How Does A Compression Fitting Work

Frequently Asked Questions: Understanding Compression Fittings

Compression fittings are a common and reliable method for connecting pipes and tubing without welding, soldering, or threading. They're used extensively in plumbing, HVAC, and various industrial applications. This FAQ answers the most common questions about how compression fittings work, making them easy to understand for homeowners and facility managers alike.

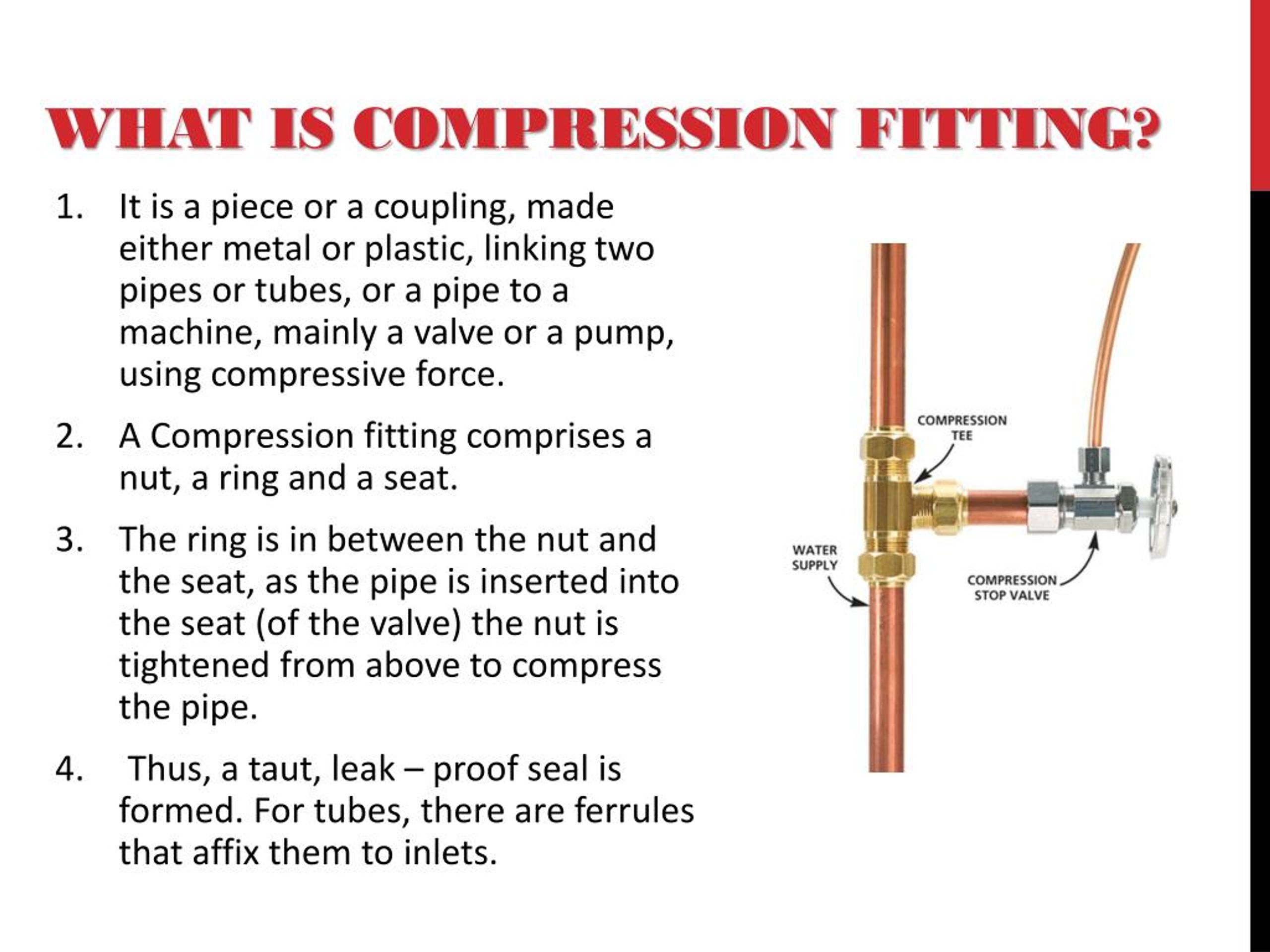

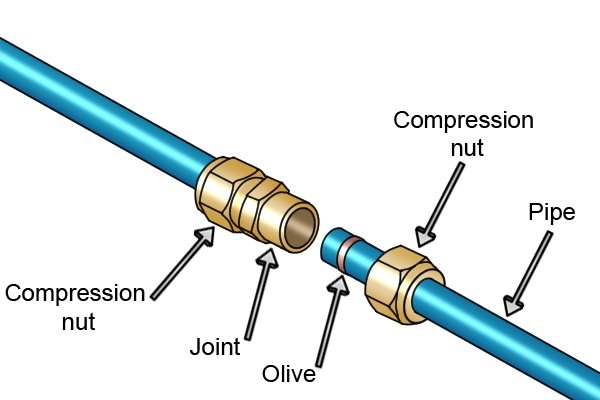

Question 1: What exactly is a compression fitting and what are its main components?

A compression fitting is a type of fitting used to join two pipes or tubes together. It creates a leak-proof seal through mechanical compression. The main components are:

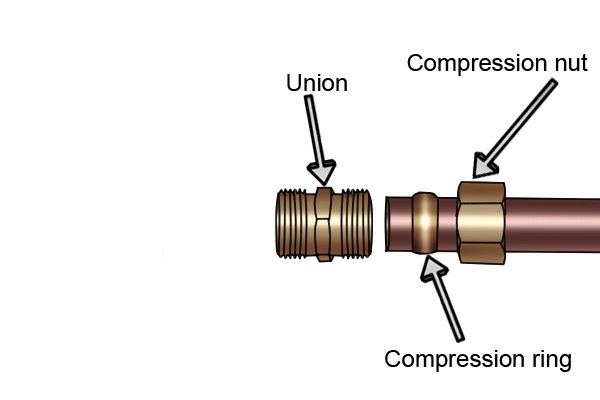

- Fitting Body: This is the main housing that connects to one of the pipes. It usually has internal threads.

- Compression Nut: This nut screws onto the fitting body, applying pressure to the other components.

- Compression Ring (or Ferrule): This is a crucial piece, typically made of brass, copper, or nylon. It sits between the nut and the pipe. When the nut is tightened, the ferrule compresses against the pipe, creating the seal. Some fittings use two ferrules.

Think of it like this: the nut squeezes the ring, which then grabs the pipe, making a tight connection.

Question 2: How does a compression fitting actually create a watertight (or airtight) seal? What's the principle behind it?

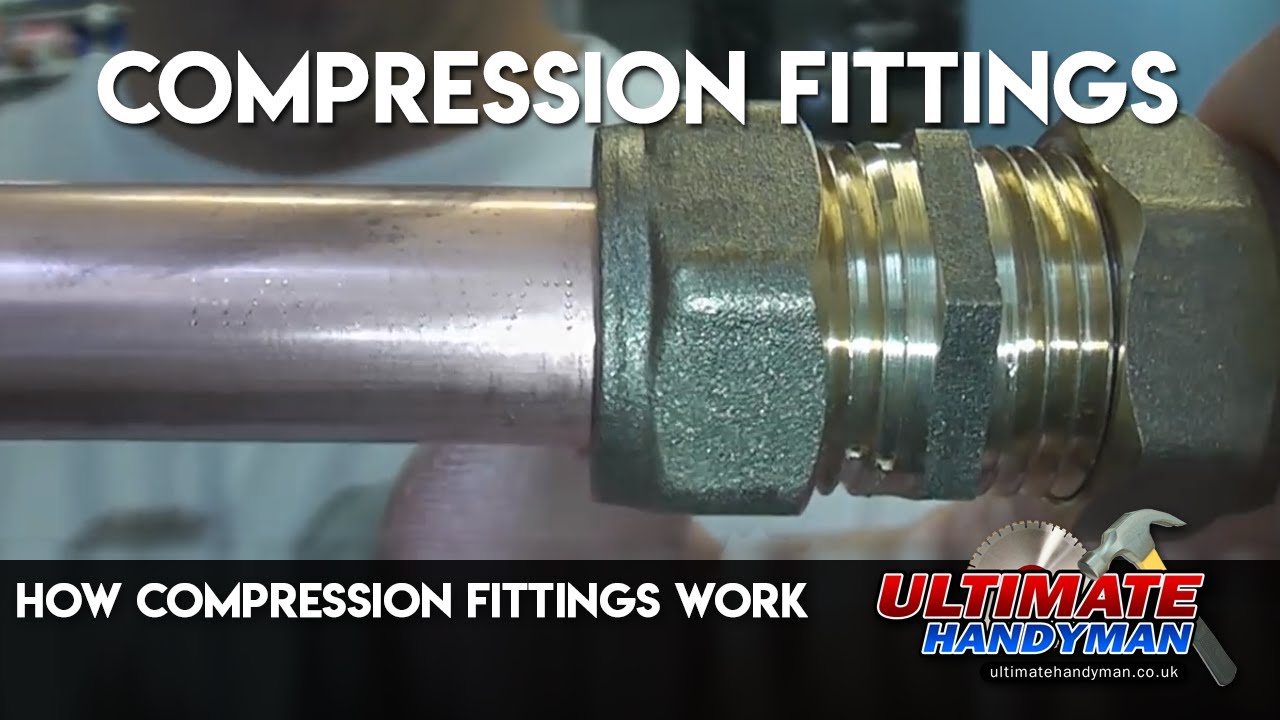

The secret lies in the ferrule's deformation. Here’s the breakdown:

- Tightening the Nut: As you tighten the compression nut onto the fitting body, it pushes the ferrule forward.

- Ferrule Compression: This force causes the ferrule to deform (compress). The ferrule is designed to grip the outer surface of the pipe or tube very tightly.

- Wedging Action: The ferrule also wedges itself against the inner surface of the fitting body.

- Seal Formation: This combined gripping and wedging action creates a strong, leak-proof seal. The pressure from the nut ensures that the ferrule remains tightly compressed, maintaining the seal even under moderate pressure.

Essentially, the controlled deformation of the ferrule is what makes the compression fitting work. It creates a mechanical bond that's strong and reliable.

Question 3: What are the advantages of using compression fittings compared to other pipe connection methods (like soldering or threading)? What are their disadvantages?

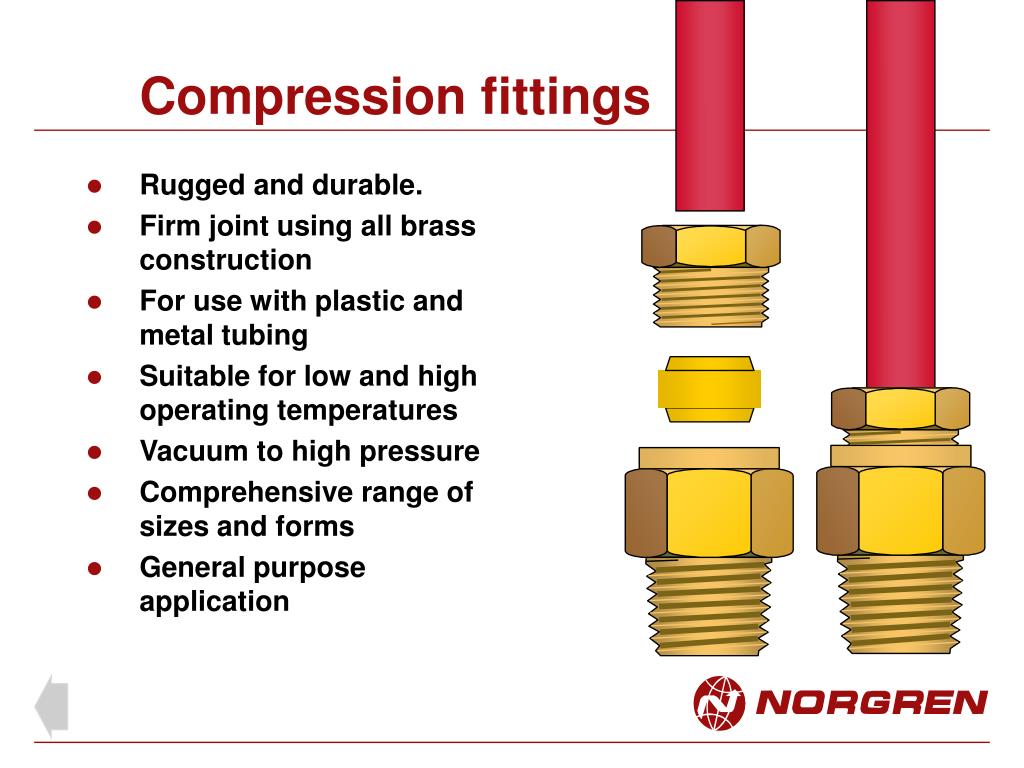

Compression fittings offer several advantages:

- Ease of Installation: No special tools like torches or threading equipment are required. This makes them ideal for DIY projects and repairs.

- Quick Installation: They can be installed much faster than soldered or threaded connections.

- Removable and Reusable (Sometimes): Compression fittings can often be disassembled and reused, although it's generally recommended to replace the ferrule each time for optimal sealing, especially after prolonged use or high pressure applications. Some ferrules are designed for single use only.

- No Heat Required: Eliminates the fire hazard associated with soldering or welding.

- Suitable for Various Materials: Can be used with copper, steel, plastic (with appropriate inserts), and other materials.

However, there are also some disadvantages:

- Potential for Leaks if Not Properly Tightened: Overtightening or undertightening can compromise the seal. This is the most common cause of leaks.

- May Loosen Over Time: Vibration or temperature fluctuations can cause the fitting to loosen. Regular inspection and retightening might be necessary.

- Not Suitable for All Applications: Generally not recommended for very high-pressure or high-temperature applications. Check the manufacturer's specifications.

- Can Be More Expensive: Individual fittings can be more expensive than solder fittings, especially for larger pipe sizes.

- Requires Careful Alignment: The pipe needs to be properly aligned for the fitting to seal correctly.

Question 4: What are some common mistakes people make when installing compression fittings, and how can I avoid them?

Avoiding these common mistakes will ensure a leak-free connection:

- Overtightening: This is a very common mistake. Overtightening can crush the ferrule and damage the pipe, leading to leaks. Use a wrench to tighten the nut until you feel resistance, then give it another quarter to half turn. Follow the manufacturer’s recommendations for torque.

- Undertightening: This is the opposite problem. An undertightened fitting won't create a proper seal and will leak. The goal is to have it tight enough to seal but not so tight that it damages the fitting or pipe.

- Using the Wrong Size Fitting: Make sure you’re using the correct size fitting for your pipe or tubing. Using the wrong size will prevent a proper seal and can damage the fitting.

- Damaged or Dirty Pipe: Ensure the pipe is clean, smooth, and free of burrs or scratches. Use a pipe cutter or deburring tool to prepare the end of the pipe. A damaged or dirty pipe surface will prevent the ferrule from making a good seal.

- Reusing Old Ferrules: While sometimes possible, it’s generally best to replace the ferrule each time you disassemble a compression fitting. An old ferrule may be deformed or damaged, preventing a proper seal.

- Forgetting the Ferrule: Sounds silly, but it happens! Always make sure the ferrule is in place before tightening the nut.

- Not Aligning the Pipe Properly: Ensure the pipe is properly aligned with the fitting body. Misalignment can cause uneven pressure on the ferrule and lead to leaks.

Always refer to the manufacturer's instructions for specific torque recommendations and installation guidelines. Practice makes perfect!

Question 5: What types of pipes and tubing can I use with compression fittings? Are there any limitations?

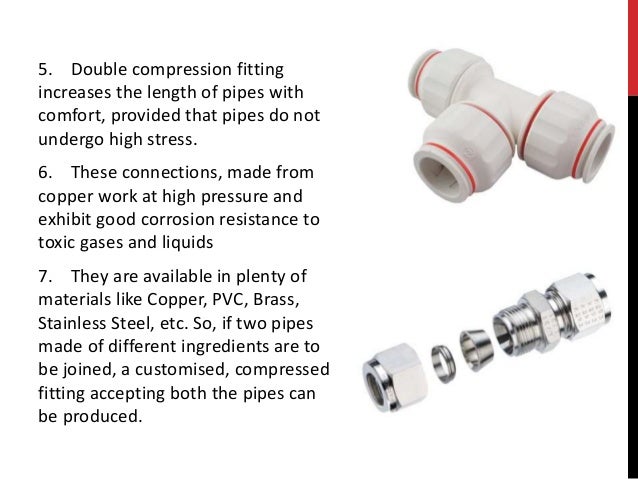

Compression fittings are versatile and can be used with a variety of materials, but it's important to choose the correct fitting for the specific material:

- Copper: Compression fittings are very common with copper pipes and tubing, especially for water lines and refrigeration systems.

- Brass: Similar to copper, brass pipes can also be joined with compression fittings.

- Steel: Steel pipes can be used with compression fittings designed specifically for steel. These fittings are often made of steel or stainless steel to prevent corrosion.

- Plastic (CPVC, PEX, etc.): Plastic pipes like CPVC and PEX can be used with compression fittings, but they typically require the use of an insert inside the pipe to prevent the pipe from collapsing under the pressure of the ferrule. Always use the insert recommended by the pipe and fitting manufacturer.

Limitations:

- Material Compatibility: Ensure the fitting material is compatible with the pipe material to avoid corrosion or other issues. For example, avoid using brass fittings with aluminum pipes.

- Pressure and Temperature Ratings: Compression fittings have pressure and temperature limitations. Check the manufacturer's specifications to ensure they are suitable for your application. High-pressure or high-temperature applications may require different types of fittings.

- Pipe Wall Thickness: The pipe wall thickness needs to be sufficient to withstand the compression force. Thin-walled tubing might collapse under pressure.

Always consult the manufacturer's guidelines to ensure compatibility and suitability for your specific application.

Question 6: How do I properly tighten a compression fitting to avoid leaks? What is the "feel" I'm looking for?

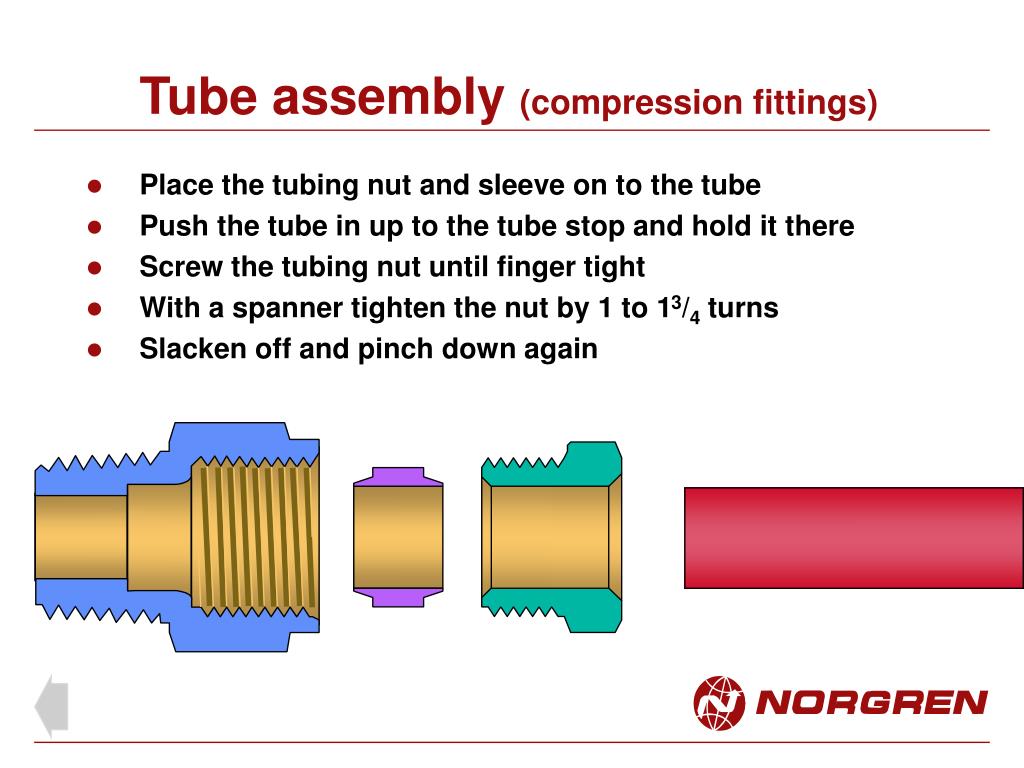

Tightening a compression fitting correctly is crucial for a leak-free seal. Here's a step-by-step guide:

- Prepare the Pipe: Cut the pipe squarely and remove any burrs or sharp edges. Clean the pipe end thoroughly.

- Assemble the Fitting: Slide the nut onto the pipe, followed by the ferrule (or ferrules). Make sure the ferrule is oriented correctly (usually with the tapered end facing the fitting body).

- Insert the Pipe: Insert the pipe fully into the fitting body. Make sure it bottoms out against the stop inside the fitting.

- Hand-Tighten: Screw the nut onto the fitting body by hand until it's snug.

- Wrench-Tighten: Use a wrench (usually two wrenches are needed - one to hold the fitting body and the other to tighten the nut). Tighten the nut gradually.

- The "Feel": This is the tricky part. You're looking for a point where the nut feels snug and you feel resistance. Then, give it an additional 1/4 to 1/2 turn. The amount of tightening depends on the size and type of fitting. A good guideline is to follow the manufacturer's instructions or look for a slight deformation of the ferrule on the pipe when disassembling. For plastic pipes, use even less torque.

- Testing: After tightening, test the connection for leaks. If you see a leak, try tightening the nut a little more (1/8 turn). If it still leaks, disassemble the fitting, inspect the ferrule and pipe for damage, and replace the ferrule.

Important Tips:

- Don't Overtighten: As mentioned before, overtightening is a common mistake. It can damage the ferrule and the pipe, leading to leaks.

- Use Two Wrenches: Always use two wrenches - one to hold the fitting body and the other to tighten the nut. This prevents the fitting from twisting and damaging the pipe.

- Check for Leaks Immediately: After tightening, check for leaks immediately. If you see a leak, try tightening the nut a little more.

- Follow Manufacturer's Instructions: Always follow the manufacturer's instructions for tightening torque.

It may take some practice to get the "feel" for tightening compression fittings correctly. It's always a good idea to practice on a scrap piece of pipe before working on a live system.

Question 7: Are there any special considerations when using compression fittings in specific applications, like underground or in harsh environments?

Yes, there are several special considerations to keep in mind when using compression fittings in demanding environments:

- Underground Applications:

- Corrosion Protection: Underground environments are often corrosive. Use compression fittings made of corrosion-resistant materials like brass or stainless steel. Consider wrapping the fitting with a waterproof tape or coating to provide additional protection against corrosion.

- Proper Burial Depth: Bury the pipe and fittings at the correct depth to protect them from freezing temperatures and physical damage.

- Backfilling: Backfill around the pipe and fittings carefully to avoid damaging them. Use a suitable backfill material that won't corrode or damage the pipe.

- Support: Provide adequate support for the pipe and fittings to prevent them from sagging or shifting over time.

- Harsh Environments (Chemical Exposure, Extreme Temperatures):

- Material Selection: Choose fittings made of materials that are resistant to the specific chemicals or temperatures in the environment. For example, use stainless steel fittings in corrosive environments or high-temperature applications.

- Sealing: Consider using thread sealant or Teflon tape on the threads of the fitting to provide an extra layer of protection against leaks.

- Insulation: In extreme temperature environments, insulate the pipe and fittings to prevent heat loss or gain.

- Protection from Physical Damage: Protect the fittings from physical damage by enclosing them in a protective box or conduit.

- Regular Inspection: In harsh environments, it's especially important to inspect the fittings regularly for signs of corrosion, damage, or leaks.

- High Vibration Environments:

- Consider Alternative Fittings: In environments with high vibration, compression fittings might loosen over time. Consider using alternative fitting types like flared fittings or welded connections, which are more resistant to vibration.

- Regular Inspection and Retightening: If compression fittings are used, inspect them regularly and retighten them as needed.

- Vibration Dampening: Implement vibration dampening measures to reduce the amount of vibration transmitted to the fittings.

In all cases, it's essential to choose fittings that are specifically designed for the intended application and to follow the manufacturer's recommendations for installation and maintenance. When in doubt, consult with a qualified plumbing or HVAC professional.