How To Vacuum An Air Conditioning System

Many homeowners experience the frustration of an air conditioning system that's not cooling effectively. Often, this isn't due to a complete system failure, but rather a loss of refrigerant or the presence of non-condensables (like air or moisture) within the sealed system. These contaminants seriously hamper the A/C unit's performance and can lead to component damage over time. While some A/C repairs require specialized knowledge and tools, understanding the importance of a proper vacuum and knowing when to call a professional can save you money and headaches.

Understanding the Need for a Vacuum

Before refrigerant can be added to an A/C system, it *must* be properly evacuated – that is, vacuumed down. This process removes air, moisture, and other non-condensables that can:

- Reduce cooling efficiency: Air and moisture displace refrigerant, lowering the system's capacity.

- Cause corrosion: Moisture reacts with refrigerant and oil, creating acids that corrode internal components.

- Lead to compressor failure: Contaminants can damage the compressor, the heart of your A/C system.

- Raise head pressure: Higher head pressure makes the system work harder and less efficiently

Think of it like this: you wouldn't try to fill a water bottle with air still inside, right? The same principle applies to your A/C system. A deep vacuum ensures a clean and efficient refrigerant charge.

Is Vacuuming My A/C System a DIY Project?

Important Safety Note: Working with refrigerants requires proper training and certification (EPA 608 certification). Improper handling can be harmful to yourself and the environment. This guide focuses on diagnosing potential issues and understanding the process, *not* on performing refrigerant work without proper credentials. If you suspect a refrigerant leak or low refrigerant levels, consult with a licensed HVAC technician.

While *adding* refrigerant is best left to the professionals, understanding the vacuuming process and identifying signs that it might be necessary can empower you to communicate effectively with your technician and make informed decisions.

Common Symptoms Suggesting a Possible Vacuum Issue:

- Poor Cooling Performance: Your A/C isn't cooling as well as it used to, even on moderately hot days.

- Longer Cooling Cycles: The unit runs for extended periods to reach the desired temperature.

- Ice Formation on Refrigerant Lines: This indicates a possible restriction or low refrigerant charge, often exacerbated by the presence of moisture.

- High Energy Bills: An inefficient system consumes more energy, leading to increased costs.

- Hissing Sounds: A hissing sound near the outdoor unit could indicate a refrigerant leak, which requires immediate attention.

DIY Diagnostic Steps (Before Calling a Pro)

Before jumping to the conclusion that your system needs a vacuum, perform these simple checks:

- Check the Air Filter: A dirty air filter restricts airflow, reducing cooling efficiency. Replace it regularly (every 1-3 months).

- Clean the Outdoor Unit: Debris like leaves, grass clippings, and dirt can block airflow around the condenser coils. Gently clean the fins with a hose (use a low-pressure nozzle) and a soft brush. Turn off the power to the unit at the breaker before cleaning.

- Inspect the Condensate Drain Line: A clogged drain line can cause water to back up, triggering a safety switch that shuts down the system. Locate the drain line (usually a PVC pipe near the indoor unit) and clear any clogs. A wet/dry vacuum can be helpful for this task.

- Check for Obvious Leaks: Visually inspect the refrigerant lines (copper pipes) for any signs of oil residue. Oil stains indicate a potential refrigerant leak.

If these simple checks don't resolve the issue, it's time to call a qualified HVAC technician.

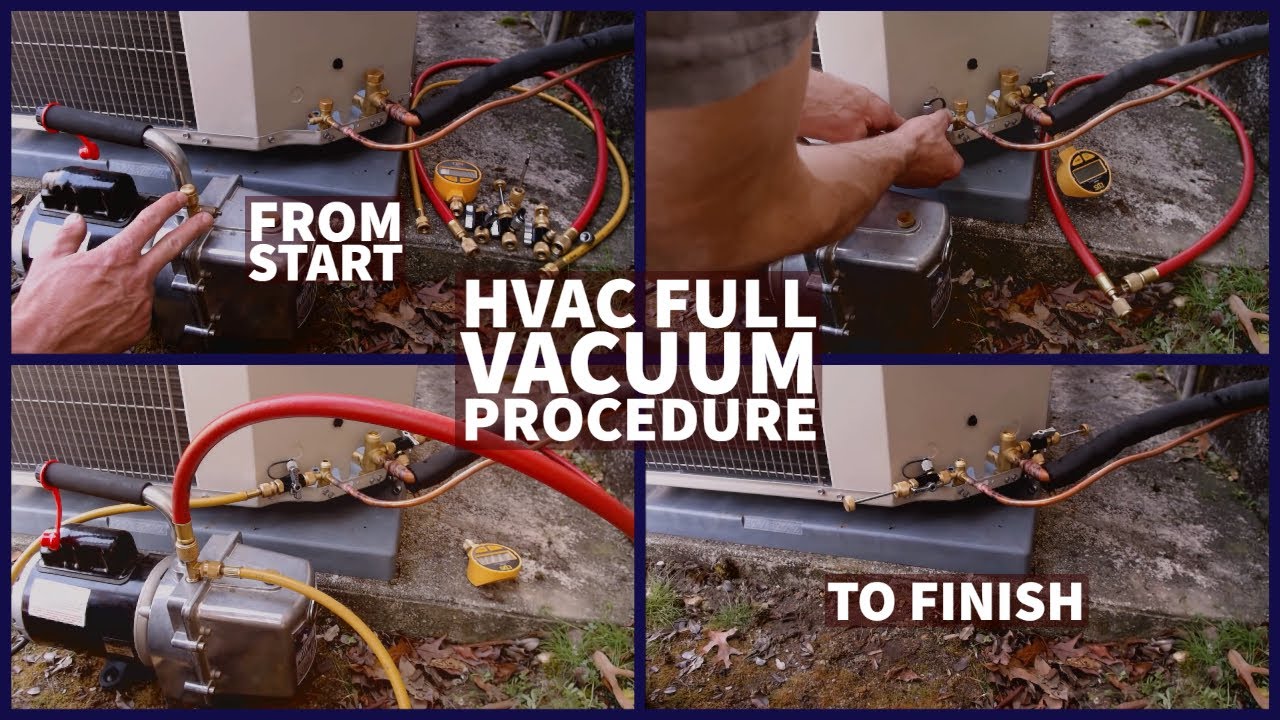

The Professional Vacuuming Process: A Step-by-Step Overview (So You Know What to Expect)

While you won't be performing this yourself, understanding the process will help you communicate with your technician and assess the quality of their work.

- Safety First: The technician will wear appropriate safety gear, including gloves and eye protection. They'll also ensure the work area is well-ventilated.

- Refrigerant Recovery (If Necessary): If the system contains refrigerant, the technician will use a specialized recovery machine to safely remove and store it according to EPA regulations. This step is crucial for environmental protection and is required by law.

- Leak Repair (If Necessary): If a leak is detected, the technician will repair it before proceeding with the vacuum. Ignoring a leak will render the vacuum process ineffective. Common repair methods include brazing (welding) or replacing damaged components.

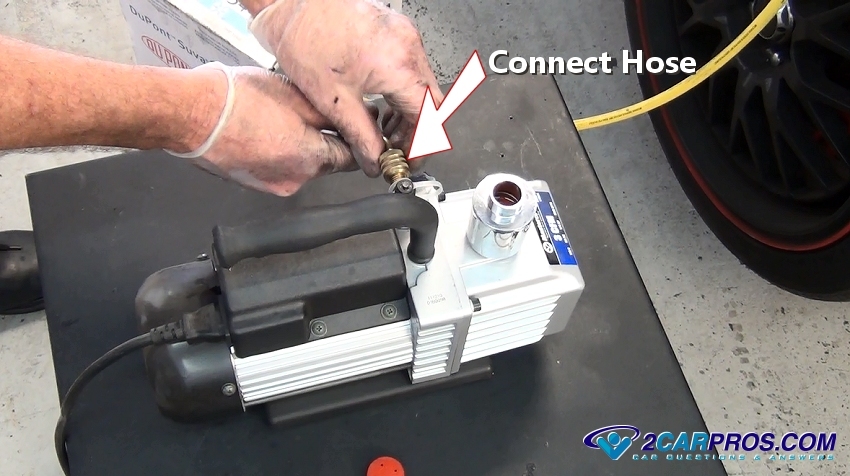

- Connecting the Vacuum Pump: The technician will connect a vacuum pump to the system's service ports (typically located on the outdoor unit). These ports provide access to the refrigerant lines.

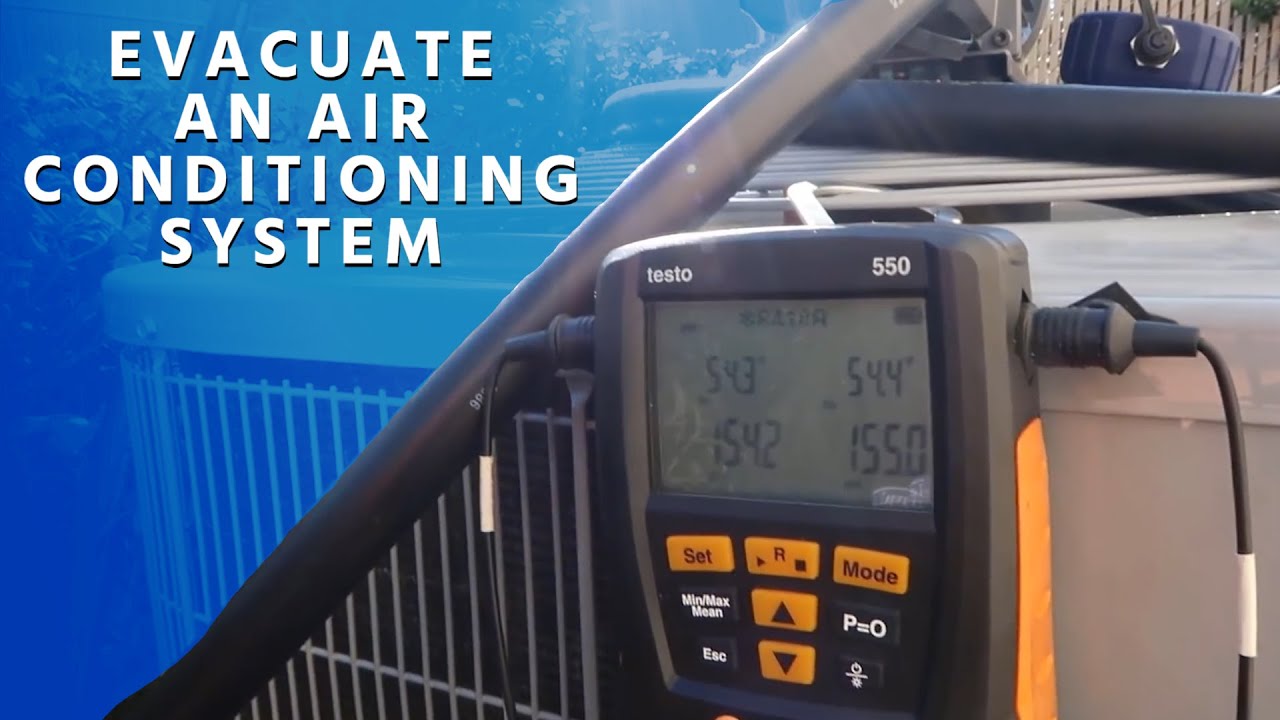

- Using a Micron Gauge: A micron gauge (also called a vacuum gauge) is a highly sensitive instrument that measures the vacuum level in microns (a unit of pressure). This is *essential* for achieving a proper vacuum. Simply running a vacuum pump for a certain amount of time isn't sufficient; the micron level must reach a specific target.

- Pulling a Vacuum: The vacuum pump will run, removing air, moisture, and other non-condensables from the system. The technician will monitor the micron gauge to track the progress. The target micron level typically falls between 500 and 250 microns, depending on the system manufacturer's recommendations.

- Standing Vacuum Test: Once the target micron level is reached, the technician will *stop* the vacuum pump and monitor the micron gauge for a period of time (typically 15-30 minutes). This is called a "standing vacuum test." If the micron level rises significantly during this test, it indicates a remaining leak or the presence of trapped moisture. This step is critical for ensuring a properly sealed and evacuated system. If the pressure rises above an acceptable level, they will re-evacuate the system and re-perform the test.

- Refrigerant Charging: Once the vacuum test is successful, the technician will carefully charge the system with the correct amount of refrigerant, as specified by the manufacturer. They will use precise weighing scales or other measuring devices to ensure accurate charging.

- System Testing: After charging, the technician will test the system's performance to ensure it's cooling effectively and operating within normal parameters. They will check pressures, temperatures, and airflow to verify proper operation.

Key Indicators of a Quality Vacuuming Job

Here's what to look for to ensure your technician is performing a thorough and professional vacuum:

- Use of a Micron Gauge: This is non-negotiable. A technician who doesn't use a micron gauge is not performing a proper vacuum.

- Standing Vacuum Test: The technician *must* perform a standing vacuum test to verify the integrity of the system.

- Proper Refrigerant Recovery: Ensure the technician uses a refrigerant recovery machine to safely remove any existing refrigerant before starting the vacuum process.

- Attention to Detail: Look for a technician who is methodical, pays attention to detail, and follows proper procedures.

- Clear Communication: The technician should be able to explain the process clearly and answer your questions thoroughly.

The Importance of a Good Vacuum Pump

The quality of the vacuum pump used also plays a crucial role in the effectiveness of the evacuation process. A high-quality, two-stage vacuum pump is essential for achieving the deep vacuum required to remove moisture and other contaminants. Ask your technician about the type of vacuum pump they use.

Common Mistakes to Avoid

Even experienced technicians can make mistakes during the vacuuming process. Here are some common pitfalls to watch out for:

- Using a Manifold Gauge Set Alone: Manifold gauges are useful for measuring pressures, but they are not accurate enough to measure the deep vacuum required for proper evacuation. A micron gauge is *essential*.

- Skipping the Standing Vacuum Test: This is a critical step that is often overlooked.

- Using Dirty or Contaminated Vacuum Pump Oil: Dirty oil can introduce contaminants into the system. The technician should use clean, fresh vacuum pump oil.

- Not Properly Sealing Connections: Leaks in the connections between the vacuum pump, micron gauge, and system can compromise the vacuum.

- Using Incorrect Hoses: Using incorrect or damaged hoses can restrict airflow and reduce the effectiveness of the vacuum pump.

When to Call a Professional (Reiterated)

If you suspect a refrigerant leak, lack the necessary tools and knowledge, or are uncomfortable working with refrigerants, it's always best to call a licensed HVAC technician. Attempting to perform refrigerant work without proper training and certification can be dangerous and illegal.

This article provides a general overview of the vacuuming process. Specific procedures may vary depending on the type of A/C system and the manufacturer's recommendations.

Preventative Maintenance: The Best Defense

Regular preventative maintenance is the best way to avoid problems with your A/C system. Schedule annual checkups with a qualified HVAC technician. They can inspect your system for leaks, check refrigerant levels, clean coils, and perform other maintenance tasks to keep your system running efficiently.

By understanding the importance of a proper vacuum and following these guidelines, you can ensure your A/C system operates efficiently and reliably for years to come.