How To Loosen A Pipe Fitting

Frequently Asked Questions: Loosening Pipe Fittings

Dealing with stubborn pipe fittings can be frustrating. This FAQ addresses common questions and provides practical guidance on how to loosen them effectively and safely.

Question 1: Why are my pipe fittings so hard to loosen?

Several factors can contribute to a pipe fitting's stubbornness. The most common reasons include:

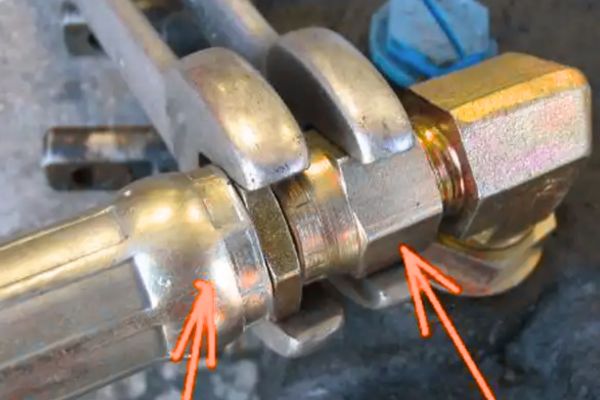

- Corrosion: Over time, especially with water pipes, corrosion builds up on the threads, essentially gluing the fitting in place. This is particularly true with dissimilar metals where galvanic corrosion can accelerate the process.

- Thread Sealant: Pipe dope or Teflon tape, while designed to create a watertight seal, can harden over time, making it difficult to break the initial bond.

- Mineral Deposits: Hard water leaves behind mineral deposits like calcium and magnesium, which can accumulate in the threads and solidify.

- Over-tightening: Previous installation might have involved excessive force, causing the threads to bind tightly.

- Age: Older pipes and fittings are naturally more prone to being stuck due to years of exposure to the elements and potential internal build-up.

Question 2: What tools do I need to loosen a stubborn pipe fitting?

Having the right tools significantly increases your chances of success without damaging the pipes or fittings. Here's a list of essentials:

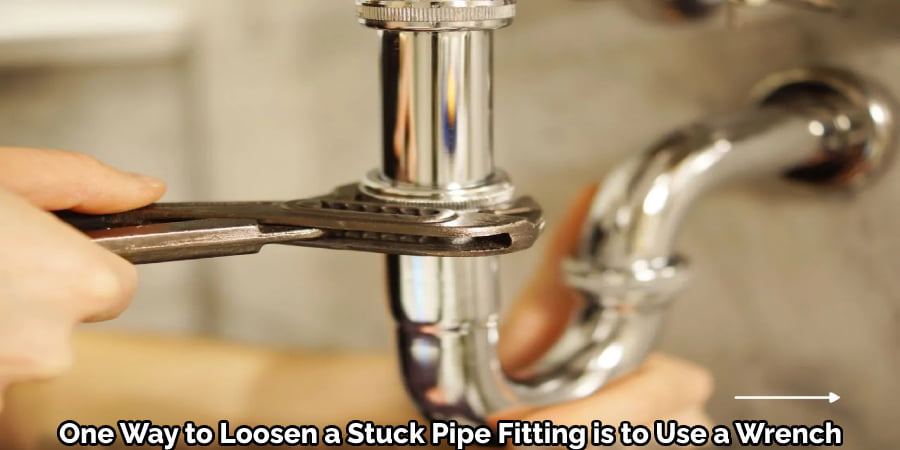

- Pipe Wrenches: These are the primary tools for gripping and turning pipes. You'll likely need two – one to hold the pipe steady and another to turn the fitting. Different sizes might be required depending on the pipe diameter.

- Penetrating Oil: A good quality penetrating oil, like WD-40, Liquid Wrench, or PB Blaster, is crucial for dissolving corrosion and loosening the threads.

- Heat Gun or Torch (with caution): Applying heat can expand the metal, breaking the bond caused by corrosion and sealant. A heat gun is generally safer than a torch, but both should be used with extreme care to avoid fire hazards.

- Propane Torch (use with extreme caution and only if necessary): Direct flame can weaken or melt PVC pipes or ignite flammable materials. Only use a torch on metal fittings, and always have a fire extinguisher nearby.

- Hammer: A hammer, used in conjunction with a pipe wrench, can provide a jarring force to help break the fitting loose.

- Safety Glasses: Protect your eyes from flying debris and splashes.

- Gloves: Protect your hands and improve your grip.

- Wire Brush: Use a wire brush to remove loose rust and debris before applying penetrating oil.

- Basin Wrench (for faucet connections): This specialized wrench is designed for loosening nuts and fittings in hard-to-reach places under sinks and behind toilets.

- Adjustable Wrench: An adjustable wrench can be helpful for smaller fittings or situations where a pipe wrench is too large.

Question 3: What's the best technique for loosening a pipe fitting?

The best approach involves a combination of techniques, applied systematically:

- Preparation: Clean the area around the fitting with a wire brush to remove any loose rust or debris. This allows the penetrating oil to reach the threads more effectively.

- Apply Penetrating Oil: Liberally apply penetrating oil to the threads where the fitting connects to the pipe. Allow the oil to soak for at least 15-30 minutes, or even longer for heavily corroded fittings. Reapply the oil periodically during the soaking period.

- Secure the Pipe: Use one pipe wrench to firmly grip the pipe near the fitting you're trying to loosen. This prevents the pipe from twisting and potentially damaging other connections. Make sure the wrench is securely positioned to avoid slipping.

- Apply Torque: Use the second pipe wrench to grip the fitting. Apply steady, even pressure in the direction you want to loosen it. Avoid jerking or sudden movements, as this can damage the fitting or pipe.

- Tapping (If Needed): If the fitting remains stuck, gently tap the fitting with a hammer while applying pressure with the wrench. The vibrations can help break the bond. Don't hit the fitting too hard, as this could damage it.

- Heat (Use with Extreme Caution): If the fitting is still stuck, carefully apply heat to the fitting using a heat gun. Move the heat gun around the fitting to heat it evenly. Avoid overheating, especially with plastic pipes. If using a propane torch on metal, apply heat sparingly and focus on the fitting itself, not the surrounding pipes or structures. Be extremely cautious about fire hazards.

- Repeat and Persist: Continue applying penetrating oil, pressure, tapping, and heat (if used) until the fitting begins to loosen. Be patient and persistent.

- Check for Damage: Once the fitting is loose, inspect the threads for any damage. If the threads are severely damaged, you may need to replace the pipe or fitting.

Question 4: What if I can't loosen the fitting, even after trying everything?

Sometimes, despite your best efforts, a fitting simply won't budge. In such cases, consider these options:

- Call a Professional Plumber: A plumber has specialized tools and expertise to handle particularly stubborn fittings. They can also assess the overall condition of your plumbing system and identify any potential problems.

- Cut the Pipe: If the fitting is completely seized, you may need to cut the pipe on either side of the fitting and replace that section of pipe and the fitting. This is often the most practical solution for severely corroded fittings. Remember to turn off the water supply before cutting any pipes.

- Consider Alternatives: Depending on the situation, there might be alternative solutions that avoid disturbing the fitting altogether. For example, if you're trying to replace a faucet, you might be able to access the connections from a different location.

Question 5: Are there any specific precautions I should take when loosening pipe fittings?

Safety is paramount when working with pipes and fittings. Here are some crucial precautions:

- Turn off the Water Supply: Before working on any water pipes, always turn off the water supply to the affected area. This prevents flooding and water damage. Locate the main water shut-off valve for your house and make sure you know how to use it.

- Wear Safety Glasses: Protect your eyes from flying debris, splashes of penetrating oil, and potential injuries.

- Wear Gloves: Gloves provide a better grip and protect your hands from sharp edges, hot surfaces, and chemicals.

- Ventilation: Work in a well-ventilated area, especially when using penetrating oils or heat.

- Fire Safety: If using a heat gun or torch, be extremely cautious about fire hazards. Keep a fire extinguisher nearby and be aware of any flammable materials in the area. Never use a torch near flammable liquids or gases.

- Don't Over-Tighten: When reassembling fittings, avoid over-tightening. Over-tightening can damage the threads and make it even more difficult to loosen the fitting in the future. Use Teflon tape or pipe dope to create a watertight seal.

- Support the Pipe: When applying torque, make sure the pipe is adequately supported to prevent it from bending or breaking. Use a pipe wrench to hold the pipe steady while you turn the fitting.

- Inspect for Leaks: After reassembling the fitting, turn the water supply back on slowly and check for leaks. Tighten the fitting further if necessary, but avoid over-tightening.

- Know your limitations: If the task seems too difficult or dangerous, don't hesitate to call a professional plumber. It's better to be safe than sorry.

Question 6: How can I prevent pipe fittings from getting stuck in the future?

Preventative measures can significantly reduce the likelihood of future problems with stuck pipe fittings:

- Use Teflon Tape or Pipe Dope: Always use Teflon tape or pipe dope on the threads when installing new fittings. This helps create a watertight seal and prevents the threads from seizing up.

- Avoid Mixing Dissimilar Metals: When possible, use fittings made of the same metal as the pipes they are connecting to. This reduces the risk of galvanic corrosion.

- Apply Anti-Seize Compound: Consider applying a thin layer of anti-seize compound to the threads, especially on fittings that are likely to be exposed to moisture or corrosive environments.

- Don't Over-Tighten: Tighten fittings securely, but avoid over-tightening. Over-tightening can damage the threads and make it more difficult to loosen the fitting in the future.

- Regular Inspection: Periodically inspect your plumbing system for signs of corrosion or leaks. Address any problems promptly to prevent them from escalating.

- Use Dielectric Unions: When connecting dissimilar metals is unavoidable, use dielectric unions to isolate the metals and prevent galvanic corrosion.

- Water Softener: If you have hard water, consider installing a water softener to reduce mineral buildup in your pipes and fittings.

Question 7: What are the specific challenges when dealing with plastic (PVC or CPVC) pipe fittings?

Plastic pipe fittings require a slightly different approach compared to metal fittings:

- Avoid Excessive Heat: Never use a torch on plastic pipes. Excessive heat can melt or weaken the plastic, leading to leaks or failure. Use a heat gun on the lowest setting if absolutely necessary, and even then, exercise extreme caution.

- Use Plastic-Specific Wrenches: Using metal pipe wrenches on plastic fittings can damage or crush them. Consider using plastic strap wrenches or specialized PVC wrenches that are designed to grip plastic without causing damage.

- Solvent Cement: PVC and CPVC pipes are joined with solvent cement, which essentially welds the fitting to the pipe. Loosening a fitting joined with solvent cement is usually not possible without cutting the pipe.

- Support is Crucial: When working with plastic pipes, proper support is essential to prevent them from bending or breaking. Use pipe clamps or other supports to hold the pipe steady while you're applying pressure to the fitting.

- Avoid Over-Tightening: Overtightening threaded plastic fittings can easily crack or strip the threads. Tighten the fitting until it is snug, but avoid applying excessive force.

- Cutting is Often Necessary: In many cases, the easiest and safest way to remove a plastic fitting is to cut the pipe and replace the fitting and a section of pipe.

- Proper Glue Selection: Always use the correct type of solvent cement for the type of plastic pipe you are working with (PVC or CPVC). Using the wrong glue can result in a weak or unreliable joint.