How To Install A Water Heater Circulating Pump

A water heater circulating pump can significantly reduce water waste and energy consumption, providing hot water on demand and eliminating the frustrating wait (and water waste) while the pipes heat up. This article will guide you through the installation process, highlighting the benefits and considerations for homeowners, businesses, and HVAC professionals alike.

Understanding Water Heater Circulating Pumps

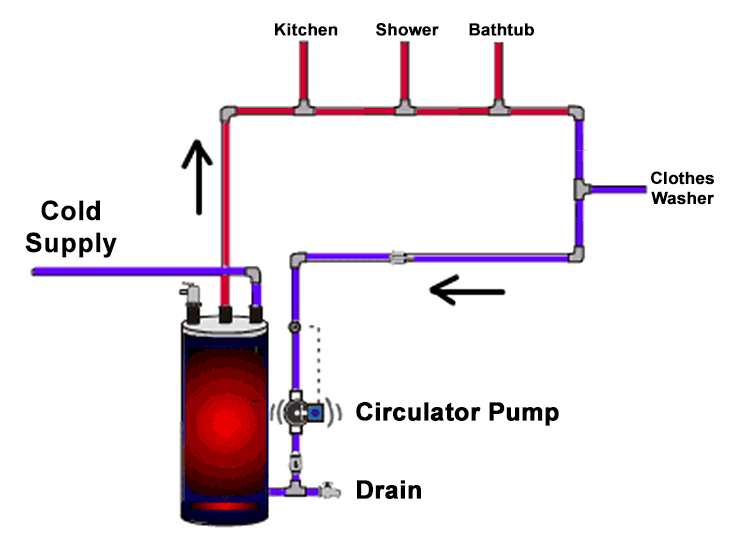

Before diving into the installation, let's understand the technology. A water heater circulating pump, also known as a recirculation pump, actively circulates hot water through your plumbing system. Without a pump, hot water sits stagnant in the pipes, cooling down and requiring you to run the tap until hot water reaches the faucet. A circulating pump ensures hot water is always readily available, leading to considerable savings.

There are two primary types of circulating pumps:

- Dedicated Return Line Systems: These require a dedicated return line running from the furthest fixture back to the water heater. This is the most efficient system, but requires more extensive plumbing.

- Comfort Systems (Under-Sink): These systems use the cold-water line as the return path. They are easier to install in existing homes as they don't require a dedicated return line, using a thermistor valve under the sink to create the loop.

Choosing the Right Pump

Selecting the correct pump size is crucial for optimal performance. Factors to consider include:

- Pipe Length: Longer pipe runs require a more powerful pump.

- Pipe Diameter: Larger diameter pipes need greater flow rates.

- Number of Fixtures: A larger home with more fixtures will need a more robust pump.

Consult the manufacturer's specifications to determine the appropriate pump size for your specific needs. Brands like Grundfos, Taco, and Watts are well-regarded and offer a range of options.

Step-by-Step Installation Guide (Dedicated Return Line System)

This guide focuses on the installation of a dedicated return line system, which offers the highest efficiency. Always consult with a qualified plumber if you are unsure about any aspect of the installation.

Tools and Materials Needed:

- Water heater circulating pump

- Pipe cutter

- Soldering torch and supplies (or compression fittings)

- Copper pipes and fittings (appropriate size for your system)

- Check valve

- Union fittings

- Teflon tape

- Adjustable wrenches

- Screwdrivers

- Drill and appropriate drill bits

- Level

- Wire stripper and connectors

- Multimeter

Installation Steps:

- Safety First: Turn off the power to your water heater at the breaker and shut off the cold-water supply to the tank. Drain a sufficient amount of water from the tank to work comfortably.

- Install the Return Line: Run a dedicated return line from the furthest fixture (typically a bathroom faucet) back to the water heater. This line should be properly insulated to minimize heat loss.

- Prepare the Connections: Clean and deburr the ends of the pipes where you will be making connections. Apply Teflon tape to threaded fittings.

- Install the Check Valve: Install a check valve on the cold water supply line to the water heater to prevent backflow of hot water into the cold water lines. Ensure the arrow on the check valve points in the direction of water flow.

- Install the Pump: Mount the circulating pump near the water heater, following the manufacturer's instructions. Ensure it is level and securely attached.

- Connect the Pump: Connect the pump to the dedicated return line and the water heater's cold water inlet using copper pipes and fittings. Use unions to facilitate future maintenance and repairs. Solder the joints (or use compression fittings) ensuring a watertight seal.

- Wiring: Wire the pump to a power source. Most pumps require a standard 120V connection. Follow local electrical codes and use a qualified electrician if necessary. Consider using a timer or a smart plug to control the pump's operation and further reduce energy consumption.

- Testing: Open the cold-water supply valve and allow the water heater to fill. Check for leaks at all connections. Turn on the power to the water heater and the pump.

- Adjust the Pump Settings: Most circulating pumps have adjustable settings to control the flow rate and temperature. Adjust these settings according to the manufacturer's recommendations and your specific needs.

Step-by-Step Installation Guide (Comfort System - Under-Sink)

These systems are easier to retrofit, using the cold water line as a return. They typically involve installing a thermistor valve under the sink furthest from the water heater.

Tools and Materials Needed:

- Water heater circulating pump

- Thermistor valve kit (included with the pump in comfort systems)

- Adjustable wrenches

- Screwdrivers

- Wire stripper and connectors

- Multimeter

Installation Steps:

- Safety First: Turn off the power to your water heater at the breaker and shut off the cold-water supply to the tank.

- Install the Pump: Mount the circulating pump near the water heater.

- Connect the Pump: Connect the pump to the hot water outlet of the water heater. This usually involves disconnecting the existing pipe and inserting the pump inline.

- Install the Thermistor Valve: Under the sink furthest from the water heater, install the thermistor valve between the hot and cold water supply lines. This valve allows water to circulate through the cold water line when the hot water in the line cools down. Follow the manufacturer's instructions for proper installation.

- Wiring: Wire the pump to a power source.

- Testing: Open the cold-water supply valve and allow the water heater to fill. Check for leaks. Turn on the power to the water heater and the pump.

- Adjust the Pump Settings: Adjust the pump settings as recommended.

Integrating with Smart Home Systems

Water heater circulating pumps can be seamlessly integrated with smart home systems for enhanced control and energy savings. Consider the following:

- Smart Plugs: Use a smart plug to control the pump's operation remotely or schedule it to run only during peak usage times.

- Smart Thermostats: Some smart thermostats can integrate with water heater circulating pumps, optimizing their performance based on occupancy patterns and temperature sensors.

- Flow Sensors: Install flow sensors to monitor water usage and identify potential leaks. This can help you optimize the pump's settings and prevent water waste.

By integrating with smart home systems, you can gain greater control over your water heating system and further reduce energy consumption. Companies like Nest and Ecobee offer smart thermostats that can integrate with some circulating pump systems.

Benefits and ROI

The benefits of installing a water heater circulating pump are numerous:

- Reduced Water Waste: Eliminate the wait for hot water and save gallons of water each year.

- Energy Savings: Reduce the energy required to heat water by minimizing heat loss in the pipes.

- Convenience: Enjoy instant hot water on demand.

- Increased Property Value: Adding energy-efficient features can increase the value of your home or business.

The ROI of a water heater circulating pump can be significant, especially for larger homes or businesses with long pipe runs. The exact payback period will depend on your water usage patterns, energy costs, and the type of pump you install.

Example: A family of four that typically wastes 2 gallons of water per day waiting for hot water can save approximately 730 gallons of water per year. At an average water cost of $0.005 per gallon, this translates to a savings of $3.65 per year on water alone. The energy savings from reduced heat loss can be even more substantial, potentially saving hundreds of dollars per year depending on your energy rates.

Energy Star and Rebates

While there aren't specific *Energy Star* ratings for circulating pumps, choosing an energy-efficient model is crucial. Look for pumps with ECM (electronically commutated motor) technology, which are significantly more efficient than traditional AC motor pumps.

Check with your local utility company for rebates and incentives on energy-efficient water heating equipment. Many utility companies offer rebates on water heater circulating pumps, which can further reduce the upfront cost of installation.

Maintenance and Troubleshooting

Proper maintenance is essential for ensuring the longevity and optimal performance of your water heater circulating pump:

- Regular Inspections: Inspect the pump and connections for leaks or corrosion.

- Cleaning: Clean the pump and impeller regularly to remove debris and prevent clogs.

- Lubrication: Lubricate the pump motor according to the manufacturer's recommendations.

Common troubleshooting issues include:

- Pump Not Running: Check the power supply, wiring, and pump motor.

- Low Flow: Check for clogs in the pump or pipes.

- Excessive Noise: Check for air in the system or a worn-out pump motor.

Conclusion

Installing a water heater circulating pump is a worthwhile investment that can save you money, reduce water waste, and provide the convenience of instant hot water. By following the steps outlined in this guide and consulting with a qualified plumber when necessary, you can successfully install a circulating pump and enjoy its many benefits.

:max_bytes(150000):strip_icc()/hot-water-recirculation-pump-installation-2719056-11-39e2fa5d0f0e488daf67337cd010eb5e.jpg)