What Causes Delayed Ignition On Gas Furnace

A gas furnace is a marvel of engineering, providing warmth and comfort during the coldest months. However, like any complex machine, it can experience issues. One common problem is delayed ignition, a potentially dangerous situation where the furnace takes longer than usual to ignite the gas after the thermostat calls for heat. Understanding the causes of delayed ignition can help homeowners, technicians, and facility managers diagnose and address the problem effectively.

What is Delayed Ignition?

Normally, when your thermostat signals for heat, the furnace goes through a sequence of events: the inducer motor starts, the pressure switch confirms proper draft, the igniter heats up, and then the gas valve opens, allowing gas to flow to the burners. The igniter then ignites the gas, creating a flame that heats the heat exchanger, which in turn warms the air circulated through your home. With delayed ignition, there's a noticeable pause – often a few seconds, but sometimes much longer – between the gas valve opening and the ignition of the gas. This can result in a small (or sometimes large) puff of gas accumulating in the combustion chamber before finally igniting, which can create a "whoomph" sound or even a minor explosion. This is not only alarming but can also damage the furnace over time.

Common Causes of Delayed Ignition

Several factors can contribute to delayed ignition in a gas furnace. These range from simple maintenance issues to more complex component failures. Here’s a breakdown of the most common culprits:

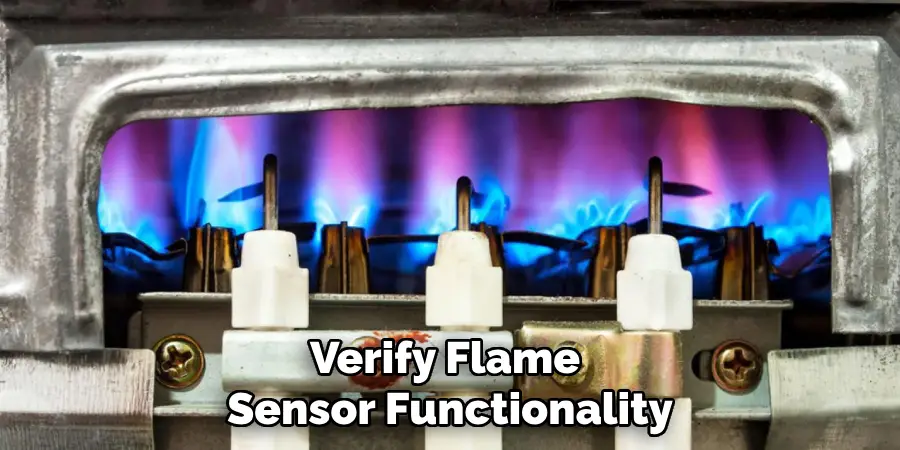

1. Dirty or Failing Flame Sensor

The flame sensor is a crucial safety device that detects the presence of a flame after the gas is ignited. If the flame sensor doesn't detect a flame, it shuts off the gas valve to prevent unburned gas from accumulating. A dirty flame sensor is one of the most frequent causes of delayed ignition and lockout (where the furnace shuts down completely). Over time, the flame sensor can become coated with carbon deposits, which insulates it and reduces its ability to detect the flame properly. This can cause the sensor to delay its signal or fail to detect the flame at all, resulting in the gas valve closing prematurely or delaying the main burner ignition.

Solution: Cleaning the flame sensor is a relatively simple task. Turn off the furnace and gas supply. Locate the flame sensor (a metallic rod typically located near the burners). Remove it and gently clean it with fine steel wool or emery cloth to remove any carbon buildup. Reinstall the sensor and test the furnace.

2. Weak or Failing Igniter

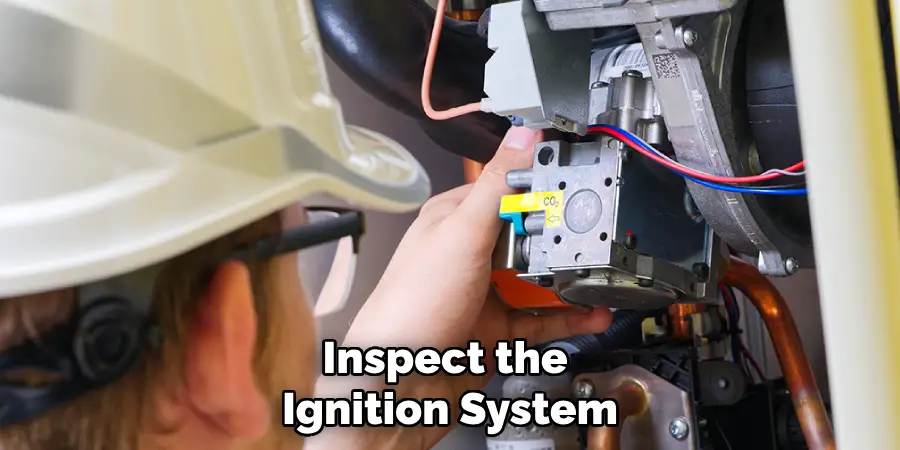

The igniter is responsible for creating the spark or heat necessary to ignite the gas. Furnaces typically use either a hot surface igniter (HSI) or a spark igniter. An HSI heats up to a very high temperature to ignite the gas. Over time, the HSI can weaken and take longer to reach the necessary temperature, leading to delayed ignition. A spark igniter generates a spark to ignite the gas. Issues with the spark igniter, such as a weak spark or a faulty module, can also cause delays.

Solution: Inspect the igniter for cracks, damage, or signs of wear. If the igniter appears weak or damaged, it should be replaced by a qualified HVAC technician. While a homeowner comfortable with electrical work can replace an igniter, it’s crucial to ensure the correct replacement part is used and that safety precautions are followed.

3. Low Gas Pressure

Insufficient gas pressure can prevent the burners from igniting quickly and efficiently. Low gas pressure can be caused by a problem with the gas supply to the house, a malfunctioning gas regulator, or a partially closed gas valve.

Solution: Check the gas supply to the house. Make sure the main gas valve is fully open. If other gas appliances are also experiencing problems, it could indicate a problem with the gas company's supply. Contact a qualified HVAC technician to check the gas pressure at the furnace and diagnose any problems with the gas regulator. This is not a DIY task! Working with gas lines requires specialized knowledge and equipment and can be dangerous if done incorrectly.

4. Clogged or Dirty Burners

Dirty or clogged burners can obstruct the flow of gas, preventing it from igniting properly. Dust, debris, and rust can accumulate on the burners over time, reducing their efficiency and causing delayed ignition.

Solution: Turn off the gas supply and carefully inspect the burners for any visible obstructions. Use a vacuum cleaner or a brush to remove any loose debris. For more stubborn clogs, a specialized burner cleaning tool may be necessary. This task is best left to a qualified HVAC technician to ensure the burners are properly cleaned and reinstalled.

5. Faulty Gas Valve

The gas valve controls the flow of gas to the burners. If the gas valve is malfunctioning, it may not open fully or may open with a delay, resulting in insufficient gas reaching the burners for proper ignition. A faulty gas valve can be caused by electrical issues, mechanical failure, or corrosion.

Solution: Diagnosing and repairing a faulty gas valve requires specialized knowledge and equipment. This task should only be performed by a qualified HVAC technician. Replacing a gas valve involves working with gas lines and electrical components and can be dangerous if done incorrectly.

6. Issues with the Inducer Motor or Pressure Switch

The inducer motor creates a draft that pulls combustion gases through the furnace and out the vent. The pressure switch confirms that this draft is present before allowing the furnace to ignite. If the inducer motor is weak or failing, it may not create sufficient draft, which can prevent the pressure switch from closing. A faulty pressure switch can also prevent the furnace from igniting, even if the inducer motor is working properly.

Solution: Check the inducer motor for proper operation. Listen for unusual noises or signs of weakness. Inspect the vent pipe for any obstructions. A qualified HVAC technician can test the pressure switch and inducer motor to determine if they are functioning correctly. Replacing either of these components requires specialized knowledge and should be performed by a professional.

7. Electrical Problems

Loose wiring, corroded connections, or a faulty control board can all contribute to delayed ignition. Electrical problems can disrupt the proper sequence of events required for ignition, causing delays or complete failure.

Solution: Inspect the wiring connections at the furnace for any signs of looseness or corrosion. Check the control board for any visible damage. A qualified HVAC technician can use a multimeter to test the electrical components and diagnose any electrical problems. Working with electrical components can be dangerous. Always turn off the power to the furnace before performing any electrical work.

Preventing Delayed Ignition

Regular maintenance is key to preventing delayed ignition and other furnace problems. Here are some tips:

- Schedule annual furnace maintenance: A qualified HVAC technician can inspect and clean the furnace, check the gas pressure, test the safety controls, and identify any potential problems before they become major issues.

- Replace the air filter regularly: A dirty air filter restricts airflow, which can cause the furnace to overheat and malfunction. Replace the air filter every 1-3 months, depending on the type of filter and the amount of dust in your home.

- Keep the area around the furnace clean and clear: Remove any flammable materials or obstructions from around the furnace to ensure proper ventilation and prevent fire hazards.

- Install a carbon monoxide detector: Carbon monoxide is a colorless, odorless gas that can be deadly. Install a carbon monoxide detector near the furnace to alert you to any leaks.

Cost Considerations

The cost of repairing delayed ignition can vary depending on the cause of the problem. Cleaning a flame sensor is a relatively inexpensive task, while replacing a gas valve or control board can be more costly. Regular maintenance can help prevent costly repairs and extend the lifespan of your furnace. Expect to pay between $75 and $200 for a typical furnace tune-up. Replacing a flame sensor may cost around $100-$200 installed. Replacing more significant components like the gas valve or igniter can range from $300 to $600 or more.

Conclusion

Delayed ignition is a common furnace problem that can be caused by a variety of factors. By understanding the potential causes and taking steps to prevent them, homeowners, technicians, and facility managers can ensure the safe and efficient operation of their gas furnaces. Remember that working with gas and electrical components can be dangerous. When in doubt, always consult a qualified HVAC technician.