How To Cut Pvc Pipe With A Saw

PVC pipe is a common material in residential HVAC systems, used for everything from condensate drain lines to vent pipes. Knowing how to properly cut it is a fundamental skill for any homeowner tackling basic repairs. This guide will walk you through various methods, ensuring a clean, accurate cut every time.

Essential Tools and Materials

Before you start, gather the necessary tools and materials. Having everything on hand will make the process smoother and safer.

- PVC Pipe Cutter: A ratcheting cutter designed specifically for PVC. Ideal for smaller diameter pipes.

- Hand Saw: A standard hand saw, preferably with fine teeth (a miter saw or backsaw works well).

- Hacksaw: Useful for cutting in tight spaces.

- Miter Box: Helps ensure straight, accurate cuts with a hand saw.

- Measuring Tape: For accurate measurements and marking.

- Marker or Pencil: For marking the cut line.

- Safety Glasses: To protect your eyes from debris.

- Gloves: To protect your hands.

- Sandpaper or Deburring Tool: For smoothing the cut edge.

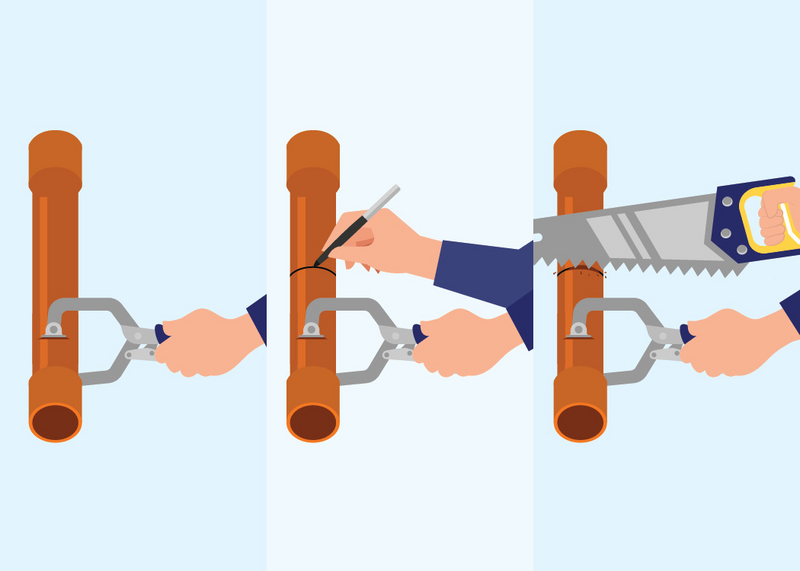

Method 1: Using a PVC Pipe Cutter

A PVC pipe cutter is often the easiest and cleanest way to cut smaller diameter PVC pipe.

- Mark the Cut Line: Use a measuring tape and marker to precisely mark where you need to cut the pipe.

- Position the Cutter: Open the jaws of the PVC pipe cutter and position the blade directly on your marked line. Make sure the pipe is seated securely in the cutter.

- Ratcheting Action: Close the cutter and begin ratcheting. With each squeeze, the blade will advance further into the pipe.

- Complete the Cut: Continue ratcheting until the blade has completely cut through the pipe.

- Deburr the Edge: Use sandpaper or a deburring tool to smooth the inside and outside edges of the cut. This removes any burrs or sharp edges that could impede water flow or create leaks.

Method 2: Using a Hand Saw or Hacksaw

A hand saw or hacksaw is a versatile option for cutting PVC, especially for larger diameters or when a pipe cutter isn't available.

- Mark the Cut Line: Measure accurately and mark the cut line around the entire circumference of the pipe. Using a wraparound guide (like a piece of paper) can help ensure a straight line.

- Secure the Pipe: Place the PVC pipe in a miter box or clamp it securely to a stable surface to prevent it from moving during the cut.

- Begin Cutting: Start sawing along the marked line, using steady and even strokes. If using a miter box, follow the guide slots for a straight cut.

- Maintain Pressure: Apply gentle pressure to the saw, allowing the teeth to do the work. Avoid forcing the saw, as this can lead to a jagged or uneven cut.

- Complete the Cut: Continue sawing until you have completely cut through the pipe.

- Deburr the Edge: Use sandpaper or a deburring tool to smooth the inside and outside edges of the cut.

Method 3: Using a Power Saw (Miter Saw or Circular Saw)

A power saw can make quick work of cutting PVC, especially when dealing with larger quantities or thicker pipes. Exercise extreme caution when using power tools.

- Safety First: Wear safety glasses and hearing protection.

- Choose the Right Blade: Use a fine-tooth blade designed for cutting plastic or PVC. A standard wood-cutting blade can chip or shatter the pipe.

- Mark the Cut Line: Accurately mark the cut line around the pipe.

- Secure the Pipe: Clamp the pipe securely to the saw's fence or work surface to prevent movement.

- Make the Cut: With the saw running, slowly lower the blade onto the pipe along the marked line. Use a smooth, controlled motion.

- Avoid Overheating: Don't force the saw, as this can cause the plastic to melt or deform.

- Deburr the Edge: Use sandpaper or a deburring tool to smooth the inside and outside edges of the cut.

Safety Precautions

Cutting PVC pipe can create dust and debris, so safety is paramount.

- Eye Protection: Always wear safety glasses to protect your eyes from flying debris.

- Ventilation: Work in a well-ventilated area to avoid inhaling PVC dust. Consider wearing a dust mask.

- Hand Protection: Wear gloves to protect your hands from sharp edges and potential cuts.

- Power Tool Safety: If using power tools, follow all manufacturer's instructions and safety guidelines.

- Sharp Blades: Handle blades with care to avoid cuts.

Troubleshooting Common Issues

Even with the best techniques, problems can arise.

- Jagged Cuts: This is often caused by using a dull blade or forcing the saw. Use a sharp blade and let the tool do the work.

- Uneven Cuts: Ensure the pipe is securely clamped or held in a miter box.

- Cracked Pipe: This can happen if the pipe is brittle due to age or cold temperatures. Use a slower cutting speed and avoid excessive pressure.

- Melting Plastic: Overheating due to friction can cause the plastic to melt. Use a sharper blade and avoid forcing the cut.

When to Call a Professional

While cutting PVC pipe is a relatively simple task, some HVAC repairs are best left to qualified professionals.

- Complex System Modifications: Altering the main ductwork or venting system requires specialized knowledge and tools.

- Refrigerant Lines: Working with refrigerant lines requires EPA certification and specialized equipment. Improper handling can lead to leaks and environmental damage.

- Gas Lines: Any work involving gas lines is extremely dangerous and should only be performed by a licensed gas fitter.

- Electrical Components: If the repair involves electrical components, such as wiring or control boards, consult a qualified electrician.

- Uncertainty: If you are unsure about any aspect of the repair, it is always best to err on the side of caution and call a professional.

Estimating Repair Costs

The cost of hiring an HVAC professional can vary depending on the complexity of the repair, the location, and the contractor's rates. Simple PVC pipe repairs, such as replacing a condensate drain line, may cost between $75 and $200. More complex repairs, such as modifying ductwork, can cost several hundred dollars or more. Always obtain multiple quotes from reputable contractors before proceeding with any work.

Disclaimer: This guide provides general information only and should not be considered a substitute for professional advice. Always consult with a qualified HVAC technician before attempting any repairs to your HVAC system.

PVC Pipe and Your HVAC System

PVC pipe plays a vital role in various parts of your home's climate control system. Here are some areas where you'll commonly find it:

- Condensate Drain Lines: These lines carry away condensation produced by your air conditioner or furnace. A clogged or damaged condensate drain line can lead to water leaks and potential water damage.

- Vent Pipes: In some HVAC systems, PVC is used for venting exhaust gases, especially from high-efficiency furnaces. Proper venting is crucial for safety and efficient operation.

- Air Ducts (Less Common): While metal ductwork is more prevalent, PVC can sometimes be used for sections of air ducts, particularly in specific installations or for transitioning between different materials.

Understanding the role of PVC in your HVAC system can help you identify potential problems early and address them before they escalate into costly repairs. Regular inspection of your condensate drain line, for instance, can prevent water damage and keep your system running smoothly.

Final Thoughts

Cutting PVC pipe is a valuable skill for homeowners and DIY enthusiasts. By following these steps and prioritizing safety, you can confidently tackle minor repairs and maintenance tasks. However, always remember to assess your skill level and the complexity of the job. When in doubt, don't hesitate to call a qualified HVAC professional to ensure the job is done safely and correctly.