Rectangular Sheet Metal Ducts Are Joined Together Using

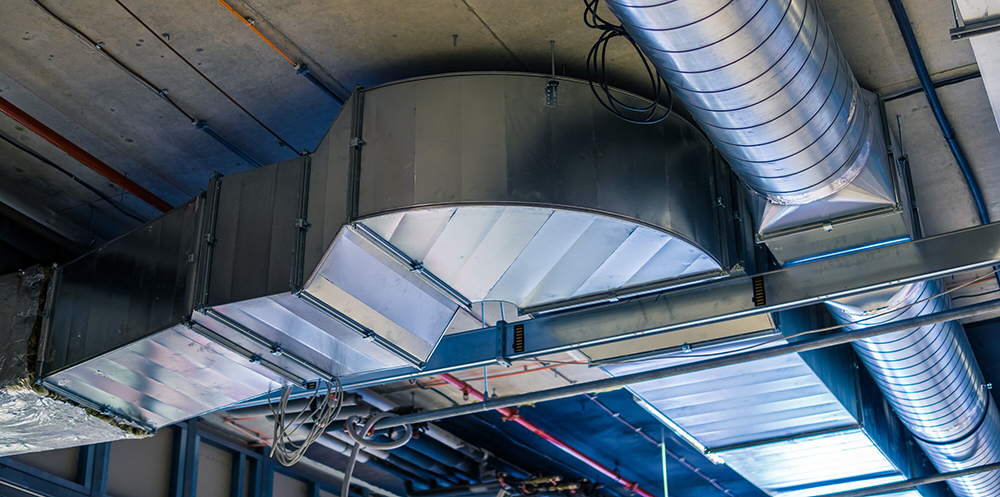

Rectangular sheet metal ducts are the workhorses of many HVAC (Heating, Ventilation, and Air Conditioning) systems. They're the pathways that deliver conditioned air – whether it's warm, cool, or simply fresh – throughout buildings, from homes to skyscrapers. But how are these essential components joined together to create a seamless and efficient air distribution network? This guide will explore the various methods used to connect rectangular sheet metal ducts, providing a clear understanding of each technique and their respective advantages.

Understanding the Basics

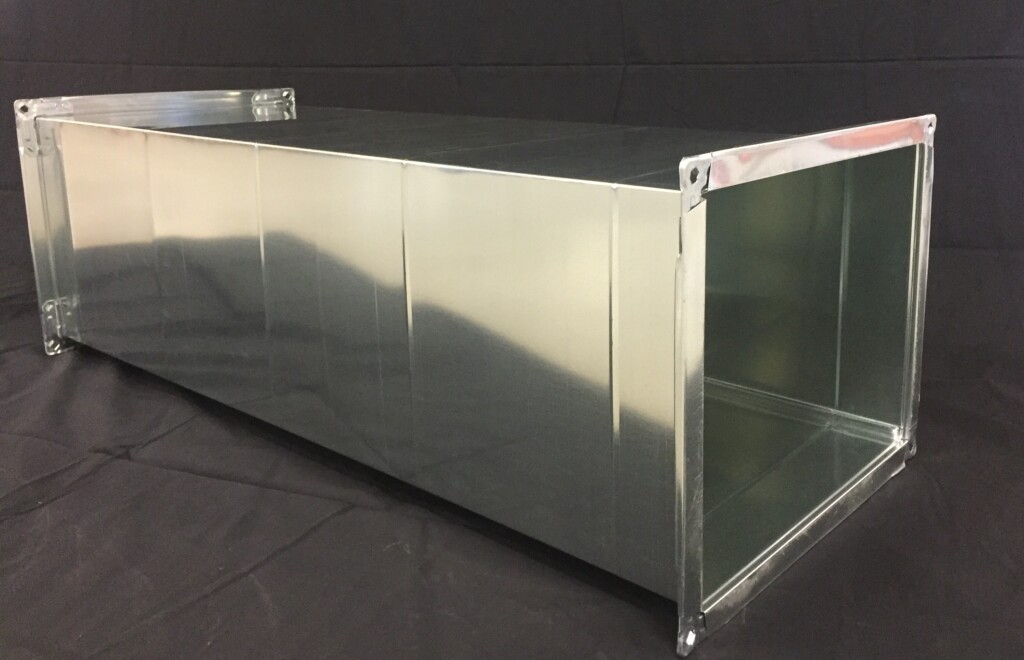

Before diving into specific joining methods, it's crucial to grasp some fundamental concepts. Rectangular ductwork typically consists of sections of sheet metal fabricated to precise dimensions. These sections need to be connected securely and airtight to prevent leakage and maintain optimal airflow. Think of it like a puzzle – each piece needs to fit perfectly to create a complete and functional picture.

The choice of joining method often depends on factors like the duct's size, the gauge (thickness) of the sheet metal, the system's operating pressure, and local building codes. Some methods are faster and more cost-effective, while others provide a stronger and more durable connection.

Key Considerations Before Joining

Before any joining happens, a few things must be in place:

- Accurate Measurements and Cuts: Precise measurements and clean cuts are essential. Inaccurate cuts will lead to gaps and leaks, defeating the purpose of an airtight duct system.

- Proper Sealing: Regardless of the joining method, sealant plays a critical role. Sealants fill any remaining gaps and ensure an airtight connection, preventing energy loss and maintaining air quality.

- Safety Precautions: Working with sheet metal involves sharp edges. Wear appropriate safety gear, including gloves and eye protection, to prevent injuries.

Common Methods for Joining Rectangular Ductwork

Now, let's explore the most common methods for joining rectangular sheet metal ducts:

1. S-Cleats and Drive Cleats

This is a widely used and relatively inexpensive method, particularly for smaller to medium-sized ductwork. S-cleats are formed metal strips that hook onto the edge of one duct section, while drive cleats are hammered into place to secure the connection. It's a bit like interlocking puzzle pieces and then using a wedge to hold them tightly together.

How it Works:

- Forming the Edges: The edges of the duct sections are typically formed to create a "pocket" or recess where the S-cleat will engage.

- Attaching S-Cleats: S-cleats are slid onto the formed edge of one duct section.

- Joining the Sections: The duct section with the S-cleat is aligned with the adjacent section.

- Securing with Drive Cleats: Drive cleats are hammered into the seam where the two sections meet, locking the S-cleats in place and creating a rigid connection. These are usually placed at intervals along the seam.

Advantages:

- Cost-effective: S-cleats and drive cleats are relatively inexpensive compared to other joining methods.

- Easy to Install: The installation process is relatively straightforward, requiring basic tools like a hammer and snips.

- Quick Assembly: This method allows for rapid assembly of ductwork sections.

Disadvantages:

- Lower Pressure Rating: S-cleats and drive cleats may not be suitable for high-pressure systems.

- Potential for Leaks: While sealant can help, the connection isn't inherently airtight and relies on the tightness of the cleats and the effectiveness of the sealant.

- Not Ideal for Large Ducts: Can become cumbersome for very large or heavy duct sections.

2. Slip and Drive Connections (Similar to S-Cleats, but with Variations)

This is a variation of the S-cleat and drive cleat method. The main difference is in the shape of the formed edges and the type of cleat used. Like S-cleats, it's still a mechanical connection, relying on the interlocking of metal pieces.

How it Works: Similar to S-cleats, but utilizes different shaped edges and cleats that slide or "slip" into place before being secured with drive cleats.

Advantages:

- Shares similar advantages to S-cleat and drive cleat connections, including cost-effectiveness and ease of installation.

- Some variations may offer slightly improved strength or airtightness compared to standard S-cleats.

Disadvantages:

- Also shares similar disadvantages, including lower pressure rating and potential for leaks.

- May require specific tools or dies for forming the edges.

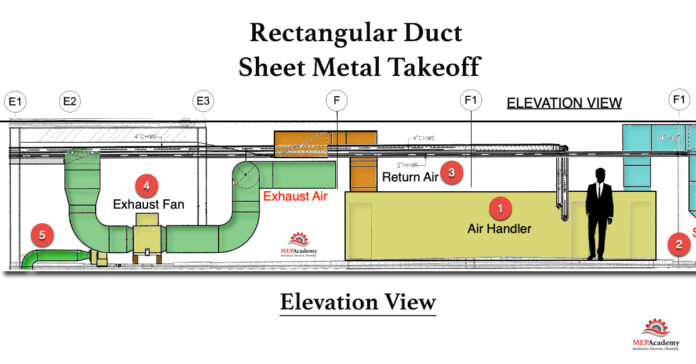

3. Flanged Connections (e.g., TDC/TDF, Ductmate)

Flanged connections represent a more robust and airtight method, especially for larger ductwork or systems with higher pressure requirements. These systems utilize a metal flange that is attached to the end of each duct section. These flanges are then bolted together, creating a strong and secure seal. Think of it like connecting sections of pipe using flanges and bolts – it's a much sturdier connection than simply sliding pieces together.

TDC (Transverse Duct Connector) and TDF (Transverse Duct Flange) are two common types of flanged systems. Ductmate is another popular brand.

How it Works:

- Attaching the Flange: The metal flange (TDC, TDF, or Ductmate flange) is attached to the end of the duct section. This is often done using specialized forming equipment that crimps or locks the flange onto the duct.

- Gasketing: A gasket is placed between the flanges to ensure an airtight seal. This gasket is often made of neoprene or a similar flexible material.

- Bolting the Flanges: The flanges are aligned and bolted together using bolts and nuts. The bolts are tightened to compress the gasket and create a strong, airtight connection.

Advantages:

- High Strength and Rigidity: Flanged connections provide a very strong and rigid connection, suitable for large ductwork and high-pressure systems.

- Excellent Airtightness: The combination of flanges, gaskets, and bolts creates a highly airtight seal, minimizing leakage and maximizing energy efficiency.

- Ease of Disassembly: While secure, flanged connections can be easily disassembled for maintenance or modifications.

Disadvantages:

- Higher Cost: Flanged systems are generally more expensive than S-cleat and drive cleat connections.

- More Labor-Intensive Installation: The installation process requires more time and specialized tools for attaching the flanges and bolting the sections together.

- Requires Precise Alignment: Proper alignment of the flanges is crucial for a good seal.

4. Welding

Welding is a permanent joining method that creates a very strong and airtight connection. However, it's generally reserved for specialized applications due to its complexity and cost.

How it Works:

- Preparation: The edges of the duct sections are carefully aligned and cleaned.

- Welding: A welding process, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding, is used to fuse the metal edges together, creating a continuous bond.

- Finishing: The weld is often ground smooth and treated to prevent corrosion.

Advantages:

- Extremely Strong and Durable: Welding creates a very strong and durable connection that can withstand high pressures and temperatures.

- Completely Airtight: A properly executed weld creates a completely airtight seal.

- Permanent Connection: Ideal for applications where a permanent and reliable connection is required.

Disadvantages:

- High Cost: Welding requires specialized equipment and skilled welders, making it a more expensive option.

- Time-Consuming: The welding process can be time-consuming, especially for long seams.

- Difficult to Modify: Welded connections are difficult to disassemble or modify.

- Heat Distortion: The heat from welding can cause distortion of the sheet metal.

5. Riveting

Riveting is another method for creating a strong and relatively permanent connection. While less common than other methods, it can be useful in specific situations.

How it Works:

- Overlapping Edges: The edges of the duct sections are overlapped.

- Drilling Holes: Holes are drilled through both layers of sheet metal.

- Inserting Rivets: Rivets are inserted into the holes and then deformed (usually by hammering or using a rivet gun) to create a tight clamp between the two layers of metal.

Advantages:

- Strong Connection: Rivets create a strong and durable connection.

- Relatively Simple: The riveting process is relatively simple and requires basic tools.

- Good for Certain Materials: Riveting can be a good option for joining dissimilar metals.

Disadvantages:

- Not Always Airtight: Riveted connections are not inherently airtight and require sealant to prevent leaks.

- Can Be Time-Consuming: Installing a large number of rivets can be time-consuming.

- Aesthetic Considerations: Rivets can be visible on the finished product, which may not be desirable in some applications.

6. Spiral Lock Seam

This method is primarily used for manufacturing the *duct* itself, rather than joining sections together in the field. It's how many long runs of rectangular duct are initially fabricated.

How it Works: A continuous spiral lock seam is formed along the length of the duct, essentially creating a mechanically locked joint. The sheet metal is folded and interlocked in a helical fashion.

Advantages:

- Strong: Creates a structurally sound duct.

- Efficient Manufacturing: Allows for efficient production of long duct runs.

Disadvantages:

- Not a Field Joining Method: Primarily used in the factory, not for connecting duct sections on-site.

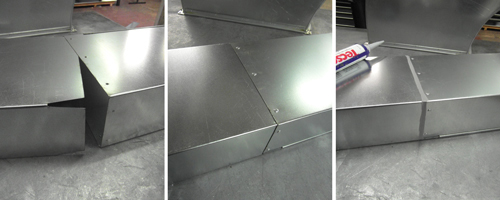

The Importance of Sealing

No matter which joining method you choose, sealing is absolutely critical. Sealant fills any remaining gaps and ensures an airtight connection. Common sealants for ductwork include:

- Mastic Sealant: A flexible, water-based sealant that is easy to apply and provides a good seal.

- Silicone Sealant: A more durable and heat-resistant sealant that is suitable for high-temperature applications.

- Foil Tape: Used to seal seams and joints, providing an airtight and vapor-tight barrier.

Proper sealing not only prevents air leaks but also helps to maintain air quality by preventing dust and other contaminants from entering the duct system.

Choosing the Right Method

Selecting the right joining method for rectangular sheet metal ducts depends on several factors. Consider these questions:

- What is the size and gauge of the ductwork?

- What is the operating pressure of the system?

- What are the local building codes and regulations?

- What is the budget for the project?

- What level of airtightness is required?

- What is the long term accessibility requirement?

By carefully considering these factors, you can choose the joining method that will provide the best performance, durability, and cost-effectiveness for your specific application.

In conclusion, joining rectangular sheet metal ducts requires careful consideration and the selection of an appropriate method. Whether you choose the simplicity of S-cleats and drive cleats, the robustness of flanged connections, or the permanence of welding, remember that proper sealing is essential for a reliable and efficient HVAC system. A well-sealed duct system translates to improved energy efficiency, better air quality, and a more comfortable indoor environment.