How To Lube Furnace Blower Motor

Maintaining your furnace is crucial for efficient heating and long-term reliability. While professional servicing is recommended, some tasks, like lubricating the blower motor, can be performed independently. This guide provides detailed instructions for homeowners, HVAC technicians, and facility managers on lubricating different types of furnace blower motors.

Understanding Furnace Blower Motors

The blower motor is the heart of your furnace's air circulation system. It pushes heated air through your ductwork and into your living spaces. Proper lubrication ensures smooth operation, reduces friction, prevents overheating, and extends the motor's lifespan. Neglecting lubrication can lead to increased energy consumption, noisy operation, and eventually, motor failure, requiring costly replacement.

Before you begin, identify the type of blower motor in your furnace. There are primarily two types:

- Sleeve Bearing Motors: These motors have oil ports (often covered with caps) for lubrication. They are typically found in older furnaces.

- Ball Bearing Motors: These motors are typically sealed and don't require regular oiling. However, some may have accessible bearings that can be lubricated.

If you're unsure about the type of motor in your furnace, consult your furnace's manual or contact an HVAC professional. Always disconnect the power to the furnace before performing any maintenance.

Tools and Materials Needed

Before starting, gather the necessary tools and materials:

- Screwdrivers (various sizes): For removing access panels and motor mounts.

- Nut drivers or wrenches: For loosening bolts.

- Oil: Use a lightweight, non-detergent electric motor oil, specifically designed for HVAC blower motors (SAE 20 or similar). Avoid using all-purpose oils, as they can damage the motor.

- Oil pump or squirt bottle: For applying oil to the bearings.

- Clean rags: For wiping up spills.

- Flashlight or work light: For better visibility.

- Safety glasses: To protect your eyes.

- Gloves: To protect your hands.

- Furnace manual: For specific instructions related to your model.

Step-by-Step Guide: Lubricating Sleeve Bearing Motors

This section outlines the process for lubricating sleeve bearing motors. Remember to always prioritize safety and consult your furnace's manual for specific instructions related to your model.

Step 1: Disconnect the Power

Turn off the furnace at the thermostat. Then, locate the circuit breaker for the furnace and switch it off. This is a crucial safety precaution to prevent electrical shock.

Step 2: Access the Blower Compartment

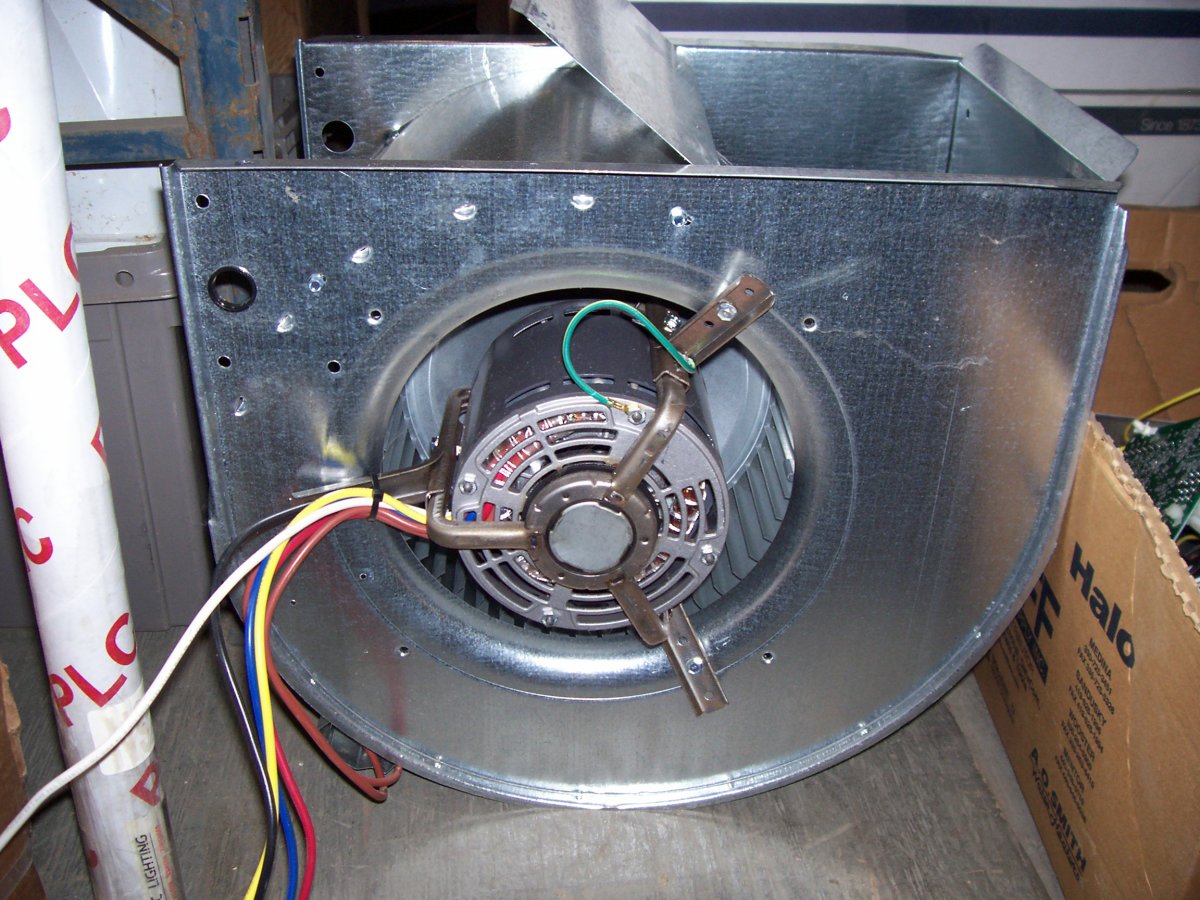

Remove the access panel to the blower compartment. This panel is usually held in place by screws or clips. Refer to your furnace's manual for the exact location and removal procedure.

Step 3: Locate the Blower Motor

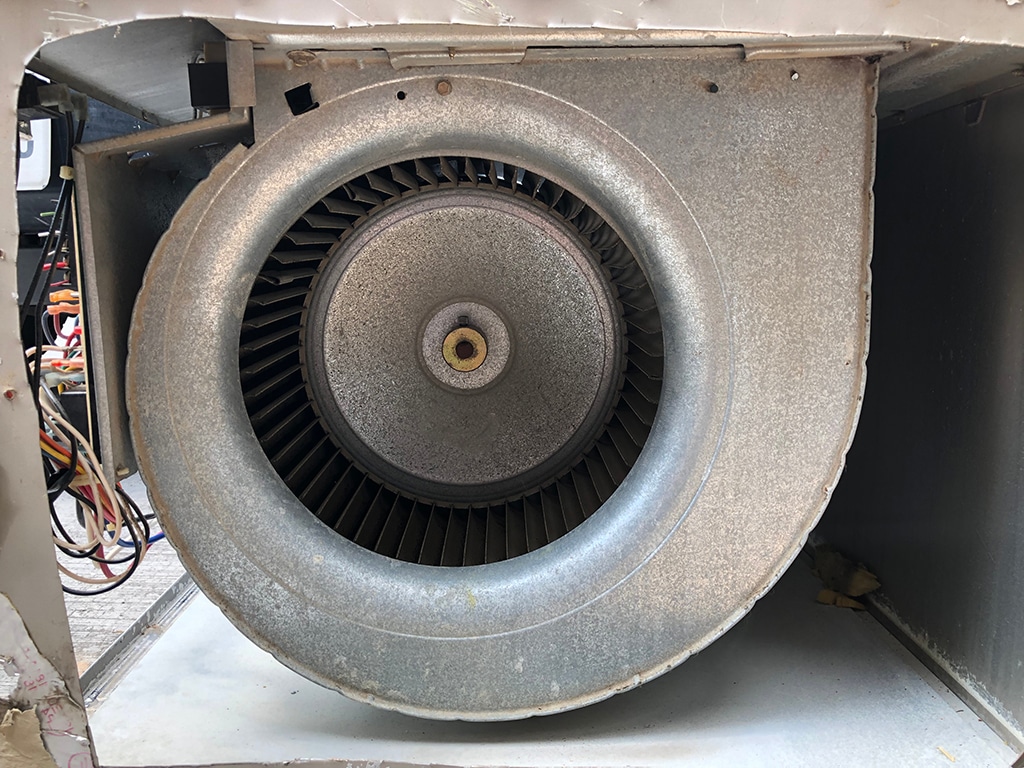

The blower motor is typically located inside the blower compartment, attached to the blower wheel (fan). Identify the motor and its oil ports. These ports are usually small holes covered with caps or plugs, often labeled "OIL."

Step 4: Prepare the Oiling Points

Remove the caps or plugs covering the oil ports. Clean the area around the ports with a clean rag to remove any dirt or debris. If the ports are clogged, use a small wire or pin to carefully clear the obstruction.

Step 5: Apply the Oil

Using the oil pump or squirt bottle, carefully apply a few drops of oil (typically 2-3 drops) into each oil port. Avoid over-oiling, as this can attract dust and dirt, which can eventually damage the motor. Less is more in this case.

Step 6: Reassemble and Test

Replace the caps or plugs on the oil ports. Reinstall the access panel to the blower compartment, securing it with the screws or clips. Turn the circuit breaker back on and switch on the thermostat. Observe the furnace as it starts up, listening for any unusual noises. If the motor runs smoothly and quietly, you have successfully lubricated it.

Step-by-Step Guide: Lubricating Ball Bearing Motors (If Applicable)

Many ball bearing motors are sealed and don't require lubrication. However, some models may have accessible bearings that can be lubricated. Follow these steps only if your ball bearing motor has lubrication points.

Step 1: Disconnect the Power

Same as with sleeve bearing motors, disconnect the power to the furnace by turning off the circuit breaker.

Step 2: Access the Blower Compartment

Remove the access panel to the blower compartment, following the instructions in your furnace's manual.

Step 3: Locate the Blower Motor and Bearings

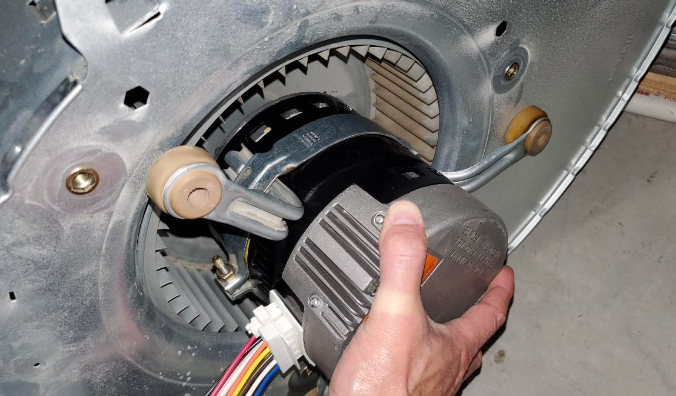

Locate the blower motor and examine it for accessible bearings. These bearings may be located at the ends of the motor shaft, near the blower wheel and at the opposite end. They may be visible or partially covered by shields.

Step 4: Clean the Bearings

Carefully clean the area around the bearings with a clean rag to remove any dirt or debris. Use a small brush to remove stubborn dirt.

Step 5: Apply the Oil

Using the oil pump or squirt bottle, carefully apply a small amount of oil (1-2 drops) to each bearing. Avoid over-oiling. Rotate the motor shaft by hand to distribute the oil evenly.

Step 6: Reassemble and Test

Reinstall the access panel to the blower compartment. Turn the circuit breaker back on and switch on the thermostat. Observe the furnace as it starts up, listening for any unusual noises.

Troubleshooting

Here are some common issues you might encounter and how to address them:

- Motor is still noisy after lubrication: The motor bearings may be worn and require replacement. Contact an HVAC professional.

- Oil ports are clogged: Use a small wire or pin to carefully clear the obstruction.

- Motor is overheating: This could be a sign of a more serious problem, such as a faulty capacitor or winding failure. Contact an HVAC professional.

- Cannot find oil ports: Your motor might be a sealed unit that doesn't require lubrication. Consult your furnace's manual.

Maintenance Schedule and Best Practices

Regular maintenance is key to keeping your furnace running efficiently. Here are some best practices:

- Lubricate sleeve bearing motors annually: At the start of each heating season.

- Inspect and clean the blower compartment regularly: Remove any dust or debris that can accumulate.

- Replace the furnace filter regularly: Clogged filters restrict airflow and can cause the motor to overheat. Changing the filter can greatly affect system performance, by allowing proper airflow.

- Schedule professional servicing annually: An HVAC technician can perform a comprehensive inspection and tune-up.

Cost Considerations

The cost of lubricating a furnace blower motor is relatively low. The cost of the oil is minimal, and the labor is free if you do it yourself. However, neglecting lubrication can lead to motor failure, which can cost several hundred dollars to replace. Professional servicing, which includes lubrication, typically costs between $100 and $300, depending on the services included.

Efficiency and Lifespan

Properly lubricating your furnace blower motor improves its efficiency, reducing energy consumption and lowering your heating bills. It also extends the motor's lifespan, preventing premature failure. A well-maintained motor can last for 10-15 years or even longer.

Variable Speed Blowers

Modern furnaces often employ variable speed blowers with ECM (Electronically Commutated Motor) technology. These are designed for optimal efficiency and airflow control. While generally requiring less maintenance, check the manufacturer's specifications. Most ECM motors are sealed and shouldn't be oiled. Consult a qualified technician if you suspect any issue with an ECM blower.

Conclusion

Lubricating your furnace blower motor is a simple but important maintenance task that can save you money and extend the life of your furnace. By following these instructions and prioritizing safety, you can keep your furnace running smoothly and efficiently for years to come.