How Does A Tiger Loop Work Diagram

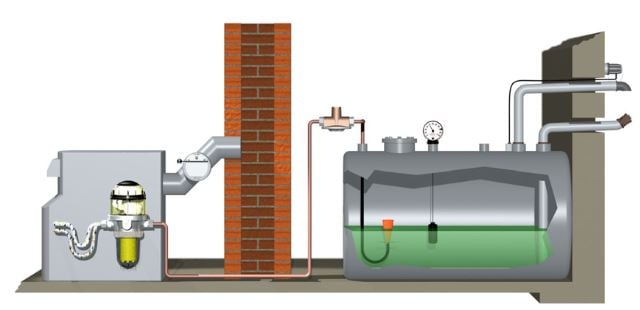

If you've ever tinkered with oil-fired heating systems, you might have stumbled upon a curious component called a Tiger Loop. It’s a seemingly simple device that plays a crucial role in ensuring a clean and efficient oil supply to your burner. Understanding how it works can help you troubleshoot common heating issues and potentially save on repair costs. In this guide, we'll delve into the intricacies of the Tiger Loop, exploring its function, components, common problems, and when it’s best to call a professional.

What is a Tiger Loop and Why is it Important?

At its core, a Tiger Loop is a de-aerator designed to remove air and foam from the oil supply line before it reaches the burner. Air in the oil line can cause a multitude of problems, including:

- Pulsating Flame: Air bubbles disrupt the steady flow of oil, leading to an inconsistent flame.

- Nozzle Clogging: Air can cause the oil to atomize unevenly, increasing the risk of nozzle clogging.

- Burner Shutdowns: Excess air can cause the burner to shut down completely as the flame sensor detects an unstable flame.

- Reduced Efficiency: An inconsistent flame reduces the overall efficiency of your heating system, leading to higher fuel bills.

A Tiger Loop addresses these issues by creating a closed-loop system where excess oil and any entrained air are continuously recirculated back to the oil tank. This ensures that only clean, air-free oil is delivered to the burner, promoting optimal combustion and a reliable heating system.

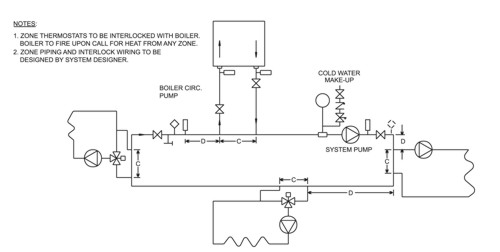

How Does a Tiger Loop Work? A Detailed Diagram Explanation

The Tiger Loop's operation is based on a simple yet effective principle: using gravity and pressure differentials to separate air from oil. Here's a breakdown of the process, often visualized in a diagram:

- Oil Intake: The oil is drawn from the tank through the supply line and enters the Tiger Loop.

- De-Aeration Chamber: Inside the Tiger Loop, the oil enters a chamber where the pressure is slightly lower than the supply line. This pressure differential encourages air bubbles to separate from the oil.

- Air Venting: The separated air rises to the top of the chamber and is vented back to the oil tank through a dedicated return line. This is a crucial step in removing air from the system.

- Clean Oil Outlet: The de-aerated oil, now free of air bubbles, is drawn from the bottom of the Tiger Loop and sent to the burner.

- Recirculation Loop: Any excess oil that is not consumed by the burner is also returned to the tank through the return line, creating a closed-loop system. This ensures a continuous supply of clean oil and prevents the buildup of air.

Key Components Typically Shown in a Tiger Loop Diagram:

- Supply Line: Connects the oil tank to the Tiger Loop.

- Return Line: Returns excess oil and vented air to the oil tank.

- De-Aeration Chamber: The main body of the Tiger Loop where air separation occurs.

- Float Valve (sometimes): Some models use a float valve to regulate the oil level in the chamber and prevent air from being drawn into the burner line.

- Vent Port: The opening where air is vented back to the tank.

- Outlet to Burner: The connection that supplies clean oil to the burner.

Common Problems with Tiger Loops and Troubleshooting Tips

While Tiger Loops are generally reliable, they can experience problems that affect their performance. Here are some common issues and how to address them:

- Air Leaks: The most common problem. Check all fittings and connections for tightness. Even a small leak can allow air to enter the system. Use pipe dope or Teflon tape on threaded connections.

- Clogged Return Line: A blocked return line prevents proper venting and recirculation, causing air to accumulate in the system. Check for kinks or obstructions in the line. Sometimes sludge from the oil tank can migrate into the return line and cause blockage.

- Defective Float Valve (if applicable): If the float valve is stuck or damaged, it can prevent proper oil flow or allow air to enter the burner line. Clean or replace the float valve.

- Damaged De-Aeration Chamber: Cracks or damage to the Tiger Loop body can compromise its ability to separate air. Replace the entire unit.

- Oil Tank Issues: Problems with the oil tank, such as a low oil level or a clogged filter, can also affect the Tiger Loop's performance. Ensure the tank has sufficient oil and that the filter is clean.

Troubleshooting Steps:

- Visual Inspection: Check for any obvious signs of damage or leaks.

- Tighten Connections: Ensure all fittings are tight.

- Check the Return Line: Disconnect the return line at the tank and blow through it to check for obstructions.

- Clean the Float Valve (if applicable): Carefully remove and clean the float valve.

- Inspect the Oil Tank: Check the oil level and filter.

Tools and Materials You Might Need

Before attempting any repairs, gather the necessary tools and materials:

- Wrenches: For tightening fittings.

- Screwdrivers: For removing access panels and components.

- Pipe Dope or Teflon Tape: For sealing threaded connections.

- Oil Filter Wrench: For changing the oil filter.

- Shop Rags: For cleaning up spills.

- Safety Glasses: To protect your eyes.

- Gloves: To protect your hands.

- Replacement Parts: Such as a new Tiger Loop, float valve, or fittings.

Safety First! Before working on any oil-fired heating system, turn off the power to the burner and close the oil supply valve to prevent spills and potential hazards.

When to Call a Professional HVAC Technician

While some Tiger Loop issues can be addressed with DIY troubleshooting, certain situations require the expertise of a qualified HVAC technician. Consider calling a professional if:

- You are uncomfortable working with oil or electrical components.

- You are unable to identify the source of the problem.

- The problem persists after attempting basic troubleshooting steps.

- You suspect a more serious issue, such as a fuel leak or burner malfunction.

- You are dealing with complex wiring or controls.

Attempting repairs beyond your skill level can be dangerous and may void your warranty. A professional HVAC technician has the knowledge, experience, and tools to diagnose and repair complex heating system problems safely and effectively. They can also ensure that your system is operating efficiently and meeting safety standards.

Estimating Repair Costs

The cost of repairing or replacing a Tiger Loop can vary depending on the specific problem, the type of Tiger Loop, and your location. Here's a general estimate:

- Minor Repairs (e.g., tightening connections, cleaning the float valve): $50 - $150

- Tiger Loop Replacement: $150 - $400 (including parts and labor)

- Additional Repairs (e.g., oil tank cleaning, burner service): Varies depending on the extent of the work.

These are just estimates, and it's always best to get a quote from a qualified HVAC technician before proceeding with any repairs. Be sure to ask for a detailed breakdown of the costs, including parts and labor.

Preventative Maintenance Tips

Regular preventative maintenance can help prevent Tiger Loop problems and extend the life of your heating system. Here are some tips:

- Annual Inspection: Schedule an annual inspection by a qualified HVAC technician.

- Oil Tank Maintenance: Keep the oil tank filled and free of debris. Consider having it professionally cleaned every few years.

- Filter Changes: Change the oil filter regularly, as recommended by the manufacturer.

- Monitor Performance: Pay attention to any changes in your heating system's performance, such as a pulsating flame or frequent shutdowns.

By understanding how a Tiger Loop works and taking proactive steps to maintain your heating system, you can ensure a reliable and efficient source of heat for your home.

Choosing the Right Tiger Loop Replacement

If your Tiger Loop needs replacing, it's important to choose the correct model. Consider these factors:

- Oil Flow Rate: Ensure the Tiger Loop is rated for the oil flow rate required by your burner.

- Connection Sizes: Match the connection sizes to your existing oil lines.

- Features: Some models include a built-in oil filter or other features that may be beneficial.

- Brand Reputation: Choose a reputable brand known for quality and reliability.

Consult with an HVAC professional to ensure you select the appropriate Tiger Loop for your specific heating system.

Disclaimer: This information is for general guidance only and should not be considered a substitute for professional advice. Always consult with a qualified HVAC technician before attempting any repairs to your heating system.