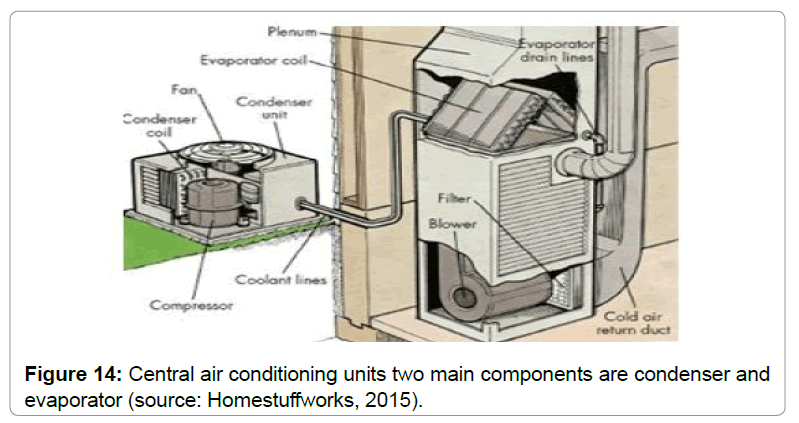

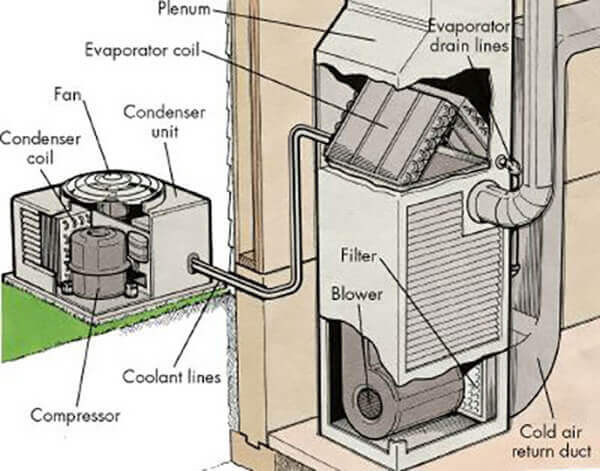

Parts Of A Central Air Conditioning Unit

Central air conditioning systems provide efficient and consistent cooling for homes and businesses. Understanding the key components of these systems, how they function, and their maintenance needs is crucial for homeowners, HVAC technicians, and facility managers alike. This article provides a comprehensive overview of the essential parts of a central air conditioning unit.

The Outdoor Unit: The Condenser

The outdoor unit, often referred to as the condenser, is responsible for releasing heat absorbed from inside the building. It's typically located outside the house or building, ensuring proper ventilation for heat dissipation. Here's a breakdown of its components:

1. Compressor

The compressor is the heart of the air conditioning system. Its primary function is to compress the refrigerant gas, increasing its pressure and temperature. This high-pressure, high-temperature refrigerant is then sent to the condenser coil. Compressor types include reciprocating, scroll, and rotary, each offering different levels of efficiency and lifespan. Scroll compressors, for example, are known for their quieter operation and higher efficiency compared to reciprocating compressors. Replacing a compressor can be a significant expense, typically ranging from $1,500 to $4,000, depending on the type and system size.

2. Condenser Coil

The condenser coil is a series of tubes that allow the high-pressure, hot refrigerant to release heat to the outside air. As the refrigerant cools, it condenses from a gas into a liquid. The coil is typically made of copper or aluminum, and its efficiency depends on its surface area and airflow. Regular cleaning of the condenser coil is essential to maintain optimal performance. A dirty coil can significantly reduce efficiency and increase energy consumption, potentially raising utility bills by 10-20%. Pressure washing the coil (with appropriate care) is recommended annually.

3. Condenser Fan

The condenser fan draws air across the condenser coil to facilitate heat transfer. This fan is typically driven by an electric motor and is designed to move a large volume of air. If the fan motor fails, the condenser cannot effectively release heat, leading to reduced cooling capacity and potential damage to the compressor. Condenser fan motors typically cost between $150 and $500 to replace, depending on the motor's size and specifications.

4. Expansion Valve or Metering Device

The expansion valve (also known as a metering device or thermal expansion valve – TXV) controls the flow of refrigerant into the evaporator coil inside the air handler. It reduces the pressure of the liquid refrigerant, allowing it to expand and cool rapidly. Older systems might use a fixed orifice, while newer, more efficient systems use TXVs to precisely control refrigerant flow based on the cooling load. TXVs offer better efficiency and temperature control compared to fixed orifices. Replacing a TXV generally costs between $200 and $600, including labor.

The Indoor Unit: The Air Handler

The indoor unit, or air handler, circulates air throughout the building and houses the evaporator coil, where the refrigerant absorbs heat from the indoor air.

1. Evaporator Coil

The evaporator coil is located inside the air handler. It's where the liquid refrigerant absorbs heat from the indoor air, causing the refrigerant to evaporate into a gas. This process cools the air, which is then circulated throughout the building. Like the condenser coil, the evaporator coil requires regular cleaning to maintain optimal performance. A dirty evaporator coil can lead to reduced cooling capacity, increased energy consumption, and potential mold growth. Professional cleaning of the evaporator coil typically costs between $100 and $300.

2. Blower Fan

The blower fan circulates air across the evaporator coil and through the ductwork, distributing cooled air throughout the building. The blower fan is powered by an electric motor, and its speed can often be adjusted to optimize airflow and efficiency. Variable-speed blowers are more energy-efficient than single-speed blowers, as they can adjust their speed based on the cooling demand. Replacing a blower motor can cost between $300 and $800, depending on the motor's type and specifications.

3. Air Filter

The air filter removes dust, pollen, and other particles from the air before it passes through the evaporator coil. Regular filter replacement is crucial for maintaining air quality and preventing dust buildup on the coil, which can reduce efficiency. Air filters come in various types, including fiberglass, pleated, and HEPA filters, each offering different levels of filtration. Replacing the air filter every 1-3 months is recommended, depending on the filter type and the level of air pollution.

4. Ductwork

The ductwork is a network of channels that distributes cooled air from the air handler to the vents throughout the building. Proper ductwork design and insulation are essential for minimizing air leaks and maximizing efficiency. Leaky or poorly insulated ductwork can result in significant energy loss, reducing the system's overall efficiency. Duct sealing and insulation can improve efficiency by 10-30%. Professional duct sealing can range from $500 to $2,000, depending on the size and complexity of the ductwork.

Other Important Components

Besides the main components, several other parts contribute to the efficient operation of a central air conditioning system:

1. Refrigerant Lines

Refrigerant lines connect the indoor and outdoor units, carrying refrigerant between the compressor, condenser coil, evaporator coil, and expansion valve. These lines must be properly insulated to prevent heat loss or gain, which can reduce efficiency. Leaks in refrigerant lines can also lead to reduced cooling capacity and environmental damage. Repairing refrigerant leaks typically costs between $200 and $1,000, depending on the location and severity of the leak.

2. Thermostat

The thermostat controls the operation of the air conditioning system, allowing users to set the desired temperature and schedule cooling cycles. Programmable thermostats can further improve energy efficiency by automatically adjusting the temperature based on occupancy patterns. Smart thermostats offer even more advanced features, such as remote control via smartphone and integration with other smart home devices. Replacing a thermostat can range from $50 to $300, depending on the features and complexity of the thermostat.

3. Electrical Components

The electrical components include wiring, circuit breakers, capacitors, and relays that control the operation of the various components of the air conditioning system. Electrical problems can lead to system malfunctions and potential safety hazards. Regular inspection and maintenance of the electrical components are essential for ensuring safe and reliable operation. The cost of repairing electrical components can vary widely, depending on the specific issue and the complexity of the repair.

Efficiency Ratings and Lifespan

The efficiency of a central air conditioning system is measured by its Seasonal Energy Efficiency Ratio (SEER). A higher SEER rating indicates greater energy efficiency. The minimum SEER rating currently mandated by the U.S. Department of Energy is 14 for most regions. High-efficiency systems can have SEER ratings of 20 or higher. Systems with higher SEER ratings generally have a higher upfront cost, but they can save significant energy costs over their lifespan.

The lifespan of a central air conditioning system typically ranges from 15 to 20 years, depending on the quality of the system, the climate, and the level of maintenance. Regular maintenance, such as cleaning the coils, replacing the air filter, and inspecting the refrigerant levels, can significantly extend the lifespan of the system. Replacing a complete central air conditioning system can cost between $5,000 and $12,000, depending on the size, efficiency, and complexity of the installation.

Conclusion

Understanding the different components of a central air conditioning unit, their functions, and their maintenance needs is crucial for ensuring efficient and reliable cooling. Regular maintenance, proper installation, and timely repairs can help extend the lifespan of the system and minimize energy consumption. Whether you're a homeowner, HVAC technician, or facility manager, a thorough understanding of these components will enable you to make informed decisions about the operation and maintenance of your central air conditioning system.

:max_bytes(150000):strip_icc()/what-are-central-air-conditioners-1152645_V2-390c6f1f6ca14b4ebc59426f226a78a8.png)