Johnson Controls Model Number Nomenclature

Frequently Asked Questions: Understanding Johnson Controls Model Numbers

Johnson Controls uses a specific system to identify their various products. Decoding these model numbers can provide valuable information about the type of equipment, its capabilities, and its specifications. This FAQ aims to demystify the Johnson Controls model number nomenclature, helping you understand the equipment you have or are considering.

Q1: What is a model number, and why is it important to understand it for Johnson Controls equipment?

A model number is a unique identifier assigned to a specific product manufactured by a company, in this case, Johnson Controls. It's like a serial number, but more structured. Understanding the model number is crucial for several reasons:

- Identification: It allows you to precisely identify the exact model of your Johnson Controls equipment.

- Maintenance & Repair: When ordering replacement parts or seeking technical support, providing the correct model number ensures you get the right components and assistance.

- Documentation: The model number is essential for accessing the correct product manuals, wiring diagrams, and other documentation specific to your equipment.

- Compatibility: Knowing the model number helps determine compatibility with other systems or accessories.

- Performance Characteristics: Often, parts of the model number reveal key performance characteristics of the equipment.

In essence, the model number is the key to unlocking all the information you need about your Johnson Controls equipment.

Q2: Are there general patterns or structures used in Johnson Controls model numbers? What do the different parts usually signify?

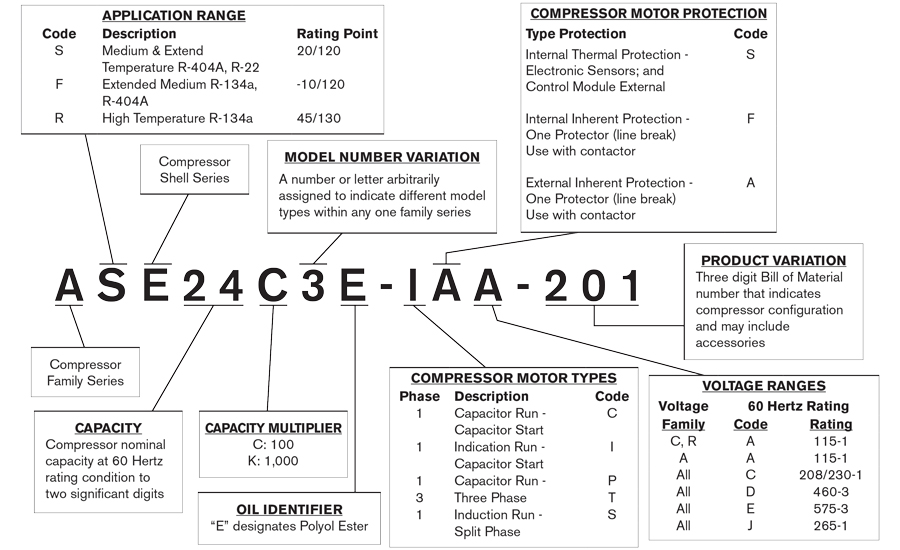

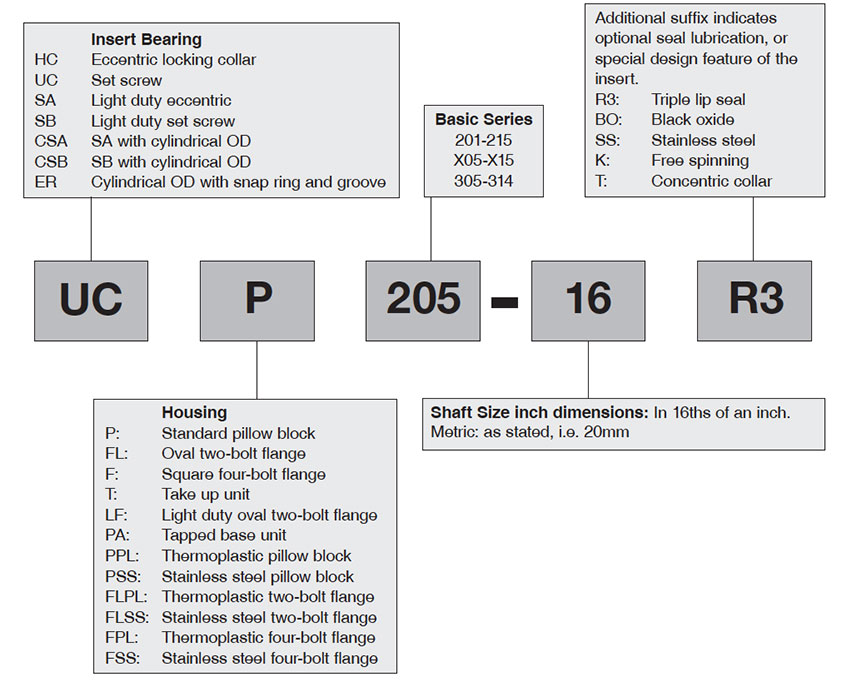

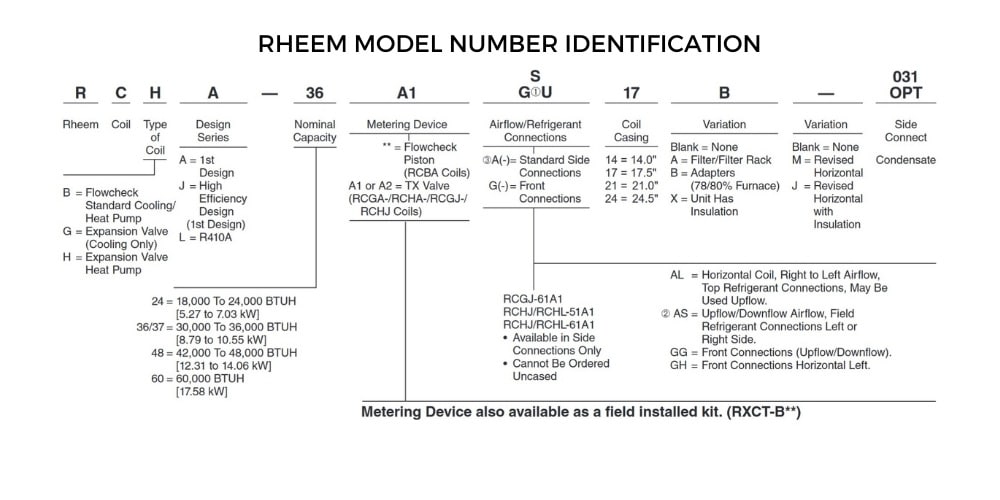

Yes, while the specifics can vary depending on the product type (e.g., HVAC controllers, valves, sensors), Johnson Controls model numbers generally follow a structured pattern. They usually consist of alphanumeric characters that represent different attributes of the equipment. Although it can be complex, here's a general breakdown:

- Prefix (Letters): Typically indicates the product family or type. For example, 'V' might stand for valve, 'TC' for temperature controller, or 'DX' for a specific type of air handling unit. Different prefixes identify the overall category of device.

- Series/Generation (Numbers): Often indicates the series or generation of the product. Higher numbers usually indicate more recent models with potentially enhanced features or performance. The numbers also separate different types of equipment within the same product line.

- Size/Capacity (Numbers): Represents the size, capacity, or flow rate of the equipment. For valves, it might indicate pipe size. For controllers, it could relate to the number of inputs/outputs it supports.

- Features/Options (Letters & Numbers): Indicates specific features, options, or variations of the base model. This could include the type of sensor used, the communication protocol supported (e.g., BACnet, Modbus), or any special modifications.

- Voltage/Power (Numbers): Designates the operating voltage or power requirements of the equipment. This is especially important for electrical components.

- Revision/Suffix (Letters & Numbers): Often a suffix indicating a specific revision or modification to the original design. This is crucial for ensuring compatibility and ordering the correct replacement parts.

Example: A hypothetical model number like 'TC-520-B2-24' might break down as follows:

- 'TC' - Temperature Controller

- '520' - Series 520

- 'B2' - Specific Feature Set (e.g., with BACnet communication)

- '24' - 24V operating voltage

Important Note: This is a simplified example. The actual structure and meaning of each character can vary considerably depending on the specific product line. Refer to the Johnson Controls documentation for a complete breakdown of the model number for your specific equipment.

Q3: Where can I find the model number on my Johnson Controls equipment?

The model number is usually printed on a label or nameplate attached directly to the equipment. The location can vary, but here are some common places to check:

- HVAC Controllers: On the front, side, or back of the controller housing.

- Valves: On the valve body itself, often near the actuator.

- Sensors: On the sensor housing or mounting plate.

- Actuators: On the actuator body.

- Air Handling Units: On the unit casing, often near the access panel.

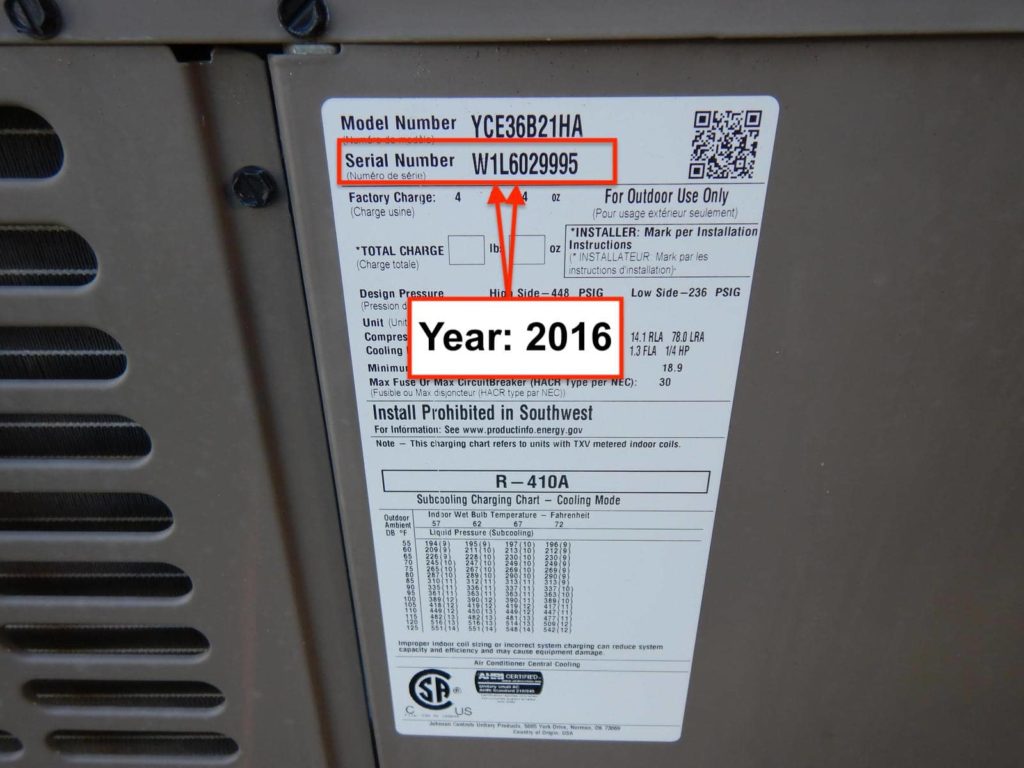

Look for a label that includes the words "Model Number" or "Model No." or similar. The label might also include the serial number and other important information. The model number is often the most prominent set of characters on the label. Sometimes you will find the model number engraved or etched into the body of the equipment rather than a paper label.

Tip: Take a clear photograph of the label, especially if it's in a difficult-to-reach location. This will ensure you always have the model number handy.

Q4: Is there a Johnson Controls online resource or tool that helps decode their model numbers?

Johnson Controls does not have a single, publicly available tool that decodes every model number across all their product lines. Due to the complexity and variations in nomenclature across different equipment types, a universal decoder is impractical. However, here's what you can do:

- Johnson Controls Website: Start by visiting the official Johnson Controls website (johnsoncontrols.com). Search for your product using keywords related to its function (e.g., "BACnet controller," "pressure sensor"). If you can find the product page, it may contain a breakdown of the model number components specific to that product line.

- Product Documentation: Download the product's datasheet, installation manual, or technical specifications from the Johnson Controls website. These documents often include a detailed explanation of the model number nomenclature for that specific product.

- Distributor Resources: Johnson Controls distributors often have access to more detailed product information and decoding tools. Contact a local distributor and provide them with the model number; they may be able to provide a breakdown.

- Technical Support: If you're still unable to decipher the model number, contact Johnson Controls technical support directly. Be prepared to provide the full model number and any other relevant information about the equipment.

Key Point: The most reliable method is to consult the official documentation for your specific product. Treat online "decoders" with caution, as they may not be accurate or up-to-date.

Q5: What if the model number is partially obscured or damaged? How can I still identify my equipment?

If the model number is partially obscured or damaged, identifying your equipment can be more challenging, but not impossible. Here are some steps you can take:

- Check Other Labels: Look for other labels or markings on the equipment that might provide clues, such as the serial number, manufacturing date, or a brief description of the product.

- Compare with Similar Products: If you have access to other similar Johnson Controls products, compare their appearance and features to the equipment you're trying to identify. This may help you narrow down the possibilities.

- Visual Identification: Take clear photographs of the equipment from multiple angles, focusing on any distinguishing features. Send these photos to a Johnson Controls distributor or technical support and ask if they can identify the product based on its appearance.

- Trace Wiring: For electrical components, trace the wiring and note the connections and voltage requirements. This information can sometimes help identify the product type.

- Describe Functionality: Prepare a detailed description of the equipment's function and its role in the system. This information can help technical support narrow down the search.

- Consider the System: Knowing what system the Johnson Controls equipment controls can aid in making educated assumptions about the model number of the device you want to identify. Example: If you see a sensor that is connected to a steam valve and controlling a steam boiler, it is very likely a temperature or pressure sensor (or transducer).

Important: When contacting technical support or a distributor, be as detailed as possible in your description. The more information you can provide, the better the chances of identifying the equipment.

Q6: Are there any common mistakes people make when trying to read or understand Johnson Controls model numbers?

Yes, several common mistakes can lead to misidentification of Johnson Controls equipment. Being aware of these pitfalls can help you avoid errors:

- Confusing Serial Numbers with Model Numbers: The serial number is a unique identifier for a specific unit, while the model number identifies the product type. Ensure you are looking at the correct identifier.

- Ignoring Suffixes: Suffixes (letters or numbers at the end of the model number) often indicate crucial variations or revisions. Failing to include the suffix can lead to ordering incorrect replacement parts.

- Assuming Similarity Based on Appearance: Two products may look similar but have different internal components or specifications. Always rely on the model number for accurate identification.

- Relying on Incomplete Information: Make sure you have the complete model number, including all prefixes, numbers, and suffixes. A partial model number is often insufficient for accurate identification.

- Misinterpreting Characters: Be careful when distinguishing between similar-looking characters, such as '0' (zero) and 'O' (the letter O), or '1' (one) and 'I' (the letter I).

- Using Outdated Information: Johnson Controls may update their model number nomenclature over time. Make sure you are using the most current documentation available.

- Not Considering Regional Variations: Some Johnson Controls products have regional variations in model numbers. Be aware of this if you are sourcing equipment from different regions.

By being mindful of these common mistakes, you can significantly improve your accuracy when interpreting Johnson Controls model numbers.

Q7: If I am replacing a Johnson Controls component, do I *have* to use the exact same model number?

Ideally, yes, you should aim to replace a Johnson Controls component with the exact same model number. This ensures compatibility and optimal performance.

However, there are situations where this might not be possible or practical:

- Discontinued Products: The original model may no longer be manufactured.

- Upgraded Versions: A newer version of the product may be available with improved features or performance.

In these cases, you need to ensure that the replacement component is a suitable substitute. Consider the following factors:

- Functionality: The replacement should perform the same function as the original.

- Specifications: The replacement should meet the same specifications (e.g., voltage, current, flow rate, pressure range).

- Compatibility: The replacement should be compatible with the existing system and any other connected components.

- Communication Protocol: If the component uses a communication protocol (e.g., BACnet, Modbus), the replacement must support the same protocol.

- Physical Dimensions: The replacement should fit in the same space and have the same mounting configuration.

Crucial: Always consult the product documentation for both the original and replacement components to verify compatibility. If you are unsure, contact a Johnson Controls distributor or technical support for guidance. They can help you identify a suitable replacement that meets your needs.

Important Disclaimer: Replacing a component with an incompatible part can lead to system malfunction, damage to equipment, or even safety hazards. Always prioritize safety and seek professional assistance when in doubt.