How To Charge A Fridge Compressor

Refrigeration is at the heart of modern life, and understanding how to properly charge a fridge compressor is a fundamental skill for any HVAC technician. This article provides a comprehensive guide to the process, along with insights into career paths, certifications, and industry trends related to refrigeration.

Understanding the Refrigeration Cycle & Charging Basics

Before diving into the charging process, it’s crucial to grasp the basics of the refrigeration cycle. The cycle consists of four main components: the compressor, condenser, expansion valve (or capillary tube), and evaporator. The compressor is the heart of the system, circulating refrigerant throughout the cycle.

Charging a fridge compressor involves adding refrigerant to the system to ensure it operates efficiently. A system that is undercharged will not cool properly, leading to food spoilage and increased energy consumption. Overcharging can also damage the compressor and other components.

Safety First: Essential Precautions

Working with refrigerant requires strict adherence to safety protocols. Refrigerants can be harmful if inhaled or exposed to skin. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and respiratory protection if working in a poorly ventilated area.

Furthermore, refrigerants are regulated substances. Improper handling or release can lead to hefty fines and environmental damage. Always follow EPA guidelines and local regulations.

Step-by-Step Guide to Charging a Fridge Compressor

This guide assumes you have already diagnosed a refrigerant deficiency and have determined that charging is necessary. It also assumes the system is properly evacuated and leak-checked.

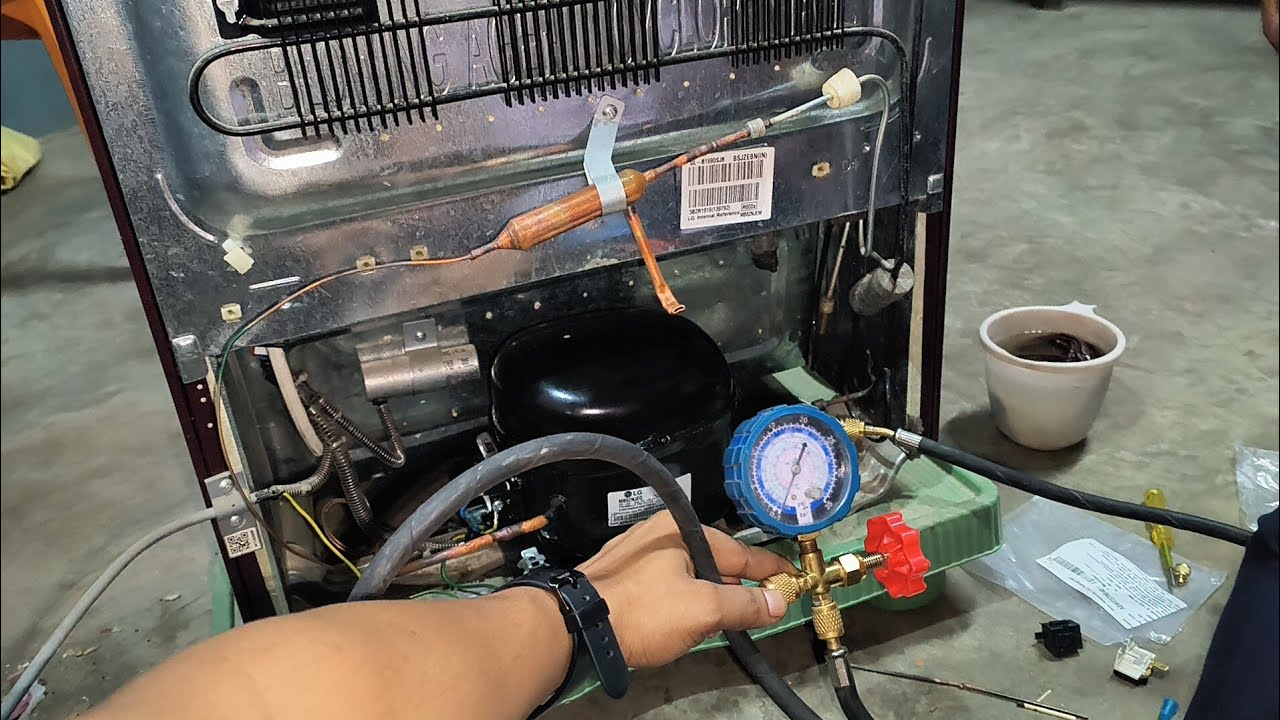

- Gather Your Tools: You'll need a manifold gauge set, vacuum pump, refrigerant scale, refrigerant cylinder, charging hoses, and a piercing valve (if the system doesn't have service ports).

- Determine the Refrigerant Type: Check the nameplate on the fridge to identify the type of refrigerant used (e.g., R-134a, R-600a). Using the wrong refrigerant can severely damage the system and is illegal.

- Connect the Manifold Gauge Set: Connect the high-side hose (usually red) to the high-pressure side of the compressor and the low-side hose (usually blue) to the low-pressure side. The yellow hose connects to the refrigerant cylinder. If the fridge doesn't have service ports, carefully install a piercing valve on the process tubing.

- Purge the Hoses: Before opening the refrigerant cylinder, purge the hoses to remove any air or moisture.

- Charge with Refrigerant: Open the refrigerant cylinder valve slightly and slowly introduce refrigerant into the system. Monitor the pressure gauges and the temperature of the evaporator coil.

- Weigh in Refrigerant: Ideally, you should weigh in the correct amount of refrigerant as specified on the fridge's nameplate. Use a refrigerant scale for accurate measurement.

- Monitor System Performance: After charging, run the fridge for a while and monitor its performance. Check the evaporator coil for proper frost pattern, the condenser for proper heat dissipation, and the compressor for excessive noise or vibration.

- Fine-Tune the Charge: Based on the system's performance, you may need to add or remove a small amount of refrigerant to achieve optimal cooling. Use the superheat and subcooling methods to determine the ideal charge.

Superheat and Subcooling Explained

Superheat and subcooling are crucial concepts for accurately charging refrigeration systems. Superheat refers to the temperature of the refrigerant vapor above its saturation temperature at the evaporator outlet. Subcooling refers to the temperature of the refrigerant liquid below its saturation temperature at the condenser outlet.

By measuring superheat and subcooling, you can determine whether the system is properly charged. Incorrect superheat or subcooling indicates either an undercharge or an overcharge.

Career Paths in Refrigeration

A career in refrigeration offers diverse opportunities. Some common career paths include:

- HVAC Technician: Install, maintain, and repair HVAC systems, including refrigerators, air conditioners, and heat pumps. The Bureau of Labor Statistics projects a growth rate of 6% for HVAC technicians from 2022 to 2032, about as fast as the average for all occupations. The median annual wage for HVAC technicians was $59,620 in May 2023.

- Refrigeration Technician: Specialize in refrigeration systems, focusing on commercial and industrial applications.

- Service Manager: Oversee a team of HVAC technicians, manage service calls, and ensure customer satisfaction.

- HVAC Sales Engineer: Design and sell HVAC systems to commercial and industrial clients.

Real-World Example: Maria started as an HVAC apprentice, learning the fundamentals of refrigeration. After several years of experience, she specialized in commercial refrigeration and obtained her NATE certification. Today, she works as a service manager for a large supermarket chain, overseeing the maintenance of their refrigeration systems.

Essential Certifications for Refrigeration Technicians

Obtaining relevant certifications can significantly enhance your career prospects and earning potential.

- EPA Section 608 Certification: Required by law for technicians who handle refrigerants. There are different types of certifications (Type I, Type II, Type III, and Universal) depending on the type of equipment you work on.

- NATE (North American Technician Excellence) Certification: Demonstrates your expertise in HVAC and refrigeration. NATE offers various certifications, including one specifically for refrigeration.

- HVAC Excellence Certification: Another reputable certification program that validates your skills and knowledge.

Employers often prefer candidates with certifications, as it demonstrates a commitment to professionalism and adherence to industry standards.

Industry Trends and the Future of Refrigeration

The refrigeration industry is constantly evolving, driven by factors such as energy efficiency, environmental concerns, and technological advancements.

- Energy Efficiency: Regulations are becoming stricter regarding energy efficiency standards for refrigerators and other refrigeration equipment. Technicians need to be knowledgeable about high-efficiency systems and best practices for optimizing performance.

- Alternative Refrigerants: Traditional refrigerants like R-134a are being phased out due to their high global warming potential. Technicians need to be trained on working with alternative refrigerants, such as R-600a (isobutane) and CO2.

- Smart Refrigeration: The integration of sensors, data analytics, and remote monitoring capabilities is transforming the refrigeration industry. Technicians need to be comfortable with diagnosing and repairing smart refrigeration systems.

- Technological Advancements: Variable speed compressors, electronic expansion valves, and advanced control systems are becoming increasingly common. Technicians need to stay up-to-date with these technological advancements through ongoing training and education.

The demand for skilled refrigeration technicians is expected to remain strong in the coming years, driven by the growing need for efficient and environmentally friendly refrigeration solutions. By acquiring the necessary skills, certifications, and knowledge, you can build a successful and rewarding career in this dynamic industry.

Important Note: This article provides general information and should not be considered a substitute for professional training or guidance. Always consult with a qualified HVAC instructor or technician before attempting to charge a fridge compressor.

In conclusion, mastering the art of charging a fridge compressor, coupled with continuous learning and professional certifications, will position you for a thriving career in the HVAC/R industry. Embrace the challenges, stay informed about the latest trends, and you'll be well-equipped to succeed in this essential field.