Parts Of A Hydronic Heating System

Understanding the Heart of Your Home: A Guide to Hydronic Heating System Parts

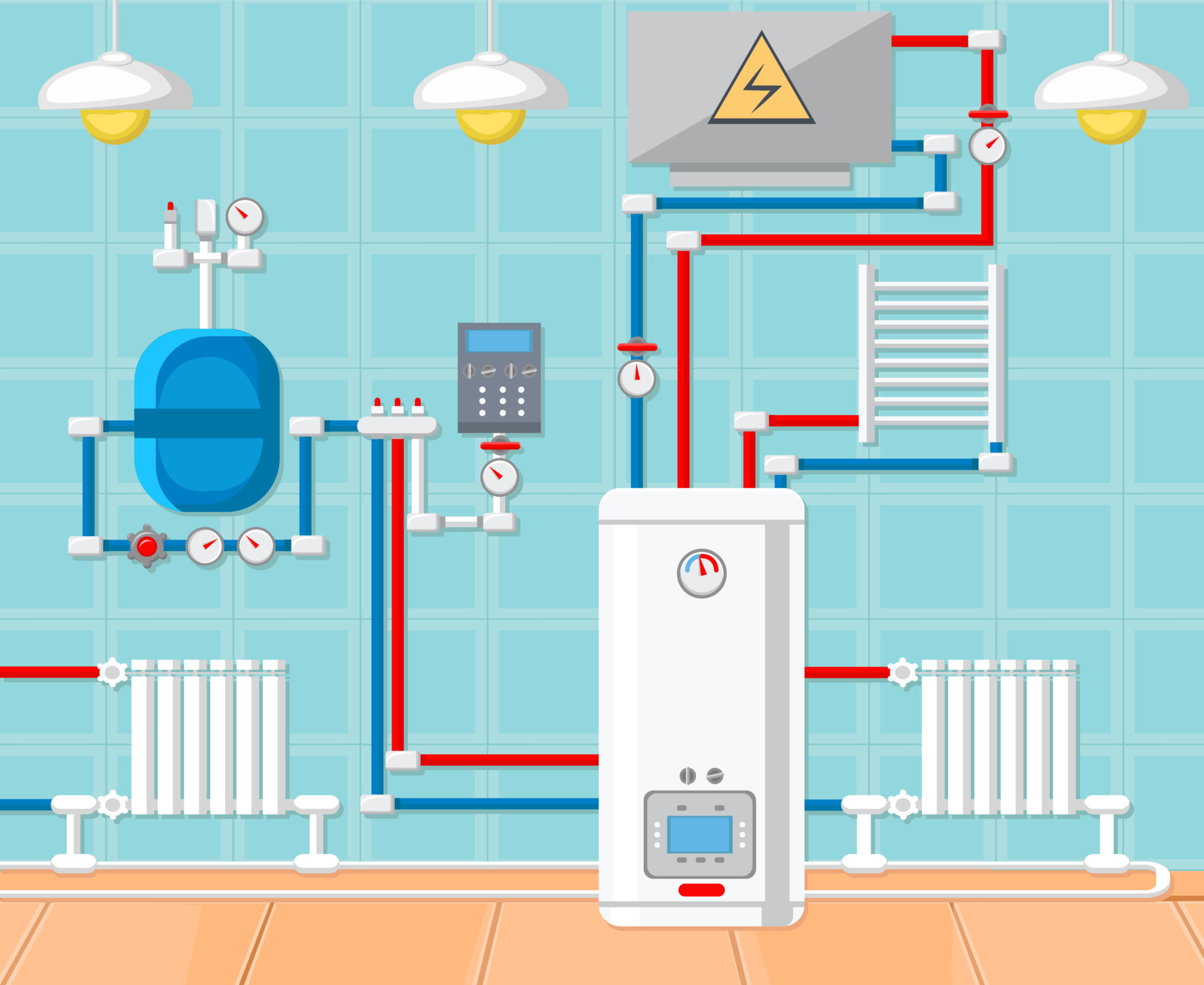

Hydronic heating, also known as radiant heating, offers a comfortable and efficient way to heat your home. Unlike forced-air systems that blow hot air, hydronic systems use hot water (or sometimes a glycol mixture) to transfer heat. This means less dust circulation and more even temperatures. But like any mechanical system, understanding the components is crucial for maintenance, troubleshooting, and knowing when to call a professional. Let's dive into the main parts of a hydronic heating system.

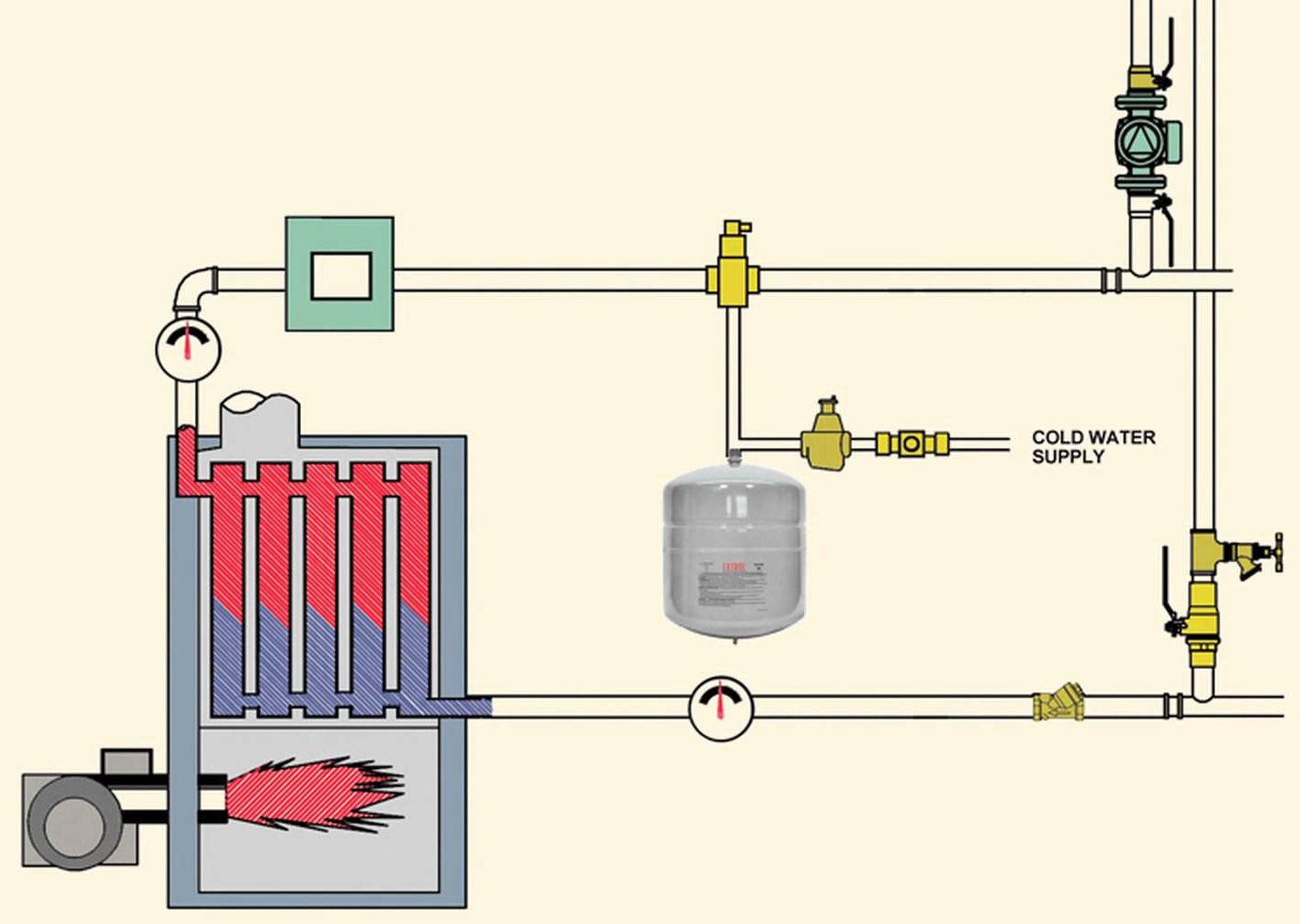

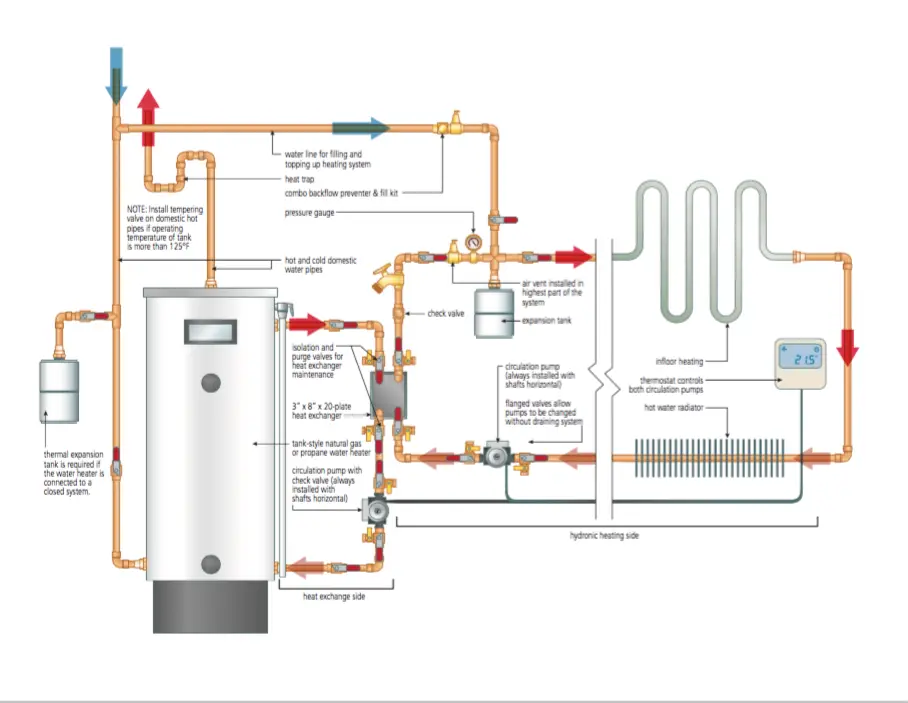

The Boiler: The Heat Source

The boiler is the heart of your hydronic system. It's responsible for heating the water that circulates throughout your home. Boilers can be fueled by natural gas, propane, oil, or electricity.

Types of Boilers:

- Conventional Boilers: These are the traditional models with a lower efficiency rating. They vent exhaust gases through a chimney.

- Condensing Boilers: These highly efficient boilers extract more heat from the exhaust gases, often exceeding 90% efficiency. They require a condensate drain.

Troubleshooting Tips:

- No Heat: Check the gas supply (if applicable), pilot light (if applicable), and circuit breaker.

- Leaking: Address leaks immediately to prevent water damage and efficiency loss. Locate the source of the leak before proceeding.

- Strange Noises: Gurgling, banging, or hissing sounds can indicate air in the system, low water pressure, or scale buildup.

Safety Tip: Never attempt to repair the gas supply line or internal components of a gas-fired boiler. Call a licensed HVAC technician or gas fitter.

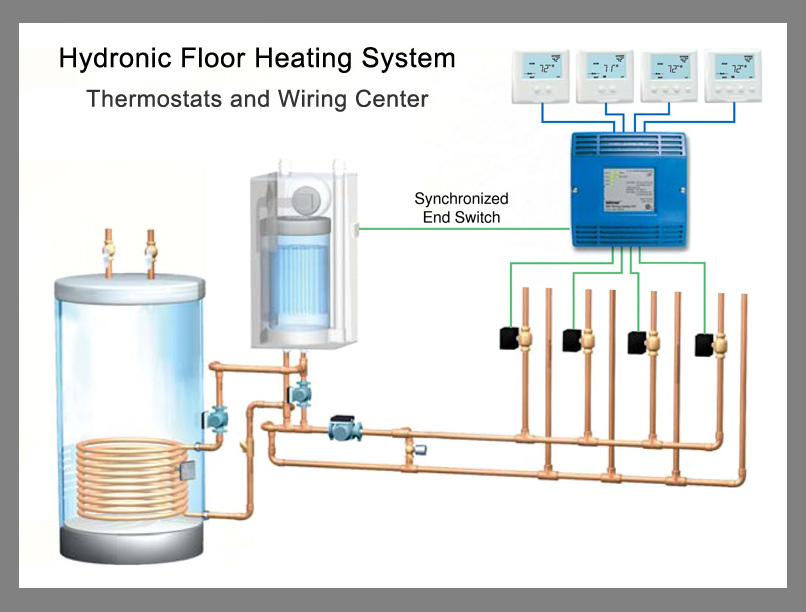

Circulator Pump: Keeping the Water Flowing

The circulator pump is the engine that drives the hot water through the pipes and radiators or radiant floor loops. Without a functioning pump, your system won't distribute heat effectively. These pumps are typically electric and relatively small.

Troubleshooting Tips:

- No Heat: If the boiler is running but you're not getting heat, check if the circulator pump is running. Listen for a hum or vibration.

- Pump is Running but No Circulation: There could be air in the system or a blockage in the pipes.

Replacement Considerations:

- Match the pump's flow rate and head pressure to your system's requirements.

- Consider a variable-speed pump for increased efficiency.

Expansion Tank: Accommodating Water Expansion

Water expands when heated. The expansion tank provides a space for this expanded water to go, preventing over-pressurization in the system. It’s usually a metal tank with a rubber bladder inside, pre-charged with air pressure.

Troubleshooting Tips:

- Pressure Relief Valve Leaking: This is a sign that the expansion tank may be waterlogged or the system pressure is too high.

- Waterlogged Tank: Tap on the tank; if it sounds full of water, the bladder may be damaged.

Checking Air Pressure: Use a tire pressure gauge to check the air pressure in the expansion tank. It should match the system's fill pressure (typically around 12-15 PSI).

Pressure Relief Valve: A Safety Net

The pressure relief valve is a safety device designed to release excess pressure in the system. It prevents catastrophic failure of the boiler or other components due to over-pressurization.

Troubleshooting Tips:

- Constant Dripping: This indicates that the system pressure is too high, the valve is faulty, or the expansion tank is failing.

Safety Note: Never attempt to block or disable the pressure relief valve. It's a crucial safety component.

Radiators/Baseboard Heaters/Radiant Floor Loops: Heat Emitters

These are the devices that actually radiate heat into your rooms. Radiators are typically cast iron or steel units, while baseboard heaters are finned copper pipes enclosed in a metal housing. Radiant floor loops are PEX tubing embedded in the floor, providing even heat distribution from below.

Troubleshooting Tips:

- Cold Spots: Air trapped in the radiator or baseboard can prevent proper heating. Bleeding the radiator or baseboard is usually the solution.

- Uneven Floor Heating: This could be due to inconsistent loop lengths, variations in floor covering thickness, or problems with the manifold.

Bleeding Radiators/Baseboards: You'll need a radiator key. Open the bleed valve slowly until water starts to come out. Close the valve when the water flows smoothly and without air bubbles.

Piping: The Arteries of the System

Pipes carry the hot water from the boiler to the heat emitters and back. Common piping materials include copper, PEX (cross-linked polyethylene), and CPVC (chlorinated polyvinyl chloride).

Troubleshooting Tips:

- Leaks: Address leaks promptly to prevent water damage and efficiency loss.

- Corrosion: Inspect pipes for signs of corrosion, especially near joints and fittings.

Pipe Insulation: Insulating pipes, especially in unheated areas, reduces heat loss and improves efficiency.

Zone Valves/Thermostats: Controlling the Heat

Zone valves control the flow of hot water to different areas (zones) of your home, allowing you to heat only the areas you need. Thermostats in each zone control the zone valves, turning them on and off based on the desired temperature.

Troubleshooting Tips:

- No Heat in a Zone: Check the thermostat settings, the zone valve for proper operation, and the wiring connections.

- Zone Valve Stuck Open/Closed: Manually override the zone valve to see if it's mechanically stuck.

Smart Thermostats: Upgrading to smart thermostats can provide more precise temperature control and energy savings.

Automatic Air Vent: Releasing Trapped Air

Automatic air vents, usually located at high points in the system, automatically release trapped air. This helps to maintain efficient circulation and prevent noise.

Troubleshooting Tips:

- Leaking: Sometimes, automatic air vents can leak after releasing air. If this happens, try tightening the cap. If it continues to leak, the vent may need to be replaced.

Fill Valve/Pressure Reducing Valve: Maintaining Water Pressure

The fill valve, also known as a pressure reducing valve (PRV), automatically adds water to the system to maintain the correct pressure. It's typically set to around 12-15 PSI.

Troubleshooting Tips:

- Low Pressure: If the system pressure is consistently low, the fill valve may be malfunctioning or there may be a leak in the system.

- High Pressure: If the system pressure is too high, the fill valve may be stuck open.

Common Hydronic Heating System Issues and Estimated Repair Costs

Here's a quick rundown of common issues and estimated repair costs. Please note that these are just estimates and actual costs may vary depending on your location and the specific problem.

- Air in System: (DIY Bleeding) - Cost: Free (if you have a radiator key)

- Circulator Pump Failure: (Professional Replacement) - Cost: $200 - $600

- Expansion Tank Failure: (Professional Replacement) - Cost: $150 - $400

- Leaking Boiler: (Professional Repair or Replacement) - Cost: $100 - $2000+ (depending on the severity)

- Zone Valve Malfunction: (Professional Replacement) - Cost: $150 - $350

- Thermostat Problems: (DIY or Professional Replacement) - Cost: $50 - $300

Tools You Might Need

- Radiator Key

- Adjustable Wrench

- Screwdrivers (various sizes)

- Multimeter

- Tire Pressure Gauge

- Bucket and Rags

- Pipe Wrench

When to Call a Professional

While some hydronic heating system issues can be addressed by homeowners, others require the expertise of a qualified HVAC technician. Call a professional if you experience any of the following:

- Gas Leaks: Any smell of gas near your boiler or gas piping.

- Boiler Malfunctions: Complex boiler problems that you can't diagnose or repair yourself.

- Electrical Issues: Problems with the wiring or electrical components of the system.

- Refrigerant Leaks: Some systems use refrigerants; only licensed professionals should handle repairs.

- You're Uncomfortable Working on the System: Safety should always be your top priority.

Important Note: This guide provides general information about hydronic heating systems. Always consult your system's manual and follow all safety precautions when performing maintenance or repairs. When in doubt, call a qualified HVAC technician.