Rheem Furnace Blower Motor Replacement

A failing blower motor in your Rheem furnace can quickly turn a cozy home into a frigid environment. Replacing it is a crucial repair that can often be managed effectively by both experienced DIYers and HVAC professionals. This comprehensive guide covers everything you need to know about Rheem furnace blower motor replacement, from understanding the motor’s function to choosing the right replacement and performing the installation.

Understanding the Blower Motor

The blower motor is the heart of your Rheem furnace's air circulation system. Located inside the furnace cabinet, its primary function is to move heated air throughout your home via ductwork. It pulls air from the return vents, passes it over the heated heat exchanger, and then forces the warmed air through the supply vents. Without a functioning blower motor, the furnace's heating process is rendered useless, as the heat remains trapped inside the unit.

Blower motors come in various types, each offering different levels of efficiency and performance. The most common types found in Rheem furnaces include:

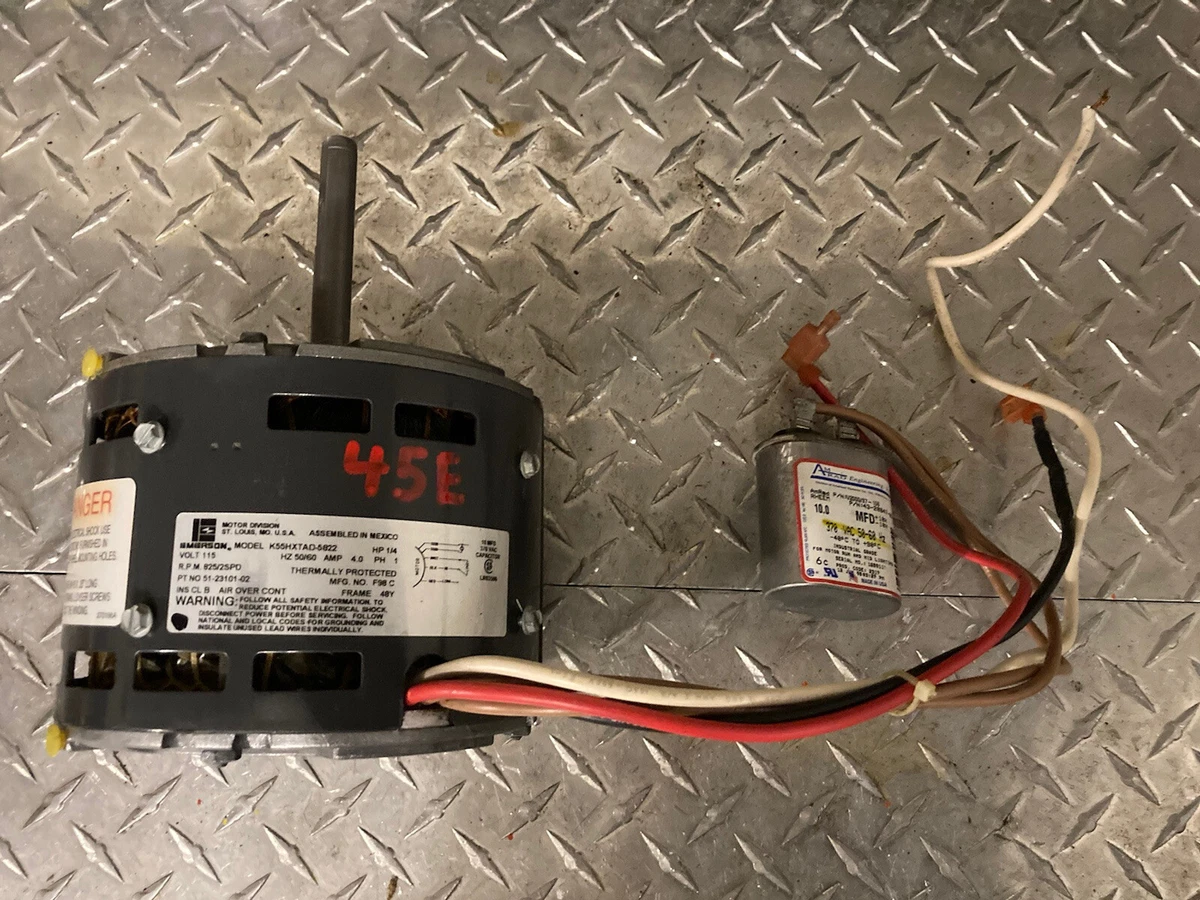

- PSC (Permanent Split Capacitor) Motors: These are the traditional, less expensive option. They operate at a constant speed and are less energy-efficient compared to newer technologies.

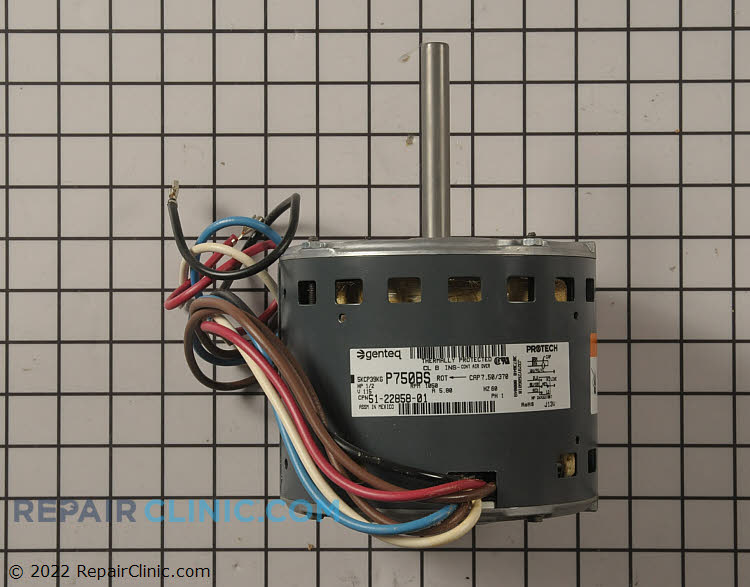

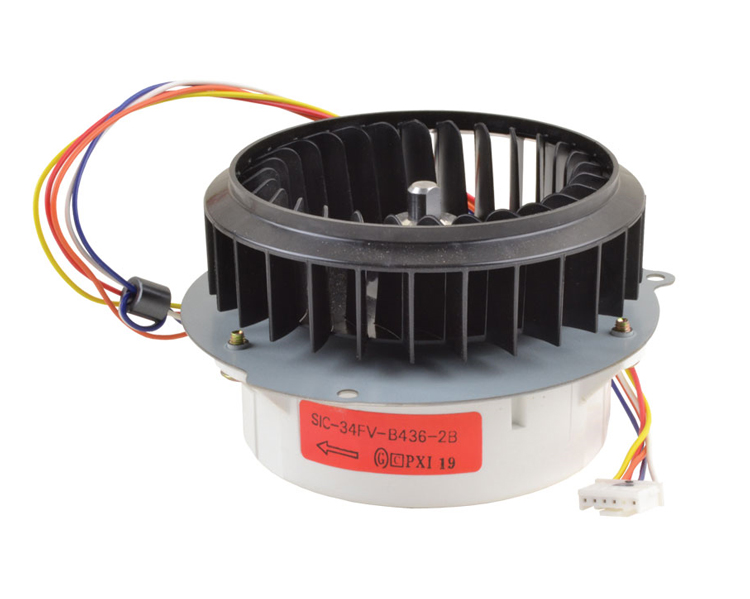

- ECM (Electronically Commutated Motor) Motors: Also known as variable-speed motors, ECMs are significantly more efficient. They can adjust their speed based on the heating or cooling demand, resulting in consistent temperature and reduced energy consumption. Some high-efficiency Rheem furnaces utilize ECMs for optimal performance.

- Multi-Speed Motors: Offer a compromise between PSC and ECM, providing a few pre-set speed options for better control and efficiency than PSC motors.

Identifying the type of blower motor in your Rheem furnace is crucial for selecting the correct replacement. This information can typically be found on the motor's nameplate or in the furnace's technical documentation. Also note the horsepower (HP), voltage, amperage, and RPM of the existing motor.

Signs of a Failing Blower Motor

Recognizing the symptoms of a failing blower motor early can prevent further damage to your Rheem furnace and potentially save you money on repairs. Common signs include:

- No Airflow: This is the most obvious sign. If the furnace is running but no air is coming out of the vents, the blower motor is likely the culprit.

- Weak Airflow: Reduced airflow can indicate a motor struggling to operate at full capacity.

- Unusual Noises: Grinding, squealing, or humming sounds coming from the furnace cabinet can suggest a failing motor bearing or other mechanical issues.

- Overheating: The motor may overheat and shut down if it's struggling to turn the blower wheel. This can trigger the furnace's high-limit switch, causing the system to shut off.

- Burning Smell: A burning odor emanating from the furnace could indicate a short circuit or insulation failure within the motor.

- Frequent Starts and Stops: A failing motor may cause the furnace to cycle on and off more frequently than normal.

Tools and Materials Needed

Before starting the Rheem furnace blower motor replacement, gather the necessary tools and materials:

- New Blower Motor: Ensure it's the correct type and specifications for your Rheem furnace model. Cross-reference the part number from the old motor with the replacement.

- Screwdrivers: A set of Phillips head and flathead screwdrivers.

- Socket Set: For removing bolts and nuts.

- Wire Strippers/Crimpers: For connecting electrical wires.

- Wire Connectors (Wire Nuts): To safely join wires.

- Electrical Tape: For insulating wire connections.

- Multimeter: To test for voltage and continuity.

- Work Gloves: To protect your hands.

- Safety Glasses: To protect your eyes.

- HVAC Tape (Foil Tape): To seal any gaps in the furnace cabinet.

- Camera or Phone: To take pictures of the wiring before disconnecting it.

Step-by-Step Replacement Process

Important Safety Note: Always turn off the power to the furnace at the breaker box before starting any electrical work. Verify the power is off using a multimeter.

- Access the Blower Motor: Open the furnace access panel. This usually requires removing screws or clips. Refer to your Rheem furnace’s manual for specific instructions.

- Locate and Disconnect the Wiring: The blower motor will be connected to the furnace's electrical system with several wires. Before disconnecting any wires, take clear pictures of the wiring configuration. This is crucial for proper re-wiring during installation. Use wire strippers to carefully disconnect the wires from the motor.

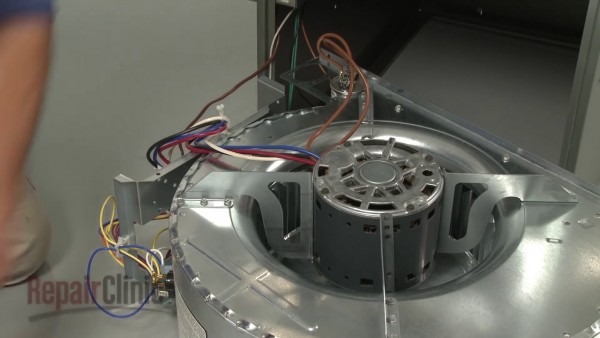

- Remove the Blower Assembly: The blower motor is typically attached to a blower assembly, which includes the blower wheel. This assembly is usually held in place by screws or bolts. Remove these fasteners and carefully slide the blower assembly out of the furnace.

- Detach the Old Motor from the Blower Wheel: The motor is connected to the blower wheel with a set screw or clamp. Loosen the set screw or clamp and carefully detach the motor from the blower wheel. Be careful not to damage the blower wheel.

- Install the New Motor: Attach the new blower motor to the blower wheel in the same orientation as the old motor. Tighten the set screw or clamp securely.

- Reinstall the Blower Assembly: Slide the blower assembly back into the furnace cabinet and secure it with the screws or bolts you removed earlier.

- Reconnect the Wiring: Using the pictures you took earlier, carefully reconnect the wires to the new blower motor. Ensure that all connections are secure and properly insulated with wire connectors and electrical tape.

- Test the Motor: Before closing up the furnace, temporarily turn the power back on and test the new blower motor. Set the thermostat to call for heat and observe the motor's operation. Listen for any unusual noises or vibrations. If everything seems to be working correctly, turn the power back off.

- Replace the Access Panel: Securely reattach the furnace access panel.

- Restore Power: Turn the power back on at the breaker box.

- Test the Furnace: Set the thermostat to call for heat and monitor the furnace's performance. Check for proper airflow and consistent temperature.

Choosing the Right Replacement Motor

Selecting the correct replacement motor is paramount for optimal performance and longevity. Consider the following factors:

- Motor Type: As mentioned earlier, identify the type of motor (PSC, ECM, or Multi-Speed) that your Rheem furnace uses. Replacing an ECM motor with a PSC motor will significantly reduce efficiency and may cause compatibility issues.

- Horsepower (HP): Match the horsepower rating of the old motor. Using a motor with a lower HP rating may result in insufficient airflow, while a motor with a higher HP rating may consume more energy than necessary.

- Voltage and Amperage: Ensure that the voltage and amperage ratings of the new motor match the specifications of your Rheem furnace's electrical system.

- RPM (Revolutions Per Minute): The RPM rating determines the speed at which the motor rotates. Match the RPM rating of the old motor for optimal airflow.

- Frame Size: The frame size refers to the physical dimensions of the motor. Ensure that the new motor has the same frame size as the old motor for proper fitment.

- Shaft Size and Orientation: Verify that the shaft size and orientation of the new motor match the blower wheel.

- Manufacturer and Warranty: Choose a reputable motor manufacturer with a good warranty. This will protect you against defects and ensure that the motor will last.

Cost Considerations

The cost of a Rheem furnace blower motor replacement can vary depending on several factors, including the type of motor, the brand, and whether you hire a professional HVAC technician. Here's a general breakdown of the costs:

- Blower Motor: PSC motors typically range from $100 to $300, while ECM motors can cost anywhere from $300 to $800 or more.

- Professional Labor: Hiring an HVAC technician to replace the blower motor can add $200 to $500 to the total cost, depending on the complexity of the job and the technician's hourly rate.

DIY replacement can save on labor costs, but it requires technical knowledge and experience. If you're not comfortable working with electrical components, it's best to hire a qualified HVAC technician.

Maintenance Tips

Proper maintenance can extend the lifespan of your Rheem furnace blower motor and prevent premature failure:

- Regular Filter Changes: A dirty air filter restricts airflow, forcing the blower motor to work harder and potentially overheat. Change your air filter every 1-3 months, depending on the air quality in your home.

- Professional Inspections: Schedule annual furnace maintenance with a qualified HVAC technician. They can inspect the blower motor for signs of wear and tear and lubricate the bearings as needed.

- Keep the Furnace Clean: Dust and debris can accumulate inside the furnace cabinet, potentially affecting the blower motor's performance. Clean the interior of the furnace periodically with a vacuum cleaner.

Troubleshooting Common Issues

Even after replacing the blower motor, you may encounter some issues. Here are some common problems and their solutions:

- Motor Not Running: Check the breaker, wiring connections, and the furnace's limit switch.

- Motor Runs But No Airflow: Check the blower wheel for obstructions and ensure that the motor is properly attached to the blower wheel.

- Motor is Noisy: Inspect the blower wheel for damage or imbalance. Also, check the motor bearings for wear and tear.

- Furnace Short Cycling: This could be due to a faulty limit switch or restricted airflow. Check the air filter and ductwork for obstructions.

When to Call a Professional

While some homeowners may be comfortable replacing a Rheem furnace blower motor themselves, there are situations where it's best to call a professional HVAC technician:

- If you're not comfortable working with electrical components.

- If you're unsure about the correct replacement motor.

- If you encounter any difficulties during the replacement process.

- If you suspect a more serious problem with your furnace.

A qualified HVAC technician has the expertise and tools to diagnose and repair complex furnace issues safely and efficiently.

Replacing a Rheem furnace blower motor is a significant repair that can restore your home's heating system to optimal performance. By understanding the blower motor's function, recognizing the signs of failure, and following the proper replacement procedures, you can ensure a comfortable and efficient heating season.