How Many Co Detectors Do You Need

Carbon monoxide (CO) is an odorless, colorless, and deadly gas. It's a silent killer produced by the incomplete burning of fuels such as natural gas, propane, oil, wood, and kerosene. Because you can't see, smell, or taste it, a carbon monoxide detector is essential for protecting your family and yourself from CO poisoning. But determining how many CO detectors you need and where to place them can be confusing. This comprehensive guide addresses these concerns for homeowners, HVAC technicians, and facility managers.

Understanding the Risks: Sources of CO in Buildings

To determine the appropriate number of CO detectors, it's crucial to understand potential CO sources within a building. These sources often include:

- Fuel-burning appliances: Furnaces (gas, oil, or propane), boilers, water heaters, stoves, ovens, clothes dryers, and fireplaces are primary CO sources. Older appliances, especially those that are poorly maintained, are more likely to produce CO.

- Attached garages: Running a car or other combustion engine in an attached garage, even with the door open, can quickly raise CO levels inside the house.

- Portable generators: These are extremely dangerous and should NEVER be used indoors or in partially enclosed spaces like garages or carports.

- Blocked chimneys or flues: Obstructions can prevent proper venting of combustion gases, leading to CO buildup. Birds' nests, debris, or even collapsed flue liners can cause blockages.

- Malfunctioning HVAC systems: Cracks in the heat exchanger of a furnace are a common cause of CO leaks. Regular HVAC maintenance is vital for preventing these leaks.

- Wood-burning stoves: Incorrect installation, faulty gaskets, or improper operation can all contribute to CO production.

For facility managers overseeing larger buildings, these sources are often multiplied, especially with multiple tenant spaces each having their own appliances.

The "One Detector Per Level" Guideline: Is It Enough?

Many building codes and safety organizations recommend at least one CO detector per level of a home, including the basement. This is a good starting point, but often insufficient. Consider a multi-story home with bedrooms on the upper level. A single detector in the basement might not provide adequate warning if CO is leaking near the sleeping areas.

For HVAC technicians, educating homeowners about the limitations of a single detector is crucial. Explain that while it meets the minimum requirement, it might not provide the fastest or most comprehensive protection.

Recommended Placement for Optimal Protection

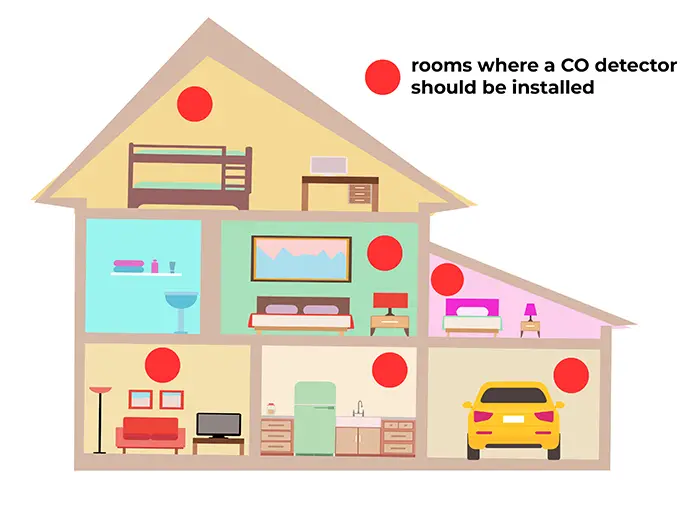

For comprehensive protection, the following placement guidelines are recommended:

- Near Sleeping Areas: Install CO detectors outside each separate sleeping area. This ensures occupants are alerted even when asleep. If bedrooms are spread out, install a detector outside each group of bedrooms.

- On Every Level: As mentioned earlier, one detector per level, including the basement, is the minimum.

- Within 10 Feet of Appliances: Place a detector within 10 feet of any fuel-burning appliance, such as a furnace, water heater, or stove. However, avoid placing it directly above or beside the appliance where it could be triggered by brief bursts of CO during normal operation.

- Inside Garages: If you have an attached garage, place a CO detector inside.

- Away from Obstructions: Don't place detectors behind curtains, furniture, or other obstructions that could block airflow to the sensor.

- Avoid High-Humidity Areas: Bathrooms, laundry rooms, and kitchens can have high humidity levels that can damage the detector over time. Choose a location that minimizes exposure to moisture.

- Consider Children's Rooms: For added safety, particularly for younger children who might not recognize the alarm, consider installing a CO detector inside each child's bedroom.

Example: A two-story house with a basement and an attached garage should ideally have at least five CO detectors: one outside the bedrooms on the second floor, one on the main floor, one in the basement, one in the garage, and one near the furnace (assuming it's not in one of the other locations).

Types of CO Detectors and Their Lifespan

There are several types of CO detectors available, each with its own advantages and disadvantages:

- Electrochemical Sensors: These are the most common type. They use a chemical reaction to detect CO. They are generally accurate and have a lifespan of 5-10 years.

- Biometric Sensors: These sensors use a gel that changes color in the presence of CO. They are less common than electrochemical sensors.

- Metal Oxide Semiconductor Sensors: These sensors use a heated metal oxide semiconductor that changes conductivity when exposed to CO. They are less sensitive than electrochemical sensors but have a longer lifespan.

Power Source: CO detectors can be battery-powered, hardwired with battery backup, or plug-in with battery backup. Hardwired detectors are generally more reliable as they don't rely solely on battery power. Battery-powered detectors are easier to install but require regular battery changes. Always replace batteries at least twice a year, and consider lithium batteries for longer life.

Lifespan: CO detectors have a limited lifespan, typically 5-10 years. The sensor degrades over time and becomes less accurate. Always check the manufacturer's instructions for the recommended replacement date. Many detectors have an end-of-life warning signal that will alert you when it's time to replace them.

For HVAC Technicians: CO Testing and Prevention

As an HVAC technician, you play a critical role in preventing CO poisoning. During routine maintenance and inspections, you should:

- Inspect for CO Sources: Thoroughly inspect all fuel-burning appliances for signs of damage, corrosion, or leaks. Pay close attention to the heat exchanger in furnaces, as cracks can be difficult to spot.

- Perform a Combustion Analysis: Use a combustion analyzer to measure CO levels in the flue gas. This will help identify incomplete combustion and potential CO leaks.

- Check Flue Systems: Inspect chimneys and flues for blockages, damage, or improper venting. Ensure that all connections are tight and that the flue is properly sized for the appliance.

- Educate Homeowners: Explain the importance of CO detectors and proper placement. Emphasize the need for regular maintenance and replacement of detectors. Provide homeowners with a written report of your inspection findings.

Example: During a furnace tune-up, you notice rust and corrosion on the heat exchanger. A combustion analysis reveals high CO levels in the flue gas. You recommend that the homeowner replace the furnace to prevent a potential CO leak. This proactive approach can save lives.

For Facility Managers: Implementing a CO Safety Plan

Facility managers are responsible for the safety of occupants in commercial buildings. Implementing a comprehensive CO safety plan is essential.

- Install CO Detectors: Install CO detectors in accordance with local building codes and industry best practices. Consider installing networked CO detectors that can be monitored centrally.

- Regular Inspections: Conduct regular inspections of all fuel-burning appliances and HVAC systems. Use qualified HVAC technicians for these inspections.

- Maintenance Schedule: Establish a preventive maintenance schedule for all fuel-burning appliances and HVAC systems. This includes cleaning, tuning, and replacing worn parts.

- Emergency Response Plan: Develop an emergency response plan in the event of a CO leak. This plan should include evacuation procedures, notification protocols, and contact information for emergency services.

- Tenant Education: Educate tenants about the dangers of CO poisoning and the importance of CO detectors. Provide them with information on how to recognize the symptoms of CO poisoning and what to do in an emergency.

Cost Considerations: While installing multiple CO detectors may seem expensive, the cost is minimal compared to the potential consequences of CO poisoning. The cost of a single detector is typically between $20 and $50. Hardwired detectors can cost more, but they offer increased reliability. Integrating the cost of detectors into the overall building safety budget is a crucial investment.

Testing and Maintenance: Ensuring Proper Function

Regardless of the type or number of CO detectors you have, regular testing and maintenance are crucial for ensuring proper function.

- Test Monthly: Test each CO detector monthly by pressing the test button. This will verify that the alarm is working.

- Change Batteries: Replace batteries at least twice a year, even if the detector is still working. Use high-quality batteries for longer life.

- Clean Regularly: Dust or vacuum CO detectors regularly to remove dirt and debris that can interfere with the sensor.

- Replace Detectors: Replace CO detectors according to the manufacturer's instructions, typically every 5-10 years.

By following these guidelines, homeowners, HVAC technicians, and facility managers can significantly reduce the risk of CO poisoning and create a safer environment for everyone.

-1920w.jpg)