What Causes Carbon Monoxide In Your Home

Carbon monoxide (CO) is an odorless, colorless gas that can be deadly. Understanding its sources and how to prevent it from entering your home is crucial for the safety of your family, tenants, or building occupants. This article delves into the common causes of carbon monoxide in residential and commercial buildings, offering practical advice for homeowners, HVAC technicians, and facility managers.

Incomplete Combustion: The Root Cause

At its core, carbon monoxide production stems from incomplete combustion. Combustion is the chemical process of burning fuel, such as natural gas, propane, oil, wood, or coal. Complete combustion requires sufficient oxygen to convert the fuel entirely into carbon dioxide (CO2) and water (H2O). However, when the oxygen supply is limited or the combustion process is inefficient, carbon monoxide is produced as a byproduct.

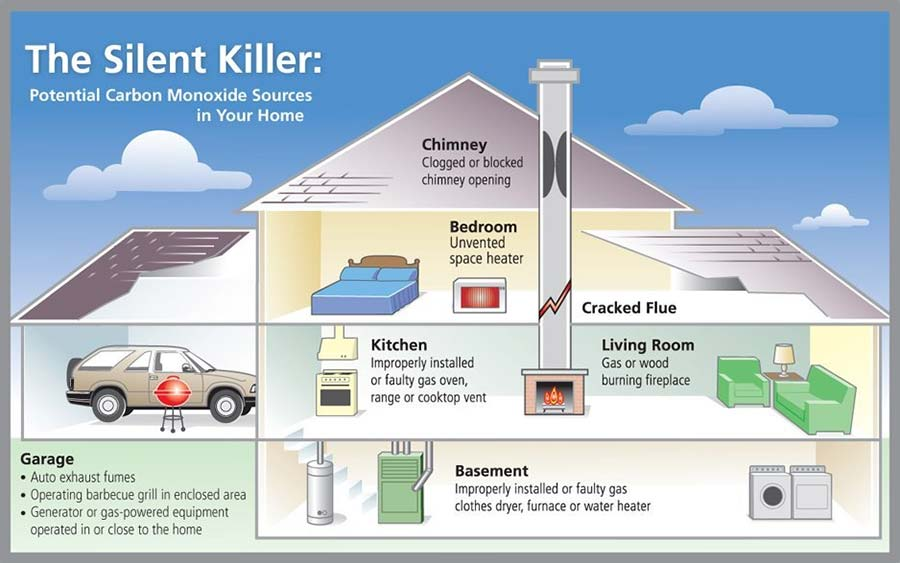

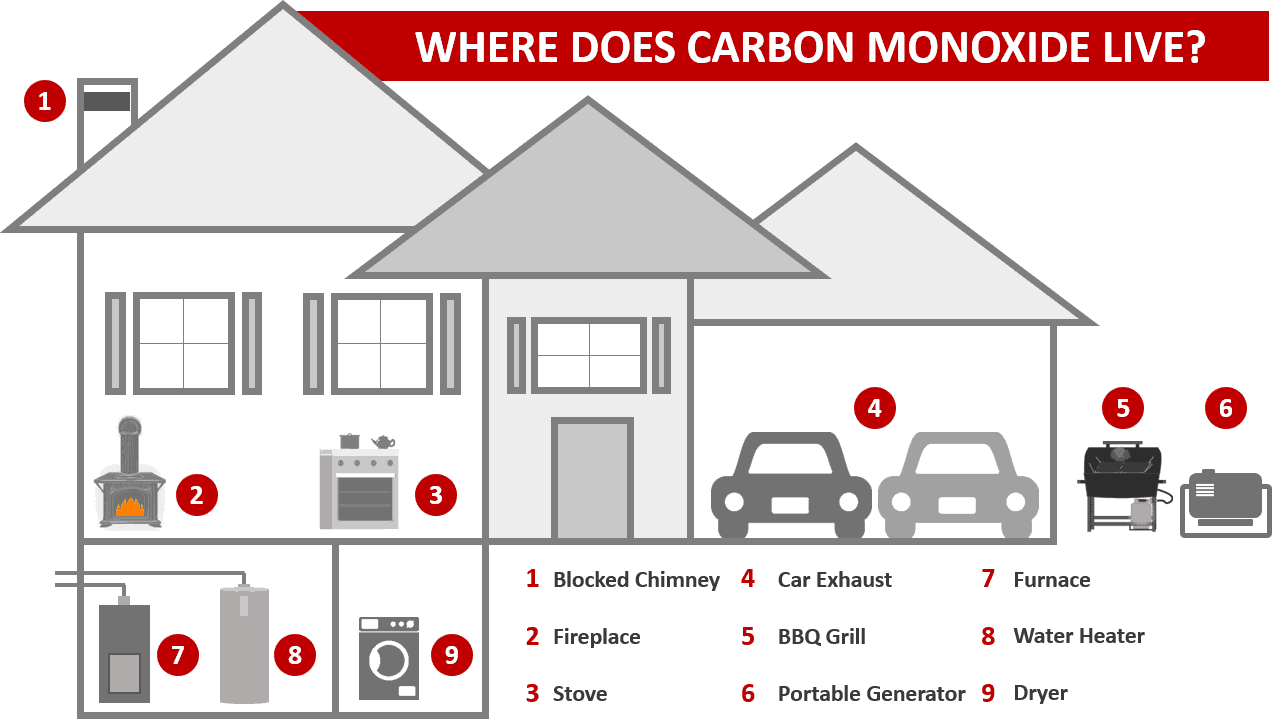

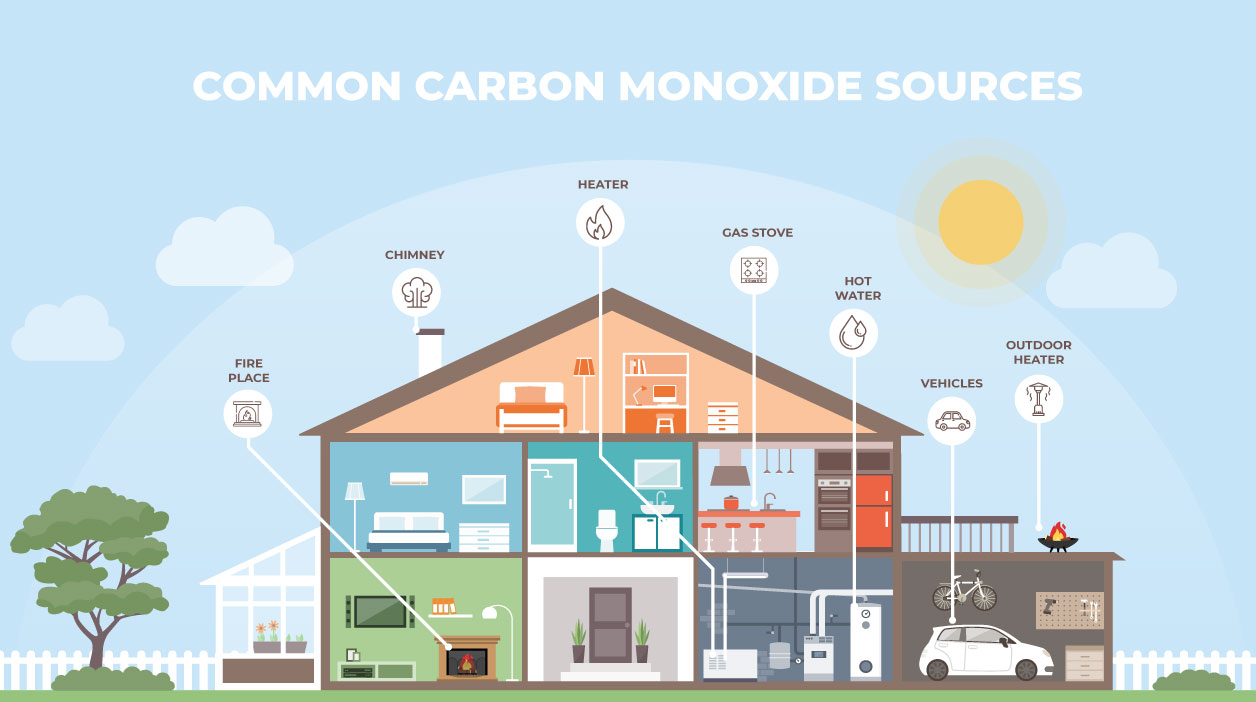

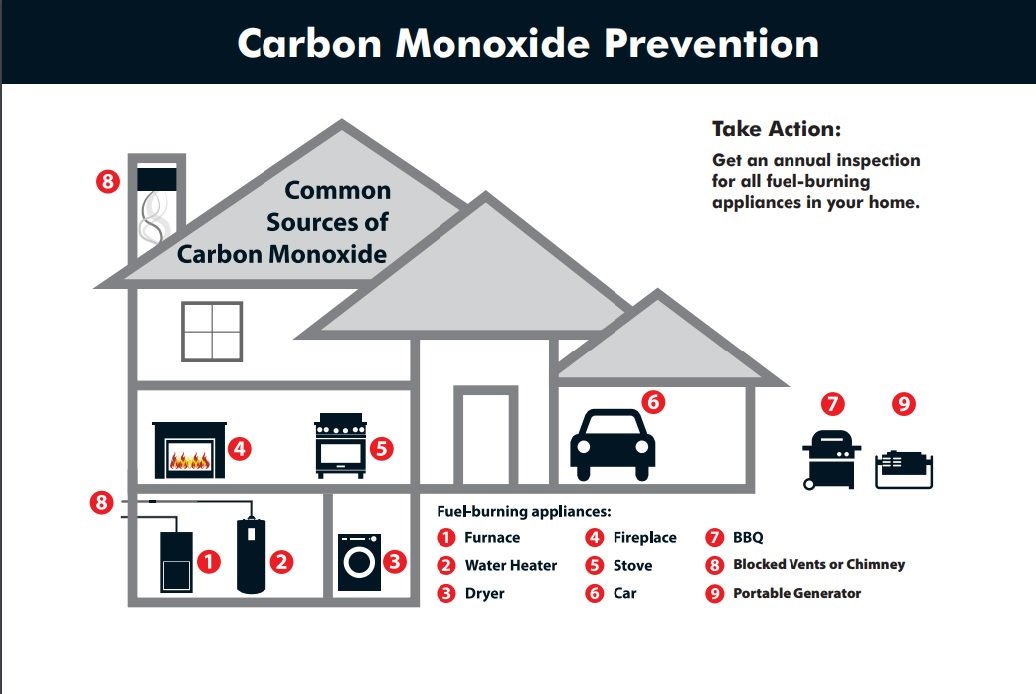

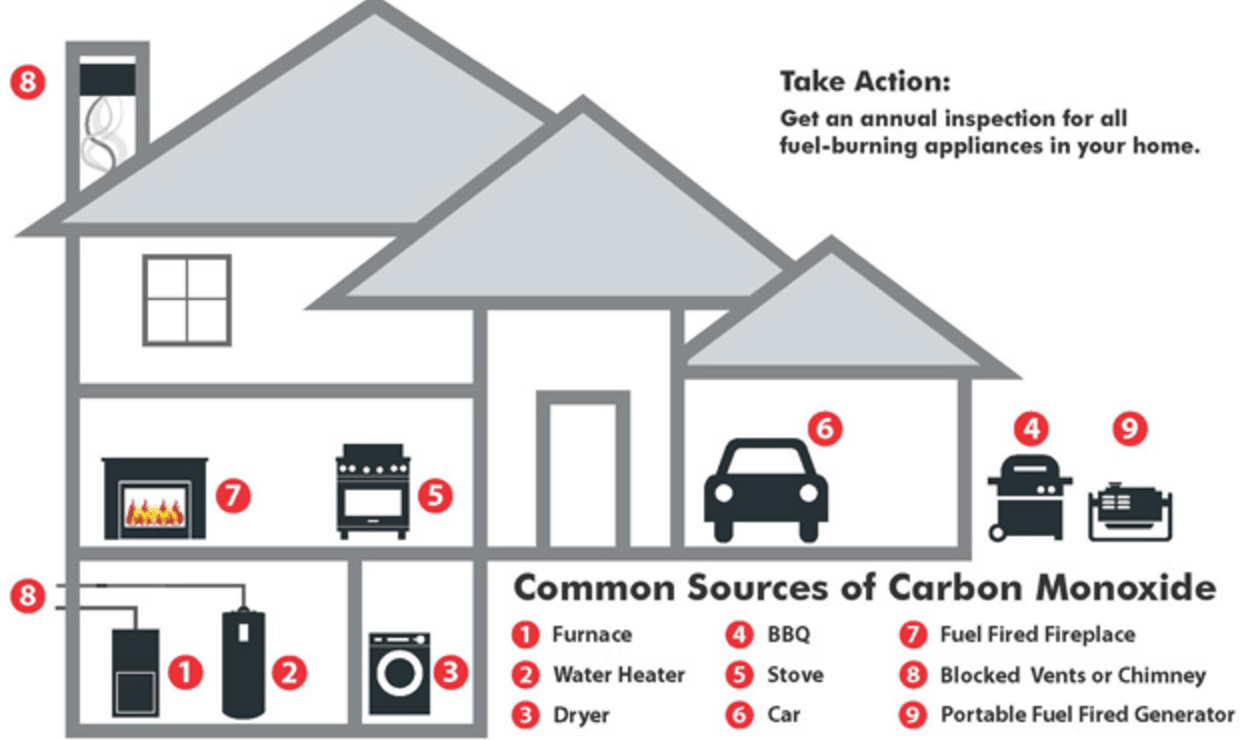

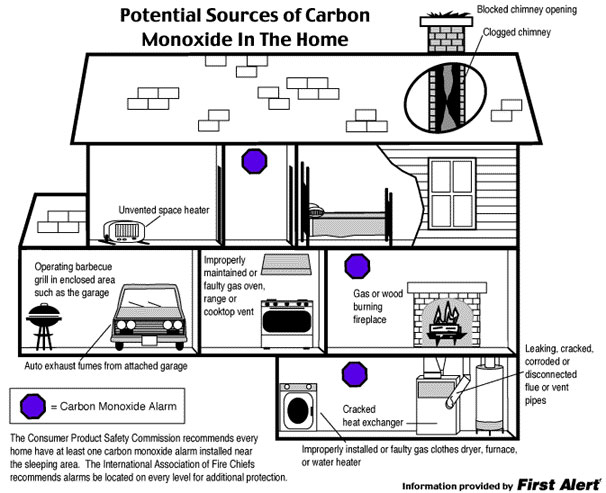

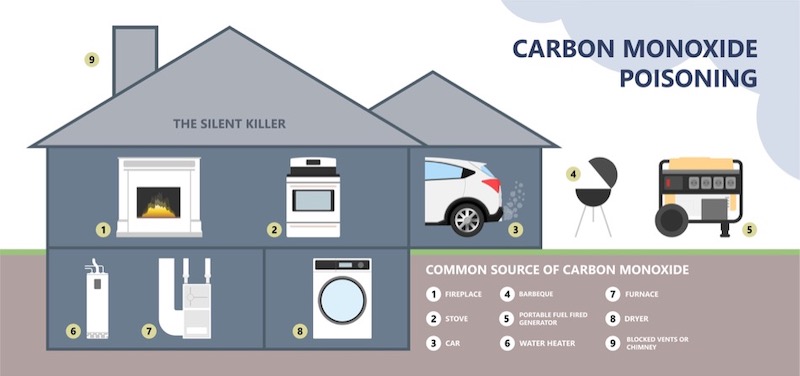

Common Sources of Carbon Monoxide in Homes

Several appliances and systems commonly found in homes can produce carbon monoxide if not properly maintained or vented. These include:

- Furnaces: Natural gas, propane, or oil-fired furnaces are a primary source of CO. Cracks in the heat exchanger, blocked flues, or improper burner adjustments can lead to incomplete combustion. A heat exchanger is the part of the furnace that heats the air circulated through your home.

- Water Heaters: Similar to furnaces, gas-powered water heaters can generate CO if the burner is not clean, the venting is obstructed, or the unit is not properly sized for the home.

- Fireplaces: Wood-burning fireplaces, while aesthetically pleasing, can release CO into the home if the chimney is blocked or if the fire is not properly managed. Closing the damper too early after the fire has burned down can trap CO inside.

- Gas Stoves and Ovens: While designed for cooking, gas stoves and ovens can produce CO, especially if the burners are dirty or the appliance is malfunctioning. It is never safe to use a gas stove or oven for heating your home.

- Portable Generators: Gasoline-powered generators produce significant amounts of CO. They should never be operated indoors, in garages, or near windows or doors. Always operate generators in well-ventilated outdoor areas.

- Vehicles: Running a car, truck, or other vehicle inside a garage, even with the door open, can quickly lead to dangerous CO levels.

- Charcoal Grills: Similar to generators, charcoal grills produce CO and should only be used outdoors.

HVAC System Specific Issues

For HVAC technicians and facility managers, understanding system-specific issues is critical for preventing CO poisoning. Here are some key areas to focus on:

- Heat Exchanger Cracks: Inspect furnace heat exchangers annually for cracks or corrosion. Even small cracks can allow CO to leak into the air supply. Use a combustion analyzer to detect CO in the flue gas and supply air.

- Flue Blockages: Ensure that flues and vents are free of obstructions, such as bird nests, debris, or collapsed liners. Blocked flues prevent CO from escaping and force it back into the building.

- Improper Venting: Verify that appliances are properly vented to the outside. Check for disconnected or damaged vent pipes. Consider using a direct-vent appliance, which draws combustion air from outside and exhausts directly outside.

- Burner Issues: Inspect and clean burners regularly to ensure proper combustion. Soot buildup, improper flame color, or erratic burner operation can indicate incomplete combustion.

- Negative Pressure: Negative pressure in a building can draw CO from appliances into the living space. This can occur when exhaust fans, clothes dryers, or other appliances create a vacuum. Ensure adequate make-up air is available.

Preventing Carbon Monoxide Poisoning

Prevention is the best defense against carbon monoxide poisoning. Here are several steps that homeowners, HVAC technicians, and facility managers can take:

- Install CO Detectors: Install carbon monoxide detectors on every level of your home, especially near sleeping areas. Test the detectors regularly and replace them according to the manufacturer's instructions. Consider interconnected detectors that will all alarm if one detects CO.

- Annual HVAC System Inspection: Schedule annual inspections and maintenance of your HVAC system by a qualified technician. This includes checking for cracks in the heat exchanger, inspecting the venting system, and cleaning the burners. Expect to pay between $75-$200 for a standard inspection.

- Regular Appliance Maintenance: Have all fuel-burning appliances, including water heaters, fireplaces, and gas stoves, inspected and maintained regularly.

- Chimney Cleaning: Have your chimney cleaned and inspected annually, especially if you use a wood-burning fireplace.

- Proper Ventilation: Ensure adequate ventilation in your home. Use exhaust fans when cooking or showering. Open windows periodically to circulate fresh air.

- Safe Generator Use: Never operate portable generators indoors, in garages, or near windows or doors.

- Educate Occupants: Educate your family members, tenants, or building occupants about the dangers of carbon monoxide and the symptoms of CO poisoning.

Symptoms of Carbon Monoxide Poisoning

Recognizing the symptoms of carbon monoxide poisoning is crucial for prompt treatment. Symptoms can vary depending on the concentration of CO and the duration of exposure. Common symptoms include:

- Headache

- Dizziness

- Weakness

- Nausea

- Vomiting

- Chest pain

- Confusion

- Loss of consciousness

If you suspect carbon monoxide poisoning, immediately move to fresh air and call 911 or your local emergency number.

The Role of HVAC Technicians and Facility Managers

HVAC technicians and facility managers play a vital role in preventing carbon monoxide poisoning. In addition to performing thorough inspections and maintenance, they should also educate homeowners and building occupants about the dangers of CO. Here are some key responsibilities:

- Combustion Analysis: Use a combustion analyzer to measure CO levels in flue gas and ensure that appliances are operating efficiently.

- Heat Exchanger Inspection: Perform a visual inspection of the heat exchanger and use tools such as a borescope or infrared camera to detect cracks or corrosion.

- Venting System Inspection: Check for proper venting and ensure that flues are free of obstructions.

- Airflow Measurement: Measure airflow to ensure that appliances are receiving adequate combustion air.

- Code Compliance: Ensure that HVAC systems are installed and maintained in accordance with local codes and regulations.

- Documentation: Maintain detailed records of inspections and maintenance performed.

The Future of CO Detection and Prevention

Technology continues to evolve, offering new and improved methods for CO detection and prevention. Some emerging trends include:

- Smart CO Detectors: Smart CO detectors can send alerts to your smartphone or other devices if CO is detected.

- Predictive Maintenance: Advanced sensors and analytics can be used to predict potential equipment failures and prevent CO leaks.

- Improved Combustion Technology: Manufacturers are developing more efficient combustion technologies that produce less CO.

- Building Automation Systems: Building automation systems can monitor CO levels and automatically adjust ventilation to maintain safe air quality.

Conclusion

Carbon monoxide poisoning is a serious threat, but it is also preventable. By understanding the sources of CO, implementing preventive measures, and staying informed about the latest technologies, homeowners, HVAC technicians, and facility managers can work together to create safer and healthier living and working environments. Regular maintenance, proper ventilation, and functioning CO detectors are key to preventing this silent killer. Remember to always consult with qualified professionals for HVAC system maintenance and repairs. Ignoring warning signs can have devastating consequences.