Nfpa 54 Gas Pipe Sizing Chart

Ensuring a safe and efficient natural gas supply is paramount for any building, whether it's a cozy home or a sprawling commercial complex. A critical tool in achieving this is the NFPA 54 Gas Pipe Sizing Chart, a resource that dictates the proper diameter of gas piping necessary to deliver adequate fuel to appliances. This article will delve into the intricacies of this chart, explaining its use and significance for homeowners, HVAC technicians, and facility managers alike.

Understanding NFPA 54 and Gas Pipe Sizing

NFPA 54, also known as the National Fuel Gas Code, provides comprehensive guidelines for the safe installation and operation of fuel gas piping systems and appliances. This code is widely adopted and enforced by jurisdictions across the United States. The gas pipe sizing chart within NFPA 54 is a key component, preventing issues like insufficient gas supply, which can lead to appliance malfunction, inefficiency, and potentially dangerous situations.

The fundamental principle behind gas pipe sizing is simple: ensure that the pipe is large enough to deliver the required volume of gas to all connected appliances at the proper pressure. Undersized piping restricts gas flow, causing appliances to struggle, operate inefficiently, and even shut down. Conversely, excessively large piping, while not inherently dangerous, increases material costs without providing any performance benefit. Therefore, accurate sizing is both a safety imperative and an economic consideration.

Factors Affecting Gas Pipe Sizing

Several factors influence the correct gas pipe size, each playing a crucial role in the calculations:

- Appliance Gas Consumption: This is usually expressed in British Thermal Units per hour (BTU/h) or cubic feet per hour (CFH). Each gas appliance, from furnaces and water heaters to stoves and fireplaces, has a specific gas consumption rate. This information is typically found on the appliance's nameplate or in the manufacturer's specifications.

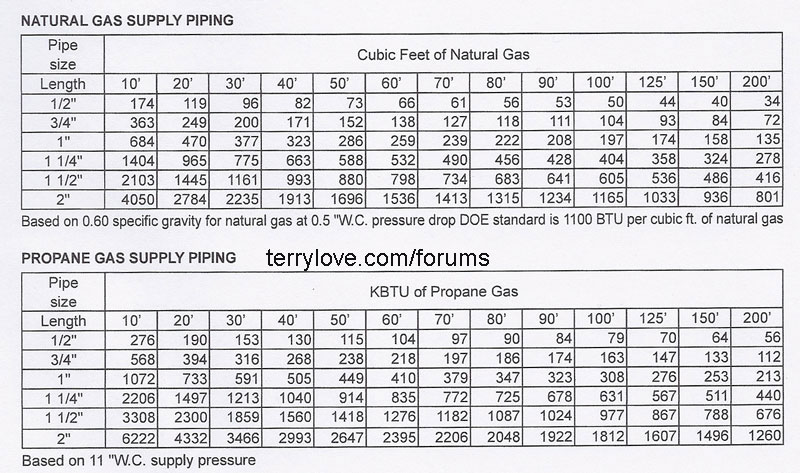

- Gas Type: Natural gas and propane have different heating values and densities, influencing the required pipe size. NFPA 54 provides separate charts for each gas type. This article primarily focuses on natural gas.

- Pipe Length: The longer the pipe run, the greater the pressure drop due to friction. Longer runs require larger diameter pipes to compensate for this pressure loss. Measuring the total length of the pipe, including all fittings (which add equivalent length), is crucial.

- Allowable Pressure Drop: NFPA 54 specifies the maximum allowable pressure drop in the gas piping system. This ensures that appliances receive gas at the correct pressure for optimal performance. Typical allowable pressure drops are 0.5 inches of water column (WC) for low-pressure systems.

- Specific Gravity of Gas: Specific gravity is the ratio of the density of the gas to the density of air. Natural gas has a specific gravity typically around 0.6. This value is used in the sizing calculations.

- Material of Pipe: The material used for the pipe also affects the calculations since the inside roughness of the pipe can affect the friction and pressure drop. Common materials are steel, copper and plastic (PE).

How to Use the NFPA 54 Gas Pipe Sizing Chart

Using the NFPA 54 gas pipe sizing chart involves a systematic process. Here's a step-by-step guide:

- Determine the Gas Consumption of Each Appliance: Sum the BTU/h or CFH ratings of all appliances connected to the gas piping system. For example, a furnace rated at 100,000 BTU/h, a water heater at 40,000 BTU/h, and a stove at 60,000 BTU/h would have a total gas consumption of 200,000 BTU/h.

- Measure the Pipe Length: Accurately measure the length of the pipe from the gas meter to the farthest appliance. Add the equivalent length of fittings (elbows, tees, etc.) to this measurement. Consult NFPA 54 for the equivalent length of common fittings. For example, a ½ inch elbow might add 1 foot of equivalent length.

- Select the Appropriate Chart: Choose the correct chart for the gas type (natural gas or propane) and the allowable pressure drop.

- Locate the Correct Pipe Size: On the chart, find the row corresponding to the total pipe length. Then, move across the row until you find a value that equals or exceeds the total gas consumption of all appliances. The column heading indicates the required pipe size.

Example: Let's say you have a natural gas system with a total appliance gas consumption of 150,000 BTU/h and a pipe length of 50 feet (including fittings). Using a standard NFPA 54 chart for natural gas with a 0.5-inch WC pressure drop, you would locate the row for 50 feet. Then, you would find the smallest pipe size column that can accommodate 150,000 BTU/h. In this example, a ¾-inch pipe might be sufficient. However, it's crucial to consult the actual chart for accurate sizing, as values vary depending on the chart's specific parameters.

Common Mistakes to Avoid

Several common mistakes can lead to incorrect gas pipe sizing:

- Ignoring Fitting Equivalent Length: Fittings significantly increase the effective pipe length and must be accounted for.

- Using the Wrong Chart: Ensure you're using the correct chart for the gas type and allowable pressure drop.

- Inaccurate Measurement of Pipe Length: Precise measurement is critical. Underestimating pipe length can lead to undersized piping.

- Failing to Account for Future Appliance Additions: If you plan to add more gas appliances in the future, factor their gas consumption into the sizing calculations. It is always best to oversize slightly to accommodate future load.

- Neglecting Elevation Changes: Significant elevation changes in the piping system can affect pressure and should be considered.

The Importance of Professional Installation and Inspection

While homeowners can familiarize themselves with the basics of gas pipe sizing, it's crucial to remember that gas piping installation and modification should always be performed by a qualified and licensed HVAC technician or plumber. These professionals have the expertise to ensure that the system is installed correctly, safely, and in accordance with all applicable codes. A professional will also perform a leak test after installation to ensure the system is gas-tight.

Regular inspections of gas piping systems are also essential for maintaining safety and efficiency. A qualified technician can identify potential issues like leaks, corrosion, and improper sizing, preventing problems before they escalate into dangerous situations. Typical inspection intervals range from annually to every few years.

Cost Considerations

The cost of gas piping varies depending on several factors, including the pipe material, diameter, length, and complexity of the installation. Copper piping tends to be more expensive than steel piping, but it offers better corrosion resistance. Larger diameter pipes, of course, cost more than smaller ones. Installation costs will also vary depending on the labor rates in your area and the complexity of the job. Obtaining multiple quotes from qualified contractors is recommended.

While it may be tempting to cut corners on gas piping to save money, doing so can be a costly mistake. Undersized piping can lead to appliance inefficiency, increased energy bills, and potential safety hazards. Investing in properly sized and installed gas piping is a wise investment that will pay off in the long run.

Efficiency Ratings and Lifespan

Proper gas pipe sizing directly impacts the efficiency of gas appliances. When appliances receive an adequate supply of gas at the correct pressure, they can operate at their rated efficiency, minimizing energy waste and lowering utility bills. Conversely, undersized piping can cause appliances to struggle, consuming more energy to produce the same amount of heat or hot water. A well-maintained gas piping system can last for many years, typically 20-50 years or more, depending on the material and environmental conditions. Regular inspections and prompt repairs can extend the lifespan of the system and prevent costly replacements. Using quality materials, like coated steel or properly installed and protected PE will also extend the life.

For Facility Managers: Large-Scale Gas Piping Systems

For facility managers overseeing large buildings, the complexities of gas piping systems are amplified. Multi-story buildings, campuses, and industrial facilities require intricate piping networks to serve numerous appliances and equipment. Accurate sizing and meticulous installation are even more critical in these environments to ensure the safety and efficiency of the entire system. Facility managers should work closely with qualified HVAC engineers and contractors to design, install, and maintain these large-scale gas piping systems.

In conclusion, the NFPA 54 Gas Pipe Sizing Chart is an indispensable tool for ensuring the safe and efficient delivery of natural gas to appliances. Whether you're a homeowner, HVAC technician, or facility manager, understanding the principles of gas pipe sizing and adhering to NFPA 54 guidelines is essential for maintaining a reliable and safe gas piping system. Remember to always consult with qualified professionals for installation, inspection, and maintenance to ensure the system operates optimally and safely.