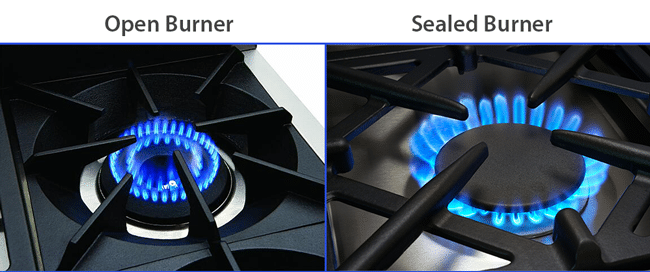

Sealed Burners Vs Open Burners Gas

Sealed Burners vs. Open Burners: A Comprehensive Guide for Homeowners, Technicians, and Facility Managers

Gas-powered appliances, particularly ranges and stoves, are a staple in many homes and commercial kitchens. At the heart of these appliances are the burners, which come in two primary designs: sealed burners and open burners. Understanding the differences between these two types is crucial for making informed decisions about appliance purchases, maintenance, and overall kitchen performance. This article provides a detailed comparison, covering aspects relevant to homeowners, HVAC technicians, and facility managers.

Understanding the Basics: Open Burners

Open burners are the traditional design found in older gas ranges and some modern, high-BTU (British Thermal Unit) professional-style ranges. They are characterized by a burner head that sits directly exposed to the cooking surface, with a gap between the burner and the grate. This design allows for more direct heat transfer to the cookware.

How They Work: Gas flows through a tube to the burner head, where it mixes with air and is ignited by a spark or pilot light. The flames rise directly around the cookware.

Key Characteristics:

- High BTU Output: Typically offer higher BTU ratings, allowing for faster heating and more intense cooking.

- Simpler Design: Generally less complex mechanically, which can translate to easier repairs in some cases.

- More Difficult to Clean: Spills and food debris can easily fall into the open space around the burner, making cleaning more challenging.

- Less Efficient: More heat is lost to the surrounding environment due to the open design.

Understanding the Basics: Sealed Burners

Sealed burners are a more modern design that features a burner head that is sealed directly to the cooktop surface. This eliminates the gap between the burner and the cooktop, preventing spills from entering the burner assembly.

How They Work: Similar to open burners, gas flows to the burner head. However, the sealed design ensures that all the gas is directed upward towards the cookware. A spark ignites the gas and air mixture.

Key Characteristics:

- Easier to Clean: The sealed design prevents spills from entering the burner assembly, making cleanup significantly easier.

- More Efficient: Less heat is lost to the surrounding environment, resulting in better energy efficiency.

- Lower BTU Output: Typically have lower BTU ratings compared to open burners, although high-end models can offer comparable performance.

- More Complex Design: Can be more complex mechanically, potentially leading to more intricate repairs.

A Detailed Comparison: Performance, Efficiency, and Maintenance

To make an informed decision, consider these factors:

Performance

Heating Speed and Power: Open burners often boast higher BTU ratings. A range with open burners might deliver 18,000-20,000 BTU on its highest setting, allowing for rapid boiling, searing, and wok cooking. Sealed burners, on the other hand, might range from 5,000-15,000 BTU. For example, quickly boiling a large pot of water for pasta might be noticeably faster on a high-BTU open burner.

Heat Distribution: Both types can offer even heat distribution, especially in modern designs with well-engineered burner heads. However, some users find that open burners provide a more intense, concentrated heat, which is beneficial for certain cooking techniques.

Simmering Capability: Sealed burners are often better at maintaining a low, consistent simmer. The sealed design helps to prevent drafts from affecting the flame. Some models offer dedicated simmer burners with extremely low BTU output.

Efficiency

Energy Consumption: Sealed burners are generally more energy-efficient because less heat escapes into the surrounding environment. This translates to lower gas bills over time. While the difference might seem small, it can add up, especially in commercial kitchens where ranges are used extensively. Consider models with Energy Star certification for optimal efficiency.

Heat Loss: Open burners, by their very design, lose more heat. This can also impact the ambient temperature of the kitchen, potentially increasing the load on your HVAC system, particularly in the summer months. This is particularly relevant for facility managers in commercial settings.

Maintenance

Cleaning: This is where sealed burners shine. The sealed design prevents spills from entering the burner assembly, making cleanup much easier. Simply wipe the surface with a damp cloth. Open burners require more effort. Food debris can fall into the burner assembly, potentially clogging the gas ports and affecting performance. Regular cleaning, often involving disassembling the burner, is necessary. For homeowners with busy lifestyles, this is a significant advantage of sealed burners. For facility managers, this translates to reduced labor costs for cleaning.

Repair: The simpler design of open burners can sometimes make repairs easier. However, modern sealed burners are generally reliable. Both types of burners can experience issues such as clogged gas ports, faulty igniters, and damaged burner heads. Regular maintenance, such as cleaning burner ports, can prevent many of these issues. When repairs are needed, it is always recommended to consult a qualified HVAC technician or appliance repair professional.

Cost

Initial Cost: The initial cost of gas ranges with sealed burners and open burners can vary depending on brand, features, and BTU output. Generally, high-end professional-style ranges with open burners tend to be more expensive. However, there are many affordable options available for both types.

Operating Costs: As mentioned earlier, sealed burners are generally more energy-efficient, leading to lower gas bills over time. While the difference might not be substantial for occasional home use, it can be a significant factor for commercial kitchens. Also, consider the potential impact on cooling costs. More heat output in a kitchen with open burners may translate into a higher load on the air conditioner.

Maintenance Costs: The easier cleaning of sealed burners can translate to lower maintenance costs over the long run. Less time spent cleaning means lower labor costs for facility managers. Fewer clogs and less build up translates to increased lifespan of the burner itself.

Choosing the Right Burner Type: Factors to Consider

The best choice depends on your individual needs and priorities:

- Cooking Style: If you frequently sear meats, boil large pots of water, or use a wok, the high BTU output of open burners might be preferable. If you primarily simmer sauces, melt chocolate, or cook delicate dishes, sealed burners might be a better choice.

- Cleaning Preferences: If you prioritize easy cleanup, sealed burners are the clear winner.

- Budget: Consider both the initial cost and the long-term operating costs.

- Kitchen Size: In smaller kitchens, the reduced heat output of sealed burners might be advantageous.

- HVAC System: In warmer climates or kitchens without robust ventilation, consider the impact of open burners on your cooling costs.

Recommendations

For Homeowners: If you value ease of cleaning and energy efficiency, sealed burners are a good choice. Look for models with a range of BTU outputs to accommodate different cooking needs. If you are a serious cook who needs high heat for certain dishes, consider a range with at least one high-BTU open burner.

For HVAC Technicians: When servicing gas ranges, be familiar with both sealed and open burner designs. Understand the common problems associated with each type and know how to properly clean and repair them. When recommending new appliances to clients, consider their cooking habits and preferences.

For Facility Managers: Evaluate the energy efficiency and maintenance costs of gas ranges in your commercial kitchens. Consider replacing older, less efficient models with newer, sealed burner ranges. Implement regular cleaning schedules to prevent clogs and ensure optimal performance. Consider the added load on HVAC systems created by open burner units during hotter months.

Conclusion

The choice between sealed burners and open burners is a personal one, based on your individual needs and priorities. By understanding the differences between these two types of burners, you can make an informed decision that will improve your cooking experience and save you money in the long run. Whether you are a homeowner, an HVAC technician, or a facility manager, this comprehensive guide provides the information you need to make the right choice. Always consult with qualified professionals for installation, maintenance, and repair of gas appliances.