How Many Gallon Air Compressor Do I Need

Are you tired of your air compressor sputtering, struggling to keep up, or completely failing mid-project? A frustratingly common problem homeowners face is using an air compressor that's simply too small for their needs. This leads to inefficiency, overheating, and ultimately, a shorter lifespan for your equipment. But before you run out and buy the biggest compressor on the market, let's figure out exactly how many gallons you actually need.

Understanding the Problem: Insufficient Air Capacity

The symptoms are often subtle at first. You might notice your nail gun slowing down after a few uses, or your paint sprayer producing an uneven finish. Eventually, the compressor might run continuously, struggling to maintain pressure, and potentially overheat. This isn't just annoying; it can damage both your compressor and the tools you're using. The root cause is that your compressor's tank size (measured in gallons) and its CFM (cubic feet per minute) output aren't sufficient to meet the demands of your air tools.

Step-by-Step Diagnosis: Determining Your Air Tool Needs

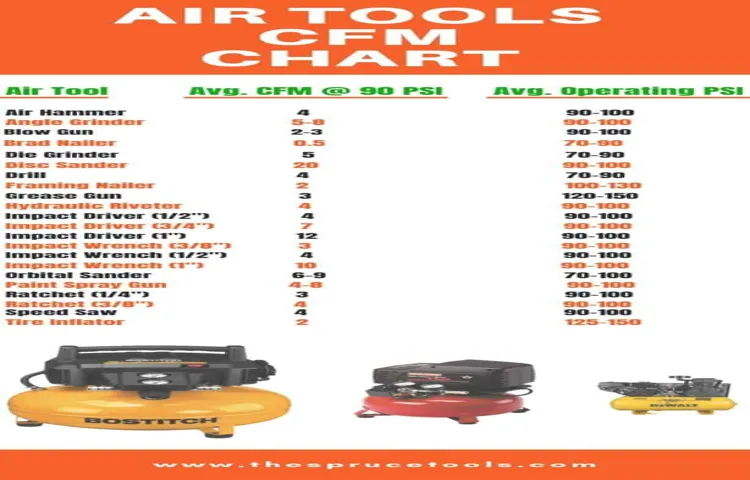

The key to choosing the right size air compressor is understanding the air consumption of the tools you plan to use. This is measured in CFM at a specific PSI (pounds per square inch). Here's how to diagnose your needs:

Step 1: Identify Your Air Tools

Make a list of all the air tools you intend to use with your compressor. Be comprehensive! Include everything from nail guns and impact wrenches to paint sprayers and sandblasters. Don't forget inflatable items like tires or pool toys, if you plan to use your compressor for those.

Step 2: Find the CFM and PSI Requirements

This is the most crucial step. For each tool on your list, you need to find its CFM and PSI requirements. This information can usually be found in one of the following places:

- The tool's manual: This is the best source for accurate information.

- The tool's label: Often, the CFM and PSI requirements are printed directly on the tool.

- The manufacturer's website: If you've lost the manual, the manufacturer's website is a good place to look.

- Online retailers: Many online retailers list the CFM and PSI requirements in the product specifications.

Pay close attention to the PSI. Some tools require 90 PSI, while others may need more or less. The CFM rating is usually given at a specific PSI (e.g., 4 CFM @ 90 PSI). Make sure you're comparing apples to apples!

Step 3: Calculate Your Total CFM Requirement

Once you have the CFM requirements for all your tools, you need to calculate the total CFM your compressor needs to deliver. This isn't as simple as just adding up all the CFM values. Here's why:

- Duty Cycle: Air tools don't run continuously. A nail gun, for example, only uses air when it's fired. A paint sprayer might run more continuously, but even it has breaks.

- Simultaneous Use: Are you likely to use multiple tools at the same time?

Here's a practical approach:

- Identify the tool with the highest CFM requirement. This is your baseline.

- Add a buffer. A good rule of thumb is to add at least 25% to the highest CFM requirement. This accounts for duty cycle and provides a safety margin. So, if your highest CFM tool requires 5 CFM, add 1.25 CFM (5 x 0.25 = 1.25) for a total of 6.25 CFM.

- Consider simultaneous use. If you plan to use multiple tools simultaneously, add the CFM requirements of those tools to your total. Be realistic! Are you really going to be using your sandblaster and impact wrench at the same time?

Example:

- Nail Gun: 2 CFM @ 90 PSI

- Impact Wrench: 4 CFM @ 90 PSI

- Paint Sprayer: 5 CFM @ 40 PSI

In this case, the paint sprayer has the highest CFM requirement (5 CFM). Adding a 25% buffer gives us 6.25 CFM. If you plan to use the nail gun and impact wrench occasionally while painting, you might add an additional 1 CFM (estimating that they won't be running constantly). This would bring your total CFM requirement to 7.25 CFM.

Step 4: Determine the Required Tank Size (Gallons)

Now that you know your CFM requirement, you can estimate the tank size you need. While there's no hard-and-fast rule, a larger tank provides a greater reserve of compressed air, allowing the compressor to cycle on and off less frequently. This is generally desirable, as it reduces wear and tear on the motor and provides a more consistent air supply.

Here's a general guideline:

- For light-duty tasks (nailing, inflating): A 6-gallon pancake or hotdog compressor might be sufficient if the CFM output is adequate.

- For intermittent use of higher CFM tools (impact wrenches, small spray guns): A 20-30 gallon compressor is often a good choice.

- For continuous use of high-CFM tools (sandblasting, large spray guns): A 60-80 gallon compressor or larger is usually necessary.

Important Consideration: The CFM rating of the compressor is more important than the tank size. A large tank with a low CFM output will still struggle to keep up with high-demand tools. Make sure the compressor's CFM rating at the required PSI meets or exceeds your calculated CFM requirement.

Simple DIY Fixes (Addressing Minor Issues)

Before you conclude that your compressor is too small, make sure you've ruled out other common problems:

1. Check for Leaks

Leaks can significantly reduce the efficiency of your compressor. Check all fittings, hoses, and connections for leaks. You can use a spray bottle filled with soapy water to identify leaks – bubbles will form where air is escaping.

Fix: Tighten loose fittings. Replace worn-out hoses or fittings. Use Teflon tape on threaded connections to create a better seal.

2. Drain the Tank

Moisture can accumulate in the tank, reducing its capacity and potentially damaging the compressor and your tools. Drain the tank regularly, especially in humid environments.

Fix: Locate the drain valve at the bottom of the tank and open it to release the accumulated water. Make sure to do this in a well-ventilated area.

3. Clean or Replace the Air Filter

A dirty air filter can restrict airflow to the compressor, reducing its performance. Clean or replace the air filter regularly.

Fix: Remove the air filter and clean it with compressed air. If the filter is heavily soiled or damaged, replace it with a new one.

4. Check the Pressure Switch

The pressure switch controls the motor, turning it on and off to maintain the desired pressure. A faulty pressure switch can prevent the compressor from reaching its full pressure.

Fix: This is a more advanced repair, but you can try cleaning the contacts on the pressure switch with electrical contact cleaner. Disconnect the power before working on the pressure switch.

When to Call a Professional

While some air compressor issues can be resolved with simple DIY fixes, others require professional intervention. Here are some signs that it's time to call a qualified technician:

- The motor is not starting or running properly. This could indicate a problem with the motor itself, the pressure switch, or the electrical wiring.

- The compressor is overheating. Overheating can be caused by a variety of factors, including a faulty motor, a blocked air filter, or a lack of lubrication. Continuing to run an overheated compressor can cause serious damage.

- The compressor is leaking air from the tank itself. This indicates a crack or other damage to the tank, which can be dangerous. Do not attempt to repair a damaged tank yourself.

- You suspect a problem with the electrical components. Working with electricity can be dangerous. If you're not comfortable working with electrical wiring, leave it to the professionals.

- You've tried the DIY fixes and the problem persists. Sometimes, a problem is simply too complex to diagnose and repair without specialized knowledge and equipment.

Safety First! Always disconnect the power to the compressor before performing any maintenance or repairs. Wear appropriate safety gear, such as safety glasses and gloves. If you're not comfortable working on electrical or mechanical equipment, leave it to the professionals.

Making the Right Choice: Choosing a New Compressor

If, after diagnosing your needs and attempting simple fixes, you determine that your compressor is indeed too small, it's time to consider buying a new one. Here are some key factors to keep in mind:

- CFM Rating: As we've discussed, the CFM rating is the most important factor. Make sure the compressor's CFM rating at the required PSI meets or exceeds your calculated CFM requirement.

- Tank Size: Choose a tank size that provides a sufficient reserve of compressed air for your needs. A larger tank is generally better, but it also takes up more space.

- Horsepower (HP): Horsepower is a measure of the motor's power. A higher horsepower motor can deliver more CFM.

- Portability: Consider whether you need a portable compressor or a stationary one. Portable compressors are smaller and lighter, making them easy to move around. Stationary compressors are larger and more powerful, making them suitable for heavy-duty applications.

- Power Source: Air compressors are typically powered by electricity or gasoline. Electric compressors are quieter and cleaner, making them ideal for indoor use. Gasoline compressors are more powerful and portable, making them suitable for outdoor use.

- Price: Air compressors range in price from a few hundred dollars to several thousand dollars. Choose a compressor that fits your budget and meets your needs.

Types of Air Compressors:

- Pancake Compressors: Small, portable, and inexpensive. Suitable for light-duty tasks.

- Hotdog Compressors: Similar to pancake compressors but with a cylindrical tank.

- Twin-Stack Compressors: Offer more air capacity than pancake or hotdog compressors.

- Single-Stage Compressors: Compress air in a single stage. Suitable for most homeowner applications.

- Two-Stage Compressors: Compress air in two stages, resulting in higher pressure and efficiency. More expensive and typically used for industrial applications.

Conclusion: Empowering You to Make the Right Decision

Choosing the right size air compressor doesn't have to be a daunting task. By understanding your air tool needs, diagnosing potential problems, and considering the factors outlined in this article, you can make an informed decision and select a compressor that will provide years of reliable service. Remember to prioritize safety and don't hesitate to call a professional when needed. With the right compressor, you can tackle a wide range of projects with confidence and efficiency.