The Air Cycle Cooling System Produces Cold Air By

Understanding refrigeration cycles is fundamental to a successful career in HVAC. While vapor-compression systems dominate the residential and commercial cooling landscape, the air cycle cooling system offers a unique approach, particularly in aviation and some industrial applications. This article will delve into the mechanics of air cycle cooling, its advantages, and its implications for HVAC professionals.

How Air Cycle Cooling Works: Producing Cold Air Through Expansion

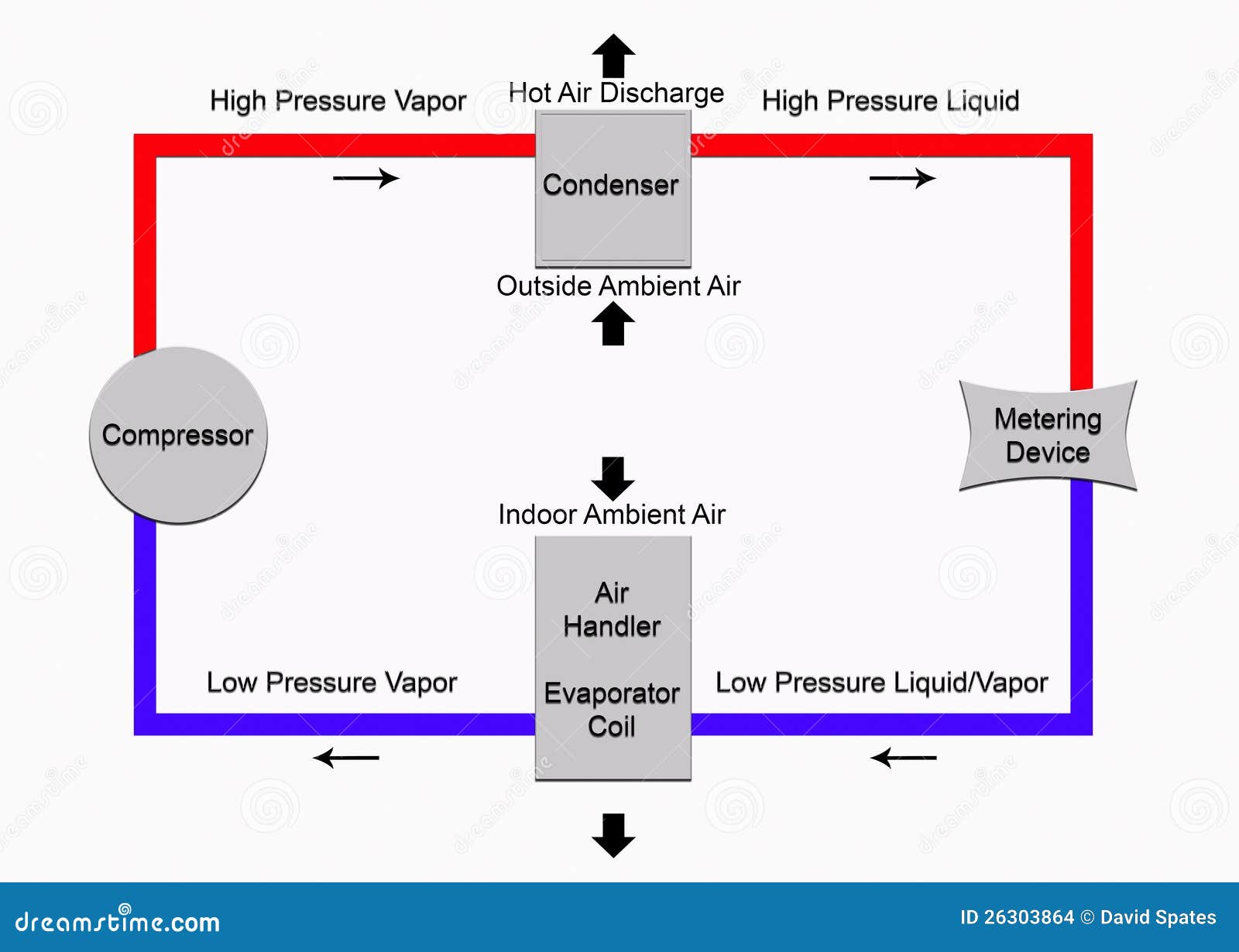

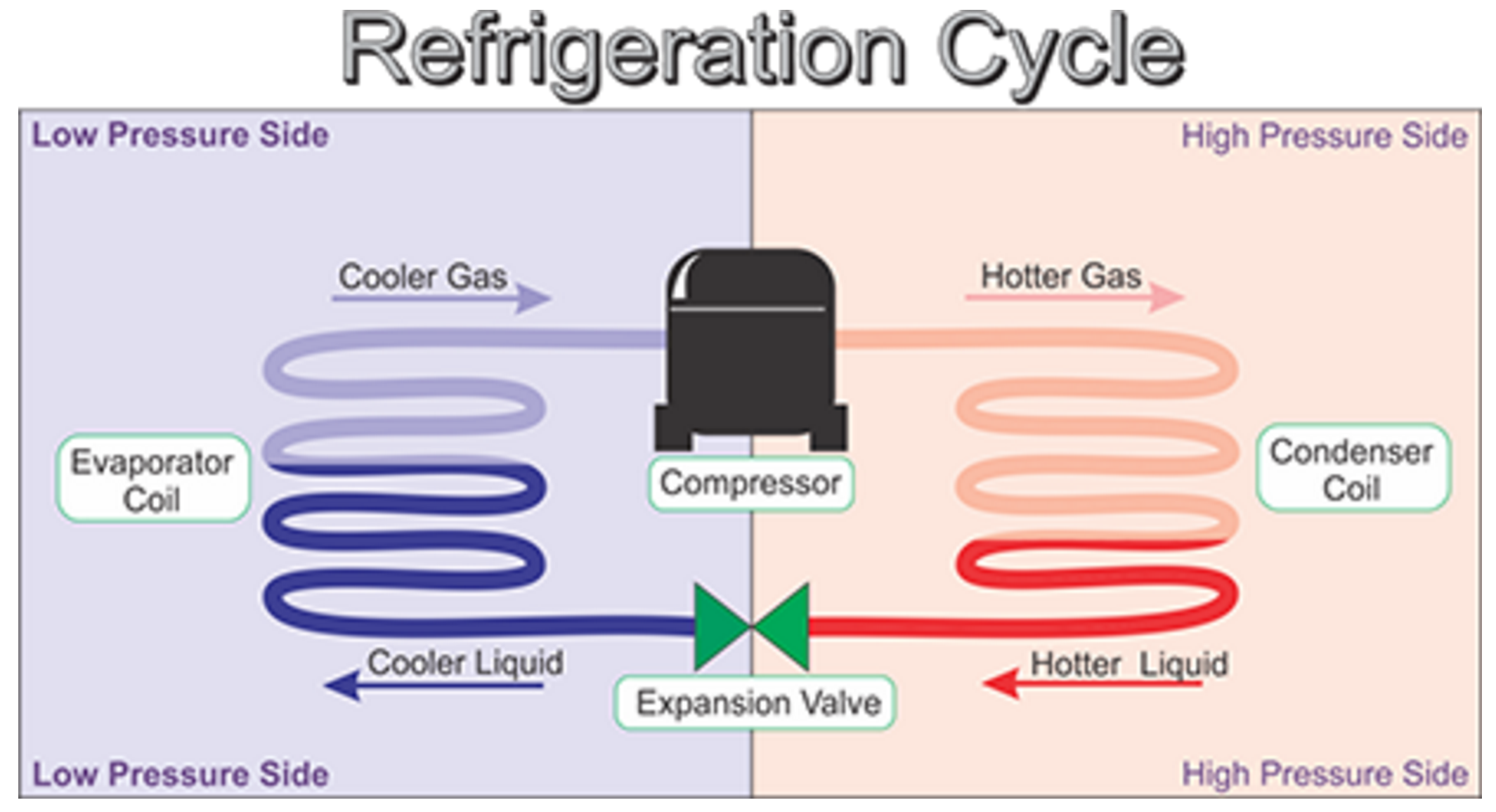

Unlike vapor-compression, which relies on phase changes of a refrigerant, the air cycle cooling system utilizes the thermodynamic principles of compressing, cooling, and expanding air to generate cold air. The core concept revolves around the Joule-Thomson effect, where the temperature of a real gas changes when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the environment. This process is also known as adiabatic expansion.

Here's a breakdown of the typical air cycle cooling system:

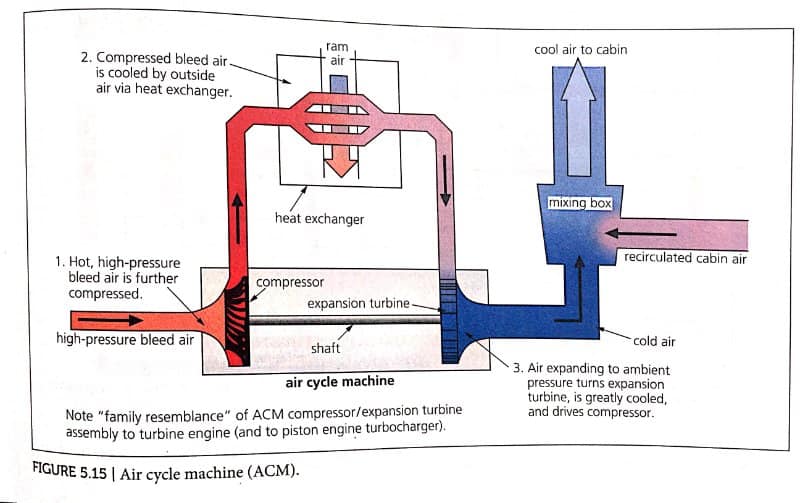

- Air Intake and Compression: Ambient air is drawn into the system and compressed by a compressor. This compression process increases the air's temperature and pressure. In aircraft, this air is often sourced from the engine's compressor stages, already at a significantly higher pressure and temperature.

- Heat Exchanger (Cooling): The hot, compressed air then flows through a heat exchanger, where it is cooled. In aircraft, this heat exchanger typically uses outside air as the cooling medium. The heat exchanger reduces the air's temperature, but it remains at a high pressure.

- Expansion Turbine (Cooling): This is the heart of the air cycle system. The cooled, high-pressure air is expanded through a turbine. As the air expands, it does work, causing a significant drop in both pressure and temperature. This expansion process is the primary mechanism for generating the cold air.

- Air Distribution: The cold air exiting the turbine is then directed into the space requiring cooling, such as the passenger cabin of an aircraft or a specific area in an industrial setting.

It's crucial to understand that the cooling effect is directly related to the pressure ratio across the expansion turbine. A higher pressure ratio results in a greater temperature drop and more effective cooling.

Advantages and Disadvantages Compared to Vapor-Compression

Air cycle cooling offers several advantages, primarily:

- Use of Air as Refrigerant: Air is readily available, non-toxic, non-flammable, and environmentally friendly. This eliminates the concerns associated with refrigerant leaks and their impact on the ozone layer.

- Lighter Weight and Smaller Size: For specific applications, air cycle systems can be lighter and more compact than comparable vapor-compression systems, a critical factor in aviation.

- Simpler Design: Air cycle systems generally have fewer components than vapor-compression systems, potentially leading to lower maintenance requirements.

However, there are also drawbacks:

- Lower Efficiency: Air cycle systems typically have lower energy efficiency (Coefficient of Performance - COP) compared to vapor-compression systems. This means they require more energy to produce the same amount of cooling.

- Higher Noise Levels: The expansion turbine can generate significant noise.

- Moisture Issues: Under certain conditions, moisture in the air stream can freeze and cause icing problems within the system.

Career Paths and Opportunities

While air cycle cooling isn't as prevalent as vapor-compression in residential or commercial HVAC, it creates niche career opportunities, particularly in:

- Aviation HVAC: Technicians specializing in aircraft environmental control systems (ECS) are responsible for maintaining and repairing air cycle cooling systems on airplanes.

- Industrial Applications: Some industrial processes requiring precise temperature control may utilize air cycle cooling.

- Research and Development: HVAC engineers and researchers continuously work on improving the efficiency and performance of air cycle cooling technology.

To succeed in these areas, a solid foundation in thermodynamics, fluid mechanics, and HVAC fundamentals is essential. Formal education, such as an associate's or bachelor's degree in mechanical engineering or HVAC technology, is highly recommended.

Certifications and Training

While specific certifications for air cycle systems are limited, holding relevant industry credentials enhances your career prospects:

- NATE (North American Technician Excellence): NATE certification demonstrates your competency in HVAC fundamentals and various specialties. Although not specific to air cycle, it provides a strong foundation.

- EPA Section 608 Certification: Required for handling refrigerants, this certification, while not directly applicable to air cycle systems using air as the refrigerant, demonstrates a commitment to environmental responsibility and safety. It's a baseline certification most HVAC employers expect.

- Aircraft-Specific Training: For aviation HVAC, specialized training on specific aircraft models and their environmental control systems is crucial. These courses are often offered by aircraft manufacturers or authorized training providers.

Continuous learning is essential in the HVAC field. Stay updated on emerging technologies, industry best practices, and evolving regulations. Online courses, workshops, and trade publications are valuable resources.

Salary and Job Outlook

The HVAC industry is experiencing steady growth, with the U.S. Bureau of Labor Statistics projecting a 6% growth rate for HVAC mechanics and installers from 2022 to 2032, about as fast as the average for all occupations. This translates to roughly 38,000 new job openings each year, on average, over the decade. This growth is driven by factors such as population increases, construction activity, and the growing demand for energy-efficient HVAC systems.

The median annual wage for HVAC mechanics and installers was $59,620 in May 2023. The lowest 10 percent earned less than $36,770, and the highest 10 percent earned more than $88,490. Salaries vary depending on experience, location, specialization, and employer. Technicians specializing in aviation HVAC or industrial applications often command higher salaries due to the specialized skills required.

Here are estimated salary ranges based on experience level (these are general estimates, and actual salaries may vary):

- Entry-Level (0-2 years): $35,000 - $45,000

- Mid-Level (3-5 years): $45,000 - $65,000

- Experienced (5+ years): $65,000 - $90,000+

Remember that these are just averages. Location plays a significant role; metropolitan areas and regions with a high demand for HVAC services tend to offer higher wages. Also, factor in overtime pay; many HVAC technicians work overtime during peak seasons, significantly boosting their annual income.

Real-World Career Examples

Here are a few examples of career paths you might pursue with knowledge of air cycle cooling:

- Aircraft ECS Technician: Maintaining and troubleshooting air conditioning, pressurization, and ventilation systems on commercial or military aircraft. This involves working with complex air cycle cooling systems and ensuring passenger comfort and safety.

- HVAC Engineer (R&D): Designing and developing innovative air cycle cooling systems for specific applications, focusing on improving efficiency and reducing noise levels.

- Industrial HVAC Specialist: Implementing and maintaining air cycle cooling systems for industrial processes requiring precise temperature control, such as in manufacturing or food processing.

The Future of Air Cycle Cooling

While vapor-compression remains the dominant technology, air cycle cooling continues to evolve. Research and development efforts are focused on improving the efficiency of air cycle systems, exploring new applications, and addressing the challenges of noise and moisture control. As environmental concerns and the demand for sustainable cooling solutions increase, air cycle cooling may see renewed interest in specific niche applications.

Staying informed about the latest advancements in HVAC technology, including air cycle cooling, is essential for a successful and rewarding career in this dynamic industry.