The Use Of Machinery To Provide Cooling.

Mechanical cooling, the process of removing heat from an enclosed space using machinery, is the cornerstone of modern comfort and productivity. From residential homes to sprawling industrial complexes, mechanical cooling systems play a vital role in maintaining comfortable indoor environments. This article delves into the various types of machinery used to provide cooling, their operational principles, efficiency considerations, and suitability for different applications.

Vapor-Compression Refrigeration: The Workhorse of Cooling

The most prevalent mechanical cooling technology is vapor-compression refrigeration. This process relies on a refrigerant, a special fluid with thermodynamic properties that allow it to absorb and release heat as it changes state. The four key components of a vapor-compression system are the compressor, condenser, expansion valve (or metering device), and evaporator.

The Refrigeration Cycle Explained

1. Compression: The compressor, driven by an electric motor, increases the pressure and temperature of the refrigerant vapor. This high-pressure, high-temperature vapor then flows to the condenser.

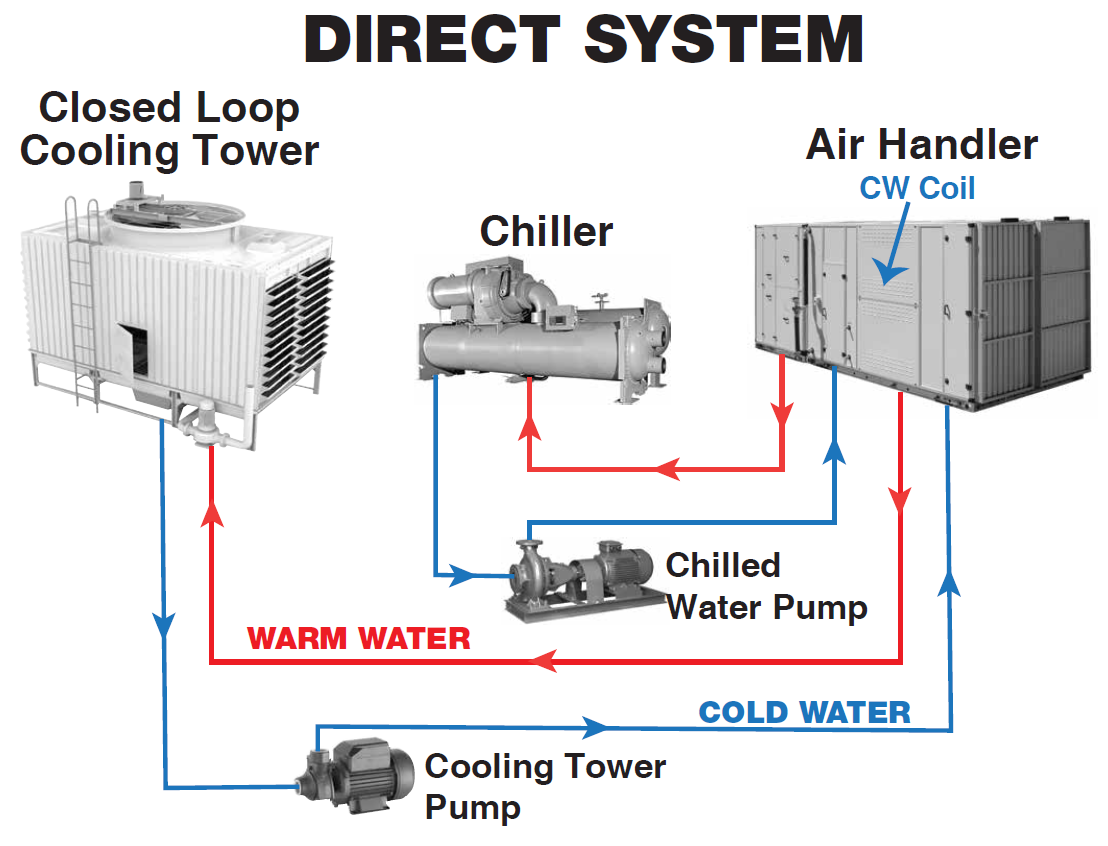

2. Condensation: In the condenser, the refrigerant releases heat to the outside environment (typically air or water), causing it to condense from a gas into a high-pressure liquid. Think of the outdoor unit of your split-system air conditioner – that's where the condenser is located. A fan helps dissipate the heat.

3. Expansion: The high-pressure liquid refrigerant passes through an expansion valve, also known as a metering device. This valve restricts the flow, causing a significant pressure drop. As the pressure drops, the refrigerant partially evaporates, resulting in a cold, low-pressure mixture of liquid and vapor.

4. Evaporation: The cold refrigerant mixture enters the evaporator, located inside the space to be cooled. Here, it absorbs heat from the surrounding air, causing the remaining liquid refrigerant to evaporate completely and become a low-pressure vapor. This heat absorption is what cools the air blowing across the evaporator coil. This cold air is then circulated throughout the space. The evaporator is typically found in the indoor unit of a split-system air conditioner or in the air handler of a central HVAC system.

The low-pressure vapor then returns to the compressor, restarting the cycle. Different refrigerants exist, each with varying environmental impacts and performance characteristics. Regulations often dictate which refrigerants are permitted, with a global shift towards those with lower Global Warming Potential (GWP).

Types of Vapor-Compression Systems

Vapor-compression refrigeration manifests in various forms:

- Split Systems: Consist of an outdoor condenser unit and an indoor evaporator unit connected by refrigerant lines. They are commonly used in residential and light commercial applications. Example: A typical central air conditioner for a house.

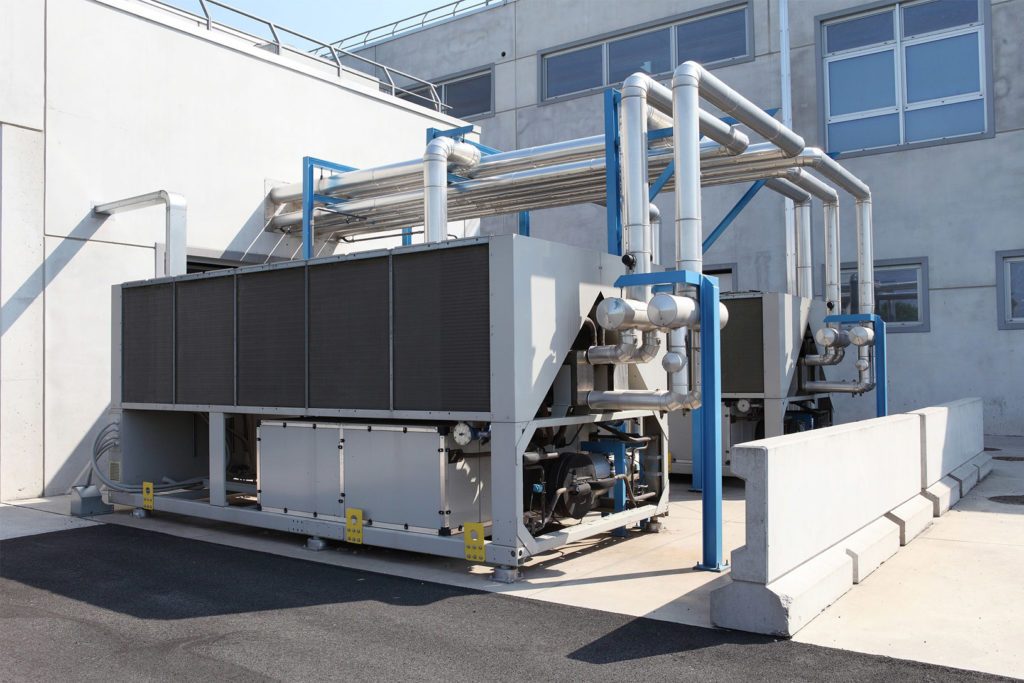

- Packaged Units: Combine all components (compressor, condenser, evaporator, and controls) into a single cabinet, typically installed on rooftops or slabs. They are common for commercial buildings. Example: A rooftop HVAC unit for a small office building.

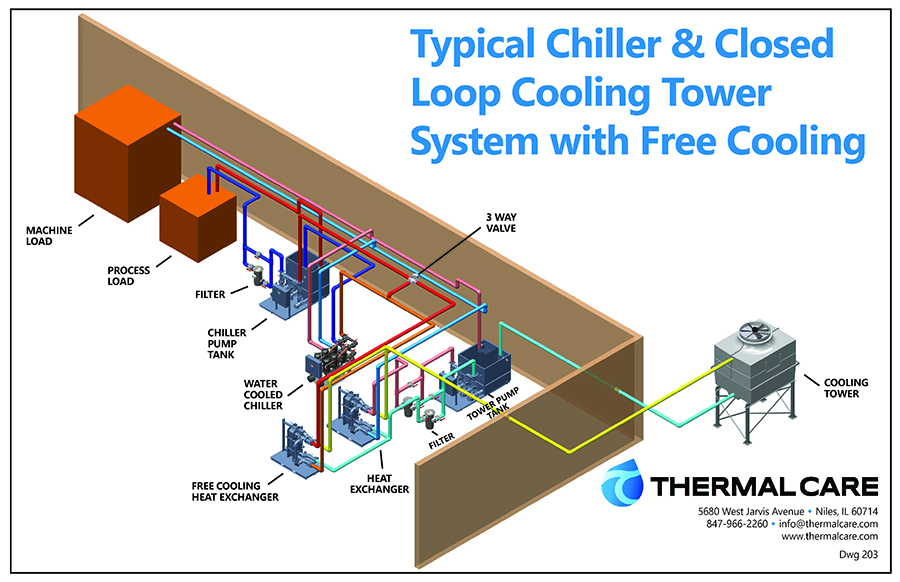

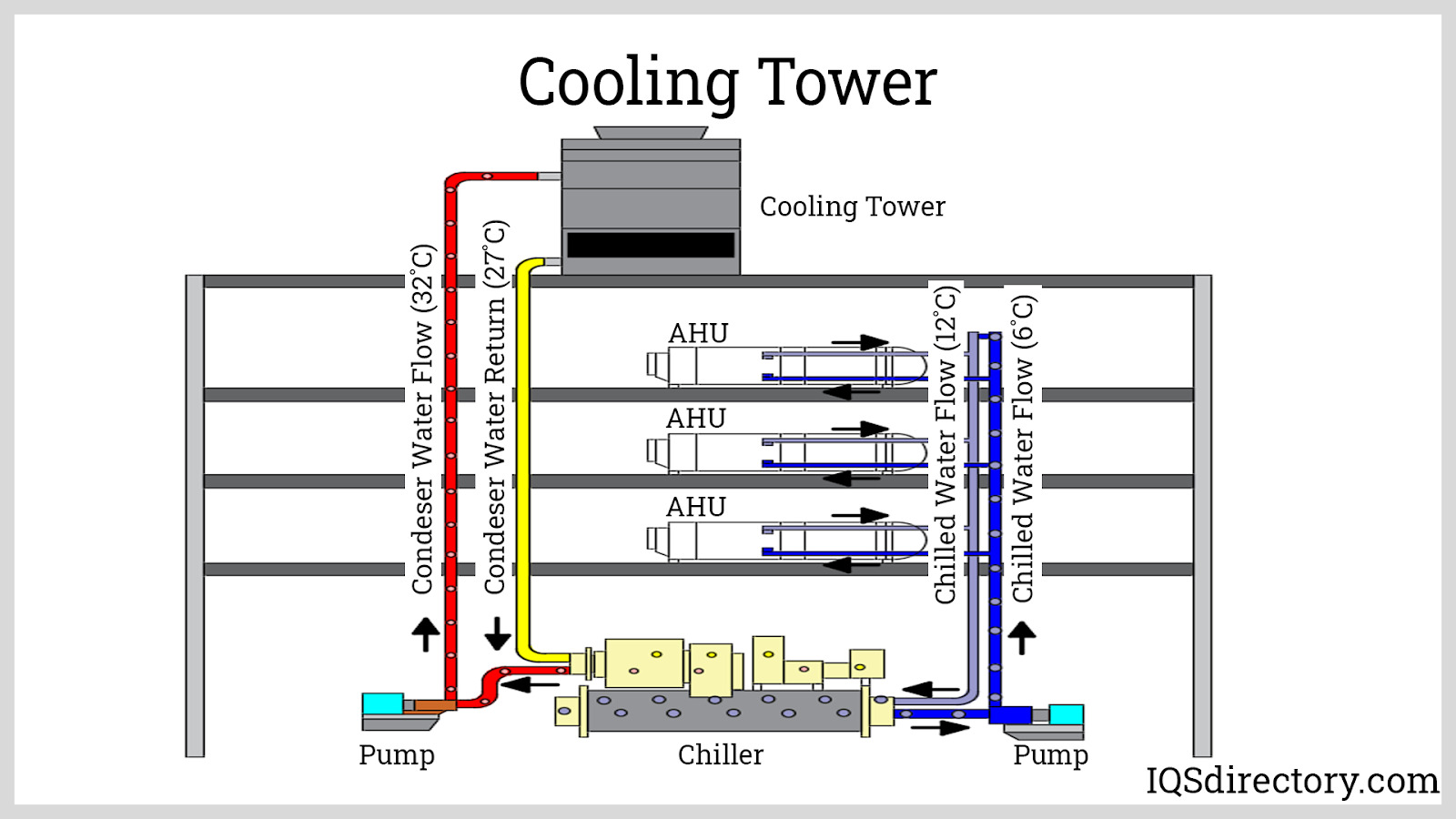

- Chillers: Cool water (or another fluid) that is then circulated to provide cooling throughout a building. Chillers are used in large commercial and industrial applications where centralized cooling is required. Example: Cooling a data center or a large hospital.

- Heat Pumps: Utilize the vapor-compression cycle to both heat and cool a space. They can reverse the flow of refrigerant to either extract heat from the outside air (even when it's cold) and transfer it indoors (heating mode), or extract heat from the indoor air and transfer it outdoors (cooling mode).

Absorption Refrigeration: Heat-Driven Cooling

Unlike vapor-compression, absorption refrigeration uses heat as its primary energy source rather than electricity. This makes it a viable option when waste heat or solar thermal energy is readily available. The most common absorption chillers use a combination of water and lithium bromide (LiBr) or ammonia and water as the working fluids.

The Absorption Cycle Explained

The absorption cycle has similar components to the vapor-compression cycle, but with the addition of an absorber and generator, and the replacement of the compressor. The key steps are:

1. Evaporation: Similar to vapor-compression, refrigerant evaporates in the evaporator, absorbing heat and providing cooling.

2. Absorption: The refrigerant vapor is absorbed by a solution (e.g., lithium bromide solution) in the absorber. This creates a vacuum that helps maintain low pressure in the evaporator.

3. Generation: The solution containing the refrigerant is pumped to the generator, where heat is applied. This heat separates the refrigerant vapor from the solution.

4. Condensation: The refrigerant vapor is condensed in the condenser, releasing heat to the surroundings.

5. Expansion: The liquid refrigerant passes through an expansion valve, reducing its pressure and temperature before entering the evaporator.

The concentrated absorbent solution returns to the absorber, completing the cycle. While absorption chillers can utilize waste heat, they typically have lower Coefficient of Performance (COP) than vapor-compression systems, meaning they provide less cooling per unit of energy input.

Applications of Absorption Chillers

Absorption chillers are often used in:

- Combined Heat and Power (CHP) Systems: Where waste heat from power generation is used to drive the chiller.

- District Cooling Systems: Where a central plant provides chilled water to multiple buildings.

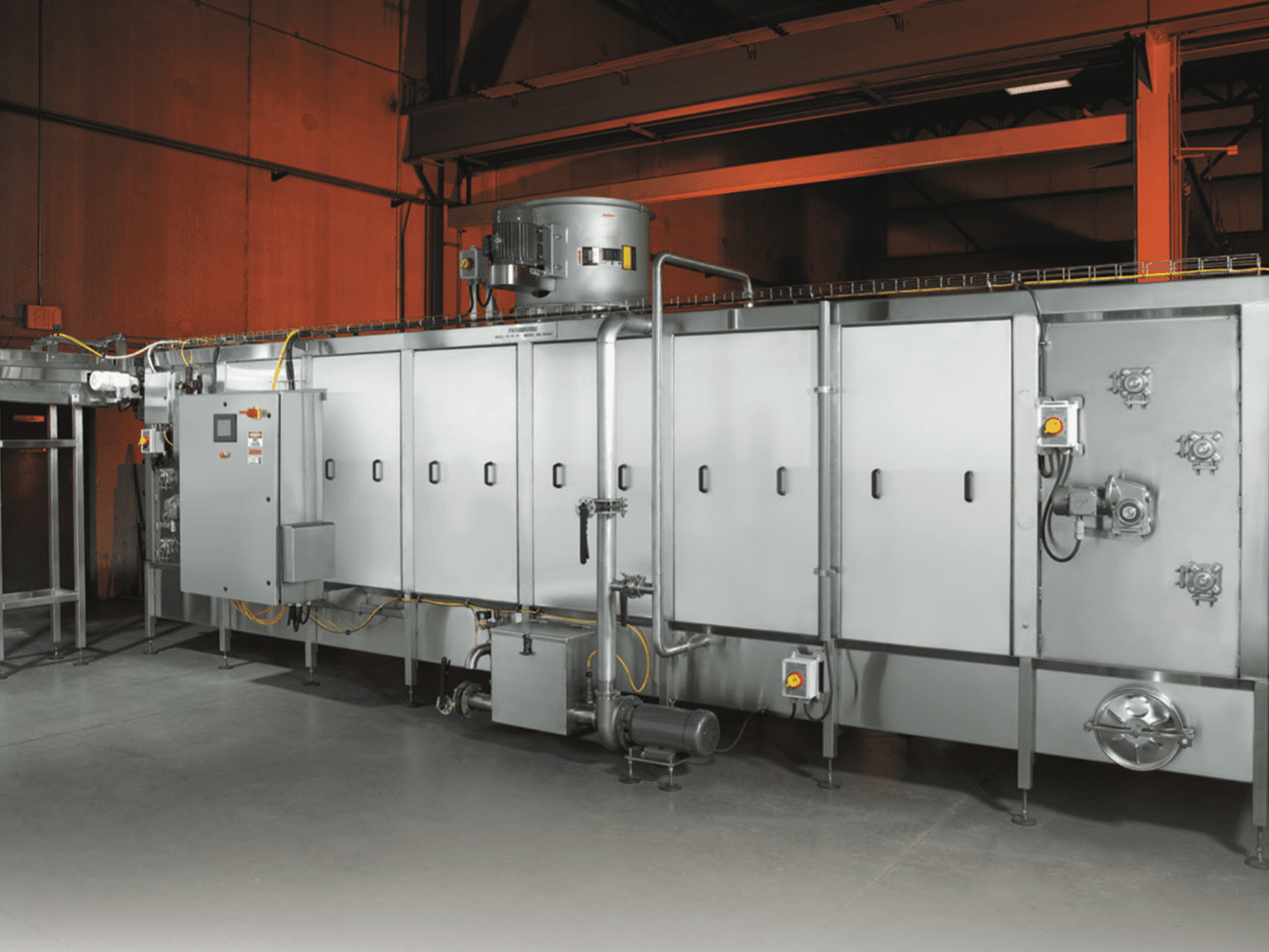

- Industrial Processes: Where waste heat from manufacturing processes is available.

- Solar Cooling Applications: Where solar thermal collectors provide the heat input for the chiller.

Evaporative Cooling: Harnessing the Power of Evaporation

Evaporative cooling, also known as swamp cooling, is a simple and energy-efficient cooling method that utilizes the principle of evaporative cooling. When water evaporates, it absorbs heat from the surrounding air, lowering the air temperature.

Types of Evaporative Coolers

There are two main types of evaporative coolers:

- Direct Evaporative Coolers: Air is passed through a wet pad or media, where water evaporates directly into the airstream. This cooled, humidified air is then circulated throughout the space. They are most effective in hot, dry climates. Example: Portable evaporative coolers used in arid regions.

- Indirect Evaporative Coolers: The air is cooled indirectly by passing it through a heat exchanger that is cooled by evaporating water. The supply air is cooled without adding moisture to it, making it suitable for more humid climates.

Limitations of Evaporative Cooling

Evaporative cooling is most effective in hot, dry climates where the humidity is low. In humid climates, the air is already saturated with moisture, so the evaporation process is limited, and the cooling effect is reduced. They also require a constant water supply and regular maintenance to prevent scale buildup and microbial growth.

Other Cooling Technologies

While vapor-compression, absorption, and evaporative cooling are the most common mechanical cooling technologies, other emerging technologies include:

- Desiccant Cooling: Uses a desiccant material to absorb moisture from the air, followed by evaporative cooling to lower the temperature.

- Thermoelectric Cooling: Uses the Peltier effect to create a temperature difference between two junctions.

- Magnetic Refrigeration: Uses the magnetocaloric effect to cool a substance by applying and removing a magnetic field.

Efficiency Ratings and Cost Considerations

When selecting a mechanical cooling system, it's crucial to consider both the initial cost and the operating costs. Efficiency ratings, such as Seasonal Energy Efficiency Ratio (SEER) for air conditioners and heat pumps, and Energy Efficiency Ratio (EER) for chillers, indicate how efficiently the system converts energy into cooling. Higher ratings generally translate to lower energy bills but may also come with a higher upfront cost.

The lifespan of a cooling system also affects its overall cost. Properly maintained systems can last for 15-20 years, but factors like usage patterns, climate, and maintenance practices can impact their longevity. Regular maintenance, including filter changes, coil cleaning, and refrigerant checks, is essential to ensure optimal performance and extend the lifespan of the system.

Conclusion

Mechanical cooling is essential for maintaining comfortable and productive indoor environments. Understanding the different types of machinery used for cooling, their operational principles, efficiency considerations, and suitability for different applications is crucial for making informed decisions when selecting and maintaining a cooling system. Choosing the right cooling technology can significantly impact energy consumption, operating costs, and overall environmental impact. Proper sizing by a qualified HVAC technician is also critical to ensure optimal performance and efficiency.