Parts Of A Split System Air Conditioner

The split system air conditioner is the workhorse of the residential and light commercial HVAC industry. Understanding its components is fundamental for anyone looking to build a career in heating, ventilation, and air conditioning. This guide breaks down the essential parts of a split system AC, offering insights valuable for students, experienced technicians, and employers.

Understanding the Split System: A Foundation for HVAC Professionals

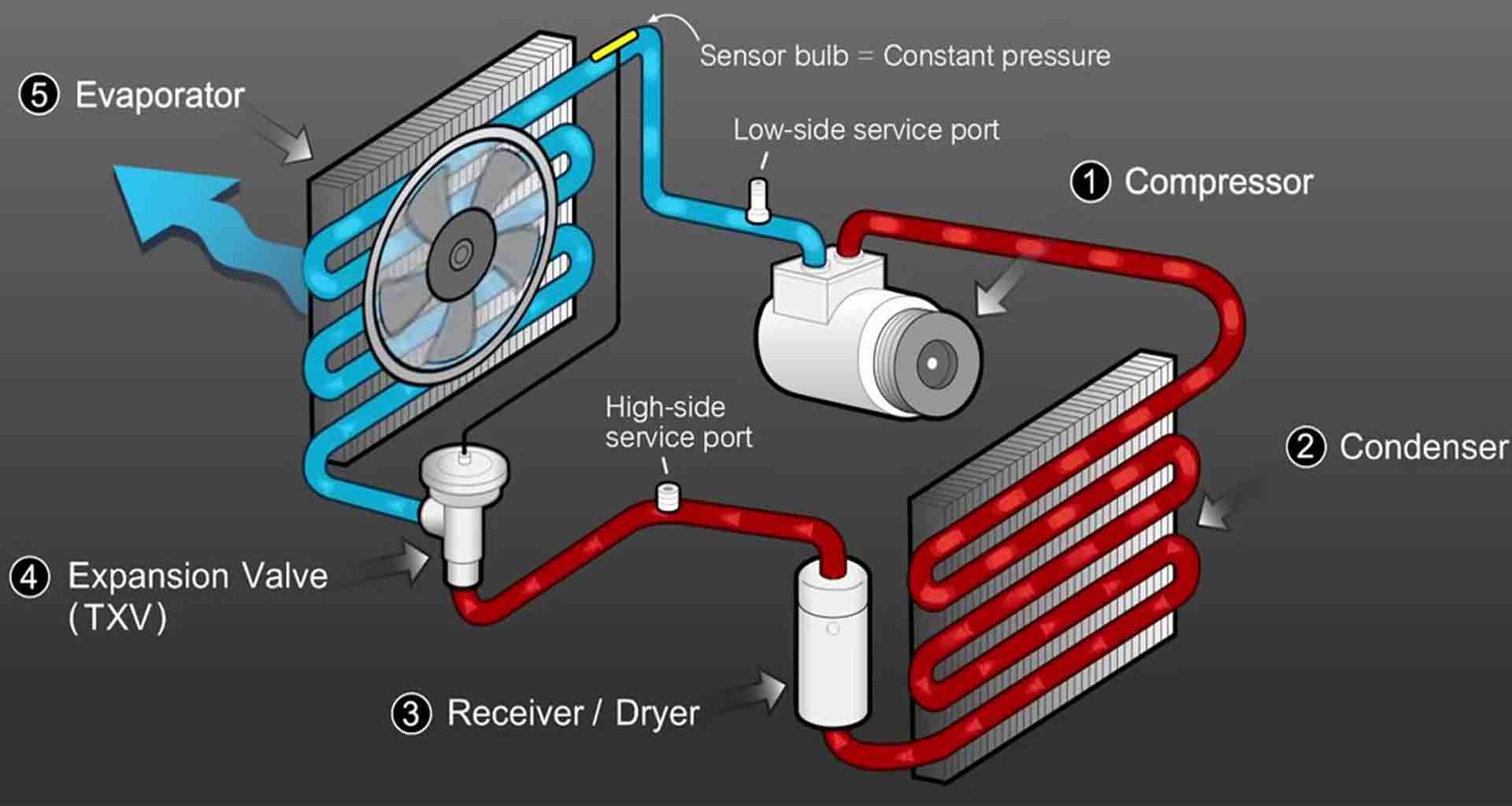

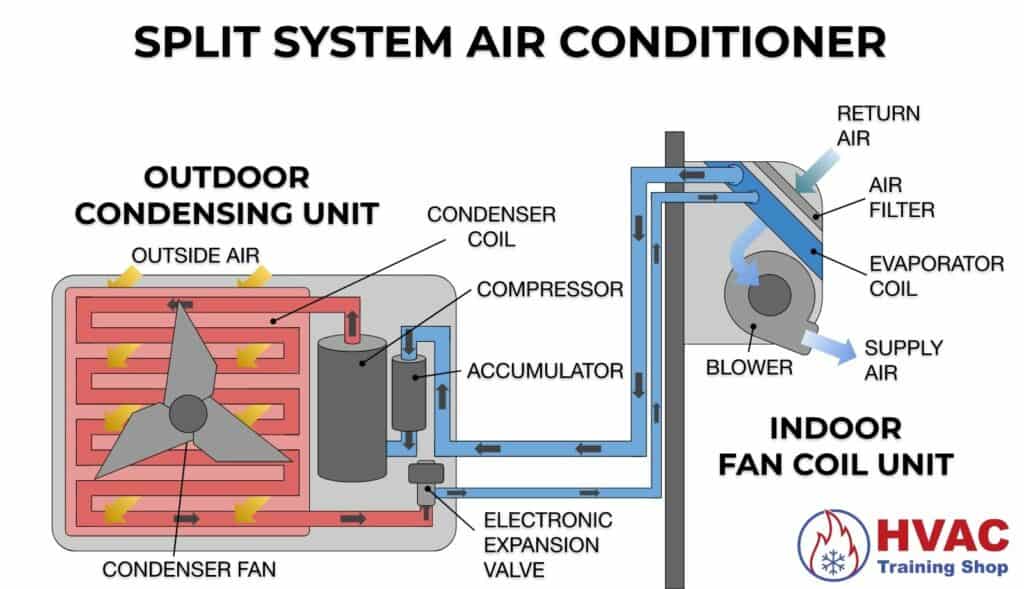

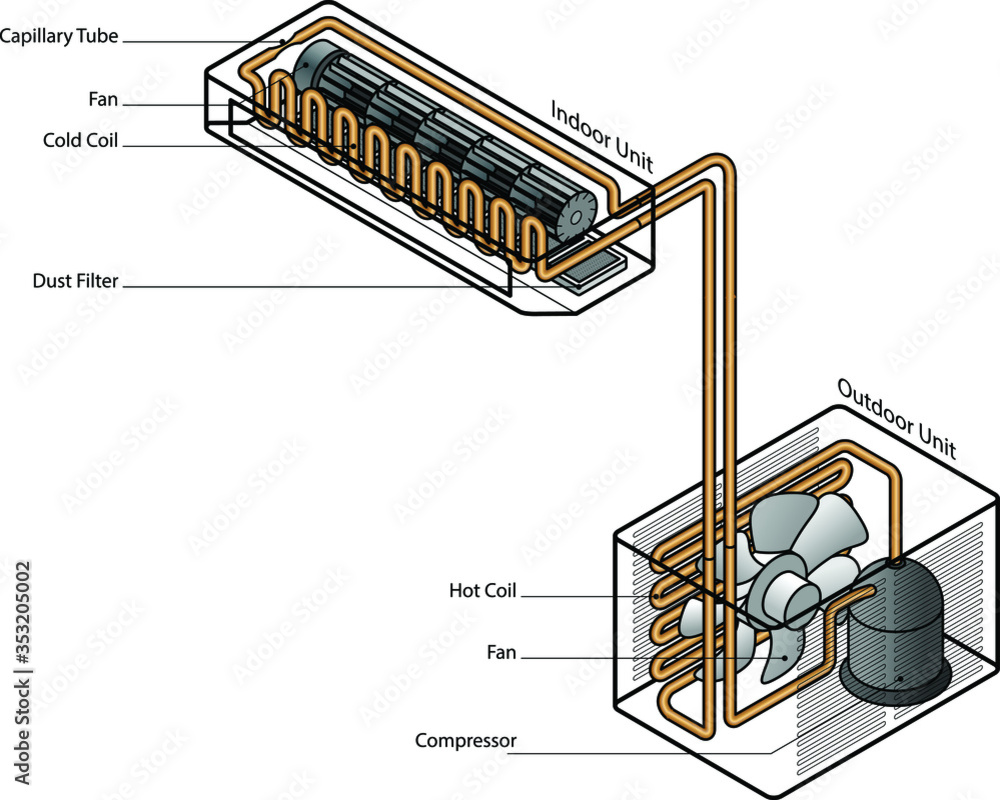

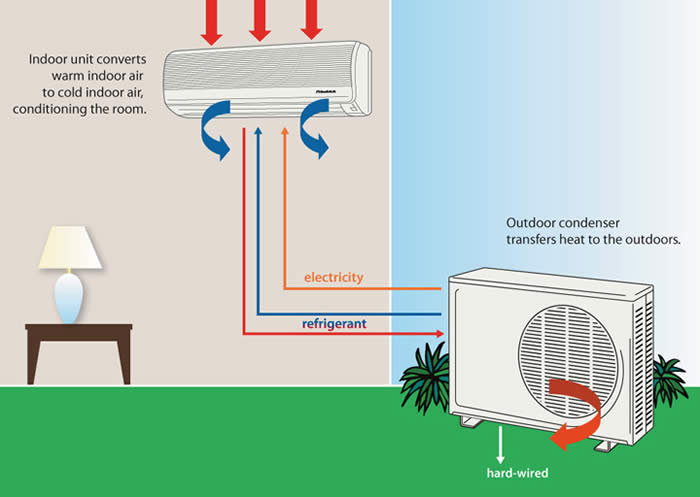

A split system air conditioner, as its name suggests, is divided into two main units: an outdoor unit (the condenser) and an indoor unit (the evaporator). This design separates the noisy components (compressor and condenser fan) from the living space, contributing to quieter operation. Before diving into the individual parts, it's crucial to understand the overall refrigeration cycle – the process by which heat is removed from the indoor air and released outside.

Outdoor Unit (Condenser) Components

The outdoor unit is responsible for rejecting heat absorbed from inside the building. Key components include:

- Compressor: The heart of the system, the compressor is a mechanical pump that circulates refrigerant and increases its pressure and temperature. Different types of compressors exist, including reciprocating, scroll, and rotary, each with varying efficiency and cost. According to the Bureau of Labor Statistics, understanding compressor types and troubleshooting is a key skill for HVAC technicians, contributing to the median annual salary of $51,390 in May 2022. Experienced technicians specializing in compressor repair and replacement can command significantly higher salaries.

- Condenser Coil: This coil is a series of tubes designed to dissipate heat. Hot refrigerant flows through the coil, and as air is blown across it by the condenser fan, heat is transferred to the outside air. Condenser coil maintenance, including cleaning, is critical for optimal system performance.

- Condenser Fan: The condenser fan pulls air across the condenser coil, facilitating heat transfer. Fan motors can be single-speed, multi-speed, or variable-speed (ECM – electronically commutated motor), offering varying levels of efficiency and noise reduction. Technicians specializing in ECM motor repair and replacement are increasingly in demand.

- Reversing Valve (Heat Pumps Only): In a heat pump system, the reversing valve allows the system to switch between cooling and heating modes by reversing the flow of refrigerant. This component requires specialized diagnostic skills.

- Accumulator (Heat Pumps Only): Prevents liquid refrigerant from entering the compressor, protecting it from damage.

- Filter Drier: This component removes moisture and contaminants from the refrigerant, protecting the system from corrosion and damage. Regular replacement is essential for longevity.

- Service Valves: Allow technicians to connect gauges and charging equipment for system diagnostics and maintenance. Proper use of service valves is critical for safe and efficient servicing.

- Control Board: Manages the operation of the outdoor unit, including the compressor, fan, and defrost cycle (in heat pumps). Modern control boards are increasingly sophisticated, requiring technicians to have strong troubleshooting skills and an understanding of electrical circuits.

Indoor Unit (Evaporator) Components

The indoor unit is responsible for absorbing heat from the inside air. Key components include:

- Evaporator Coil: This coil absorbs heat from the indoor air. As warm air is blown across the coil by the blower fan, the liquid refrigerant inside the coil evaporates, absorbing heat and cooling the air.

- Blower Fan: The blower fan circulates air across the evaporator coil and throughout the ductwork, distributing cool air throughout the building. Similar to condenser fan motors, blower fan motors can be single-speed, multi-speed, or ECM, influencing efficiency and comfort.

- Expansion Valve (or Metering Device): This device controls the flow of refrigerant into the evaporator coil, ensuring optimal cooling performance. Common types include TXV (thermostatic expansion valve) and fixed orifice.

- Air Filter: This filter removes dust, pollen, and other contaminants from the air, improving indoor air quality and protecting the evaporator coil from becoming dirty. Regular filter replacement is essential.

- Drain Pan and Drain Line: Collects condensation that forms on the evaporator coil and directs it outside. A clogged drain line can lead to water damage and mold growth.

- Control Board: Manages the operation of the indoor unit, including the blower fan and the defrost cycle (in heat pumps).

Refrigerant: The Lifeblood of the System

Refrigerant is the working fluid that absorbs and releases heat as it cycles through the system. Older refrigerants like R-22 are being phased out due to environmental concerns, replaced by more environmentally friendly alternatives like R-410A and, increasingly, newer low-GWP (Global Warming Potential) refrigerants. EPA 608 certification is mandatory for technicians who handle refrigerants, demonstrating competency in safe handling and disposal practices. Failure to comply with EPA regulations can result in significant fines. The industry is actively training technicians on these newer refrigerants, creating a demand for skilled professionals. Certifications in refrigerant handling contribute significantly to a technician's marketability and earning potential.

Essential HVAC Certifications and Career Paths

While formal education (vocational schools, community colleges) provides a solid foundation, certifications are often crucial for career advancement and demonstrating competency. Some key certifications include:

- NATE (North American Technician Excellence): NATE certification is a widely recognized industry standard that demonstrates a technician's knowledge and skills. Achieving NATE certification can lead to higher earning potential and increased job opportunities. Employers often prioritize NATE-certified technicians, as it signifies a commitment to professional development.

- EPA 608 Certification: As mentioned earlier, this is legally required for technicians handling refrigerants.

- HVAC Excellence: Another highly respected certification program that offers various certifications based on specific areas of expertise.

Career Paths in HVAC: A deep understanding of split system components opens doors to various career paths:

- Installation Technician: Installing new HVAC systems in residential and commercial buildings.

- Service Technician: Diagnosing and repairing malfunctioning HVAC systems.

- Maintenance Technician: Performing routine maintenance on HVAC systems to ensure optimal performance and prevent breakdowns.

- HVAC System Designer: Designing and specifying HVAC systems for new construction and renovation projects.

- HVAC Sales Engineer: Selling HVAC equipment and services to customers.

- Building Automation Specialist: Integrating HVAC systems with building automation systems for improved energy efficiency and control.

Real-World Example: Sarah, a recent graduate of an HVAC program, started her career as an installation technician. After gaining experience and earning her NATE certification, she transitioned to a service technician role, specializing in diagnosing and repairing complex HVAC systems. Her expertise in diagnosing compressor failures and understanding refrigerant properties allowed her to command a higher salary and become a valuable asset to her company.

The Future of Split Systems: Trends and Opportunities

The HVAC industry is constantly evolving, with new technologies and regulations driving innovation. Key trends shaping the future of split systems include:

- Variable-Speed Technology: Variable-speed compressors and fans offer significant energy savings and improved comfort.

- Smart HVAC Systems: Integrating HVAC systems with smart thermostats and home automation systems allows for remote control and optimization.

- Eco-Friendly Refrigerants: The transition to low-GWP refrigerants is driving innovation and requiring technicians to adapt to new technologies.

- Increased Focus on Indoor Air Quality: Concerns about indoor air quality are driving demand for advanced filtration and ventilation systems.

These trends create numerous opportunities for HVAC professionals with the right skills and knowledge. Technicians who are proficient in diagnosing and repairing variable-speed systems, integrating HVAC systems with smart home technology, and working with eco-friendly refrigerants will be in high demand.

For Employers: Finding and Retaining Skilled HVAC Technicians

Attracting and retaining skilled HVAC technicians is a challenge for many employers. Offering competitive salaries, benefits, and opportunities for professional development are essential. Consider the following strategies:

- Offer competitive salaries and benefits: Research industry benchmarks to ensure your compensation package is competitive.

- Provide opportunities for training and certification: Invest in training programs that help technicians stay up-to-date with the latest technologies and regulations. Support technicians in pursuing certifications such as NATE and EPA 608.

- Create a positive work environment: Foster a culture of teamwork, respect, and continuous improvement.

- Offer career advancement opportunities: Provide clear career paths and opportunities for technicians to advance within the company.

- Partner with local vocational schools and community colleges: Establish relationships with local educational institutions to recruit talented graduates.

By understanding the components of a split system air conditioner, staying current with industry trends, and investing in professional development, both technicians and employers can thrive in the dynamic HVAC industry. The demand for skilled HVAC professionals is projected to grow by 6 percent from 2022 to 2032, according to the Bureau of Labor Statistics, highlighting the long-term career prospects in this essential field.