Positive Pressure Ventilation Vs Negative Pressure Ventilation

Positive Pressure Ventilation vs. Negative Pressure Ventilation: A Comprehensive Guide

Ventilation is the cornerstone of indoor air quality, impacting everything from comfort and health to energy efficiency and building integrity. Two primary methods for controlling airflow are positive pressure ventilation and negative pressure ventilation. Understanding the nuances of each system is crucial for homeowners, HVAC technicians, and facility managers alike. This article provides an in-depth look at these two approaches, comparing their functionalities, applications, costs, and potential benefits.

Understanding Air Pressure Basics

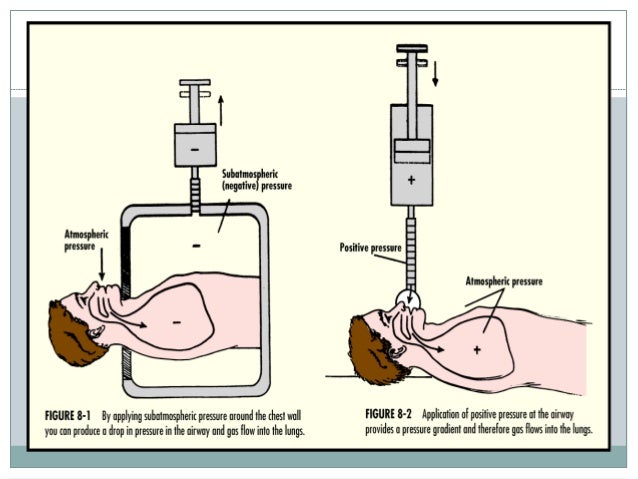

Before diving into the specifics of positive and negative pressure, it's important to understand the basic principles of air pressure. Air naturally moves from areas of high pressure to areas of low pressure. Ventilation systems leverage this principle to control the direction and flow rate of air within a building.

Imagine a balloon: When you blow air into it, you increase the pressure inside the balloon. As soon as you release the nozzle, the air rushes out towards the low pressure outside. Ventilation systems work similarly, albeit in a more controlled and sophisticated manner.

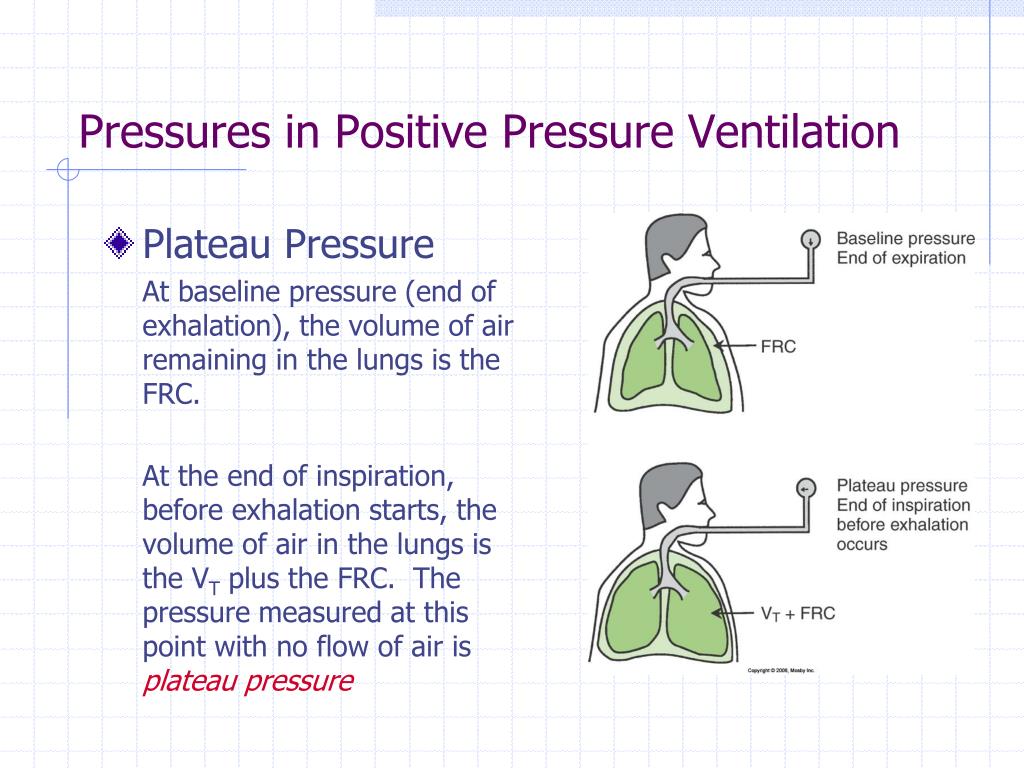

Positive Pressure Ventilation: Pushing Air In

Positive pressure ventilation systems work by introducing more air into a space than is exhausted. This creates a higher air pressure inside the building compared to the outside. The excess air then escapes through any available openings, such as windows, doors, cracks, and ventilation outlets. Essentially, the indoor air is "pushed" outwards.

How it Works: A typical positive pressure system involves a supply fan that forces fresh, filtered air into the building. This fan is usually connected to a ductwork system that distributes the air evenly throughout the space. The system may also incorporate a filter to remove dust, pollen, and other contaminants from the incoming air.

Applications:

- Homes in areas with high levels of outdoor pollutants: By maintaining positive pressure, the system minimizes the infiltration of unfiltered air from outside.

- Cleanrooms and laboratories: These environments require a high level of air purity. Positive pressure helps prevent contaminants from entering the space.

- Buildings with moisture problems: Positive pressure can help reduce humidity levels by continuously flushing out moist air.

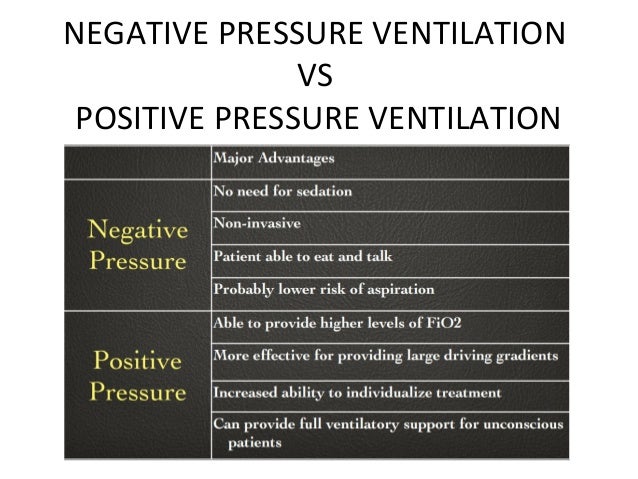

Advantages:

- Improved indoor air quality: Minimizes the infiltration of pollutants and allergens.

- Reduced moisture buildup: Helps prevent mold growth and structural damage.

- Energy efficiency: By controlling airflow, positive pressure ventilation can help reduce the need for excessive heating or cooling.

Disadvantages:

- Potential for structural damage: If the system is not properly balanced, excessive positive pressure can force moisture into wall cavities, leading to rot and decay.

- Increased energy consumption: Depending on the size of the fan and the efficiency of the system, positive pressure ventilation can increase energy bills.

- Noise: The fan can generate noise, especially if it's not properly maintained.

Negative Pressure Ventilation: Pulling Air Out

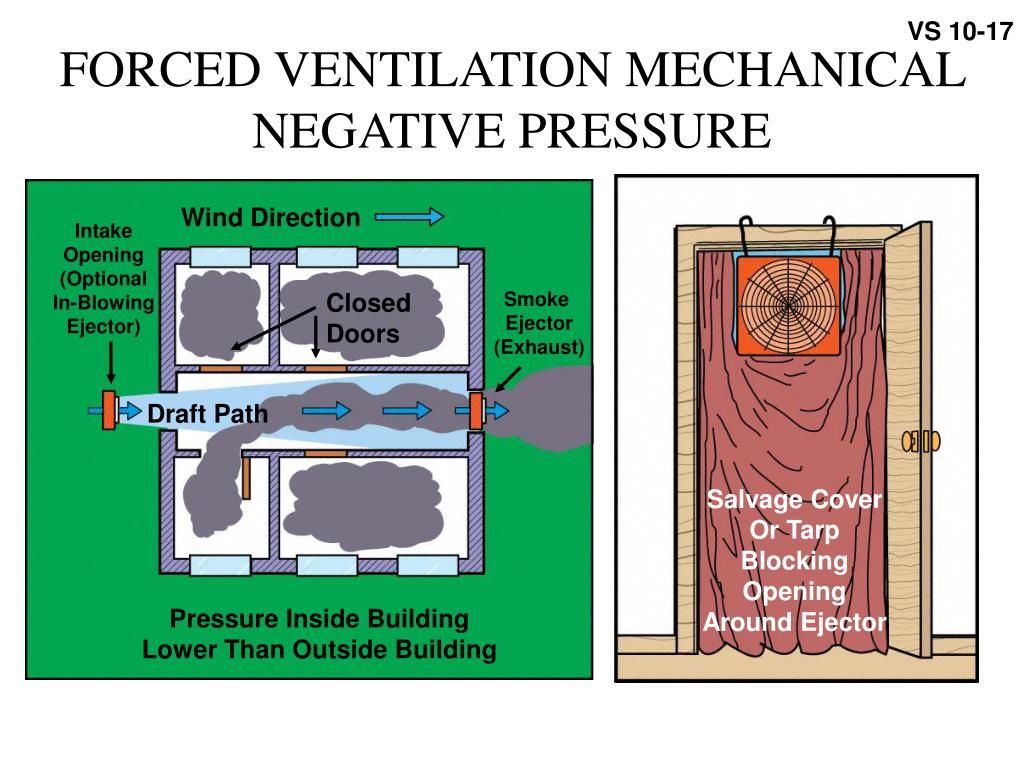

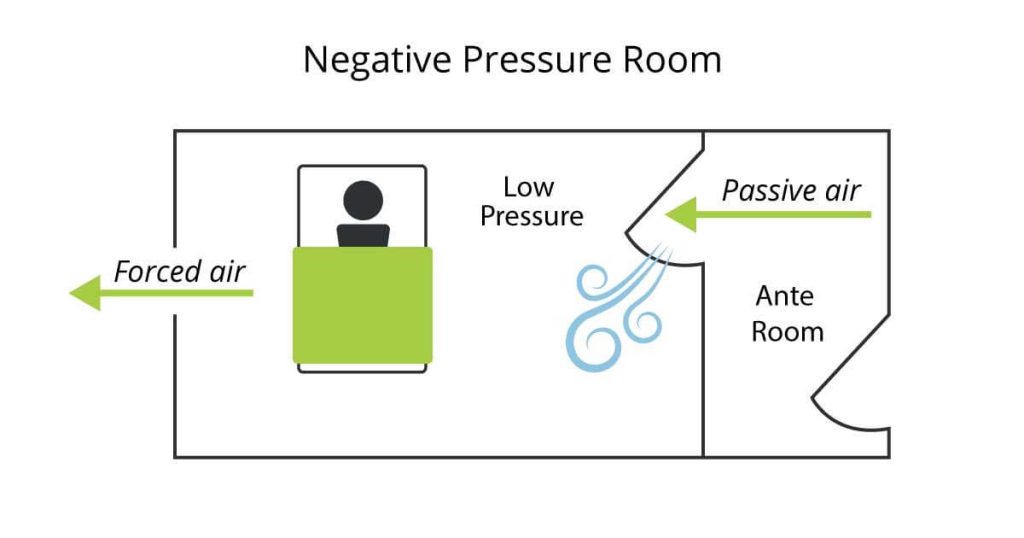

Negative pressure ventilation systems operate in the opposite manner. They exhaust more air from a space than is supplied. This creates a lower air pressure inside the building compared to the outside. As a result, outdoor air is drawn into the building through available openings to equalize the pressure. The indoor air is being "pulled" outwards.

How it Works: Negative pressure systems typically use exhaust fans to remove air from specific areas, such as bathrooms, kitchens, and laundry rooms. As air is exhausted, outside air is drawn in through windows, doors, and other openings.

Applications:

- Bathrooms and kitchens: Removing moisture and odors is the primary goal.

- Industrial settings: Controlling dust, fumes, and other airborne contaminants. For example, welding shops use exhaust fans to remove harmful fumes from the air.

- Isolation rooms in hospitals: Preventing the spread of infectious diseases.

Advantages:

- Effective removal of odors and pollutants: Ideal for areas with high levels of moisture, odors, or contaminants.

- Relatively low cost: Exhaust fans are generally inexpensive to install and operate.

- Simple installation: Basic negative pressure systems can be easily installed by homeowners.

Disadvantages:

- Potential for backdrafting: Negative pressure can draw combustion gases from appliances like furnaces and water heaters back into the living space, posing a serious health risk (carbon monoxide poisoning).

- Uncontrolled air infiltration: Air is drawn in through any available opening, potentially bringing in unfiltered air and outdoor pollutants.

- Energy inefficiency: Can lead to drafts and increased heating or cooling costs.

Cost Comparison

The cost of a ventilation system depends on several factors, including the size of the building, the type of system, and the complexity of the installation.

Positive Pressure Systems: Generally more expensive than negative pressure systems due to the need for a supply fan, ductwork, and filtration. A whole-house positive pressure system can range from $2,000 to $10,000, including installation.

Negative Pressure Systems: Typically less expensive, with exhaust fans costing anywhere from $50 to $500 per unit. Installation costs are also generally lower.

Operating Costs: Both systems will add to electricity bills. The operating costs depend on the fan's wattage and how often it runs. A well-designed positive pressure system with an efficient fan might have lower running costs than several continuously running exhaust fans in a negative pressure setup.

Energy Efficiency and Lifespan

Energy Efficiency: The energy efficiency of a ventilation system is determined by its ability to provide adequate ventilation while minimizing energy consumption. Look for Energy Star-rated fans and consider using a programmable thermostat to control fan operation.

Lifespan: The lifespan of a ventilation system depends on the quality of the components and the level of maintenance. Fans typically last 10-15 years, while ductwork can last much longer. Regular maintenance, such as cleaning filters and lubricating fan motors, can extend the lifespan of the system.

Maintenance Requirements

Proper maintenance is essential for ensuring the optimal performance and longevity of any ventilation system.

Positive Pressure Systems:

- Filter replacement: Replace air filters regularly (every 1-3 months) to maintain airflow and air quality.

- Duct cleaning: Clean ductwork periodically (every 3-5 years) to remove dust and debris.

- Fan maintenance: Lubricate fan motors and inspect for any signs of wear or damage.

Negative Pressure Systems:

- Fan cleaning: Clean fan blades and housings regularly to remove dust and debris.

- Ventilation checks: Ensure that exhaust vents are not blocked by debris or obstructions.

- Backdraft damper inspection: Ensure backdraft dampers (if installed) are functioning properly to prevent air from flowing back into the building.

Balancing the System: Crucial for Both Types

Whether you opt for positive or negative pressure ventilation, achieving a balanced system is paramount. Balanced ventilation refers to a system where the amount of air supplied equals the amount of air exhausted. An unbalanced system can lead to several problems, including:

- Pressure imbalances: Can cause discomfort, drafts, and increased energy consumption.

- Structural damage: Excessive pressure can damage building materials.

- Poor air quality: Can lead to the buildup of pollutants and moisture.

To ensure a balanced system, it's essential to work with a qualified HVAC technician who can perform a blower door test and other diagnostic procedures to assess the airflow characteristics of the building.

Heat Recovery Ventilation (HRV) and Energy Recovery Ventilation (ERV)

For those seeking a more energy-efficient solution, Heat Recovery Ventilation (HRV) and Energy Recovery Ventilation (ERV) systems offer a significant improvement over basic positive or negative pressure systems. Both HRV and ERV systems pre-condition incoming fresh air by transferring heat or both heat and moisture from the outgoing air. This significantly reduces the energy required to heat or cool the incoming air.

HRV systems are best suited for colder climates where the primary goal is to recover heat from the exhaust air.

ERV systems are better suited for warmer, more humid climates where the focus is on recovering both heat and moisture from the exhaust air.

Choosing the Right System

Selecting the appropriate ventilation system depends on various factors, including your climate, building type, budget, and specific indoor air quality needs. Consult with a qualified HVAC professional to determine the best solution for your situation. Consider the long-term costs and benefits of each system, as well as the potential impact on your health and comfort.

In Summary:

- Positive Pressure: Best for minimizing outdoor pollutants and moisture, but requires careful balancing to prevent structural damage.

- Negative Pressure: Simple and inexpensive for removing odors and moisture from specific areas, but can lead to backdrafting and uncontrolled air infiltration.

- HRV/ERV: Offers superior energy efficiency by recovering heat or energy from exhaust air.

By understanding the principles of positive and negative pressure ventilation, you can make informed decisions about your HVAC system and ensure a healthy and comfortable indoor environment.