How To Fix Clogged Condensate Drain Line

A clogged condensate drain line is a common HVAC issue, and troubleshooting it is a fundamental skill for any HVAC professional. This article serves as a comprehensive guide for students, experienced technicians, and employers alike, covering diagnostics, repair techniques, preventative measures, and the importance of this skill within the broader HVAC industry.

Understanding the Condensate Drain Line

The condensate drain line's purpose is simple: to remove water produced during the air conditioning process. As air passes over the evaporator coil, moisture condenses, collecting in a drain pan and flowing through the drain line. A clog prevents this drainage, leading to potential water damage, reduced system efficiency, and even mold growth. Ignoring this problem can escalate into costly repairs or replacements, underlining the importance of regular maintenance and prompt troubleshooting.

Recognizing the Signs of a Clogged Drain Line

Early detection is crucial. Look for these telltale signs:

- Water Leaks: Around the indoor unit or furnace. This is the most obvious indicator.

- System Shutdown: Many units have a safety float switch that shuts down the system when the drain pan is full.

- Musty Odor: Standing water in the drain pan promotes mold and mildew growth.

- Visible Mold: Around the indoor unit or drain pan.

- Reduced Cooling Efficiency: A clogged drain can cause the evaporator coil to freeze, hindering cooling performance.

Step-by-Step Guide to Clearing a Clogged Condensate Drain Line

Before you begin, always disconnect the power to the HVAC system to prevent electrical shock.

Tools and Materials Needed:

- Wet/Dry Vacuum

- Stiff Brush or Condensate Drain Line Brush

- Nitrogen Tank or CO2 Cartridge (optional, for clearing stubborn clogs)

- Drain Line Flush or Vinegar

- Safety Glasses

- Gloves

- Adjustable Wrench (for accessing the drain line)

Procedure:

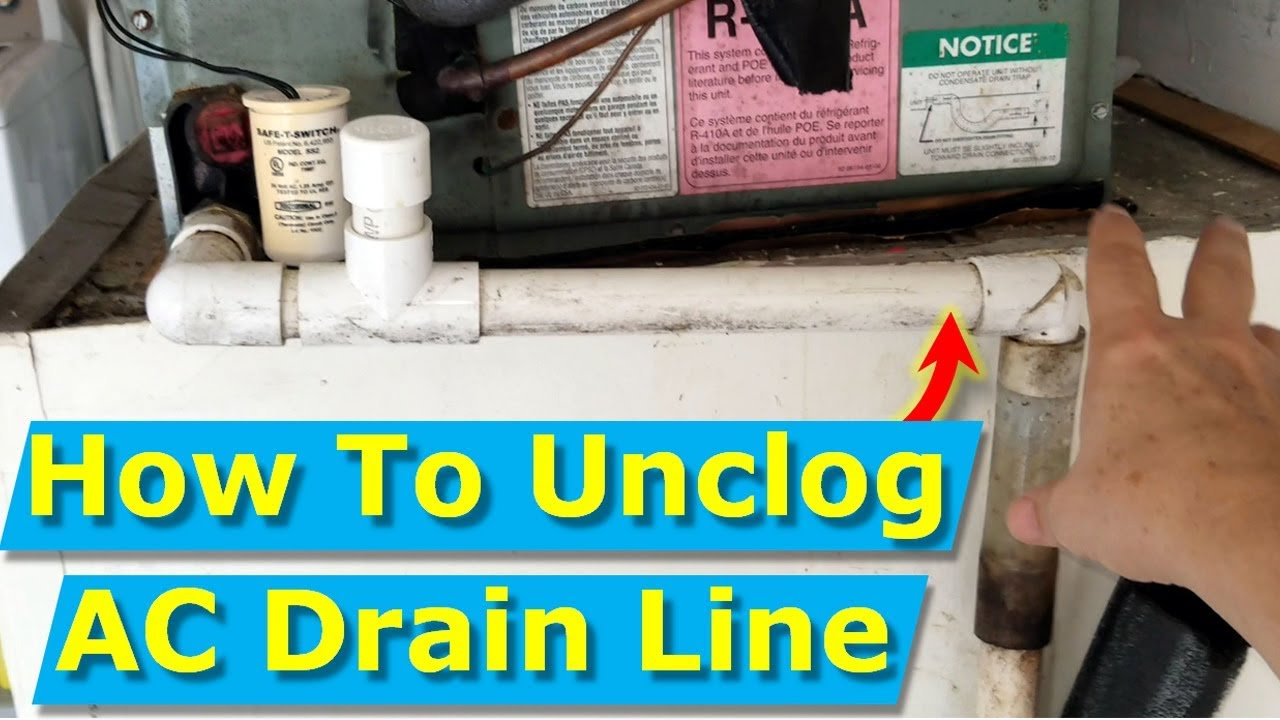

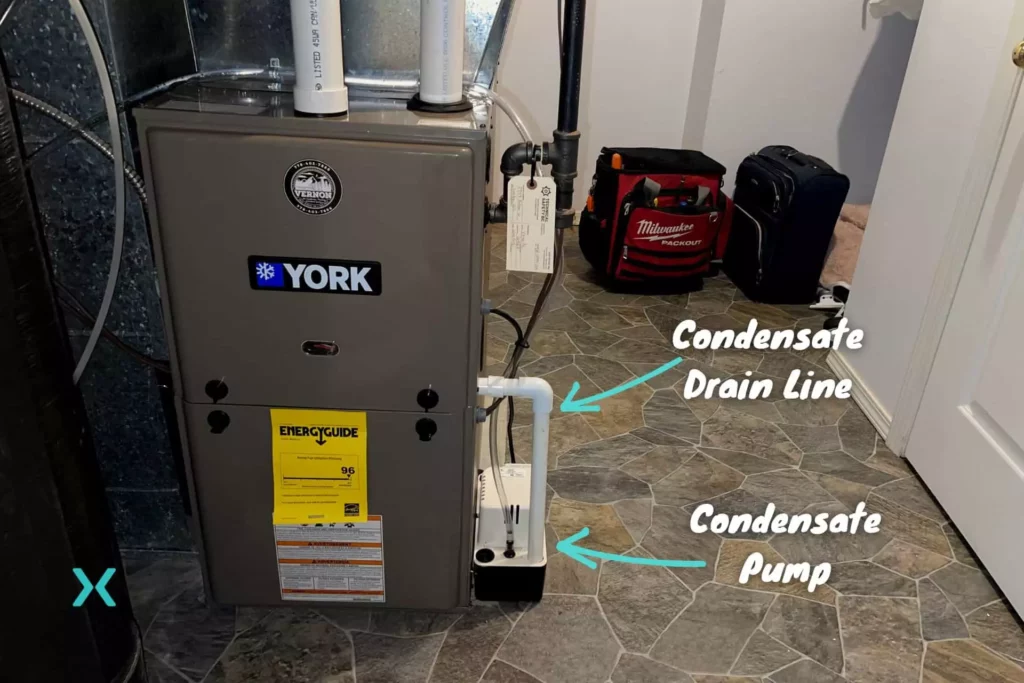

- Locate the Drain Line: The primary drain line typically exits the indoor unit and runs outside. There may also be a secondary drain line.

- Inspect the Drain Pan: Check for standing water and debris. Remove any visible obstructions.

- Vacuum the Drain Line: This is often the most effective first step.

- Attach the wet/dry vacuum to the end of the drain line outside.

- Seal the connection as best as possible with tape or a rag.

- Turn on the vacuum for several minutes. The suction should dislodge the clog.

- Flush the Drain Line: If vacuuming doesn't work, try flushing the line.

- Locate the access point on the drain line (usually a T-fitting).

- Pour a cup of drain line flush (available at HVAC supply stores) or white vinegar into the access point. Vinegar is a natural and effective cleaner.

- Let it sit for 30 minutes to an hour.

- Flush the line with water.

- Use a Brush or Wire: If the clog persists, use a stiff brush or a flexible wire to break it up.

- Insert the brush or wire into the drain line and gently push it through to dislodge the clog.

- Be careful not to puncture or damage the drain line.

- Nitrogen Purge (Advanced Technique): This method should only be attempted by experienced technicians.

- Isolate the drain line.

- Connect a nitrogen tank or CO2 cartridge to the access point.

- Briefly and carefully purge the line with nitrogen or CO2 to dislodge the clog.

- Important: Use low pressure to avoid damaging the drain line.

- Reassemble and Test: After clearing the clog, reassemble any disconnected parts and pour water into the drain pan to ensure proper drainage.

- Preventative Measures: To prevent future clogs:

- Pour a cup of white vinegar into the drain line monthly.

- Clean the drain pan regularly.

- Consider installing a drain line algaecide treatment.

The Importance of Proper HVAC Training and Certification

While clearing a condensate drain line might seem straightforward, understanding the underlying HVAC system and safety protocols is paramount. Formal training programs provide comprehensive knowledge and hands-on experience. Many HVAC technicians start with apprenticeships, gaining on-the-job training under the supervision of experienced professionals.

Key Certifications in HVAC:

- EPA Section 608 Certification: Required for technicians who handle refrigerants. This certification demonstrates competency in refrigerant handling and recovery, preventing harm to the environment. There are different levels of certification (Type I, Type II, Type III, and Universal) depending on the type of equipment the technician works on.

- NATE (North American Technician Excellence): NATE certification is a voluntary credential that demonstrates a technician's knowledge and skills in specific areas of HVAC. NATE certifications are highly valued by employers and customers.

- HVAC Excellence: Another respected certification organization offering a range of certifications for HVAC technicians.

Career Paths and Salary Expectations

The HVAC industry offers diverse career paths, from entry-level technician positions to specialized roles such as system designers, project managers, and energy auditors. With experience and further education, technicians can advance to supervisory or management positions, or even start their own businesses.

According to the U.S. Bureau of Labor Statistics, the median annual wage for HVACR mechanics and installers was $51,390 in May 2021. The job outlook is projected to grow 5 percent from 2021 to 2031, about as fast as the average for all occupations. About 38,300 openings for HVACR mechanics and installers are projected each year, on average, over the decade.

Salaries can vary significantly based on experience, location, certifications, and specialization. Entry-level technicians typically earn less, while experienced technicians with specialized skills and certifications can command higher salaries. For example, a NATE-certified technician specializing in commercial refrigeration in a major metropolitan area can potentially earn upwards of $70,000 or more per year.

Employer Perspectives: Hiring Skilled HVAC Technicians

Employers in the HVAC industry seek skilled technicians who possess a strong understanding of HVAC systems, problem-solving abilities, and a commitment to safety. Key qualities employers look for include:

- Technical Skills: A solid foundation in HVAC principles, including thermodynamics, refrigeration cycles, and electrical systems.

- Troubleshooting Skills: The ability to diagnose and repair HVAC system problems efficiently and effectively.

- Communication Skills: The ability to communicate effectively with customers, colleagues, and supervisors.

- Customer Service Skills: A focus on providing excellent customer service and building positive relationships with clients.

- Certifications: EPA 608 and NATE certifications are highly valued by employers.

- Safety Consciousness: A commitment to following safety protocols and procedures to prevent accidents and injuries.

Employers often provide ongoing training and development opportunities for their technicians to stay up-to-date with the latest technologies and industry best practices. Investing in employee training and certification is crucial for attracting and retaining skilled workers in this competitive industry.

Emerging Trends in the HVAC Industry

The HVAC industry is constantly evolving, with new technologies and trends shaping the future of the profession. Some key trends include:

- Smart HVAC Systems: Increasingly, HVAC systems are being integrated with smart home technology, allowing for remote monitoring and control. Technicians need to be familiar with these systems and their integration with other smart devices.

- Energy Efficiency: There is a growing emphasis on energy-efficient HVAC systems, driven by environmental concerns and rising energy costs. Technicians need to be knowledgeable about energy-efficient technologies and practices.

- Renewable Energy: Geothermal and solar-powered HVAC systems are gaining popularity, creating new opportunities for technicians with expertise in these areas.

- Refrigerant Regulations: Regulations regarding refrigerants are constantly evolving, with a focus on phasing out ozone-depleting substances. Technicians need to stay informed about the latest refrigerant regulations and handle refrigerants responsibly.

Conclusion

Mastering the skill of clearing a clogged condensate drain line is just one piece of the puzzle for a successful HVAC career. Continuing education, staying up-to-date with industry trends, and obtaining relevant certifications are essential for long-term career growth and success. The HVAC industry offers rewarding opportunities for skilled professionals who are dedicated to providing quality service and maintaining comfortable and healthy indoor environments.

Whether you're a student just starting out, an experienced technician looking to advance your career, or an employer seeking to hire top talent, understanding the fundamentals of HVAC systems and the importance of ongoing training and certification is key to success in this dynamic and essential industry.